Patents

Literature

31results about How to "High coefficient of retroreflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Regression reflective fabric and its production method

InactiveCN1641099AGood flexibilityExcellent coefficient of retroreflectionVacuum evaporation coatingSputtering coatingGramReflective layer

This invention discloses a kind of regression reflect fabric, including one reflection component, a metal reflection layer, a adhesive layer and one basic material, the reflection component layer is implied 30-130 grams of tiny glass beads with each square arranged intensively. The fabric's reflection function is good, the anti-coefficient can amount to the 70-700 cds / Lx / square m.

Owner:CHINESE TEXTILE ACAD +1

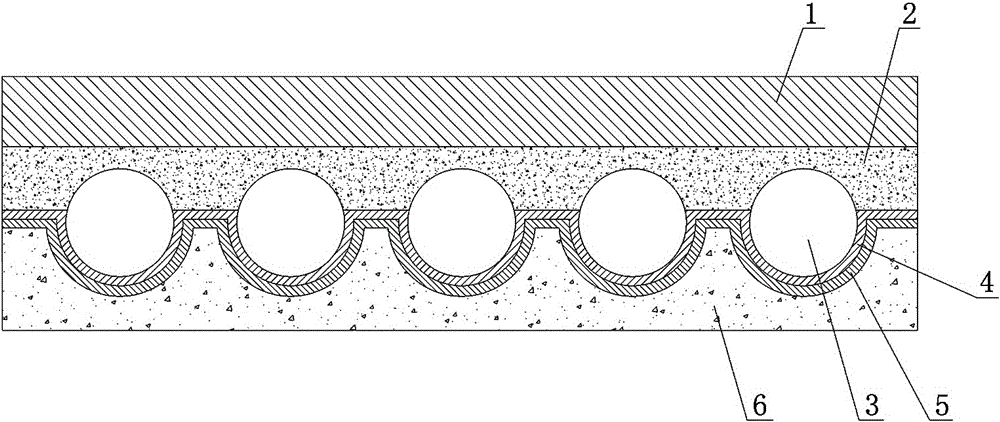

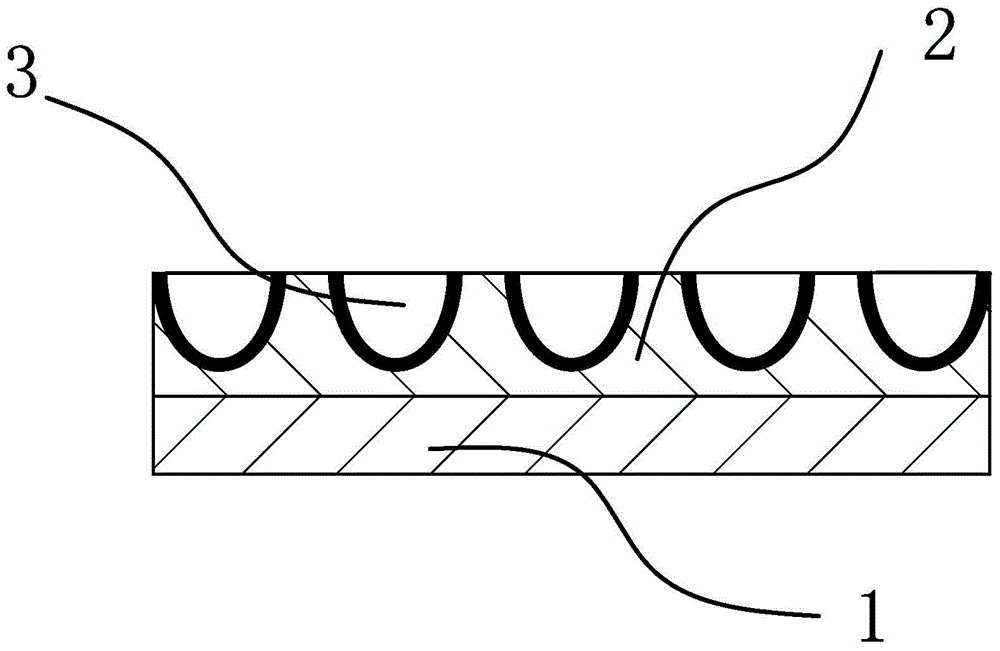

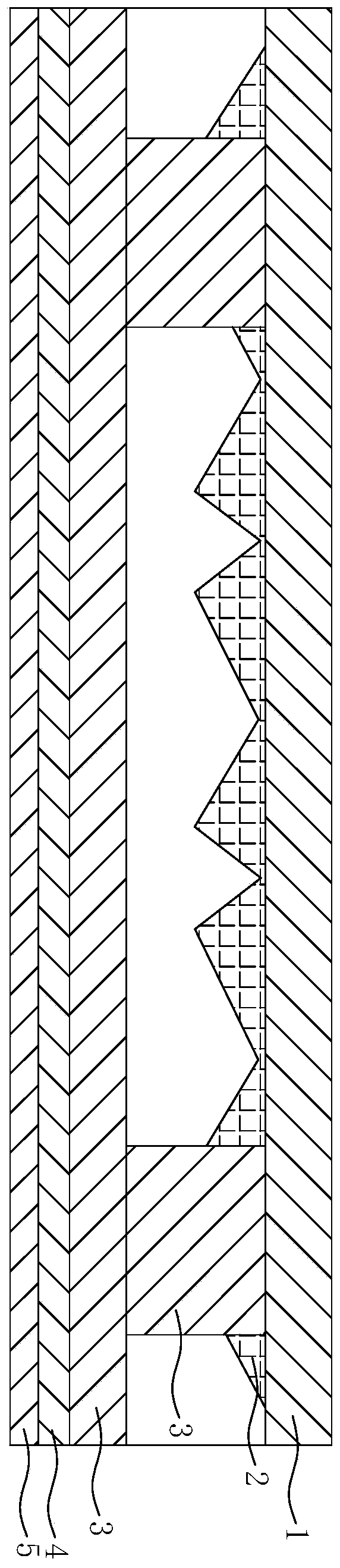

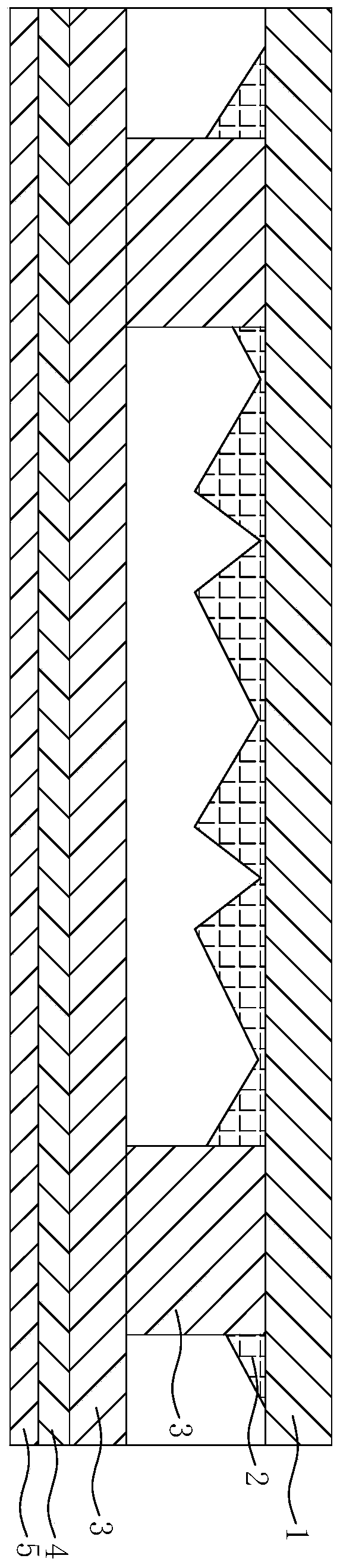

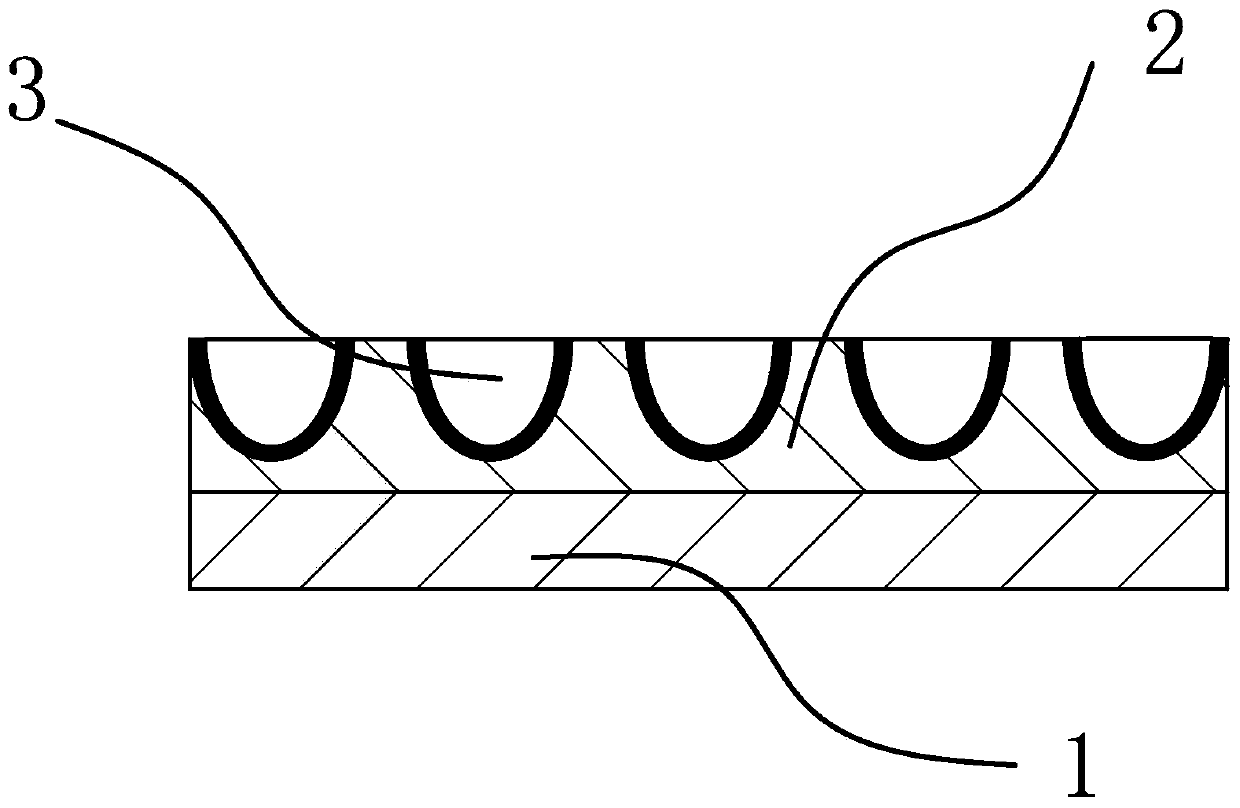

Colorful high-brightness hot-sticking reflective cloth and manufacturing process

InactiveCN106707387AMeet the increasing personalizationMeet needsLamination ancillary operationsSynthetic resin layered productsEngravingMetallurgy

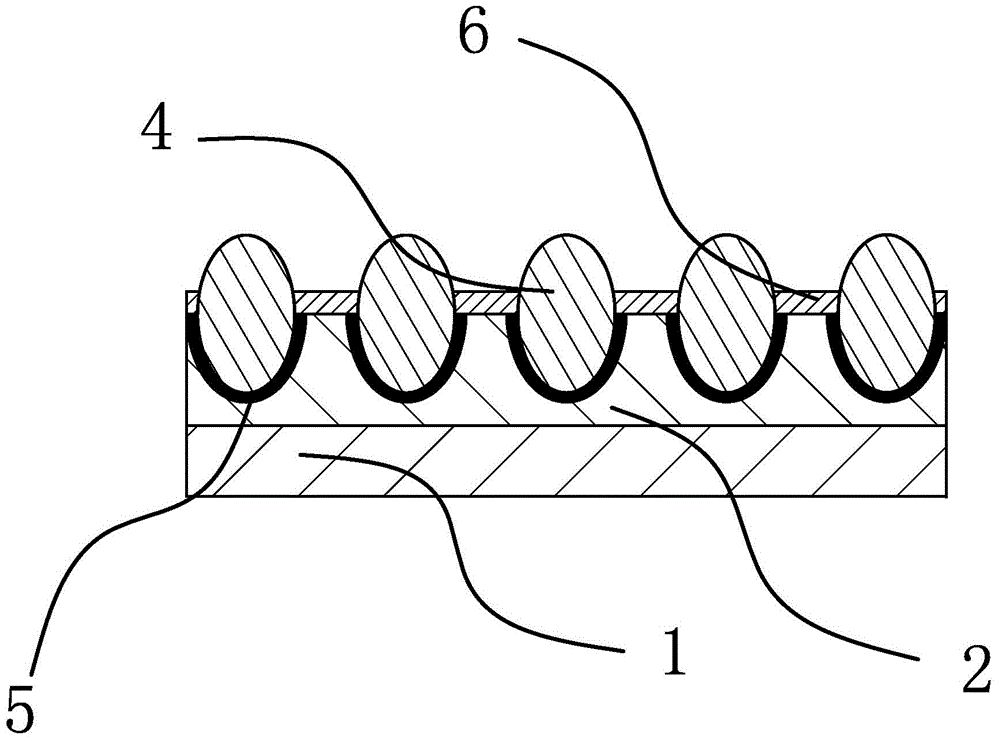

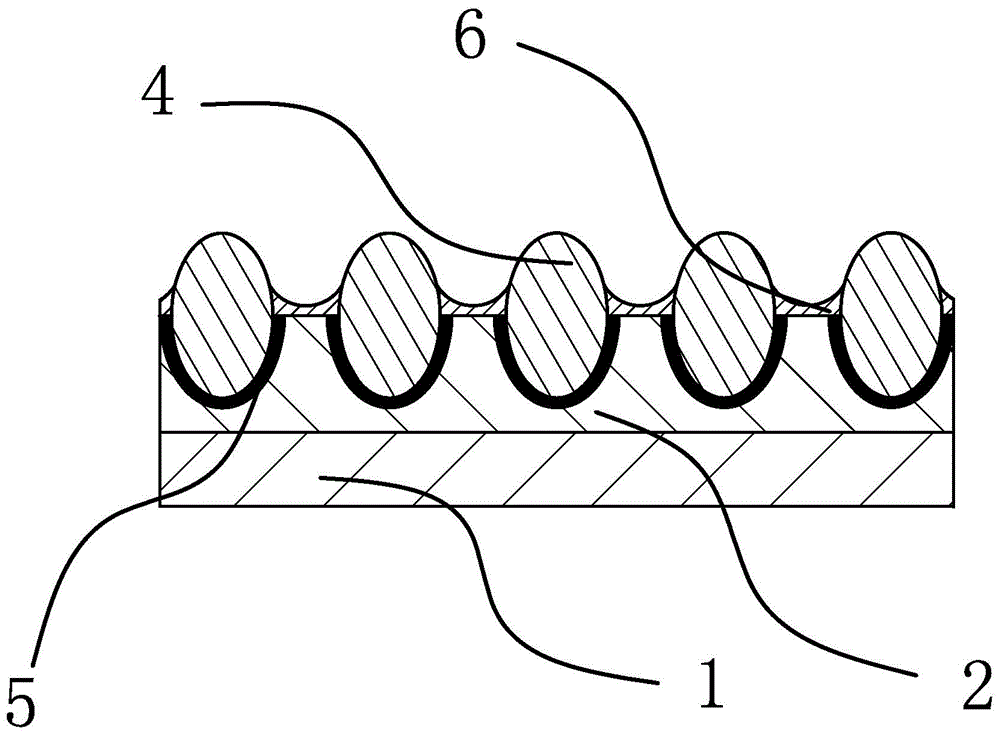

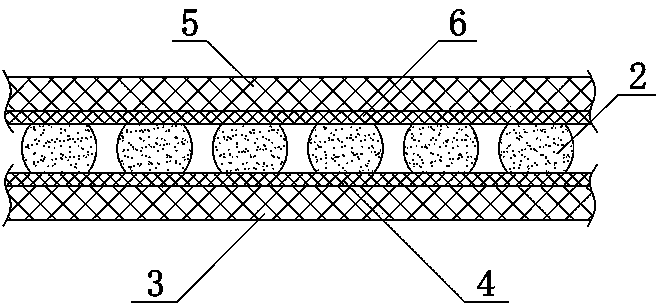

The invention discloses a colorful high-brightness hot-sticking reflective cloth. The colorful high-brightness hot-sticking reflective cloth comprises a base material (1), a bead planting layer (2), glass microbeads (3), a zinc sulfide layer (4), an aluminum layer (5) and a hot melt adhesive layer (6), wherein the thickness of the base material (1) is 10-125 microns; the bead planting layer (2) is arranged at the lower surface of the base material (1); a plurality of glass microbeads (3) with different particle diameters are arranged between the zinc sulfide layer (4) and the bead planting layer (2); the lower half part of each microbead is embedded into the zinc sulfide layer (4); the particle-diameter size of each glass microbead (3) is 5-120 microns; the refractive index of the glass microbeads is 1.90-1.93; and the thickness range of the bead planting layer (2) is more than 0.1 micron and is less than one third of the average particle diameter of the glass microbeads (3). The colorful high-brightness hot-sticking reflective cloth disclosed by the invention has the beneficial effects that the manufacturing process is simple, the colorful effect is good, the retro-reflecting coefficient is high, the increasingly individualized and fashionable market demand for customers can be met, and the product can be used for character engraving and hot sticking.

