Negative pressure control method for compact spinning negative pressure system

A technology of compact spinning and negative pressure, which is applied in pump control, spinning machine, textile and paper making, etc. It can solve the problems of fan motor burning motor and affecting the quality of yarn, so as to ensure stability, good protection and ensure load The effect of pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

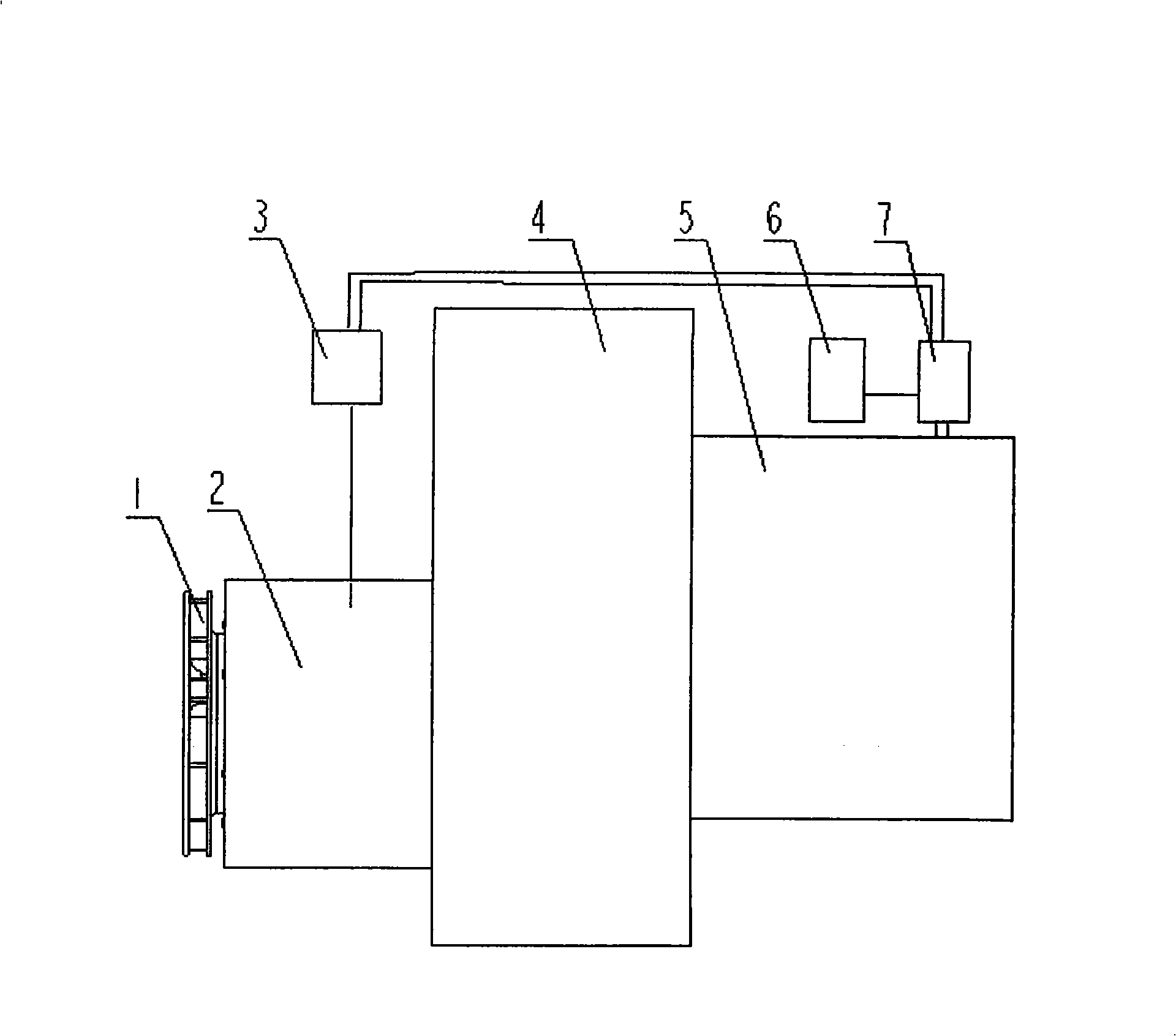

[0009] figure 1 Shown is the compact spinning negative pressure system involved in the present invention. In this system, under the action of the negative pressure centrifugal fan 1, the flow direction of the negative pressure airflow is: the airflow enters the air duct 5 and the filter device 4 sequentially through the compact spinning device , bellows and fan 1 are discharged. Because the negative pressure system is used in textile factories, the special working environment and equipment characteristics such as flying flowers, dust and cotton linters in the workshop, the length of the air duct 5 is relatively long, so the pressure sensor 7 is installed far away from the place where the negative pressure changes most obviously. At one end of the fan 1, the pressure sensor 7 and the fan motor frequency converter 3 perform two-way communication to form a closed-loop control system. The pressure sensor 7 communicates one-way with the alarm device 6, and the sensor 7 outputs a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com