All-weather high-refraction reflective micro-crystal ceramic bead

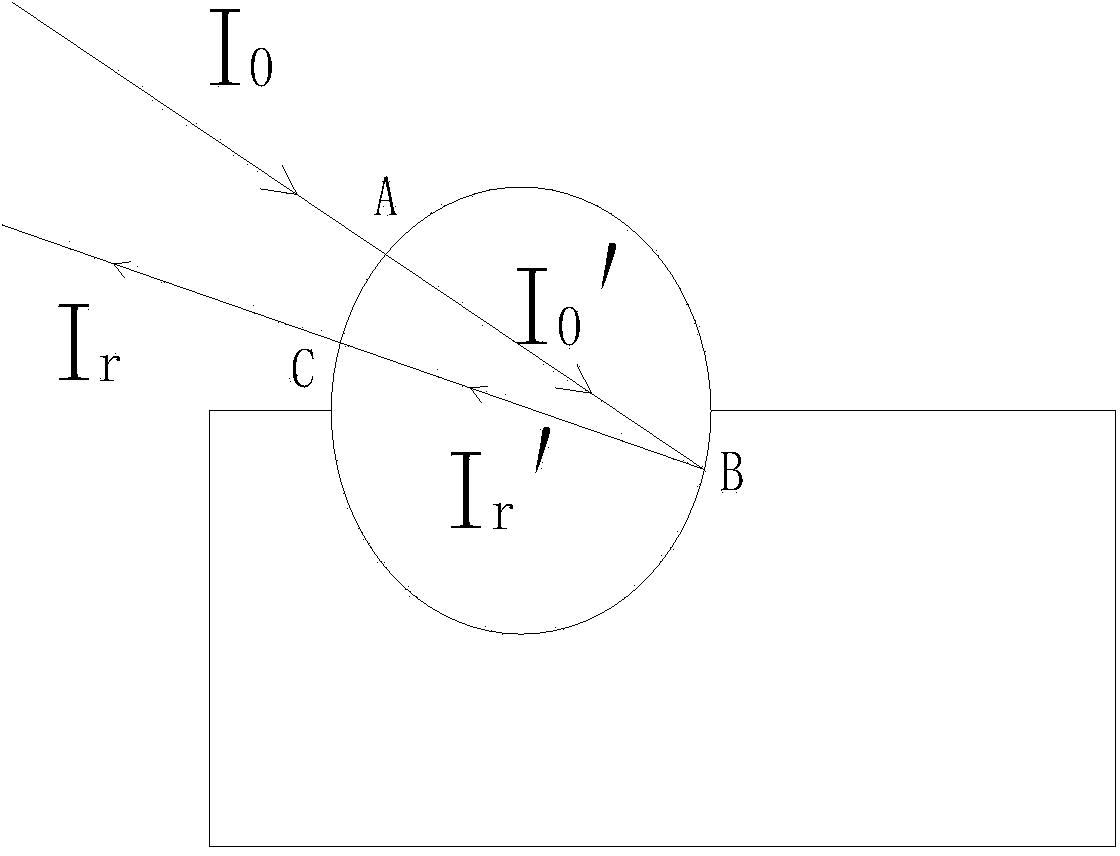

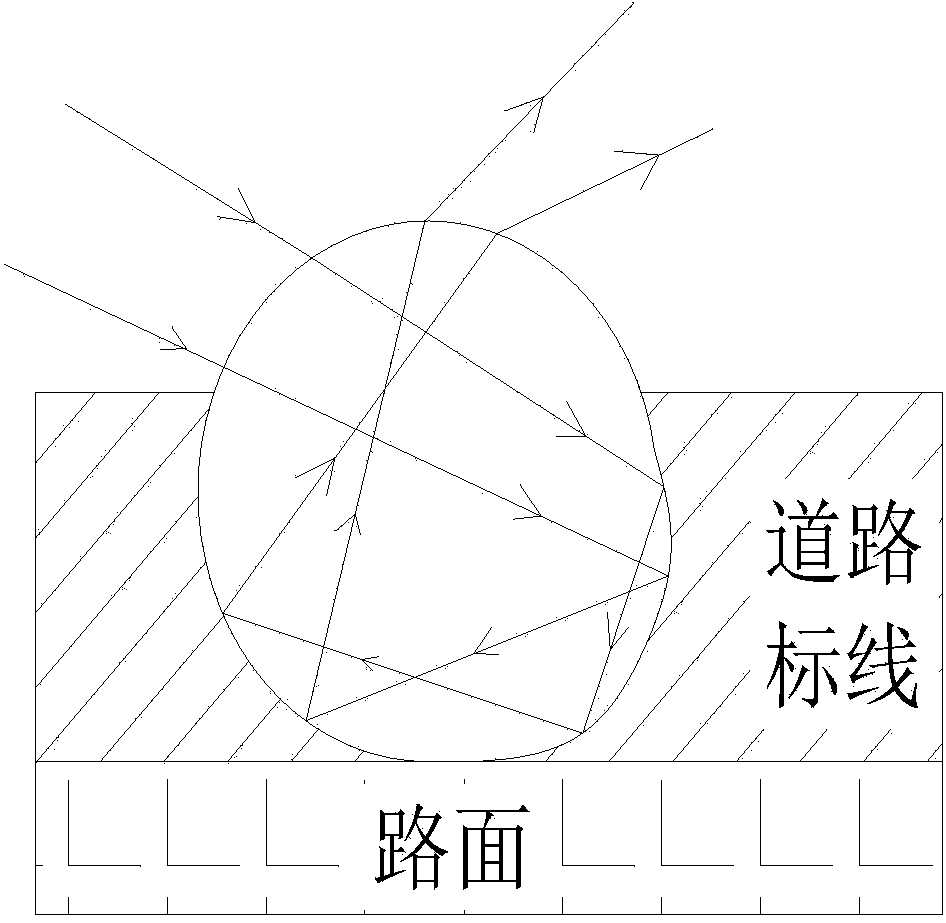

A high-refractive, all-weather technology, used in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor retroreflection effect, reduce the incidence, increase the refractive index, and enhance the visibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

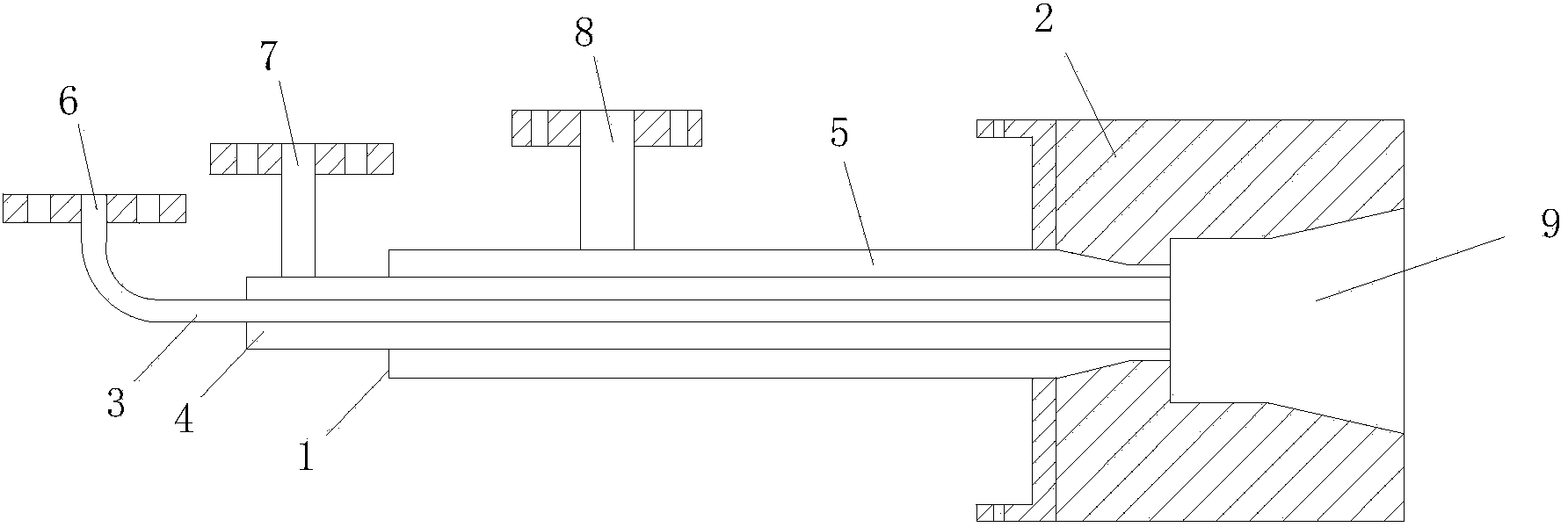

[0023] All-weather high refraction reflective microcrystalline ceramic beads, including inner core and core reflective element, the core reflective element includes the following components: titanium dioxide, calcium oxide, zirconia, boron oxide, aluminum oxide and inorganic salt additives;

[0024] The preparation process of the core reflective element includes the following steps: step 1, mixing titanium dioxide, calcium oxide, zirconia, boron oxide, aluminum oxide and inorganic salt additives, grinding and high-speed dispersion in a nano sand mill to obtain an inorganic slurry Step 2, the inorganic slurry is granulated by spray drying, and the particle size of the dried particles reaches 200-250 mesh; Step 3, the dried particles are sintered into particles in a high-temperature oxygen-enriched environment; Step 4, the particles are cooled and collected , Obtain the core reflective element after sieving;

[0025] The preparation process of the all-weather high-refraction ref...

Embodiment 2

[0058] The difference from Example 1 is that in the core reflective element, by mass percentage, the content of titanium dioxide is 60%-85%, the content of calcium oxide is 1.5%-15%, and the content of zirconia is 5%-10%. , The content of boron oxide is 2%-15%, and the content of aluminum oxide is 1%-10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com