Owner:浙江海川安全防护用品有限公司

High-weather-resistance household washing permanent-color high-strength reflecting material with TC (terylene cotton) fabric as base

InactiveCN102998727AHigh coefficient of retroreflectionStrong weather resistanceGlass/slag layered productsOptical elementsWeather resistanceLight source

The invention discloses a high-weather-resistance household washing permanent-color high-strength reflecting material with a TC (terylene cotton) fabric as a base. The high-weather-resistance household washing permanent-color high-strength reflecting material comprises a base material, an adhesion layer, a color bottom layer, a reflecting layer, a transparent color layer, a protective layer and glass beads. Incident light is sequentially transmitted through the glass beads and the transparent color layer to reach the reflecting layer to be focused and reflected, reflected light is further transmitted through the glass beads so that a visual colored light reflection effect is realized, other light rays of an incident light source are simultaneously diffused on the transparent color layer among the glass beads and are mapped to the glass beads, a visual comprehensive color light reflection effect is realized under the joint action of focusing and reflecting of the other light rays, incident light rays are transmitted through gaps among the glass beads, the transparent color layer and the reflecting layer to reach the color bottom layer, and colors of the bottom layer are mapped on the glass beads to realize a color light reflection effect. The high-weather-resistance household washing permanent-color high-strength reflecting material has a high coefficient of retroreflection, and is high in weather resistance and color retainability.

Owner:SUZHOU CUIZHI NEW TECH DEV

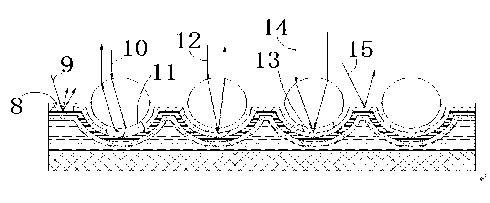

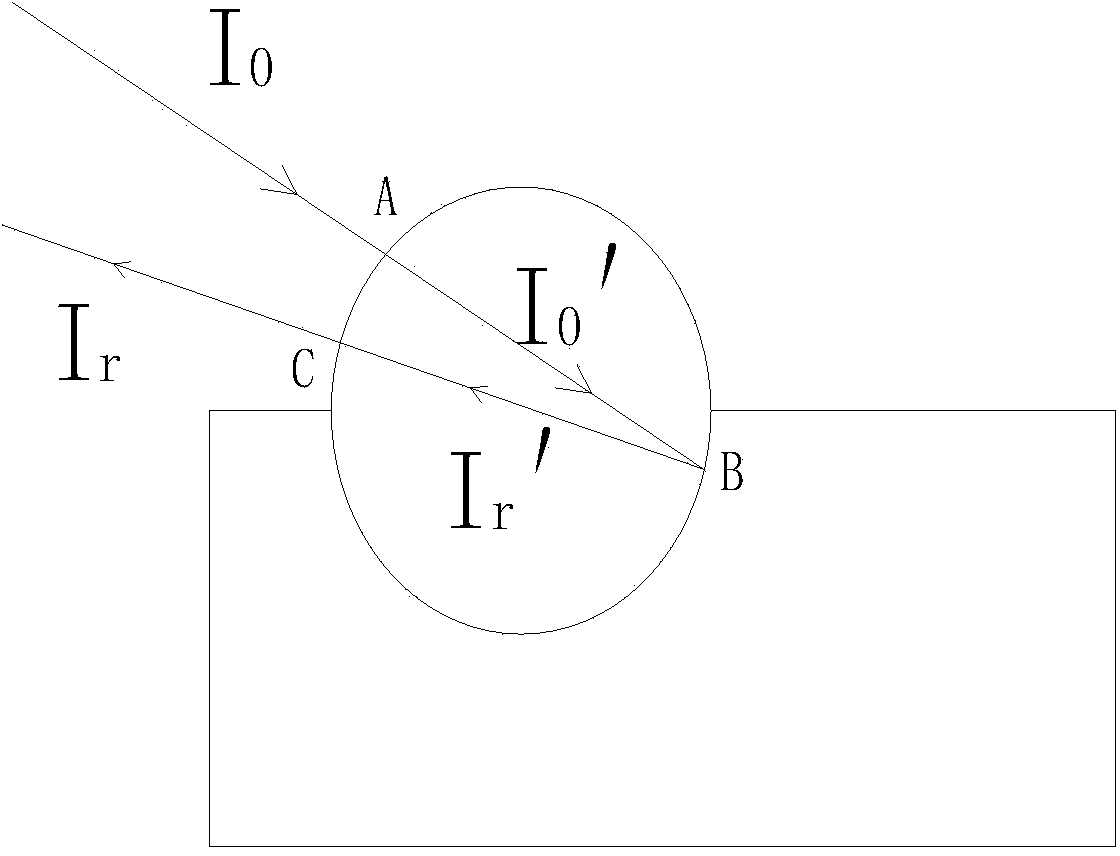

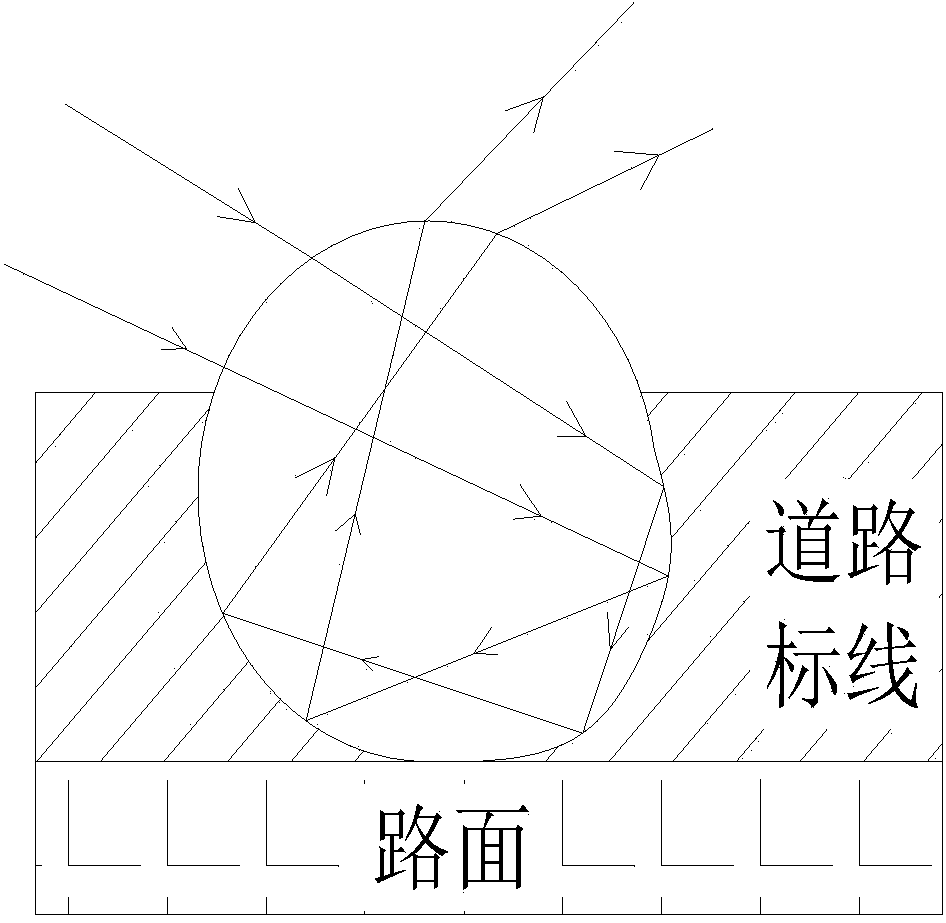

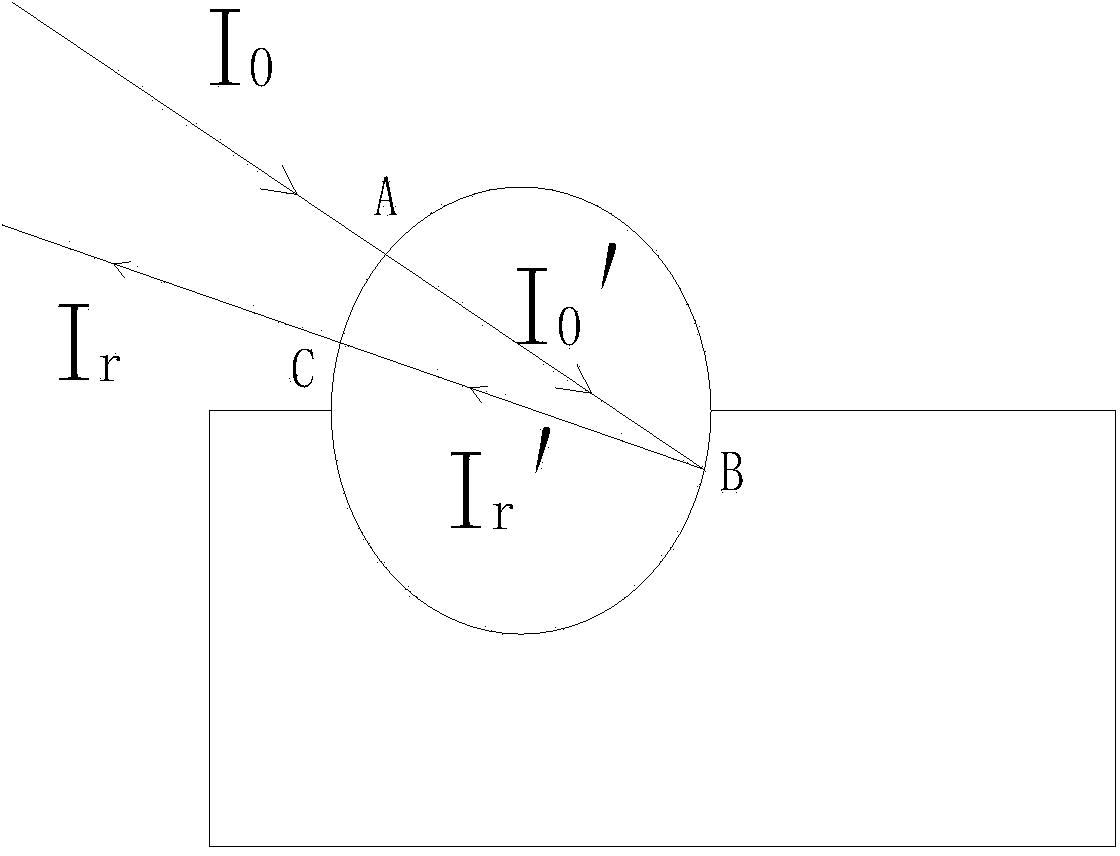

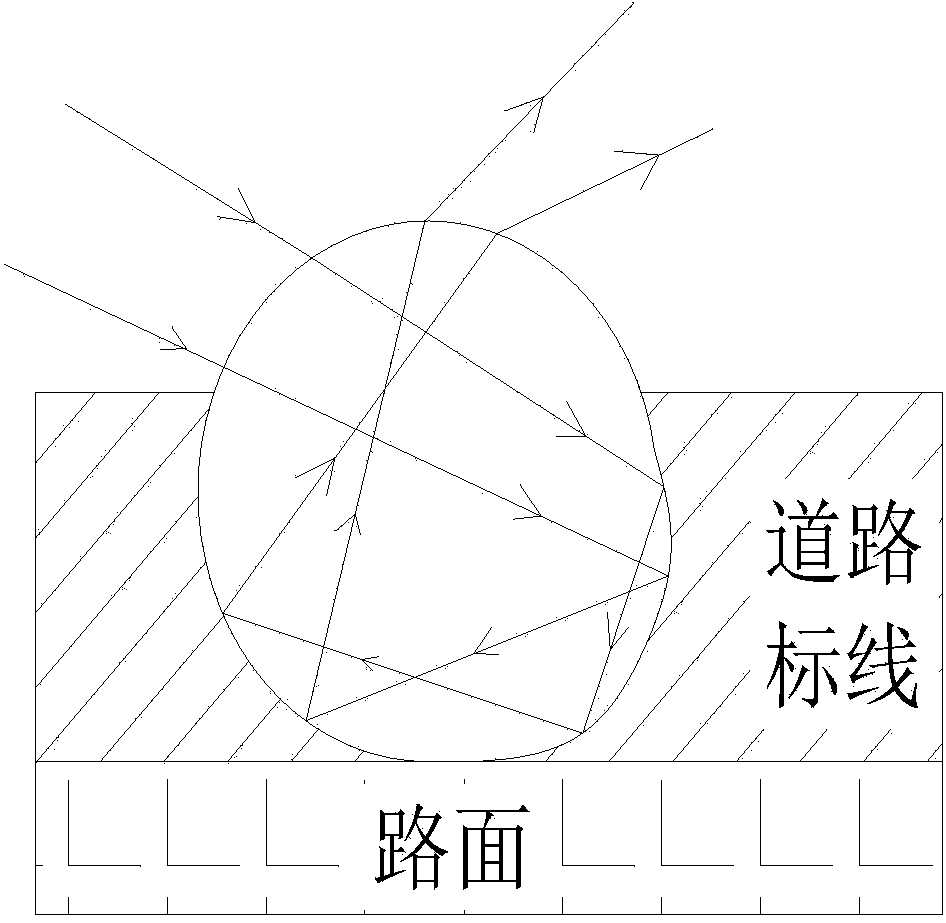

Road marking reflective bead

InactiveCN104046116AHigh technology contentReduce incidenceReflecting/signal paintsRefractive indexSlurry

The invention provides a road marking reflective bead comprising titanium dioxide, calcium oxide, zirconium oxide, boron oxide, aluminum oxide and an inorganic salt additive, a preparation process of the road marking reflective bead comprises the following steps: step 1, using a sand mill for grinding and high speed dispersion of the titanium dioxide, calcium oxide, zirconium oxide, boron oxide, aluminum oxide and inorganic salt additive to obtain inorganic slurry; step 2, granulating by spray drying of the inorganic slurry; step 3, sintering the dried particles in the high-temperature oxygen-enriched environment into fine grains; step 4, cooling, collecting and screening the fine grains to obtain the road marking reflective bead. By improvement of product components, the refraction rate of crystallite ceramic beads can reach above 2.2, and the weather-proof, wear-resisting, water-tolerant and alkali resistant functions of the product and coating adhesion can be improved, so that the product has high hardness and high wear resistance, the all-weather reflective effect of the product can be ensured, and the consistency of the service life of the ceramic beads and a marking can be ensured.

