Water-based system reflective pulp and application thereof in sportswear fabric

A water-based system and reflective technology, which is applied in the field of reflective paste, can solve the problems of limited application, hardening of clothing fabrics, and reduced softness, and achieve the effects of repeated washing resistance, soft texture, and high retroreflection coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

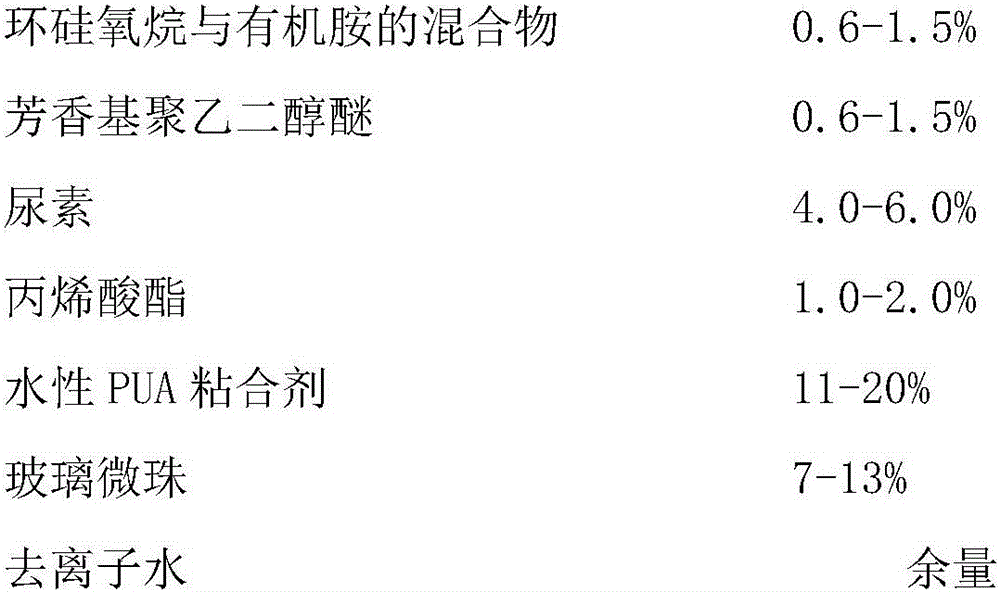

[0019] This embodiment relates to a water-based system reflective paste, which includes the following components in terms of mass percentage:

[0020]

[0021] As a preferred embodiment, the viscosity of the above-mentioned water-based reflective paste is 20000 cps, and the pH value is 6.0. The mixing ratio of cyclosiloxane and organic amine is 9:16, wherein the organic amine is ethanolamine; the water-based PUA adhesive is a mixture of water-based polyurethane and polyacrylate (PA), wherein water-based polyurethane and polyacrylate (PA) ) in a mixing ratio of 7:3.

[0022] The water-based system reflective paste prepared by the present embodiment is printed on the sports fabric by the following method:

[0023] (1) Print reflective paste: according to pattern design, use 800# mesh to make printing screen, scraper with 65H hardness, print described water-based system reflective paste on sports fabric;

[0024] (2) Baking: use a width-type setting machine, bake at 150 degr...

