An accident scene protection warning retractor

An accident scene, retractor technology, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of high labor intensity, shortened visual distance, unfavorable safety warnings, etc., to improve the protection safety factor, and reflect a wide range of viewing angles. , the effect of improving traffic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

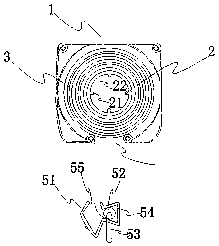

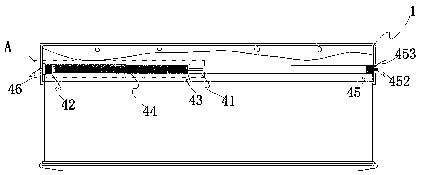

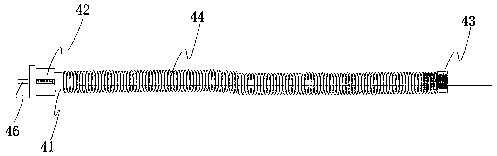

[0033] refer to Figure 1 to Figure 7 Implementation 1 of the present invention discloses an accident scene protection warning retractor, comprising a retractor casing 1, a winding core tube 2 arranged in the retractor casing 1, and a full-body coil wound on the surface of the winding core tube 2. Sealed microprism reflective cloth 3 and a rewinding device 4 located in the rewinding core tube 2, the retractor shell 1 is provided with a rewinding port 11 for the free end of the fully sealed microprism reflective cloth 3 to freely expand and contract. The free end of the fully-sealed micro-prism reflective cloth 3 is also provided with a bottom protection bead 5, the bottom protection bead 5 prevents the free end of the fully-sealed micro-prism reflective cloth 3 from being fully received in the winding mouth 11, and the The bottom protection bead 5 includes a protective outer frame 51, an annular bar-shaped bead 52 and a spring bar 53, and the length of the end surface of the p...

Embodiment 2

[0043] The mechanical mechanism of the accident scene warning retractor described in Embodiment 2 is exactly the same as that in Embodiment 1, the difference is that:

[0044] refer to Figure 8 , the fully sealed micro-prism reflective cloth 3 is made of reflective film and polyester warp-knitted cloth 31, and the reflective film includes an inkjet layer 32, a transparent surface film 33, a reflective layer 34, and a metal protective layer arranged sequentially from top to bottom. 35. The transparent surface film 33 is a fluorescent yellow-green PVC film, and the reflective layer 34 is a microprism resin pyramid layer composed of a plurality of microprism resin pyramids. The cross section is triangular in shape, the polyester warp knitted fabric 31 is bonded with the metal protection layer 35 through a composite glue layer 36, the side of the metal protection layer 35 on the reflective film is provided with a hexagonal honeycomb texture, and the inkjet layer 32 The thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com