Owner:湖州远光路标涂料有限公司

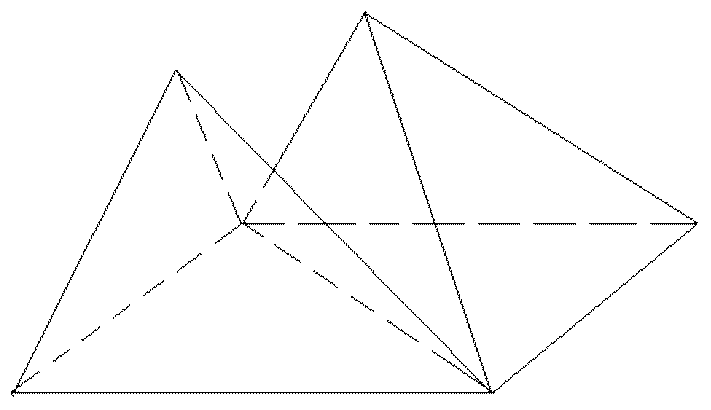

Preparation method of micro-prism working mould with subsequent continuous processing function

InactiveCN104032335AEasy to adjustHigh coefficient of retroreflectionElectroforming processesSaccharinMetallic Nickel

The invention discloses a preparation method of a micro-prism working mould with a subsequent continuous processing function, relating to micro-prism reflection films. The preparation method comprises the following steps: adding water into an electroforming tank, and adding nickel sulfate hexahydrate and nickel chloride in sequence; adding boric acid into hot water, boiling, adding lauryl sodium sulfate, dissolving, pouring into the electroforming tank, adding saccharin and 1,4-butynediol into the electroforming tank, filling up water in the electroforming tank, and adjusting the pH value to be 4.0-4.4 to obtain an electroforming liquid; continuously copying a metal master mould on a PVC material to obtain a sheet-like template with a micro-pyramid structure on one side, wherein each side length of the micro-pyramid of the sheet-like template is 100-200 microns; keeping the micro-pyramid structure on the inner side, defining a barrel by the sheet-like template, performing butt welding to obtain an annular template, and performing electroforming pre-treatment on the inner surface of the annular template; putting an anode nickel plate into an annular anode basket, and connecting to an anode; and putting the annular template into the electroforming tank, connecting to a cathode while ensuring that the cathode is concentric with the anode, electroforming, and performing cathodic de-moulding to obtain the micro-prism working mould.

Owner:JIMEI UNIV

Thermosensitive type light reflection film capable of being jet printed

ActiveCN104932047AGood inkjet effectHigh coefficient of retroreflectionSynthetic resin layered productsGlass/slag layered productsLight reflectionReflective layer

The invention relates to a thermosensitive type light reflection film capable of being jet printed, and belongs to the technical field of reflecting materials. The existing problem that high retro-reflecting coefficient and jet printing can not be achieved simultaneously is solved, the light refection film comprises a thermosensitive adhesive layer and a resin layer which are overlapped in sequence from top to bottom and fixed, multiple grooves are formed in the upper portion of the resin layer, each groove is internally embedded with a glass bead, a reflecting layer is laid between a groove wall of each groove and the corresponding glass bead, coatings capable of being jet printed are arranged on the upper surface of the resin layer, and the upper portion of each glass bead is higher than the corresponding coating capable of being jet printed. The thermosensitive type light reflection film capable of being jet printed has a better jet printing effect, and the double-effect of higher retro-reflecting coefficient is achieved. The coatings capable of being jet printed between each two glass beads are designed to be shaped like a sunken arc surface, so that the effect that the retro-reflecting coefficient is greater than 400 cd.lx<-1>.m<-2> is achieved.

Owner:ZHEJIANG YGM TECH CO LTD

All-weather high-refraction reflective micro-crystal ceramic bead

InactiveCN103964676AHigh technology contentReduce incidenceGlass shaping apparatusInorganic saltsRefractive index

The invention provides an all-weather high-refraction reflective micro-crystal ceramic bead. The all-weather high-refraction reflective micro-crystal ceramic bead comprises an inner core and a core reflective element, wherein the core reflective element comprises the following components: titanium dioxide, calcium oxide, zirconium oxide, boron oxide, aluminum oxide and inorganic salt additives. By improvement of the product components, the refractive index (ND value) of the micro-crystal ceramic bead can reach more than 2.2; when high refractive index is reached, the weather resistant function, the abrasion resistant function, the water resistant function and the alkali resistant function of products and the adhesive force of the products with paints are improved, so that the products have high hardness and high abrasion resistant performance, the condition that the products reach the all-weather reflective effect is ensured, and at the same time, the consistency of the service lives of the ceramic bead and graticules is ensured.

Owner:湖州远光路标涂料有限公司

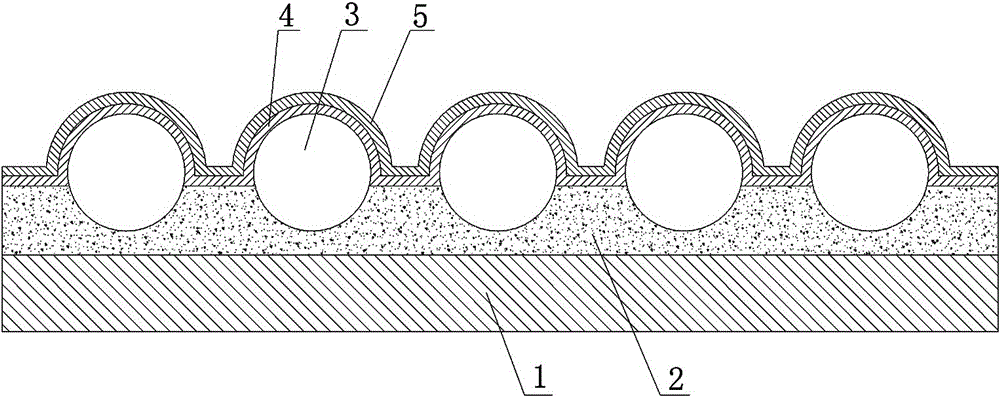

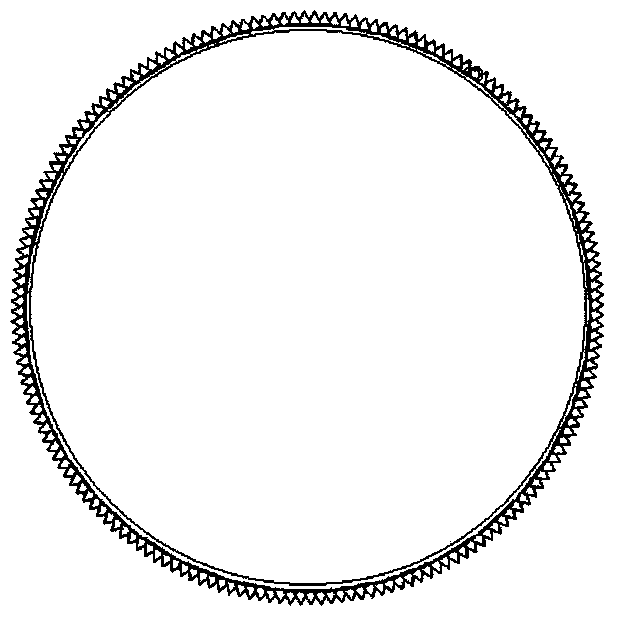

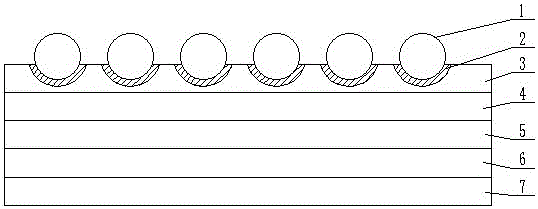

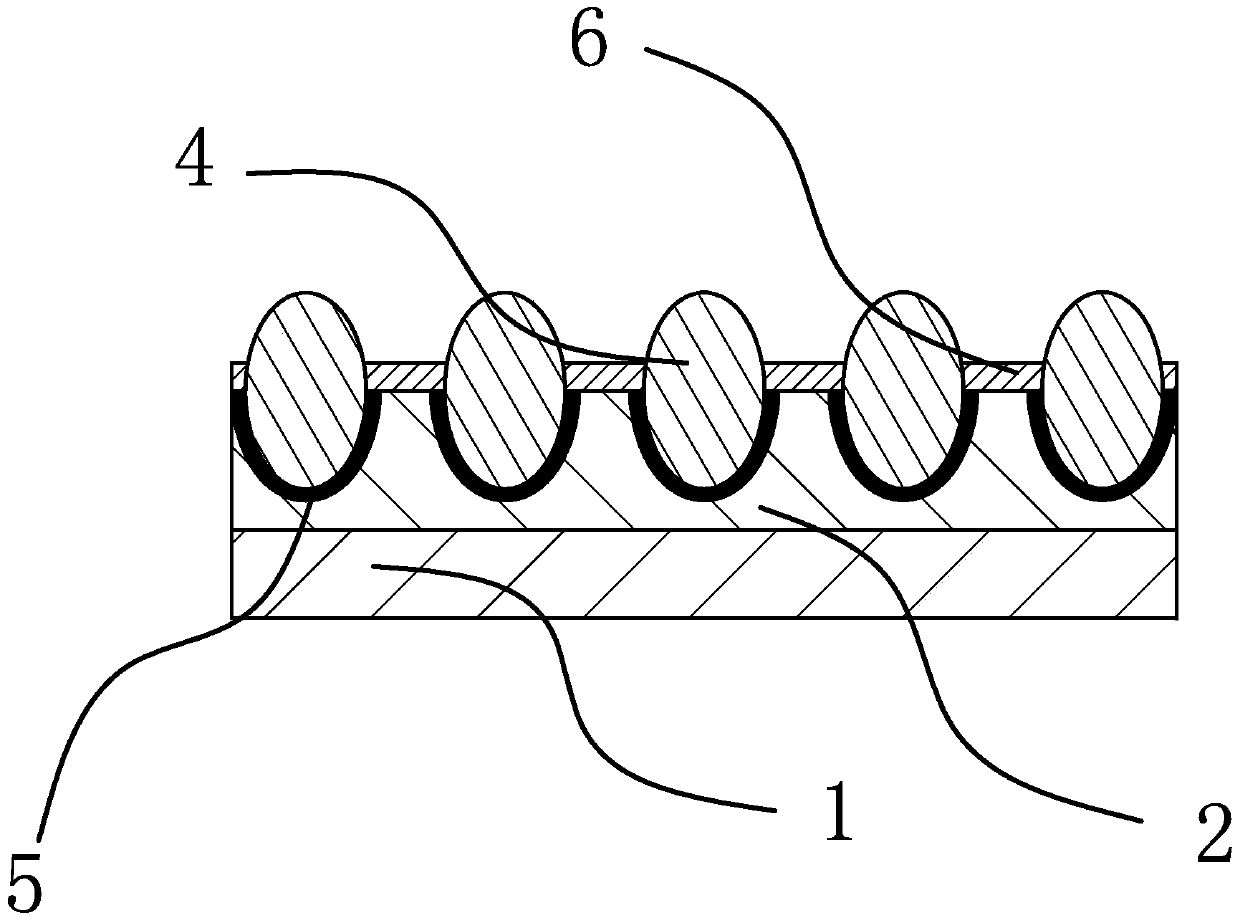

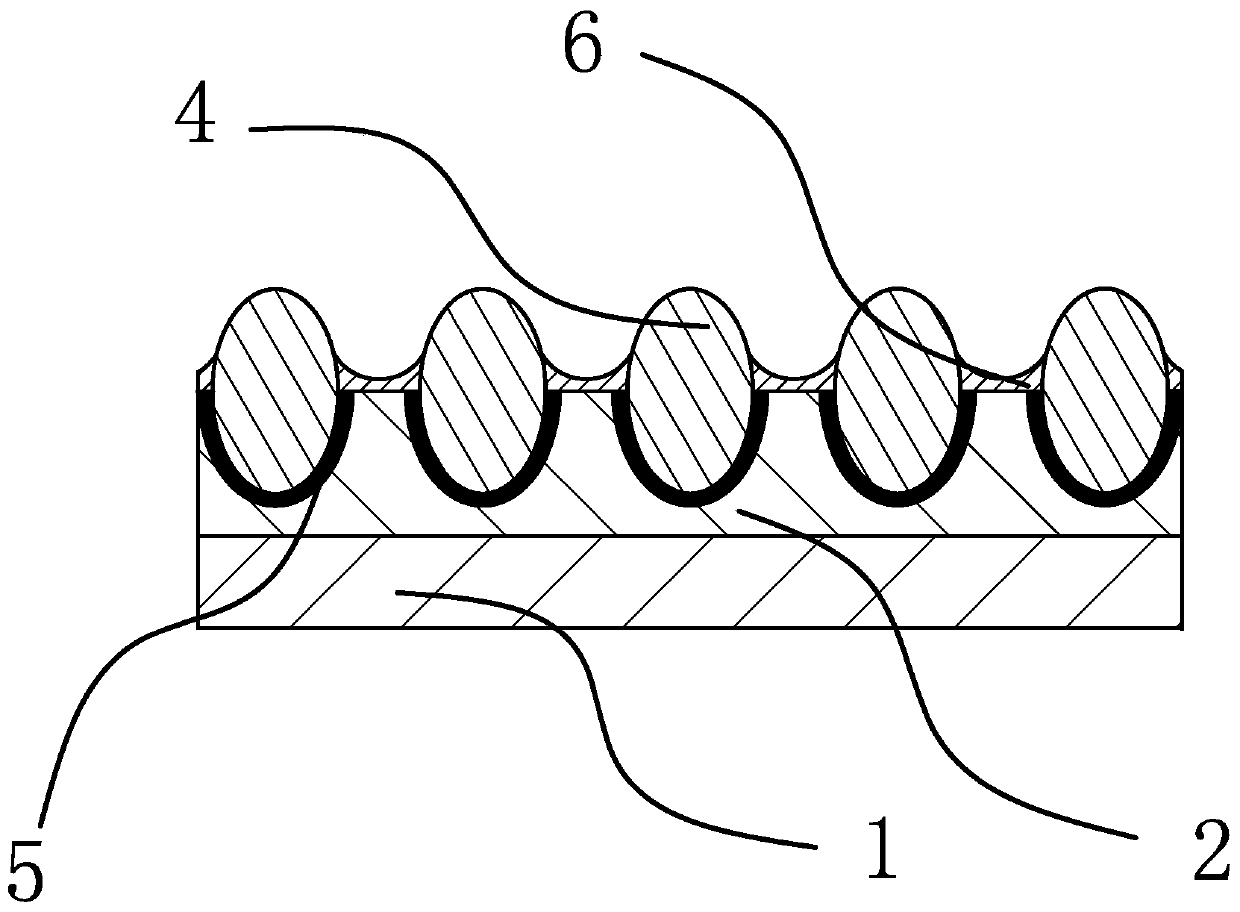

Bead exposing type dazzling reflection light storing film and manufacturing process thereof

InactiveCN107526125AAdd colorful effectTaking into account the function of safety protectionIlluminated signsOptical elementsOptoelectronicsZinc sulfide

The invention relates to a bead exposing type dazzling reflection light storing film, comprising a glass bead (1), a zinc sulfide layer (2), a connecting layer (3), a light storing layer (4), a reflection layer (5), a bonding layer (6), and a release layer (7). The connecting layer (3) is embedded with a plurality of glass beads (1). The contact surface of the lower side of the glass bead (1) and the connecting layer (3) is provided with the zinc sulfide layer (2). The light storing layer (4), the reflection layer (5) and the release layer (7) are sequentially disposed at the lower part of the connecting layer (3). The reflection layer (5) is connected to the release layer (7) through the bonding layer (6). The manufacturing process comprises the steps of S1 preparing bead film; S2 connecting the light storing layer (4) to the reflection layer (5); S3 connecting the release layer (7); S4 molding finally.

