Bead exposing type dazzling reflection light storing film and manufacturing process thereof

A manufacturing process and colorful technology, which is applied in the field of bead-exposed colorful reflective light-storing film and its manufacturing process, can solve the problem of inability to meet the needs of individualization and fashion, the low retroreflection coefficient of the reflective part, and the inability to meet the safety factor and other problems, to achieve the effect of good luminosity, good colorful effect, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

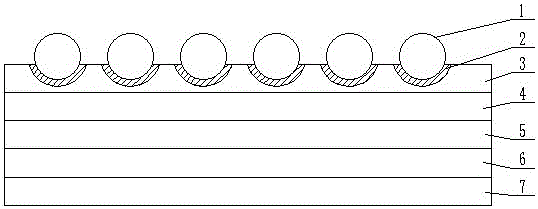

[0026] Such as figure 1 As shown, a microbead-exposed colorful reflective light-storage film, which includes glass beads 1, zinc sulfide layer 2, connection layer 3, light-storage layer 4, reflective layer 5, adhesive layer 6 and release layer 7, the The connecting layer 3 is embedded with several glass beads 1, and the contact surface between the lower side of the glass beads 1 and the connecting layer 3 is provided with a zinc sulfide layer 2, and the light storage layer 4 and the reflective layer 5 are The release layer 7 and the release layer 7 are sequentially arranged under the connection layer 3 , and the reflective layer 5 and the release layer 7 are connected by an adhesive layer 6 .

[0027] The refractive index of the glass microspheres 1 is 1.90, the particle size range of the glass microspheres 1 is 5-40 μm, and the particle size difference between the largest glass microsphere and the smallest glass microsphere is 5 μm. Here, it is necessary to screen the glass ...

specific Embodiment approach 2

[0034] Its structure is the same as the specific embodiment 1.

[0035] The refractive index of the glass microspheres 1 is 1.92, the particle size range of the glass microspheres 1 is 40-80 μm, and the particle size difference between the largest glass microsphere and the smallest glass microsphere is 8 μm. Here, it is necessary to screen the glass microspheres 1 of various particle diameters first, and then select a single particle diameter or different particle diameters and mix them in proportion according to the requirements of product performance indicators, and then plant the beads.

[0036] The zinc sulfide layer 2 is evaporated on the glass microspheres 1, and the thickness of the zinc sulfide layer 2 is 400nm.

[0037] A manufacturing process of microbead-exposed colorful reflective light-storing film, which comprises the following steps:

[0038] S1. Preparation of bead-planting film: coating the bead-planting layer on the substrate, and adhering the glass microsph...

specific Embodiment approach 3

[0042] Its structure is the same as the specific embodiment 1.

[0043] The refractive index of the glass microsphere 1 is 1.93, the particle diameter of the glass microsphere 1 is 80-120 μm, and the particle diameter difference between the largest glass microsphere and the smallest glass microsphere is 10 μm. Here, it is necessary to screen the glass microspheres 1 of various particle diameters first, and then select a single particle diameter or different particle diameters and mix them in proportion according to the requirements of product performance indicators, and then plant the beads.

[0044] The zinc sulfide layer 2 is evaporated on the glass microspheres 1, and the thickness of the zinc sulfide layer 2 is 14000nm.

[0045] A manufacturing process of microbead-exposed colorful reflective light-storing film, which comprises the following steps:

[0046] S1. Preparation of bead-planting film: coating the bead-planting layer on the substrate, and adhering the glass micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com