Thermosensitive type light reflection film capable of being jet printed

A reflective film, heat-sensitive technology, applied in optics, optical components, instruments, etc., can solve the problems of color fixation, inability to give reflective cloth color, photo or pattern effect, and no inkjet printability, etc. Inkjet effect, high retroreflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

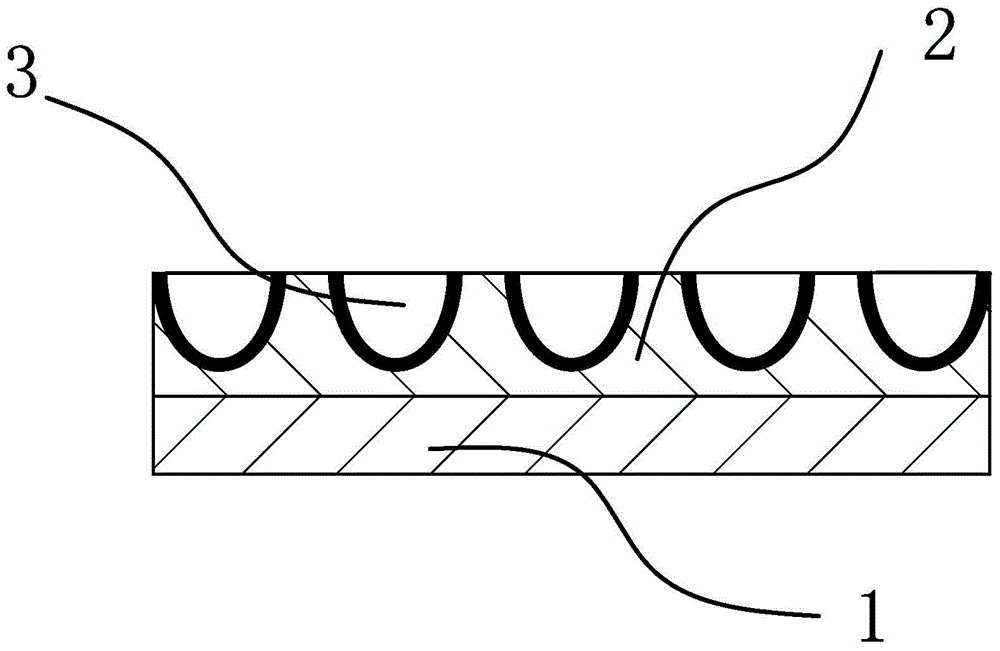

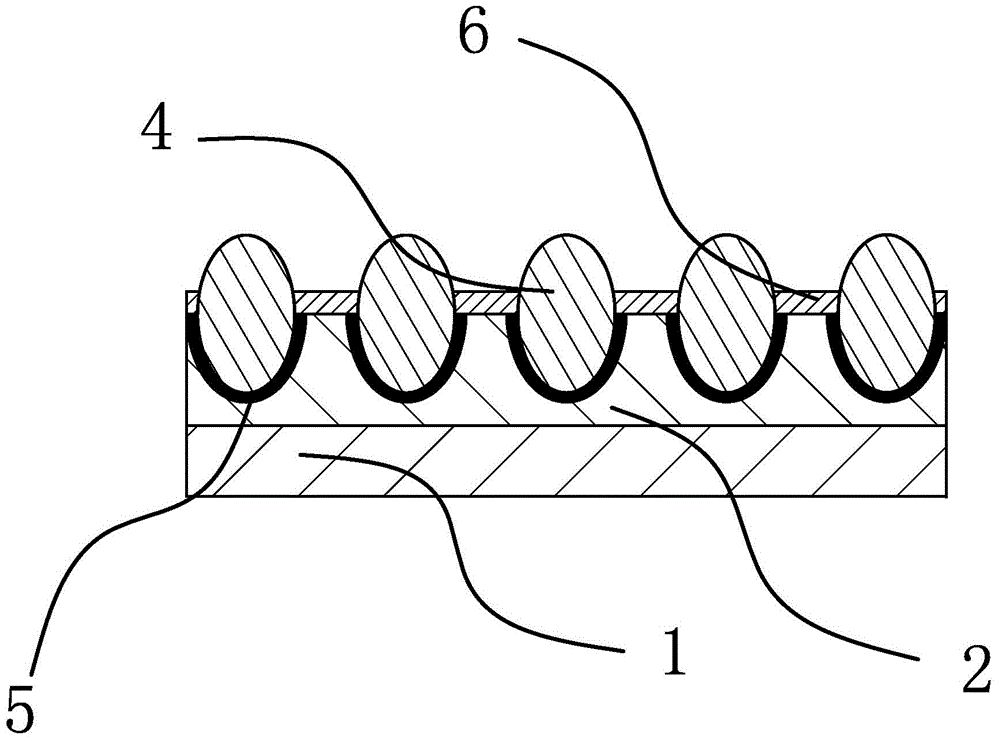

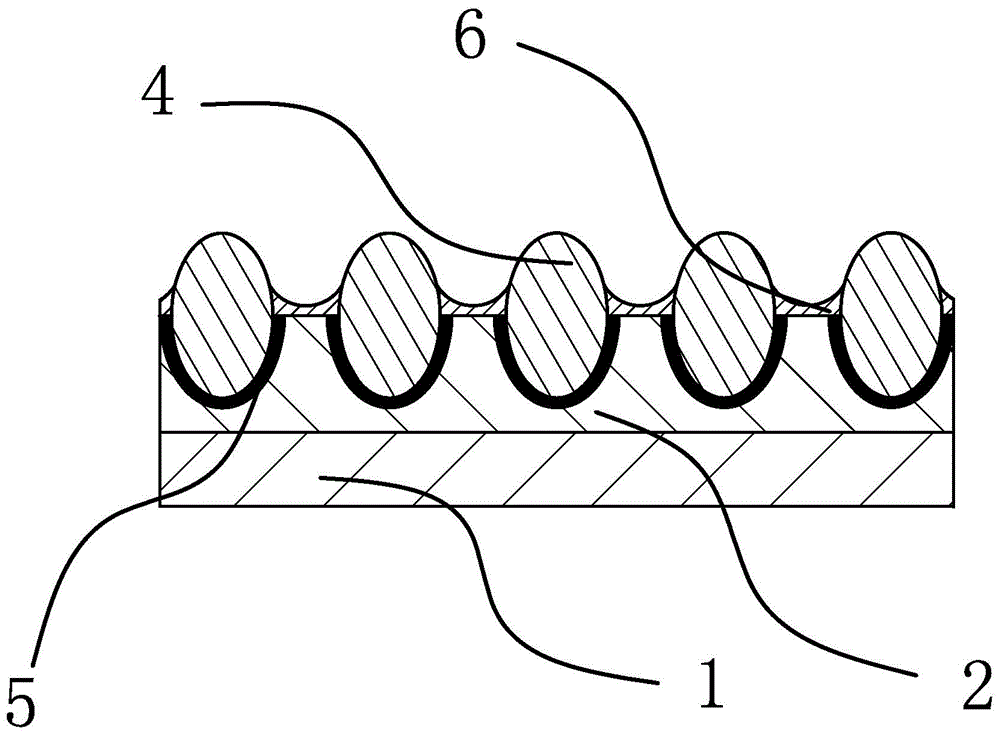

[0031] The heat-sensitive reflective film that can be sprayed in this embodiment includes a heat-sensitive adhesive layer 1 and a resin layer 2 that are sequentially stacked and fixed from bottom to top, and the heat-sensitive adhesive layer 1 is made of polyester PES. 1, and the thickness of the heat-sensitive adhesive layer 1 is 50 μm, the thickness of the resin layer 2 is 40 μm, and the resin layer 2 is made of acrylic resin; the upper part of the resin layer 2 is provided with several Grooves 3, the number of grooves 3 can be determined according to the actual needs of the glass beads 4 to be inlaid, at least one groove 3 can be set, and multiple rows of grooves 3 can also be set, and each groove 3 is inlaid There is a glass bead 4, the maximum diameter of the glass bead 4 is 40 μm, and the out-of-roundness and devitrification rate of the glass bead 4 are both ≤3%, the refractive index of the glass bead 4 is 1.94, and the mosaic The ratio of the distance from the bottom of...

Embodiment 2

