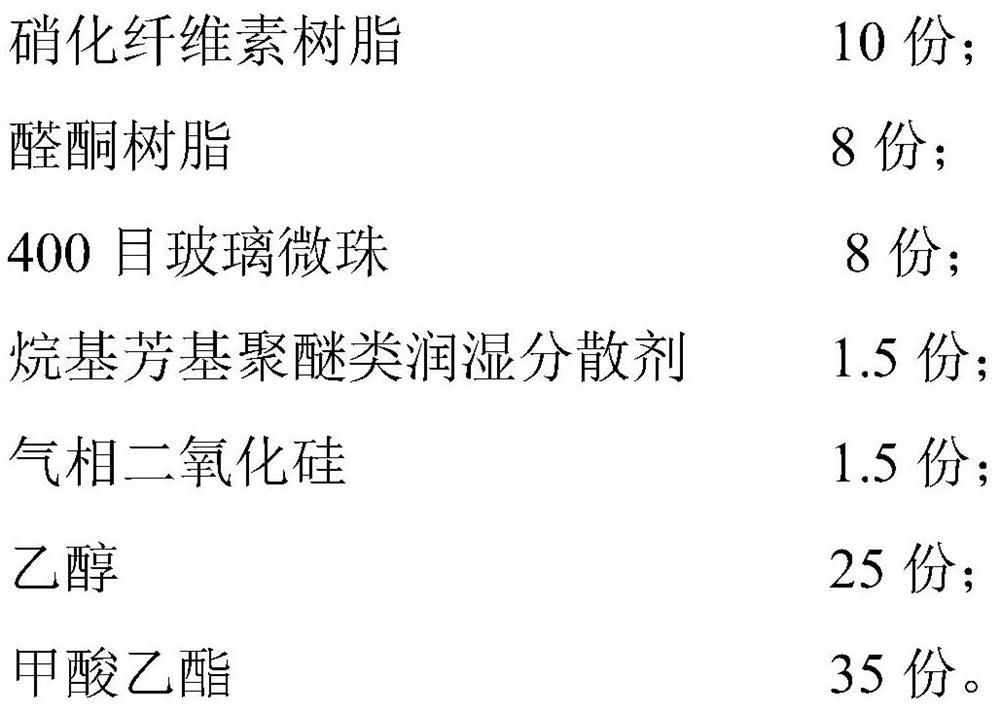

Reflective ink and its preparation method, tobacco paper and its preparation method

A light-reflecting and ink technology is applied in the field of ink technology and cigarettes, which can solve the problems of inconvenient use of cigarettes, inability to distinguish the position of cigarettes, insufficient visual discrimination of tobacco paper, etc., and achieves low production cost, remarkable light-reflecting effect, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The embodiment of the present invention provides a preparation method of reflective ink, comprising:

[0047] S10, adding the resin matrix nitrocellulose resin and the aldehyde and ketone resin into the solvent, dissolving the resin matrix and then adding the glass microspheres to obtain a first solution;

[0048] S11, stirring the first solution to uniformly disperse the glass microspheres in the first solution;

[0049] S12, sequentially adding the wetting and dispersing agent and the anti-sedimentation aid to the first solution to obtain a second solution;

[0050] S13, stirring the second solution, so that the components in the second solution are uniformly mixed to obtain the reflective ink.

[0051] In the step S11, the stirring speed of the first solution is preferably 600 r / min, and the stirring time is 30 minutes.

[0052]In the step S13, the speed of stirring the second solution is preferably 800r / min-1000r / min, and the stirring time is 30 minutes.

[0053]...