Owner:SICHUAN JINYING TECH CO LTD

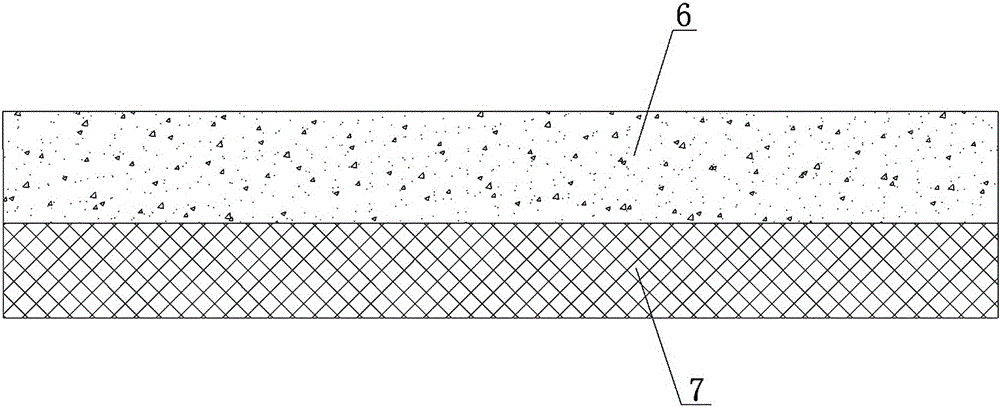

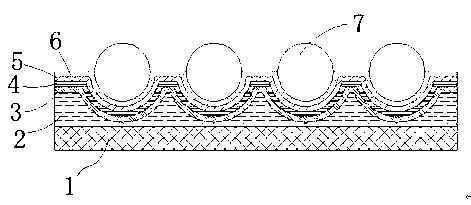

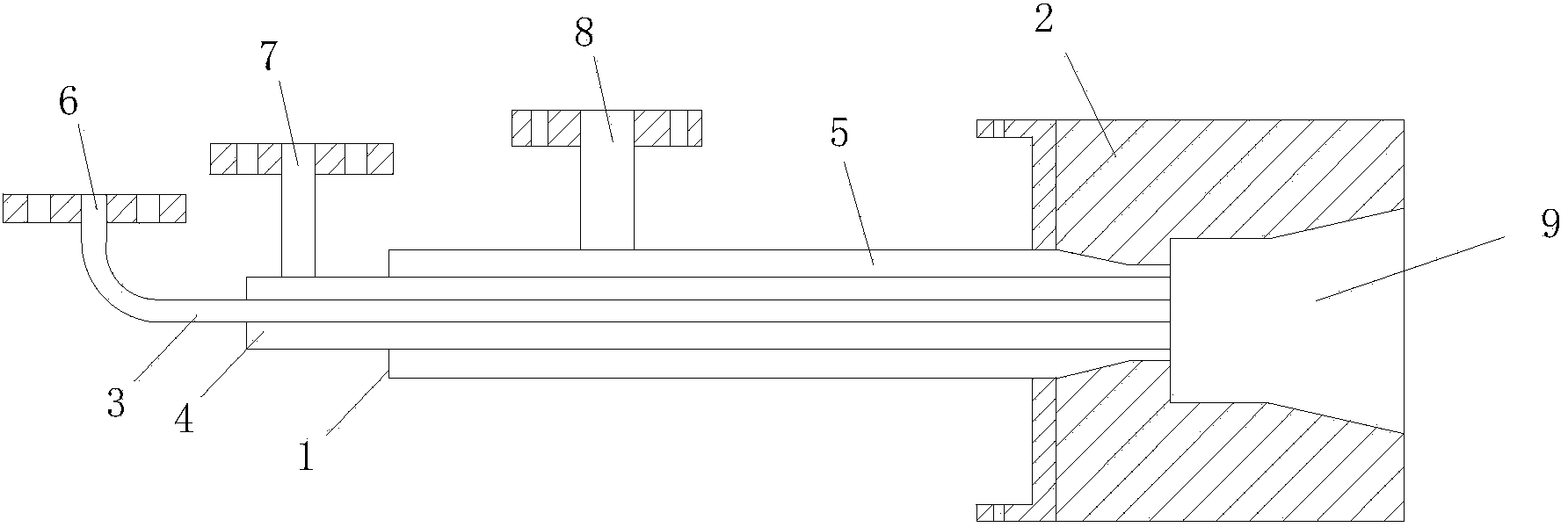

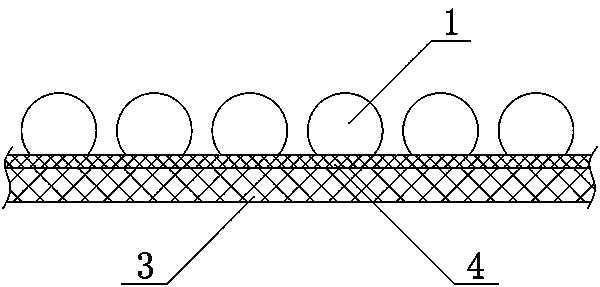

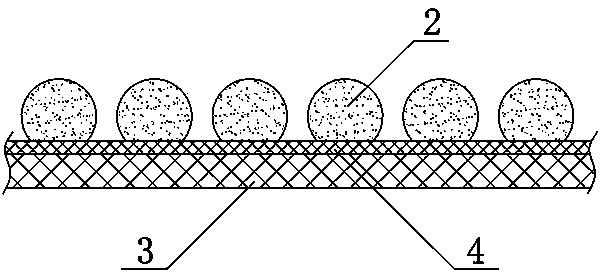

Full-aluminizing high-refractive-index glass microbead as well as production process thereof

InactiveCN103823265AControl the depth of settlementEasy to operateOptical elementsLight reflectionRefractive index

The invention relates to a full-aluminizing high-refractive-index glass microbead. The full-aluminizing high-refractive-index glass microbead comprises a glass microbead body (1) and an aluminizing layer (2), wherein the aluminizing layer (2) completely covers the outer surface of the glass microbead body (1); the refractive index of the glass microbead body (1) is 1.90-2.21; the thickness of the aluminizing layer (2) is 300 angstroms to 1,200 angstroms. The production process comprises the following steps: S1, planting a bead; S2, aluminizing once; S3, compounding; S4, peeling and aluminizing for the second time; S5, removing a planted bead resin layer B (6) to obtain the full-aluminizing glass micro bead. The full-aluminizing high-refractive-index glass microbead and the production process thereof, which are provided by the invention, have the advantages that the coating thickness is controlled by a coating machine, and the operation is simple; because the planted bead resin layer B is water soluble resin, and is soluble in water, the aluminized glass micro bead can be conveniently separated away from a base material, and the appearance cannot be damaged, and the product percentage of pass is high; the full-aluminizing high-refractive-index glass microbead is high in retroreflection coefficient, and a light reflection effect is good.

Owner:SICHUAN ZHONGKE BETTER TECH

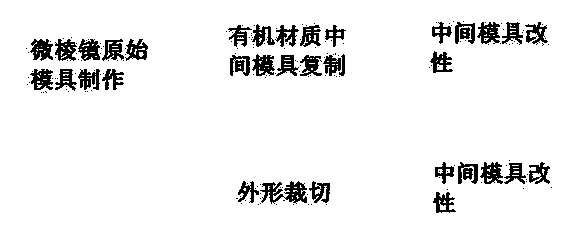

Microprism reflecting material manufacturing method

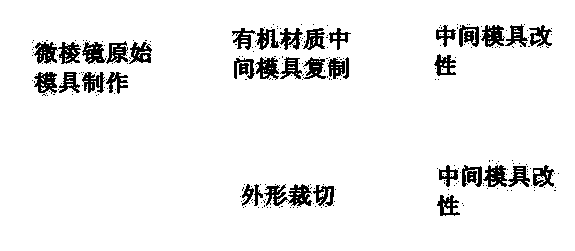

Provided is a microprism reflecting material manufacturing method, comprising employing the diamond lathe ultra-precision cutting process to manufacture a microprism structure reflecting material original graphic mould on materials such as plastic, metal, colloid, crystal, etc.; manufacturing modules of PDMS, PC, PMMA, photosensitive gel, etc. out of an original mould with a microprism pattern through thermocuring, ultraviolet curing, and duplication processes; plating a duplicated intermediate mould with a layer of fluorine containing macromolecules, and improving nickel mould surface demoulding; coating the modified intermediate mould with material solutions of PMMA, PC, photosensitive gel, etc. to perform curing processing, and then performing separated demoulding between the module and a target reflective membrane; and finally decorating the demoulded microprism reflecting material membrane into a designed shape. The method effectively solves the problems of great manufacturing difficulty, poor preserving effect, large processing technology tolerance, etc. of a present microprism reflecting material intermediate work mould.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

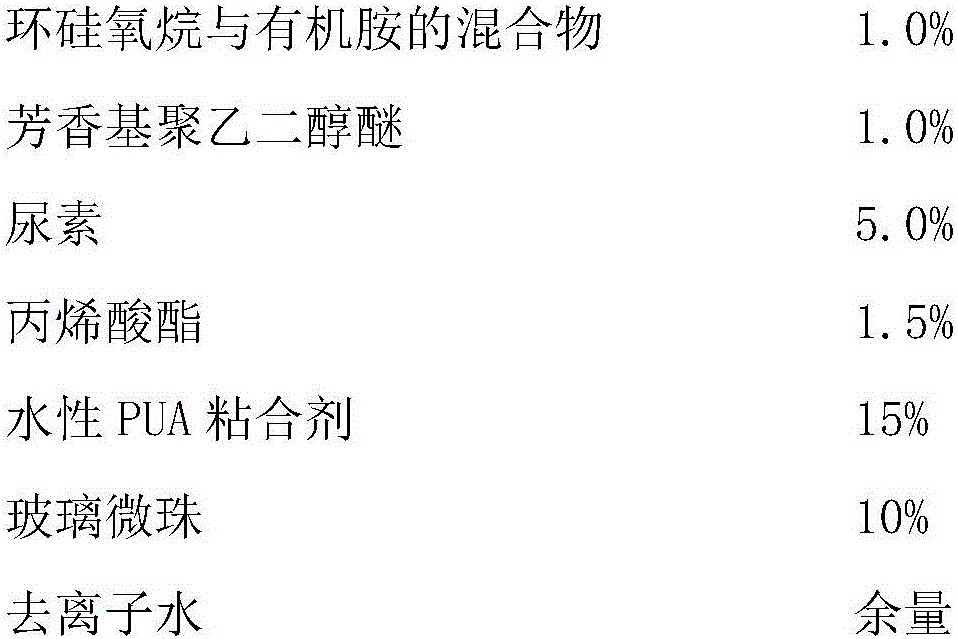

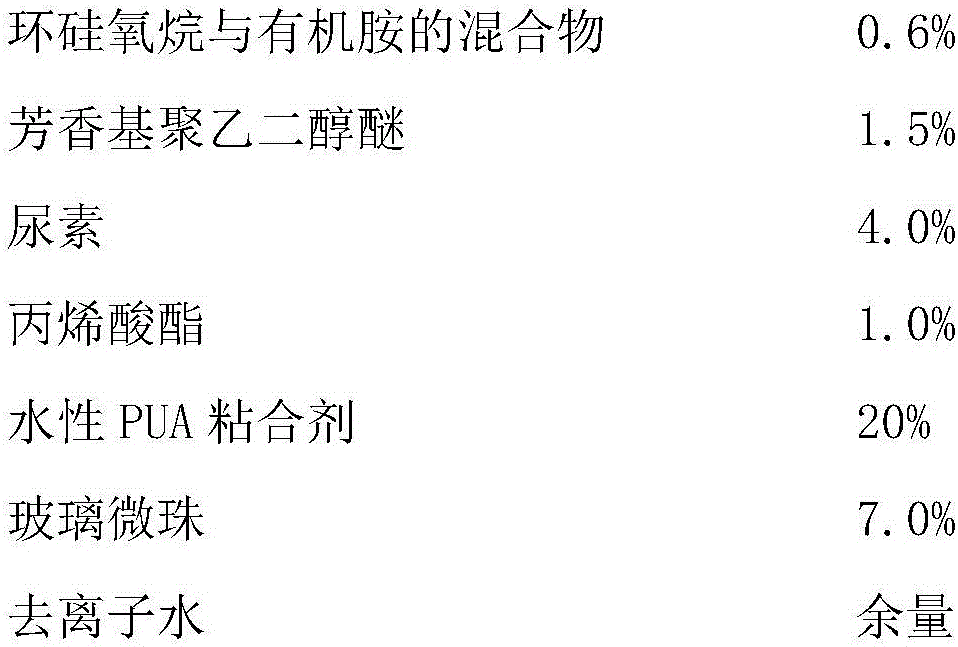

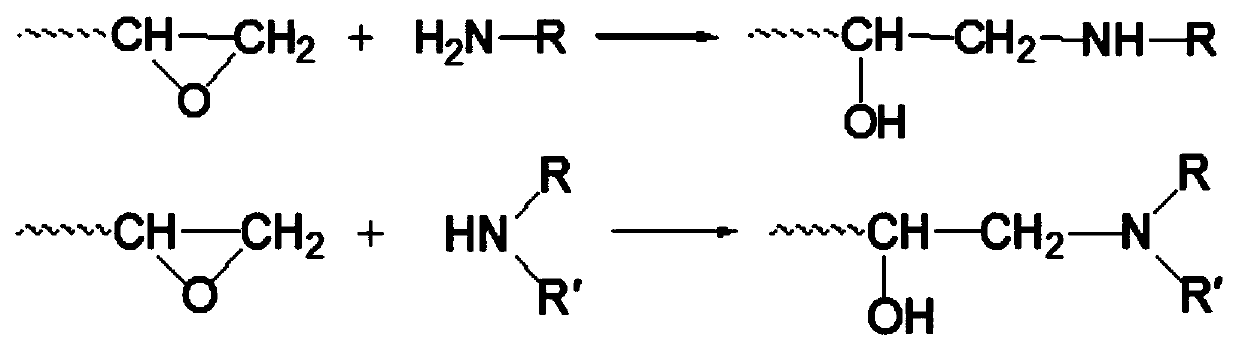

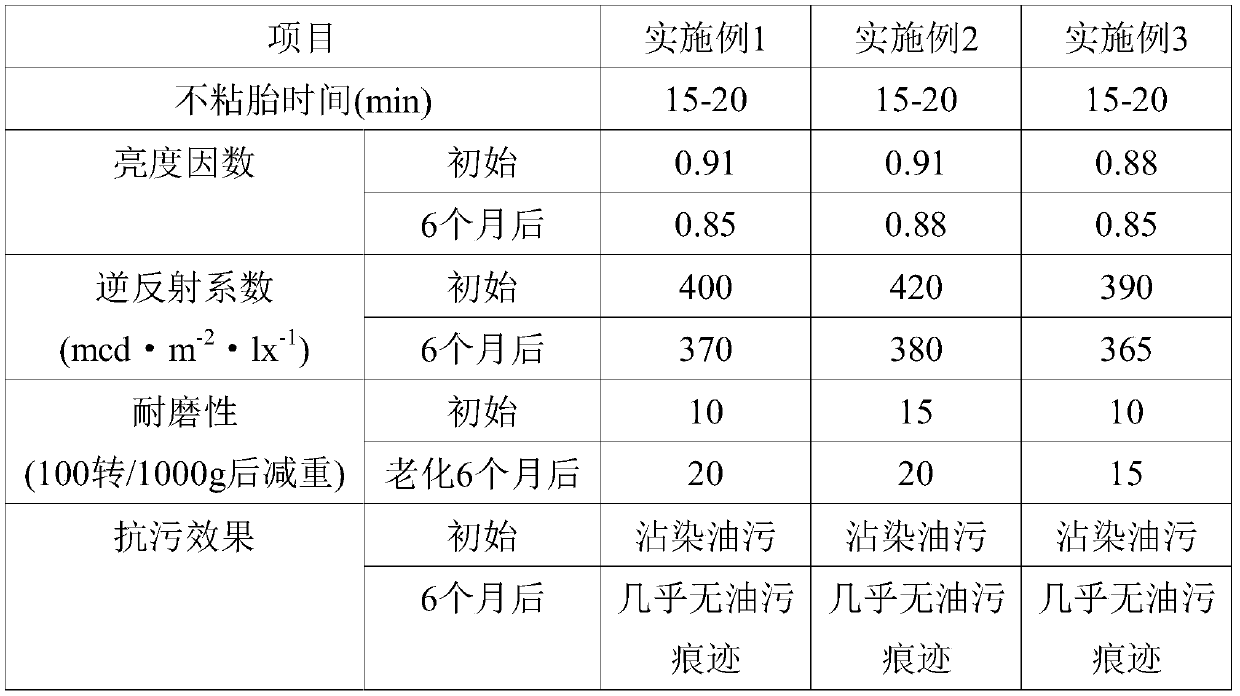

Water-based system reflective pulp and application thereof in sportswear fabric

ActiveCN106638043AImprove adhesionGood anti-adhesionDyeing processLiquid/gas/vapor textile treatmentWater basedEther