[0033] The heat-sensitive reflective film that can be sprayed in this embodiment includes a heat-sensitive adhesive layer 1 and a resin layer 2 that are stacked and fixed sequentially from bottom to top, and the heat-sensitive adhesive layer 1 is made of thermoplastic polyurethane TPU. 1, and the thickness of the heat-sensitive adhesive layer 1 is 80 μm, the thickness of the resin layer 2 is 70 μm, and the resin layer 2 is made of acrylic resin; the upper part of the resin layer 2 is opened with several Grooves 3, the number of grooves 3 can be determined according to the actual glass beads to be inlaid, at least one groove 3 can be set, and multiple rows of grooves 3 can also be set, each groove 3 is inlaid with a Glass beads 4, the maximum diameter of the glass beads 4 is 60 μm, and the out-of-roundness and devitrification rate of the glass beads 4 are ≤3%, the refractive index of the glass beads 4 is 1.70, when inlaid The ratio of the distance from the bottom of the glass m...

Embodiment 3

[0035] The heat-sensitive reflective film that can be sprayed in this embodiment includes a heat-sensitive adhesive layer 1 and a resin layer 2 that are stacked and fixed sequentially from bottom to top. The heat-sensitive adhesive layer 1 is made of polyester polyurethane PA. Layer 1, and the thickness of the heat-sensitive adhesive layer 1 is 100 μm, the thickness of the resin layer 2 is 100 μm, and the resin layer 2 is made of acrylic resin; the upper part of the resin layer 2 is provided with Several grooves 3, the number of grooves 3 can be determined according to the actual glass beads to be inlaid, at least one groove 3 can be set, and multiple rows of grooves 3 can also be set, and each groove 3 is inlaid There is a glass bead 4, the maximum diameter of the glass bead 4 is 100 μm, and the out-of-roundness and devitrification rate of the glass bead 4 are both ≤3%, the refractive index of the glass bead 4 is 1.80, and the mosaic The ratio of the distance from the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com