Colorful high-brightness hot-sticking reflective cloth and manufacturing process

A technology for manufacturing technology and reflective cloth, which is applied in optics, optical components, instruments, etc., can solve problems such as low retroreflection coefficient, poor warning safety performance, and inability to meet high requirements for retroreflection coefficient, and achieve high retroreflection coefficient and high manufacturing process. Simple, colorful and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

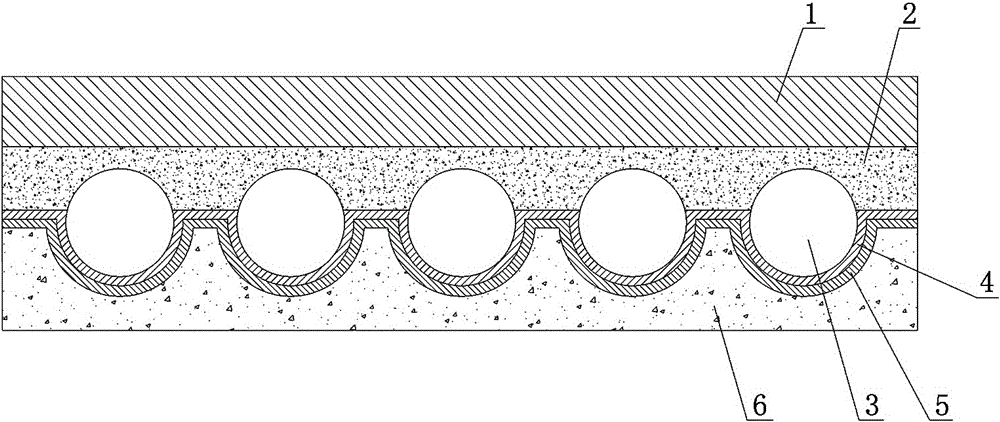

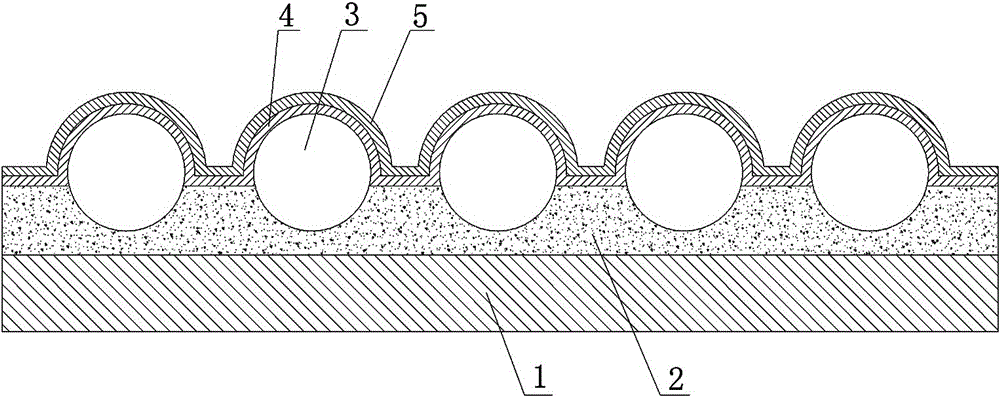

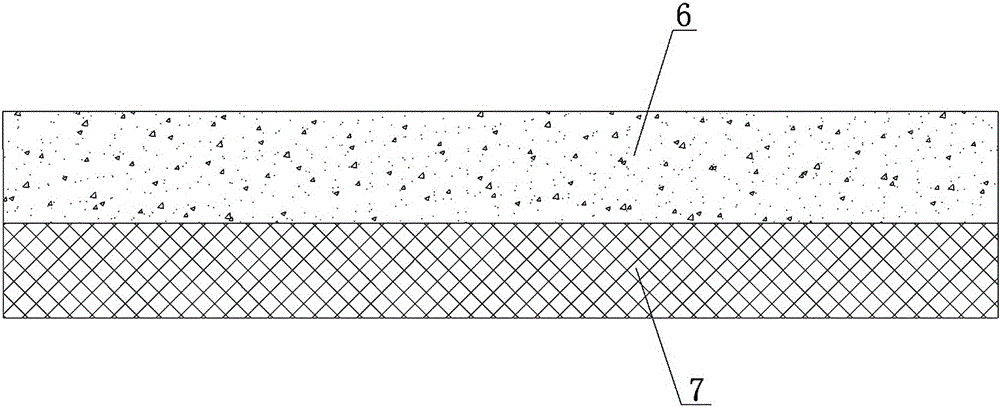

[0016] Such as figure 1 As shown, a colorful high-brightness hot-post reflective cloth includes a base material 1, a bead-planting layer 2, glass beads 3, a zinc sulfide layer 4, an aluminum layer 5 and a hot-melt adhesive layer 6. The base material 1 is biaxially stretched PET, and paper can also be used instead of biaxially stretched PET. The thickness of the paper used is 50-200 μm, the thickness of the substrate 1 is 10-125 μm, and the lower surface of the substrate 1 is provided with a bead-planting layer 2. Layer 2 is adhesive or hot melt adhesive, and can also be PE. The upper surface of the hot melt adhesive layer 6 is provided with an aluminum layer 5 , and the upper surface of the aluminum layer 5 is provided with a zinc sulfide layer 4 . Such as figure 1 As shown, a plurality of glass b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com