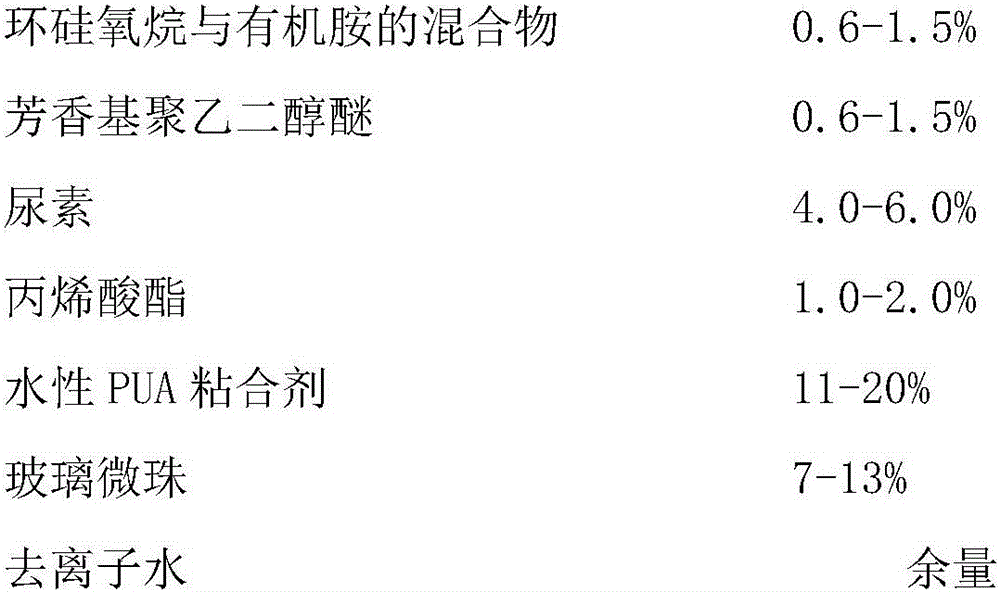

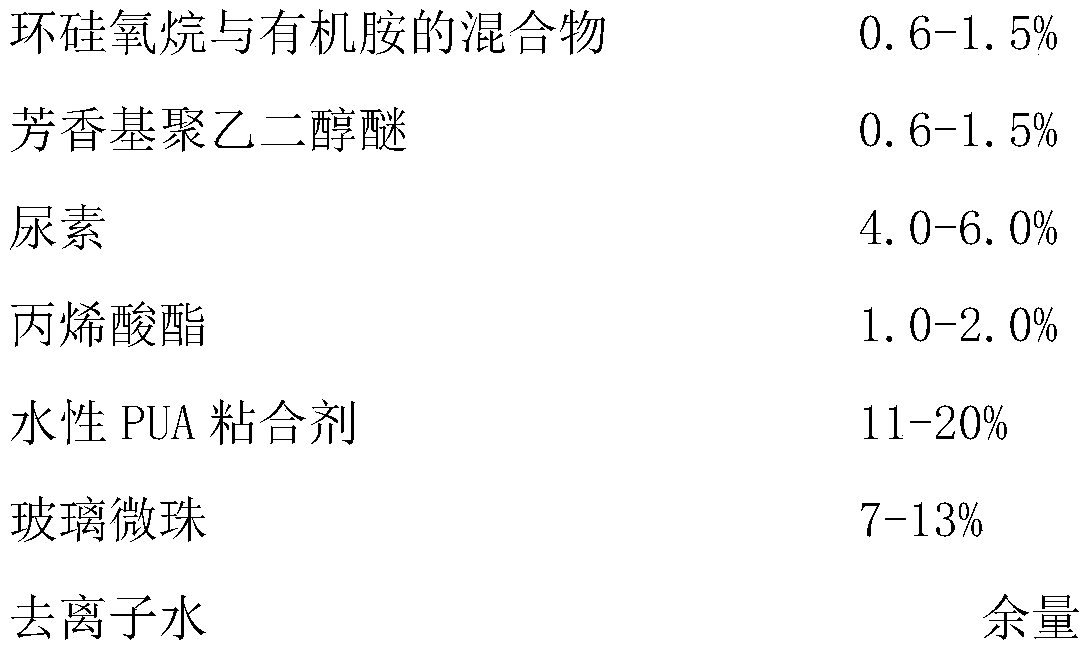

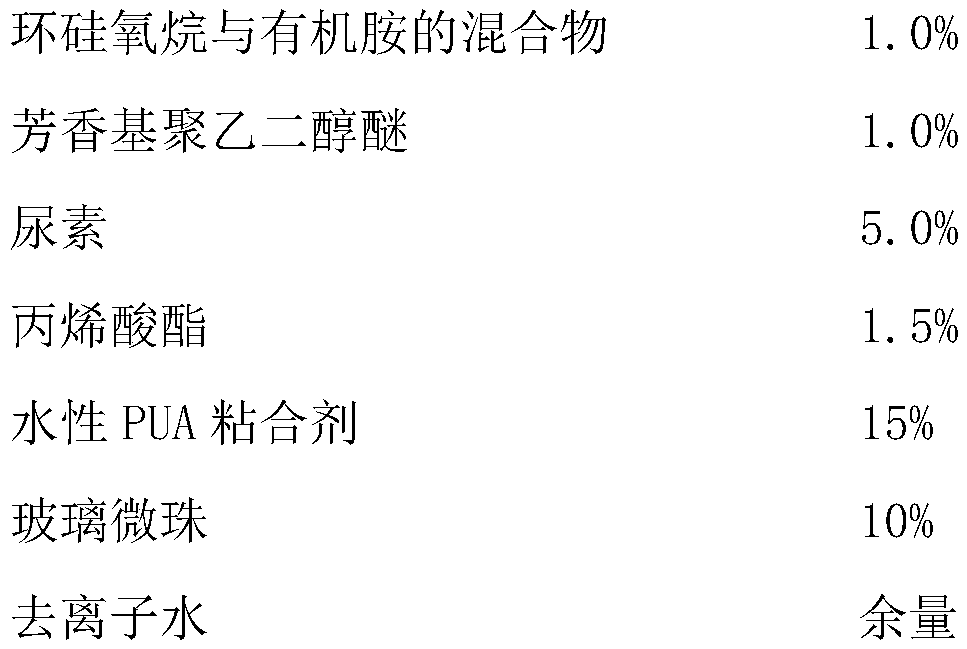

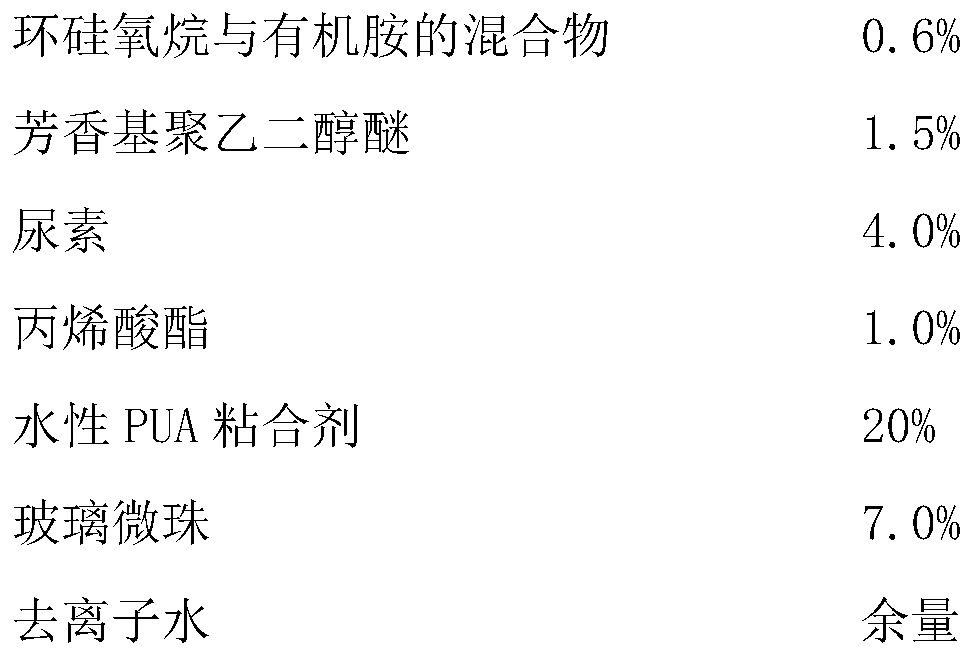

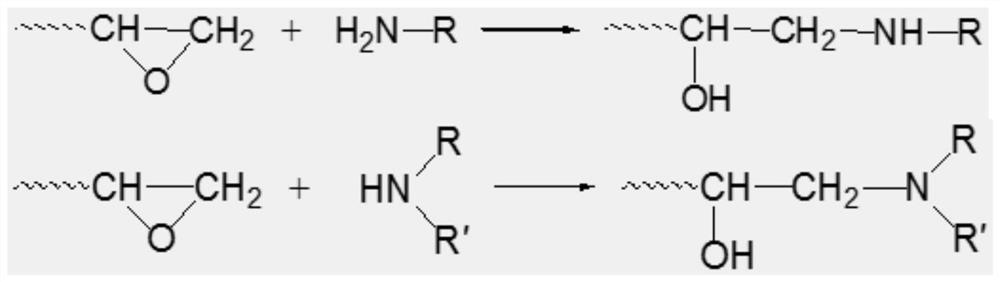

The invention relates to water-based system reflective pulp. The environment-friendly water-based reflective pulp low in pollution is prepared from components as follows: 0.6%-1.0% of a mixture of cyclosiloxane and organic amine, 0.6%-1.0% of aromatic polyglycol ether, 4.0-6.0% of urea, 1.0%-2.0% of acrylate, 11%-20% of an aqueous PUA binder, 7.0%-13% of glass beads and the balance of deionized water. The glass beads with the size of 10 microns can be applied to the sportswear fabric. After the water-based system reflective pulp is printed on the sportswear fabric, the effect of sportswear fabric reflective patterns required individually is realized, the reflective pulp has the effects of soft texture, high elasticity and high retroreflective coefficient and is resistant to multi-time washing, and reflective printing has richer expression effects.

Owner:GUANGZHOU SHENGQIN IND

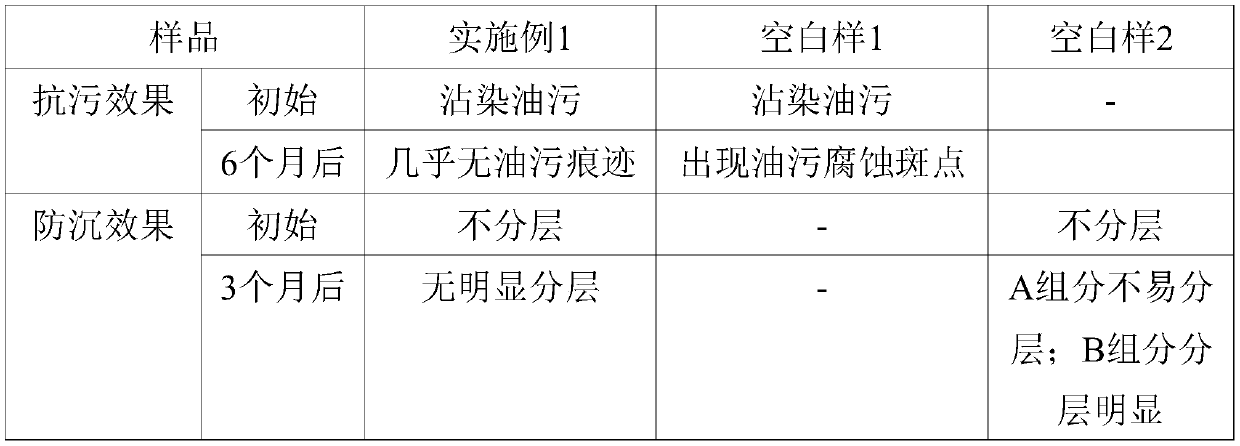

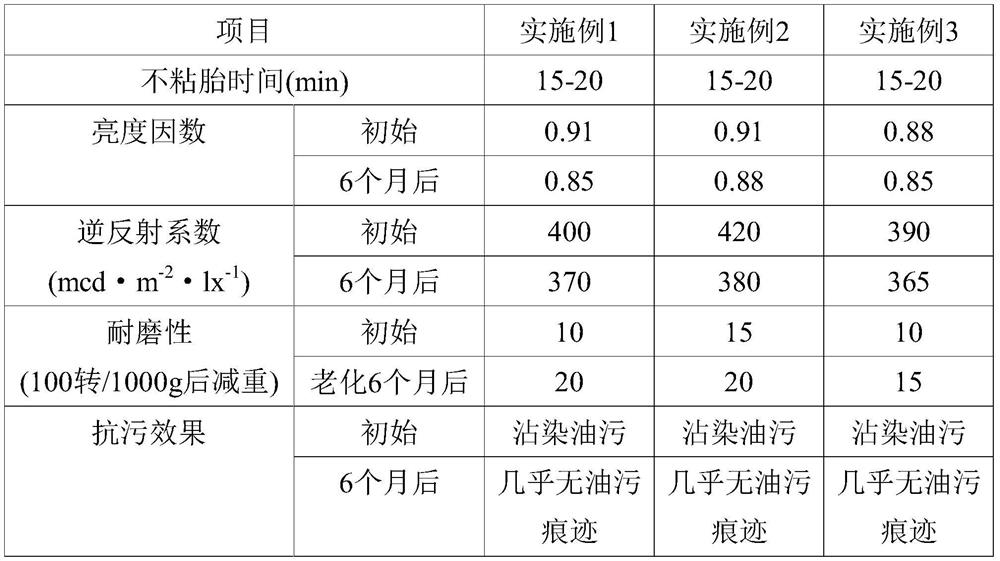

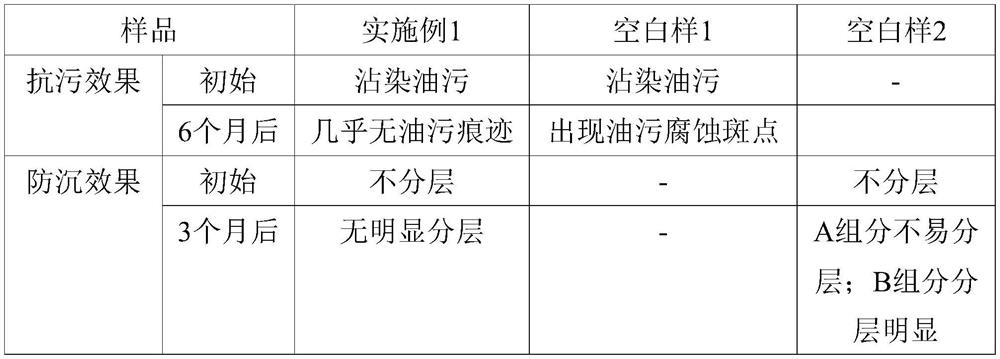

Blade coating type two-component road marking coating and preparation method thereof

ActiveCN111303726AStrong adhesionHigh solid contentAntifouling/underwater paintsPaints with biocidesPolymer scienceFirming agent

The invention discloses a blade coating type two-component road marking coating and a preparation method thereof, and relates to the technical field of transportation coatings. The coating comprises acomponent A with the mass fraction of 57.45% and a component B with the mass fraction of 42.55%, and the component A is prepared from, by mass, 45%-55% of modified epoxy resin, 5%-10% of pigment, 35%-40% of filler, 0.5%-1% of auxiliaries and 0.2%-0.7% of thixotropic agents; the component B is prepared from the following components in percentage by mass: 30 to 40 percent of epoxy curing agent, 10to 15 percent of pigment, 50 to 55 percent of filler, 0.5 to 1 percent of auxiliary agent and 0.2 to 0.7 percent of thixotropic agent, wherein the component A and the component B are uniformly mixed for use according to the mass ratio of (1-1.5): 1. The blade coating type double-component epoxy marking coating has the advantages of strong adhesion to pavements and glass beads, good wear resistanceand water resistance, long service cycle, low maintenance cost, high solid content, no influence on the body health of constructors and high curing speed.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

Preparation method of magnetic complete-aluminum-plating reflective glass micro-bead

InactiveCN107285643AHigh coefficient of retroreflectionIncrease reflectionCoatingsMicrosphereLight reflection

The invention discloses a preparation method of a magnetic complete-aluminum-plating reflective glass micro-bead. According to the present invention, a magnetic Ni-P alloy layer is arranged on the surface of the core of a glass micro-bead by using a chemical composite plating process, and an aluminum-plating layer is precipitated on the surface of the alloy layer through two high temperature plating treatments, such that the all-round aluminum plating on the surface of the glass microsphere can be achieved, and it can be ensured that the aluminum-plating layer is attached onto the surface of the glass micro-bead being not embedded into the bead embedding film after the bead embedding treatment so as to substantially improve the reflex reflection coefficient and provide the excellent light reflection effect; and the product prepared by using the glass micro-bead has the magnetic property so as to enhance the use performance, and can provide advantages of convenient use, convenient replacement and convenient washing in the application in the reflective warning labeling.