Embodiment 2

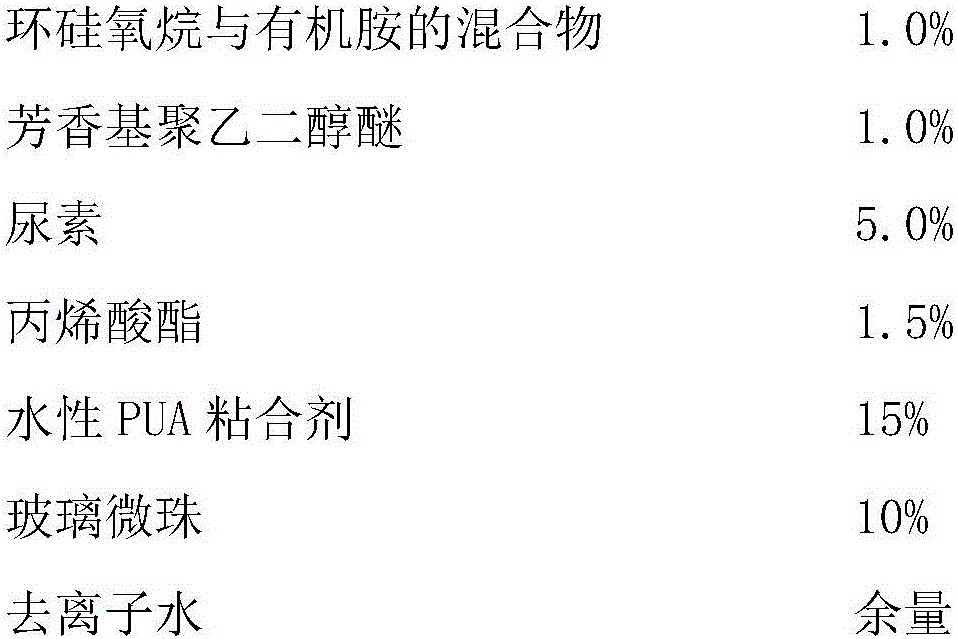

[0027] This embodiment relates to a water-based system reflective paste, which includes the following components in terms of mass percentage:

[0028]

[0029] As a preferred embodiment, the viscosity of the above-mentioned water-based system reflective paste is 20000 cps, and the pH value is 6.5. The mixing ratio of cyclosiloxane and organic amine is 9:16, wherein the organic amine is ethanolamine; the water-based PUA adhesive is a mixture of water-based polyurethane and polyacrylate (PA), wherein water-based polyurethane and polyacrylate (PA) ) in a mixing ratio of 7:3.

[0030] The water-based system reflective paste prepared by the present embodiment is printed on the sports fabric by the following method:

[0031] (1) Print reflective paste: according to pattern design, use 800# mesh to make printing screen, scraper with 65H hardness, print described water-based system reflective paste on sports fabric;

[0032] (2) Baking: use a width-type setting machine, bake at 1...

Embodiment 3

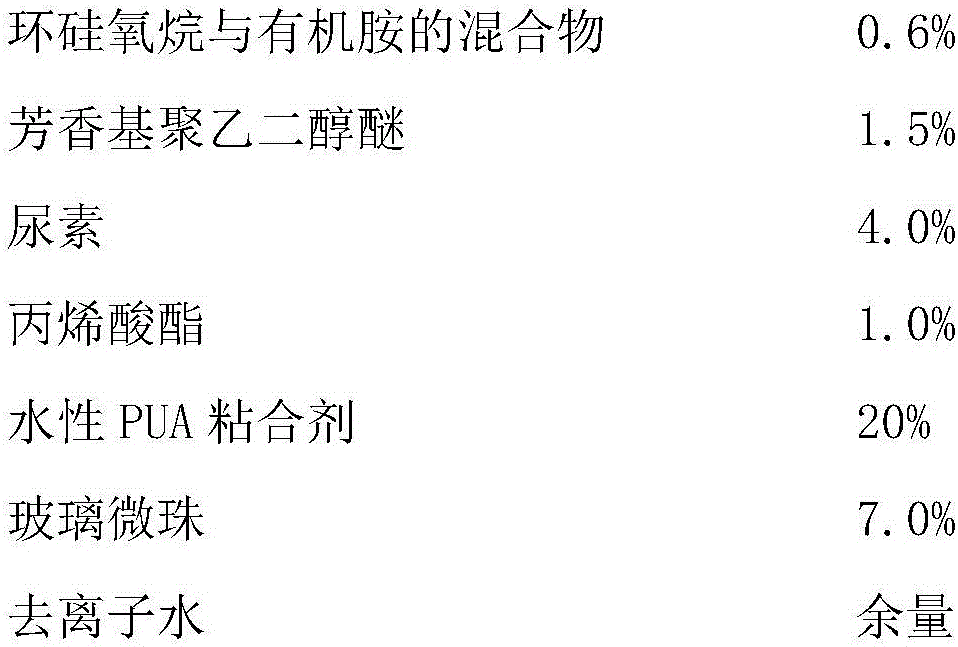

[0035] This embodiment relates to a water-based system reflective paste, which includes the following components in terms of mass percentage:

[0036]

[0037]

[0038] As a preferred embodiment, the viscosity of the above-mentioned water-based reflective paste is 20000 cps, and the pH value is 7.0. The mixing ratio of cyclosiloxane and organic amine is 9:16, wherein the organic amine is ethanolamine; the water-based PUA adhesive is a mixture of water-based polyurethane and polyacrylate (PA), wherein water-based polyurethane and polyacrylate (PA) ) in a mixing ratio of 7:3.

[0039] The water-based system reflective paste prepared by the present embodiment is printed on the sports fabric by the following method:

[0040] (1) Print reflective paste: according to pattern design, use 800# mesh to make printing screen, scraper with 65H hardness, print described water-based system reflective paste on sports fabric;

[0041] (2) Baking: use a width-type setting machine, bake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com