A kind of ultra-white water-based ceramic inkjet ink and preparation method thereof

A ceramic inkjet and ink technology, applied in inks, household appliances, applications, etc., can solve the problem of difficult to directly apply ceramic inkjet inks, etc., to solve the problems of long time and high energy consumption, high whiteness, and lower sintering temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

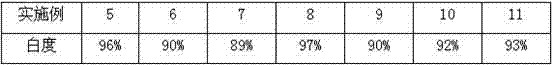

Examples

Embodiment 1

[0054]This embodiment provides a special white water-based ceramic inkjet ink, the ceramic pigment is a sol prepared by a sol-gel method between a precursor of zirconia and a precursor of silicon oxide, wherein the sol is 0:1 ≤The number of moles of silica: the number of moles of zirconia≤1:1. In this embodiment, the sol contains silica sol, and the molar ratio of silica to zirconia in the sol is less than or equal to 1:1. Other The composition is basically the same as that of ordinary water-based ceramic inkjet ink.

[0055] In this embodiment, the precursor of the above-mentioned zirconia is zirconium oxychloride or ammonium zirconia. Of course, the precursor of zirconia can also be other substances, as long as it can be prepared by sol-gel method to obtain zirconia sol. Yes; the precursor of the above-mentioned silicon oxide is one or more of tetraethoxy silicon, tetramethoxy silicon and water glass, wherein the modulus of water glass is equal to or greater than 2, and of c...

Embodiment 2

[0058] A kind of special white water-based ceramic ink-jet ink of the present embodiment, except ceramic pigment, other components are deionized water, water-based dispersant, surfactant, water-soluble organic solvent and ink auxiliary agent, this special white water-based ceramic ink-jet ink is made of Composition of the following weight percentages:

[0059] Deionized water 20~55%

[0060] Sol 35~60%

[0061] Water-based dispersant and surfactant 2~10%

[0062] Water-soluble organic solvent 2-10%

[0063] Ink additives 2~6%

[0064] Wherein, the weight of the sol is calculated by the dry weight of zirconia and silicon oxide after the ink is fired, and the molar ratio of zirconia and silicon oxide is 1:1.

[0065] Wherein, the weight of deionized water, the dry weight of the sol after ink burning, the weight of water-based dispersant and surface activity, the quality of water-soluble organic solvent and the weight of ink additives are the total weight, and the weight perc...

Embodiment 3

[0081] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. A kind of ultra-white water-based ceramic inkjet ink of this embodiment also contains silane coupling agent, when preparing ultra-white water-based ceramic ink-jet ink, add coupling agent when adding water-soluble organic solvent, surfactant, coupling agent mainly There are water-soluble silane coupling agents and titanate coupling agents, specifically aminopropyl triethoxy silicon, aminopropyl trimethoxy silicon, glycidyl triethoxy silicon, glycidyl trimethoxysilane etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com