Owner:HEFEI DINGLIANG OPTICAL TECH

Method for preparing light-reflecting and heat-insulating film for vehicle roof

InactiveCN107390310AEasy to cleanGood heat insulationIlluminated signsOptical elementsPliabilityEngineering

The invention discloses a method for preparing a light-reflecting and heat-insulating film for a vehicle roof. Magnetic glass beads are used as a raw material, certain magnetic performance is given to a product, and replacement and the cleaning of a vehicle body are facilitated. Then an electrostatic spraying method is used to deposit a TiO2 thin film on the surface of a resin film substrate which is subjected to bead planting, a base film which is plated with the TiO2 thin film has good heat insulating property and flexibility and can be bent arbitrarily in a bearable range, and convenience is brought to the use and collection of the product. Then the retro-reflecting coefficient of the product is greatly improved after spraying and aluminum plating, the product has an excellent reflective effect and plays an excellent conspicuous warning role, and a purpose of reducing the temperature in a vehicle is achieved.

Owner:HEFEI DINGLIANG OPTICAL TECH

Hot melt adhesive for reflective film, reflective film and manufacturing method of reflective film

InactiveCN110028907AHigh coefficient of retroreflectionNon-macromolecular adhesive additivesFilm/foil adhesivesSolventChemistry

The invention provides a hot melt adhesive for a reflective film. The hot melt adhesive comprises the following raw materials in parts by mass: 45-50 parts of saturated polyester resin, 27-32 parts ofa solvent, 0.3-0.7 part of a dispersing agent, 12.5-13 parts of 1,6-hexanediol diacrylate, 0.2-0.4 part of an anti-oxidation auxiliary agent, 0.8-1.2 parts of an ultraviolet absorbent and 5-6 parts of glass beads. The invention also provides a preparation method of the hot melt adhesive for the reflective film, the reflective film and a preparation method of the reflective film. The retro-reflection coefficient of the reflective film can be enhanced, so that the reflective film is suitable for more occasions.

Owner:FUJIAN SANHAO TECH CO LTD

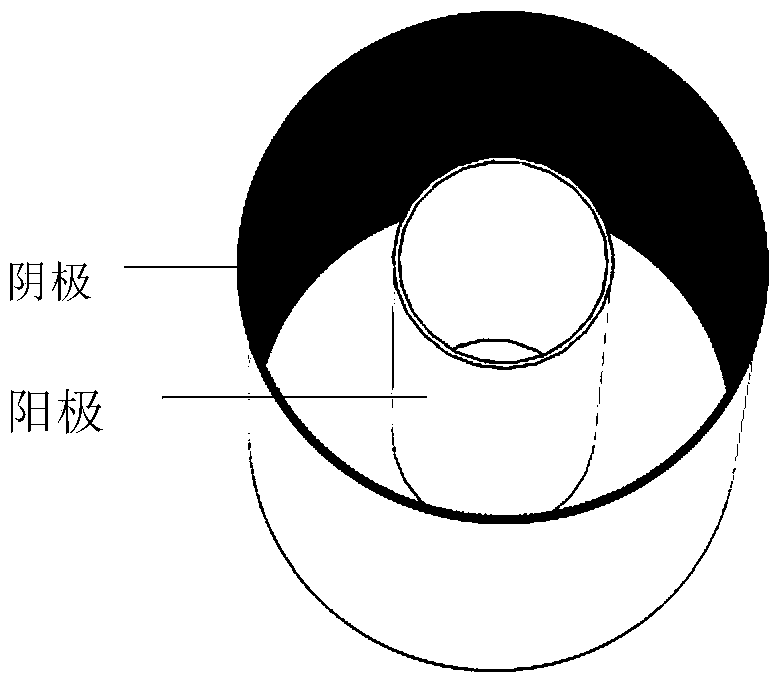

Production concentric reflecting-film curve focusing layer

InactiveCN1854772AHigh strengthHigh coefficient of retroreflectionSynthetic resin layered productsOptical elementsWork in processPolyurethane coating

A process for preparing a reflecting curved surface focus layer with the same circle center of reflecting film includes coating adhesive on surface resin and binding glass micro ball on surface resin by static ball lay out, pressing glass micro ball to let its bottom on the same plane of glass micro ball layer then coating modified aryloid coating on micro ball bottom; drying coated semi product through drying channel to form curved surface focus layer with the same circle center of glass micro ball at micro ball bottom naturally.

Owner:陆亚建

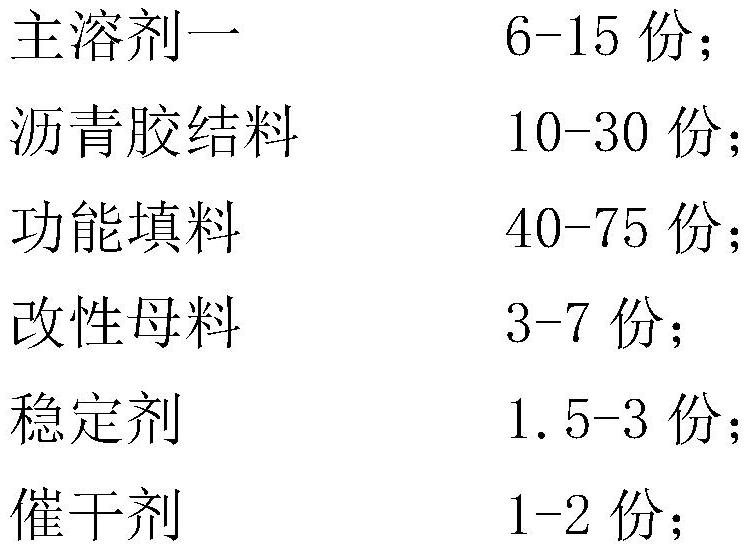

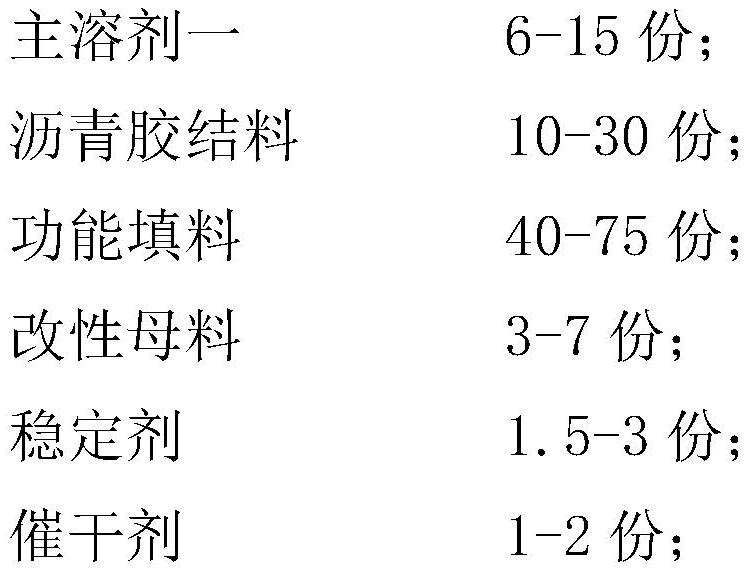

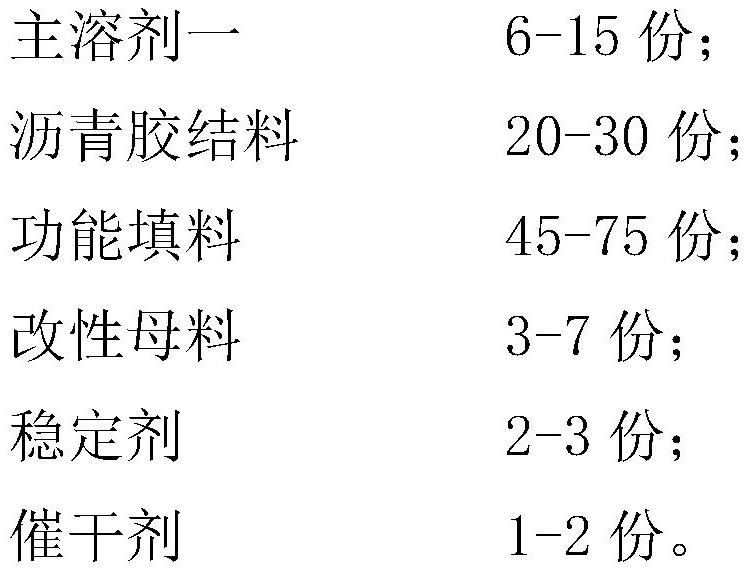

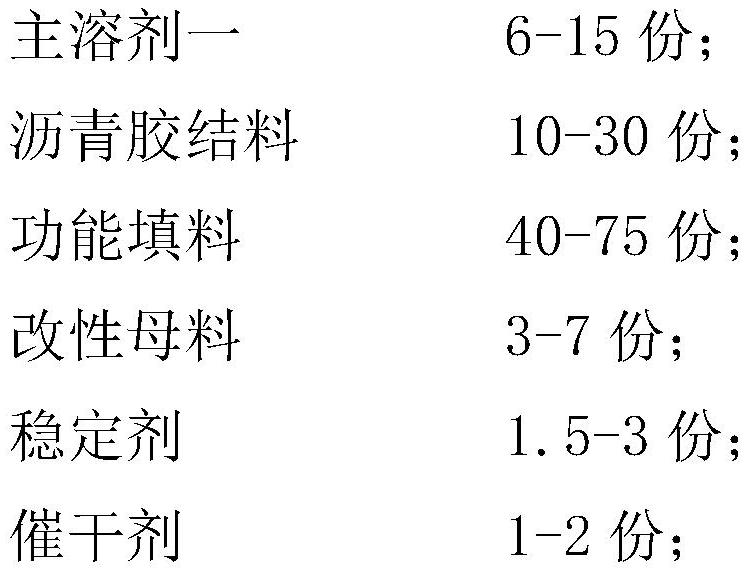

Reflective coating layer material for tunnel pavement and preparation method of reflective coating layer material

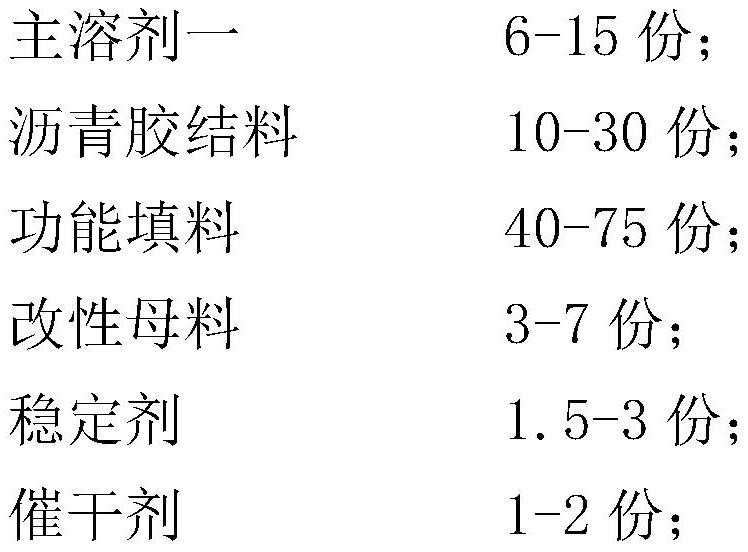

ActiveCN113480940ALow labelHigh softening pointCellulose coatingsBituminous coatingsIlluminanceRoad engineering

The invention discloses a reflective coating layer material for a tunnel pavement and a preparation method of the reflective coating layer material, and belongs to the field of road engineering. The coating layer material is prepared from a main solvent I, an asphalt cementing material, a functional filler, a modified master batch, a stabilizer and a drier according to a specific ratio, is sprayed on the surface of a tunnel pavement, can increase the retroreflection coefficient of the pavement to 10 mcd.(1x.M<2>)<-1> or above, and can greatly increase the brightness and uniformity of the pavement compared with a conventional pavement, so that the illumination in the tunnel is improved, the illumination energy consumption is saved, the driving safety of the tunnel is improved, the implementation process is simple and convenient, the performance is stable, and good popularization and application values are achieved.