Embodiment 1

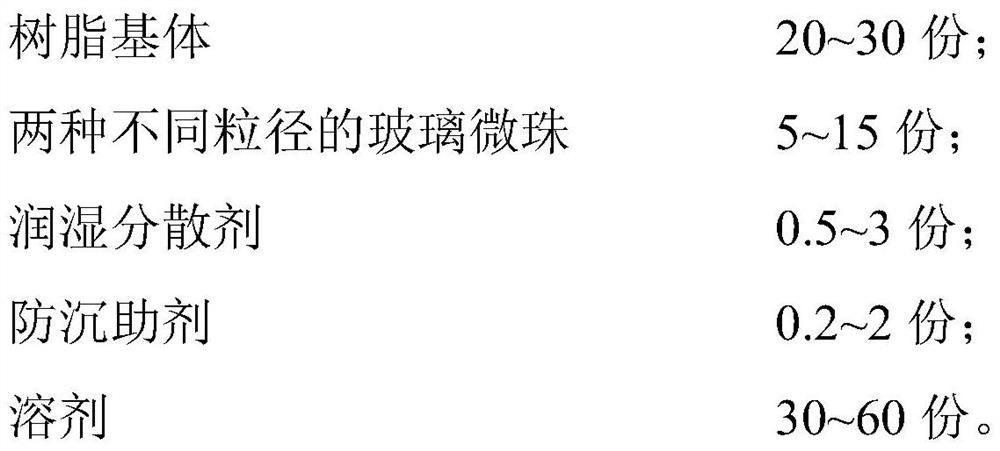

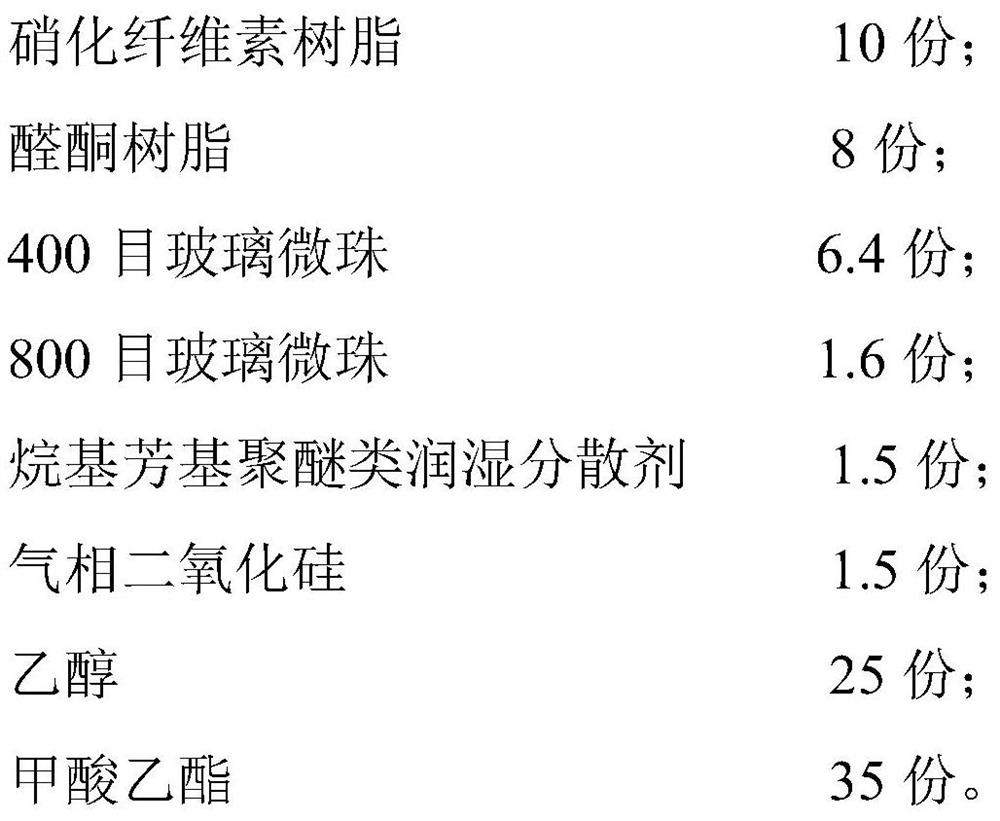

[0073] A reflective ink, comprising the following components by weight:

[0074]

[0075] The preparation method of described reflective ink comprises:

[0076] S10, adding the nitrocellulose resin and the aldehyde and ketone resin into the mixed solvent of the ethanol and the ethyl ester, and adding the 400-mesh glass microscope after the nitrocellulose resin and the aldehyde and ketone resin are dissolved Bead and described 800 order glass microspheres, obtain the first solution;

[0077] S12, stirring the first solution at a speed of 600r / min for 30 minutes, so that the glass beads are uniformly dispersed in the first solution;

[0078] S13, sequentially adding the alkylaryl polyether wetting and dispersing agent and the fumed silica into the first solution to obtain a second solution;

[0079] S14, stirring the second solution at a speed of 400 r / min for 30 minutes, so that the components in the second solution are uniformly mixed to obtain the reflective ink.

experiment example 11

[0110] Print the reflective ink prepared by Example 1 and Comparative Examples 1.1-1.5 on the same substrate, and use a retroreflection coefficient tester (model: SMD-2001 type, Tianjin Jinanrui Instrument Co., Ltd.) to measure the reflective ink layer The results of retroreflection coefficients at different angles are shown in Table 1:

[0111] Table 1

[0112]

[0113]

[0114] As can be seen from the above table, the reflective ink comprising glass beads of two different particle sizes in Example 1 has a higher reflective ink than the reflective ink comprising only glass beads of one particle size in Comparative Examples 1.1-1.5. Reflection coefficient: From Comparative Examples 1.1-1.5, it can be seen that the smaller the number of glass microspheres, the larger the particle size of the glass microspheres, and the higher the retroreflection coefficient of the reflective ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com