Scratch-coating type two-component road marking paint and preparation method thereof

A road marking, two-component technology, used in the field of transportation coatings, can solve the problems of long drying time of epoxy resin, and achieve the effects of shortening the road sealing period, long-lasting retroreflection coefficient and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

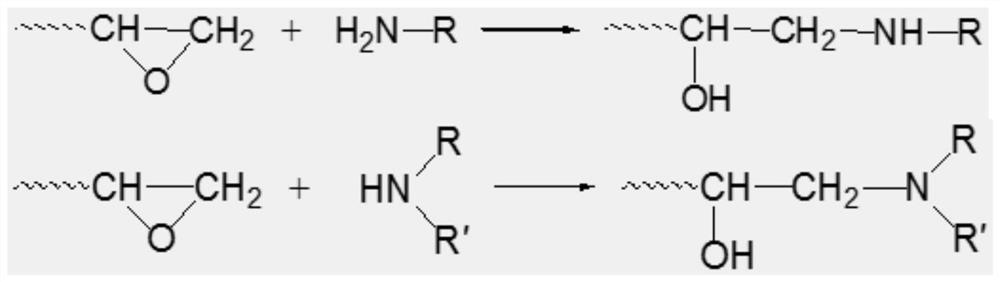

Method used

Image

Examples

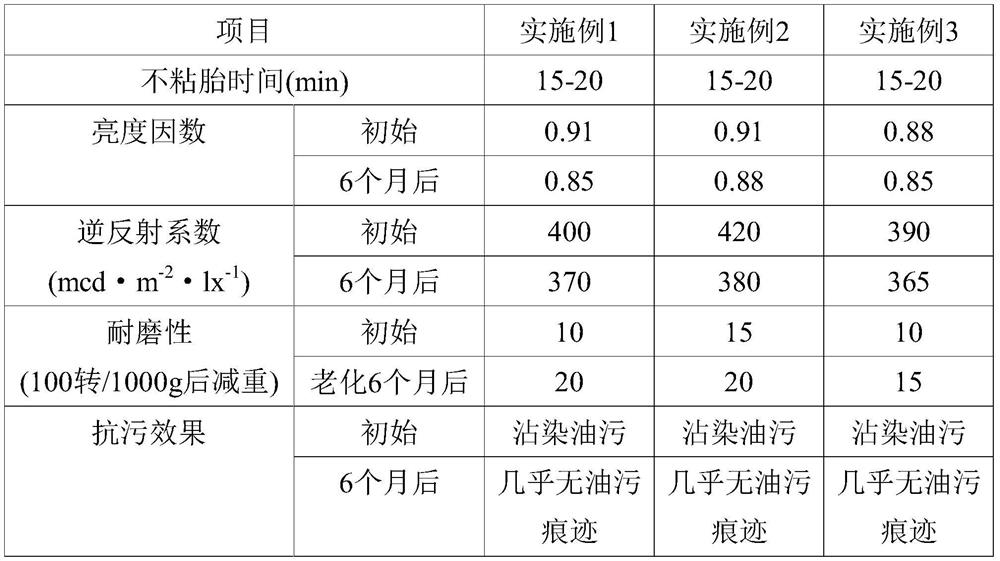

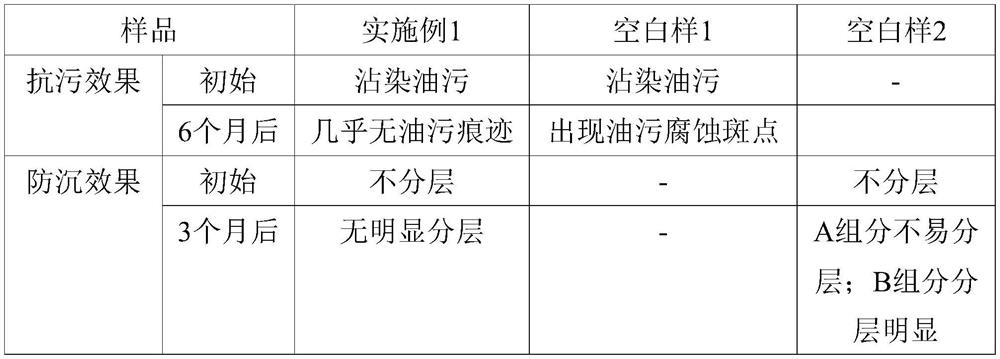

Embodiment 1

[0048] Weigh 2000g modified epoxy resin, then weigh and add 345g titanium dioxide / barium sulfate compound (the compounding ratio of titanium dioxide and barium sulfate is 2:1, the same below), 1200g heavy calcium, 200g whisker silicon , 15g fumed silicon, 4g defoamer, 8g anti-settling agent, 15g anti-flow agent, after pre-stirring, transfer to a grinder or emulsifier for further emulsification and dispersion to obtain component A;

[0049] Weigh 1000g epoxy curing agent, then weigh and add 345g titanium dioxide / barium sulfate compound, 1300g heavy calcium, 150g whisker silicon, 18g gas silicon, 3g defoamer, 6g anti-settling agent, 10g anti-flow agent , after pre-stirring, transfer to a grinder or an emulsifier for further emulsification and dispersion to obtain component B;

[0050] Transfer components A and B to the corresponding cavities of the scraping machine that have been cleaned in advance, adjust the discharge ratio, and push the scraping machine to carry out scraping ...

Embodiment 2

[0052] Weigh 1800g modified epoxy resin, then weigh and add 320g titanium dioxide / barium sulfate compound, 1000g heavy calcium, 180g whisker silicon, 12g gas silicon, 3g defoamer, 6g anti-settling agent, 13g anti-flow agent, pre-stirred and then transferred to a grinder or emulsifier for further emulsification and dispersion to obtain component A;

[0053] Weigh 900g epoxy curing agent, then weigh and add 320g titanium dioxide / barium sulfate compound, 1150g heavy calcium, 130g whisker silicon, 16g gas silicon, 3g defoamer, 5g anti-settling agent, 9g anti-flow agent , after pre-stirring, transfer to a grinder or an emulsifier for further emulsification and dispersion to obtain component B;

[0054] Transfer components A and B to the corresponding cavities of the scraping machine that have been cleaned in advance, adjust the discharge ratio, and push the scraping machine to carry out scraping construction along the pre-drawn marking paint positioning marks. Ensure that the mixt...

Embodiment 3

[0056] Weigh 2100g modified epoxy resin, then weigh and add 350g titanium dioxide / barium sulfate compound, 1300g heavy calcium, 210g whisker silicon, 16g gas silicon, 5g defoamer, 10g anti-settling agent, 16g anti-flow agent, pre-stirred and then transferred to a grinder or emulsifier for further emulsification and dispersion to obtain component A;

[0057] Weigh 1050g epoxy curing agent, then weigh and add 350g titanium dioxide / barium sulfate compound, 1350g heavy calcium, 160g whisker silicon, 20g gas silicon, 4g defoamer, 8g anti-settling agent, 11g anti-flow agent , after pre-stirring, transfer to a grinder or an emulsifier for further emulsification and dispersion to obtain component B;

[0058] Transfer components A and B to the corresponding cavities of the scraping machine that have been cleaned in advance, adjust the discharge ratio, and push the scraping machine to carry out scraping construction along the pre-drawn marking paint positioning marks. Ensure that the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com