Owner:SHANDONG JIAOTONG UNIV +1

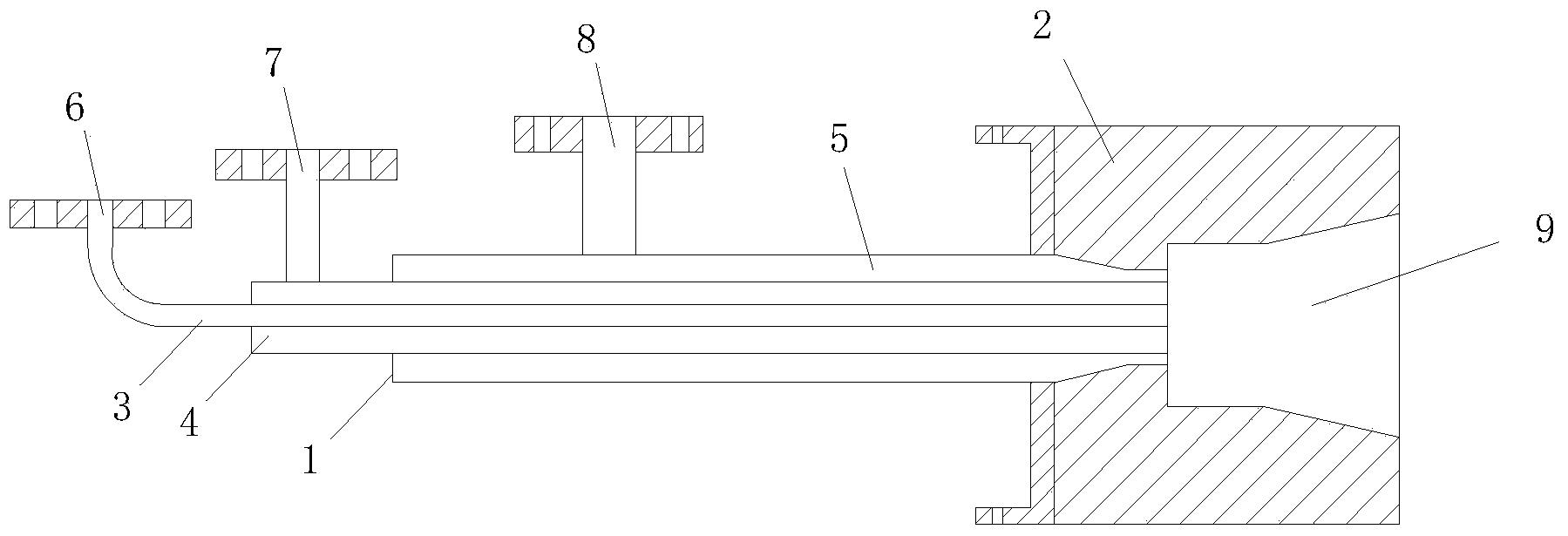

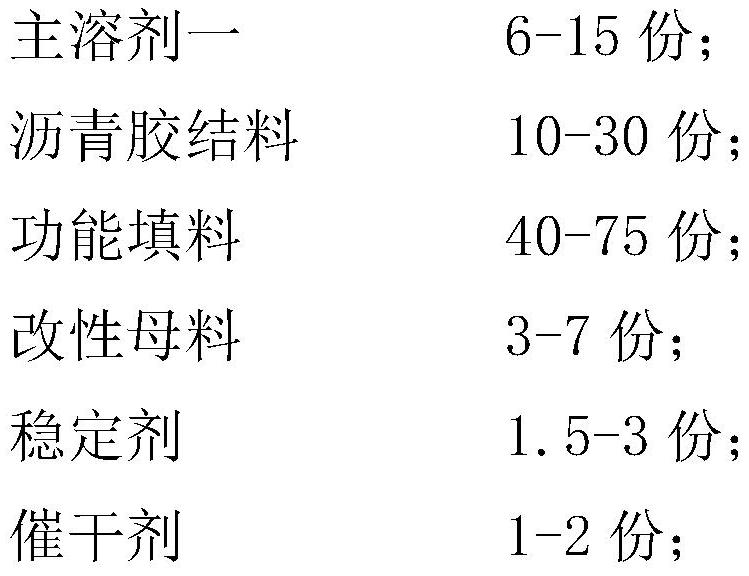

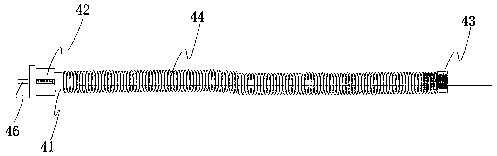

An accident scene protection warning retractor

The invention relates to the field of safety warning technology, and provides a simple structure and convenient operation accident scene protection warning retractor, which can greatly reduce the operation time for establishing warning signs, improve the efficiency of warning sign establishment, and quickly meet the warning function of the accident scene, and A separate large-area fully sealed micro-prism reflective cloth structure not only has the advantages of concentrated reflective area, large reflective area, and wide range of reflective viewing angles, but also has the advantages of convenient retraction and operation of fully sealed micro-prism reflective cloth, small footprint, and retractable Mounting on the roof of a police vehicle facilitates efficient and quick deployment.

Owner:福建跃发光新材料股份有限公司

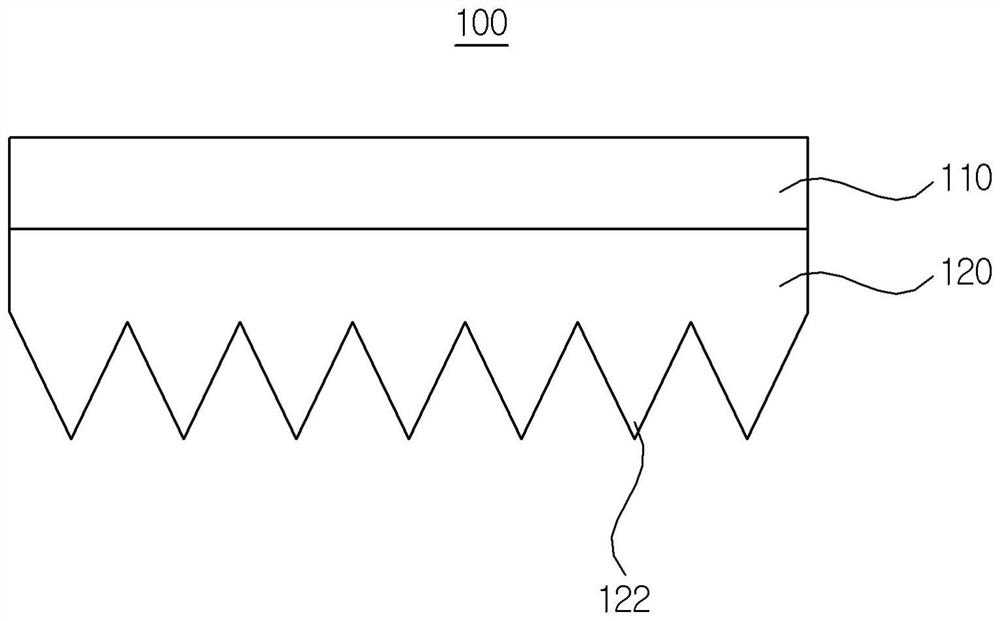

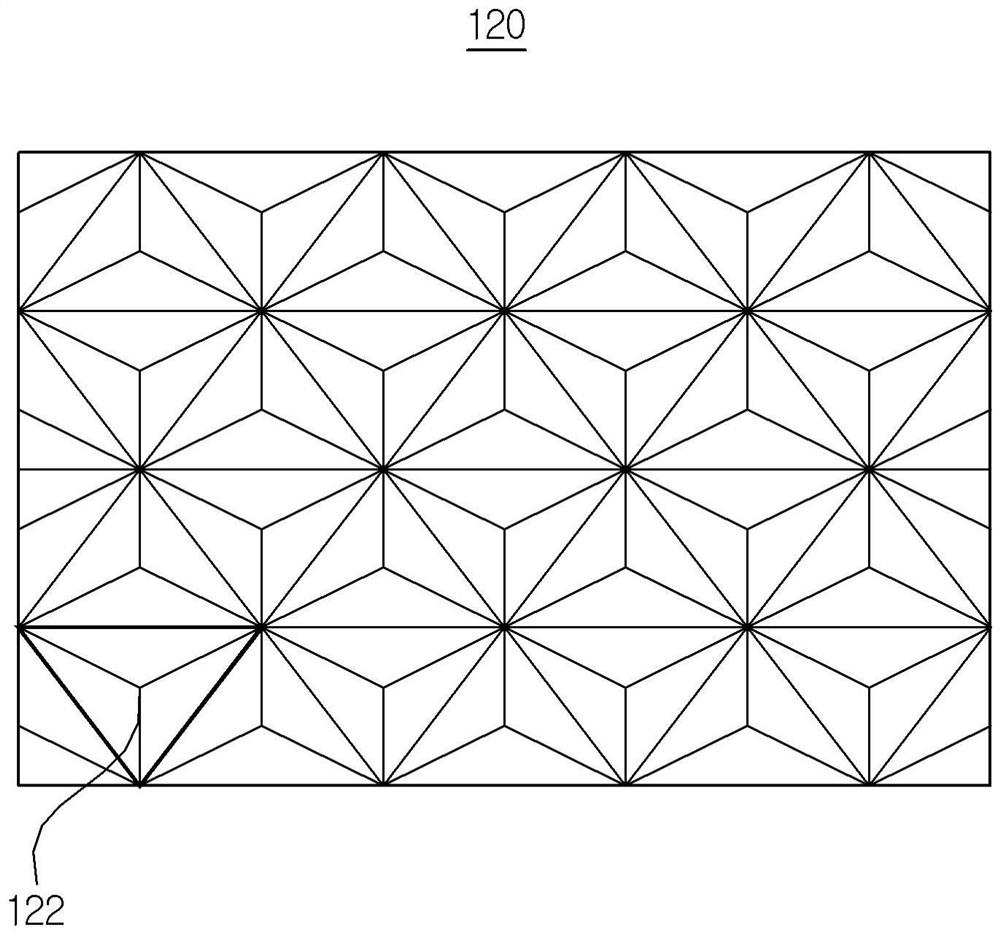

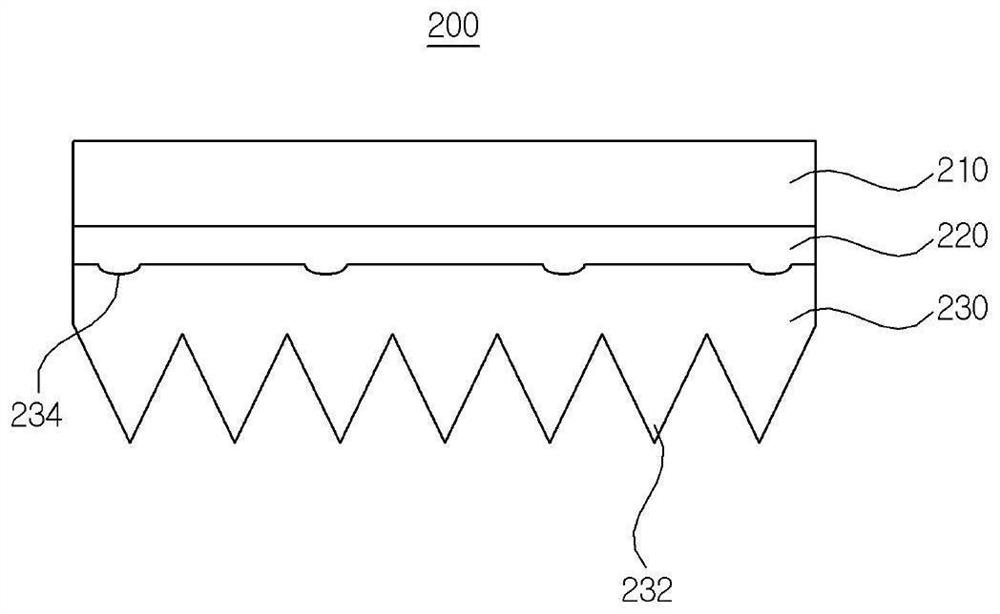

Retroreflective sheet provided with pattern for improving retroreflection coefficient

PendingCN114424096AImprove visibilityHigh coefficient of retroreflectionOptical elementsPolymer resinMaterials science

Disclosed is a retroreflective sheet including a pattern for improving a retroreflective coefficient. A retroreflective sheet according to an embodiment of the present invention comprises: a substrate layer comprising a polymer resin; a light path induction layer which is in contact with the lower surface of the substrate layer and contains an adhesive resin; and a pattern layer which is in contact with the lower surface of the optical path induction layer and has a cube corner pattern and an additional pattern formed on different surfaces.

Owner:MIRAENANOTECH

A kind of water-based system reflective paste and its application in sports fabrics

ActiveCN106638043BImprove adhesionGood anti-adhesionDyeing processLiquid/gas/vapor textile treatmentWater basedEther

The invention relates to water-based system reflective pulp. The environment-friendly water-based reflective pulp low in pollution is prepared from components as follows: 0.6%-1.0% of a mixture of cyclosiloxane and organic amine, 0.6%-1.0% of aromatic polyglycol ether, 4.0-6.0% of urea, 1.0%-2.0% of acrylate, 11%-20% of an aqueous PUA binder, 7.0%-13% of glass beads and the balance of deionized water. The glass beads with the size of 10 microns can be applied to the sportswear fabric. After the water-based system reflective pulp is printed on the sportswear fabric, the effect of sportswear fabric reflective patterns required individually is realized, the reflective pulp has the effects of soft texture, high elasticity and high retroreflective coefficient and is resistant to multi-time washing, and reflective printing has richer expression effects.

Owner:GUANGZHOU SHENGQIN IND

Scratch-coating type two-component road marking paint and preparation method thereof

ActiveCN111303726BStrong adhesionHigh solid contentAntifouling/underwater paintsPaints with biocidesPolymer scienceFirming agent

Owner:安徽省交规院工程智慧养护科技有限公司

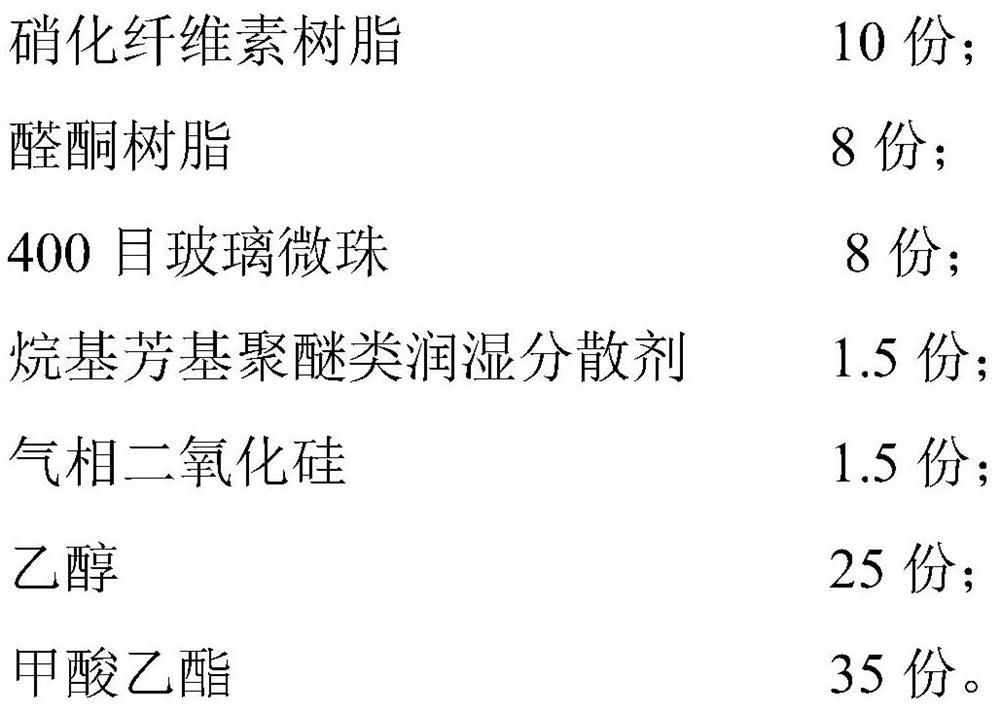

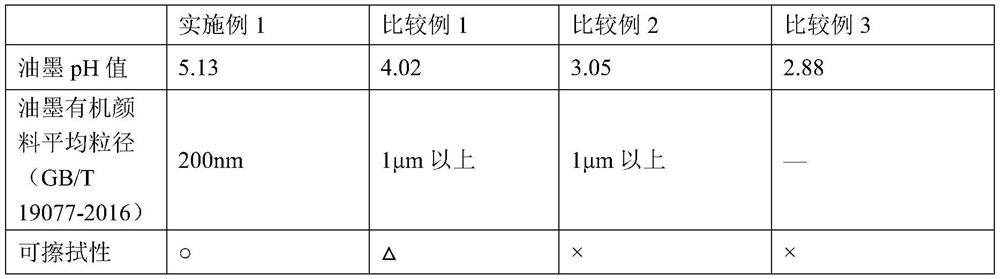

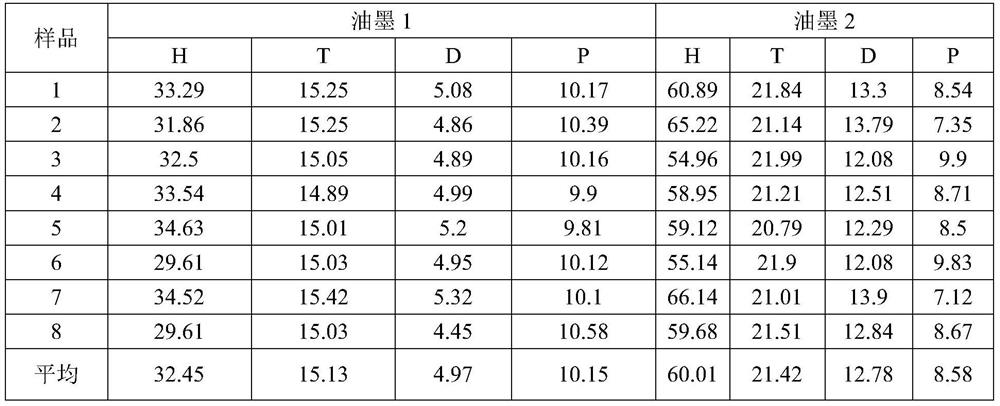

Reflective ink and its preparation method, tobacco paper and its preparation method

