Hot melt adhesive for reflective film, reflective film and manufacturing method of reflective film

A technology of hot-melt adhesive and reflective film, applied in the field of hot-melt adhesive, can solve the problems of limited applicable occasions, insufficient retroreflection coefficient, etc., and achieve the effect of enhanced retroreflection coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

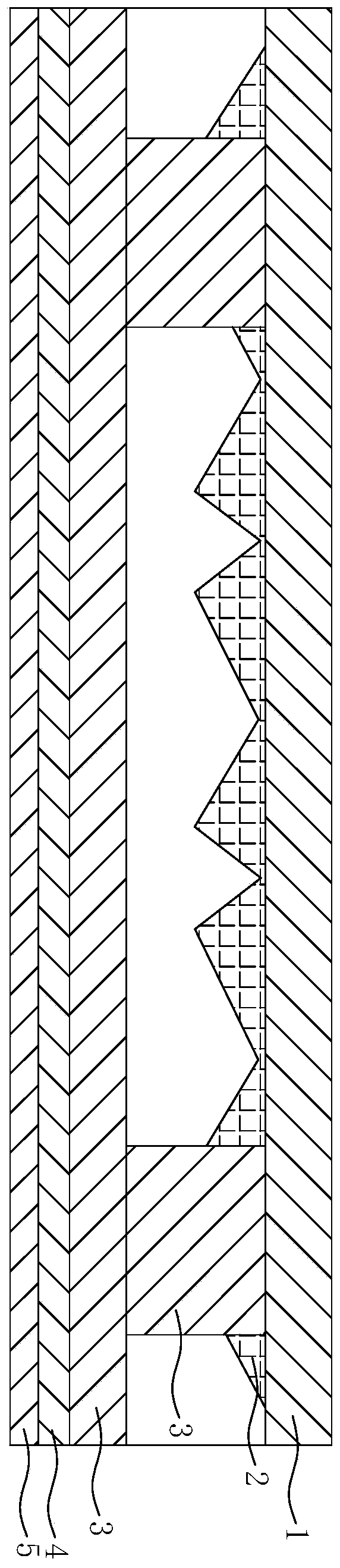

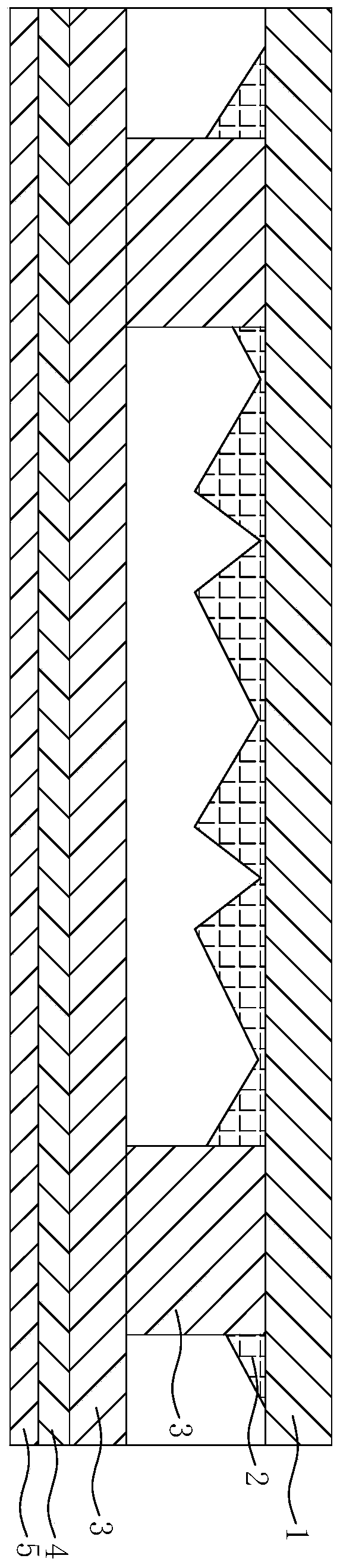

[0045] The reflective film comprises a base material layer 1, a microprism layer 2, an encapsulation layer 3, an adhesive layer 4 and a release layer 5 arranged sequentially from top to bottom, and a hot melt adhesive is arranged between the encapsulation layer 3 and the microprism layer 2, The hot melt adhesive contains glass beads, the base material layer 1 is made of PVC material, the microprism layer 2 is formed on the base material layer 1 by UV technology, and the encapsulation layer 3 is made of white PET film.

[0046] The hot melt adhesive includes the following raw materials in parts by mass: 45 parts of saturated polyester resin, 27 parts of solvent, 0.3 part of dispersant, 12.5 parts of 1,6-hexanediol diacrylate, 0.2 part of antioxidant additive, 0.8 part of ultraviolet absorber 5 parts, 5 parts of glass microspheres and 2 parts of aromatic isocyanate, and the number of glass microspheres is 250 mesh.

[0047] The hot melt adhesive made without adding aromatic isoc...

Embodiment 2

[0060]The reflective film comprises a base material layer 1, a microprism layer 2, an encapsulation layer 3, an adhesive layer 4 and a release layer 5 arranged sequentially from top to bottom, and a hot melt adhesive is arranged between the encapsulation layer 3 and the microprism layer 2, The hot melt adhesive contains glass beads, the base material layer 1 is made of PVC material, the microprism layer 2 is formed on the base material layer 1 by UV technology, and the encapsulation layer 3 is made of white PET film.

[0061] The hot melt adhesive includes the following raw materials in parts by mass: 50 parts of saturated polyester resin, 32 parts of solvent, 0.7 part of dispersant, 13 parts of 1,6-hexanediol diacrylate, 0.4 part of antioxidant additive, 1.2 parts of ultraviolet absorber 6 parts, 6 parts of glass microspheres and 4 parts of aromatic isocyanate, and the number of glass microspheres is 400 mesh.

[0062] The hot melt adhesive made without adding aromatic isocya...

Embodiment 3

[0075] The reflective film comprises a base material layer 1, a microprism layer 2, an encapsulation layer 3, an adhesive layer 4 and a release layer 5 arranged sequentially from top to bottom, and a hot melt adhesive is arranged between the encapsulation layer 3 and the microprism layer 2, The hot melt adhesive contains glass beads, the base material layer 1 is made of PVC material, the microprism layer 2 is formed on the base material layer 1 by UV technology, and the encapsulation layer 3 is made of white PET film.

[0076] The hot melt adhesive includes the following raw materials in parts by mass: 47 parts of saturated polyester resin, 30 parts of solvent, 0.5 part of dispersant, 12.7 parts of 1,6-hexanediol diacrylate, 0.3 part of antioxidant additive, 1 part of ultraviolet absorber 5.5 parts of glass microspheres and 3 parts of aromatic isocyanate, and the number of glass microspheres is 250 mesh.

[0077] The hot melt adhesive made without adding aromatic isocyanate (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com