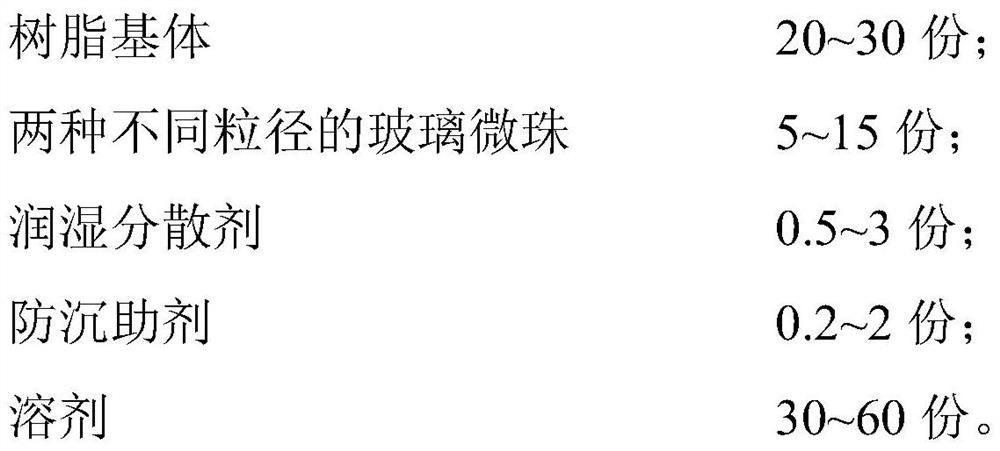

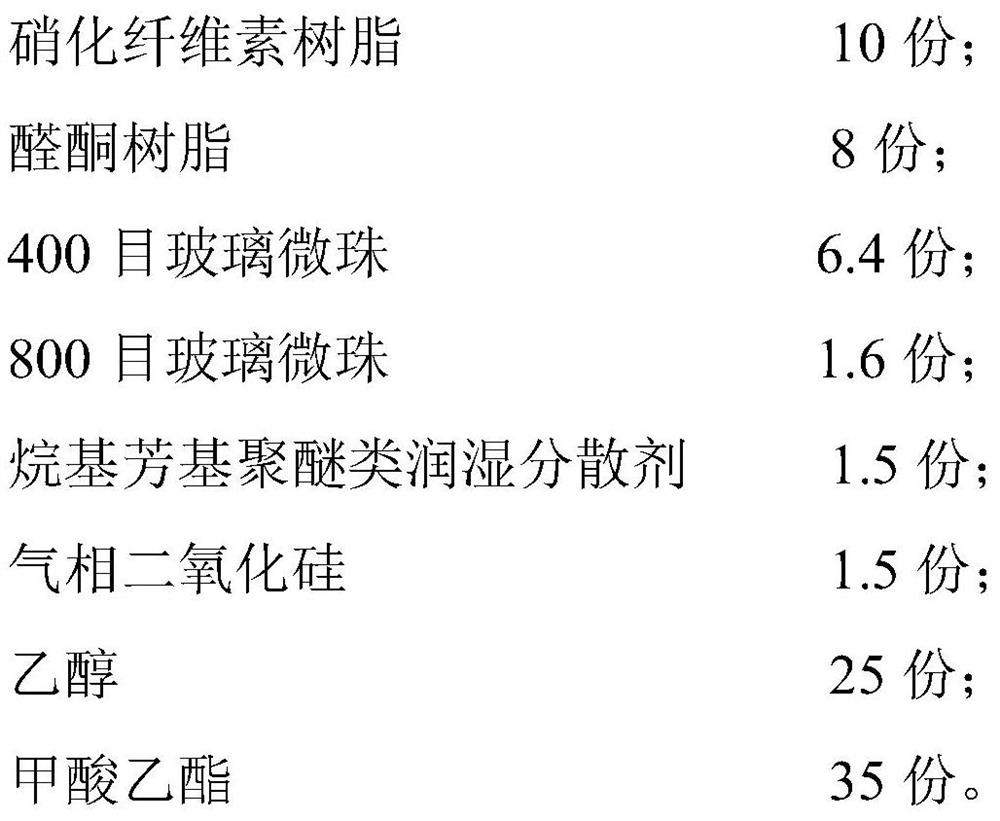

ActiveCN109651878BIncrease reflectionHigh coefficient of retroreflectionTobacco preparationFlexible coversPolymer scienceResin matrix

The present invention involves a reflective ink and its preparation methods, tobacco paper and its preparation method.15 copies; 0.5 to 3 copies of wetting dispersions; 0.2 to 2 copies of anti -sinking auxiliary agent; 30 to 60 solvents.

Owner:ANHUI JIYOU NEW MATERIAL CO LTD

A heat-sensitive reflective film that can be sprayed

ActiveCN104932047BGood inkjet effectHigh coefficient of retroreflectionSynthetic resin layered productsGlass/slag layered productsPolymer scienceLight reflection

Owner:ZHEJIANG YGM TECH CO LTD

Glass bead for guide post reflective film and preparation method thereof

InactiveCN104965252AImprove reflective effectImprove qualityGlass shaping apparatusOptical elementsSlagRefractive index

The invention discloses a glass bead for guide post reflective film and a preparation method thereof. The glass bead is prepared from the following raw materials by weight: 35-55kg of quartz sand, 21-39kg of pyrophillite, 14-27kg of aventurin, 17-33kg of pandermite, 15-25kg of manganese slag, 12-18kg of zirconium silicate, 10-15kg of crystalline graphite powder, 4-6kg of cerium oxide, 20-30kg of kyanite, 5-7kg of cocamidopropylamine oxide, 4-6kg of triethanolamine N-Coco acy-L-Glutamate, 6-8kg of sodium dodecyl benzene sulfonate, and 6-12kg of additives. The glass bead has excellent comprehensive properties, corrosion resistance property, light aging resistance property, and heat resistance property, and is high in refractive index and compressive strength, and moreover, the guide post reflective film prepared by the glass bead is high in reverse reflection coefficient, good in reflection effect, good in weatherability, durable in use, and good in market prospect.

Owner:HEFEI DINGLIANG OPTICAL TECH

Manufacturing method of microprism reflective material

Provided is a microprism reflecting material manufacturing method, comprising employing the diamond lathe ultra-precision cutting process to manufacture a microprism structure reflecting material original graphic mould on materials such as plastic, metal, colloid, crystal, etc.; manufacturing modules of PDMS, PC, PMMA, photosensitive gel, etc. out of an original mould with a microprism pattern through thermocuring, ultraviolet curing, and duplication processes; plating a duplicated intermediate mould with a layer of fluorine containing macromolecules, and improving nickel mould surface demoulding; coating the modified intermediate mould with material solutions of PMMA, PC, photosensitive gel, etc. to perform curing processing, and then performing separated demoulding between the module and a target reflective membrane; and finally decorating the demoulded microprism reflecting material membrane into a designed shape. The method effectively solves the problems of great manufacturing difficulty, poor preserving effect, large processing technology tolerance, etc. of a present microprism reflecting material intermediate work mould.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Regression reflective fabric and its production method

InactiveCN1313673CGood flexibilityExcellent coefficient of retroreflectionVacuum evaporation coatingSputtering coatingReflective layerComposite material

This invention discloses a kind of regression reflect fabric, including one reflection component, a metal reflection layer, a adhesive layer and one basic material, the reflection component layer is implied 30-130 grams of tiny glass beads with each square arranged intensively. The fabric's reflection function is good, the anti-coefficient can amount to the 70-700 cds / Lx / square m.

Owner:CHINESE TEXTILE ACAD +1

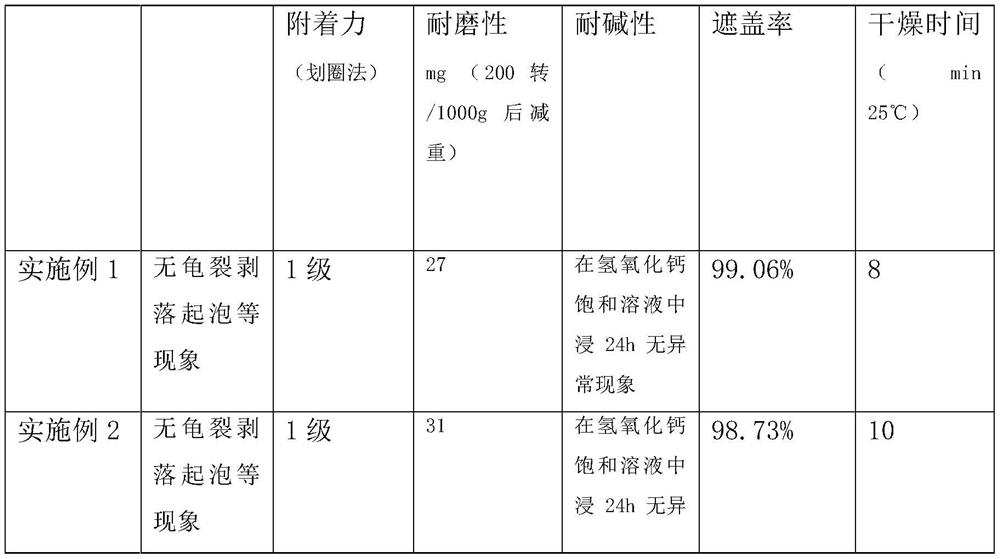

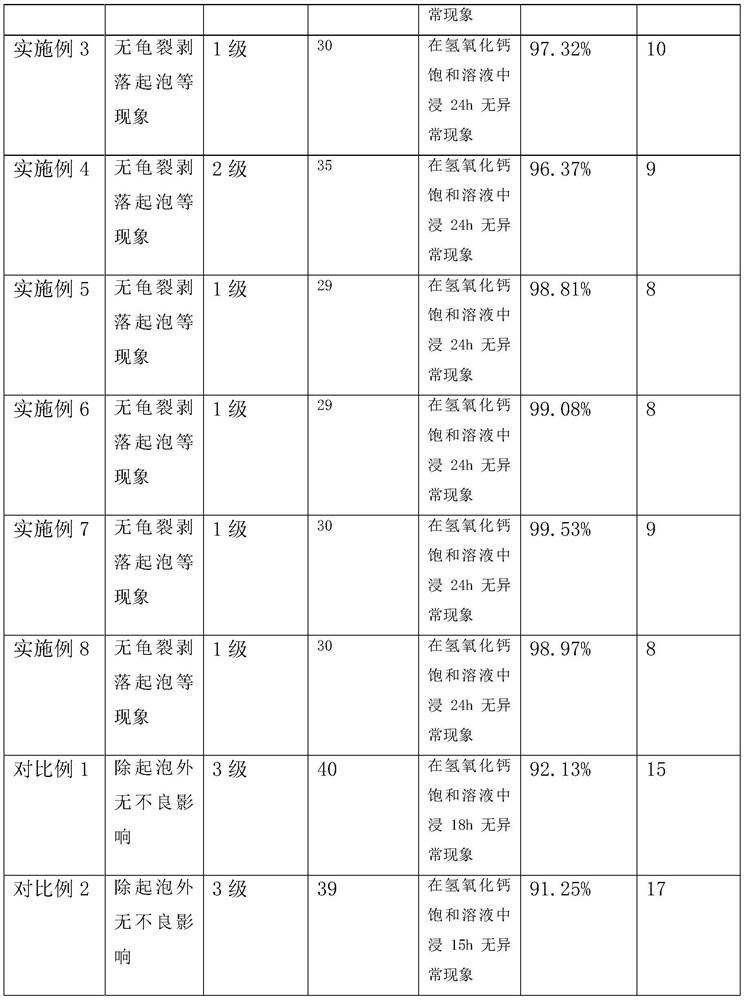

High-efficiency retroreflective hot-melt road marking and its manufacturing method

ActiveCN112322136BHigh coefficient of retroreflectionIncrease reflectionAnti-corrosive paintsReflecting/signal paintsThermodynamicsLight reflection

This application relates to a high-efficiency retroreflective hot-melt road marking and its production method, including the following steps: S1: heating the marking paint to 180-220 °C, stirring evenly, and keeping it warm for 5-10 minutes; S2: maintaining the temperature at 180-200 ℃ temperature, at 0.3~0.35kg / m 2 Sprinkle glass beads on the surface of the marking paint; S3: maintain the temperature of 180~190°C, discharge the material, and obtain high-efficiency retroreflective hot-melt highway markings. The markings prepared by this application have a high retroreflection coefficient, And it has good reflectivity in rainy nights, and it also has high wear resistance, water resistance and alkali resistance, which can achieve a long-lasting reflective effect.

Owner:TIANJIN HIGHWAY ENG GENERAL

Retroreflective sheet and preparation method thereof

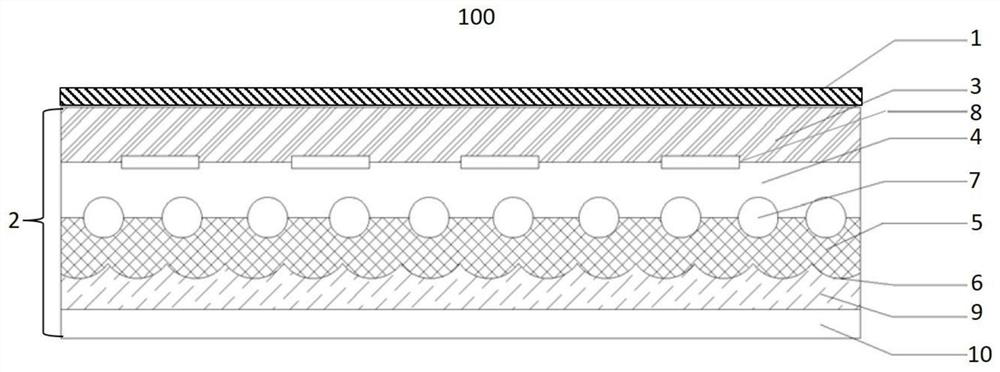

PendingCN114690296AExcellent wipeabilityHigh coefficient of retroreflectionVehicle componentsOther printing apparatusEngineeringReflective layer

The invention relates to a retroreflective sheet and a preparation method thereof. The retroreflective sheet sequentially comprises an erasable layer and a reflective layer body containing glass beads, the erasable layer is an ink layer containing organic pigment, and the particle size of the organic pigment does not exceed 600 nm. The retro-reflection sheet provided by the invention has the advantages of good wiping performance, high retro-reflection coefficient, low haze, high light transmission and good storage stability. The retroreflective sheet can be directly used for preparing the license plate, reduces the printing process, is convenient to manufacture and reduces the cost.

Owner:NIPPON CARBIDE INDS HANGZHOU

Reflective coating material for tunnel pavement and preparation method thereof

ActiveCN113480940BLow labelHigh softening pointCellulose coatingsBituminous coatingsMasterbatchIlluminance

The invention discloses a reflective coating material for tunnel pavement and a preparation method thereof, belonging to the field of road engineering. The coating material is prepared from a specific ratio of main solvent 1, asphalt binder, functional filler, modified masterbatch, stabilizer, and drier, and is sprayed on the surface of the tunnel pavement to increase the retroreflection coefficient of the pavement to 10mcd (1x m 2 ) ‑1 As mentioned above, compared with the conventional road surface, the coating material of the present invention can greatly increase the brightness and uniformity of the road surface, improve the illuminance in the tunnel, not only save lighting energy consumption, but also increase the driving safety of the tunnel, and the implementation process is simple , Stable performance, has good promotion and application value.

Owner:SHANDONG JIAOTONG UNIV +1

An acrylic emulsion and fast overcoating highly retroreflective environmentally friendly marking paint

The invention provides an internally cross-linked modified acrylic emulsion and a water-based coating containing the same, wherein the polymerizable monomers in the acrylic emulsion include epoxy vinyl monomers, ethyleneimine, acrylic acid and methacrylic acid ester. The marking paint is non-toxic, harmless, non-polluting, has good adhesion, has good reflective performance at night and in rainy days, is durable, wear-resistant, weather-resistant, skid-resistant, fast recoatable and suitable for industrial production.

Owner:浙江欧路德交通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com