Ink-jet apparatus and method for eliminating air bubble of ink jet head

An inkjet device and inkjet head technology, applied in printing and other directions, can solve the problems of increased cost, time-consuming and laborious, etc., and achieve the effects of improving utilization rate, reducing maintenance time, and good inkjet effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

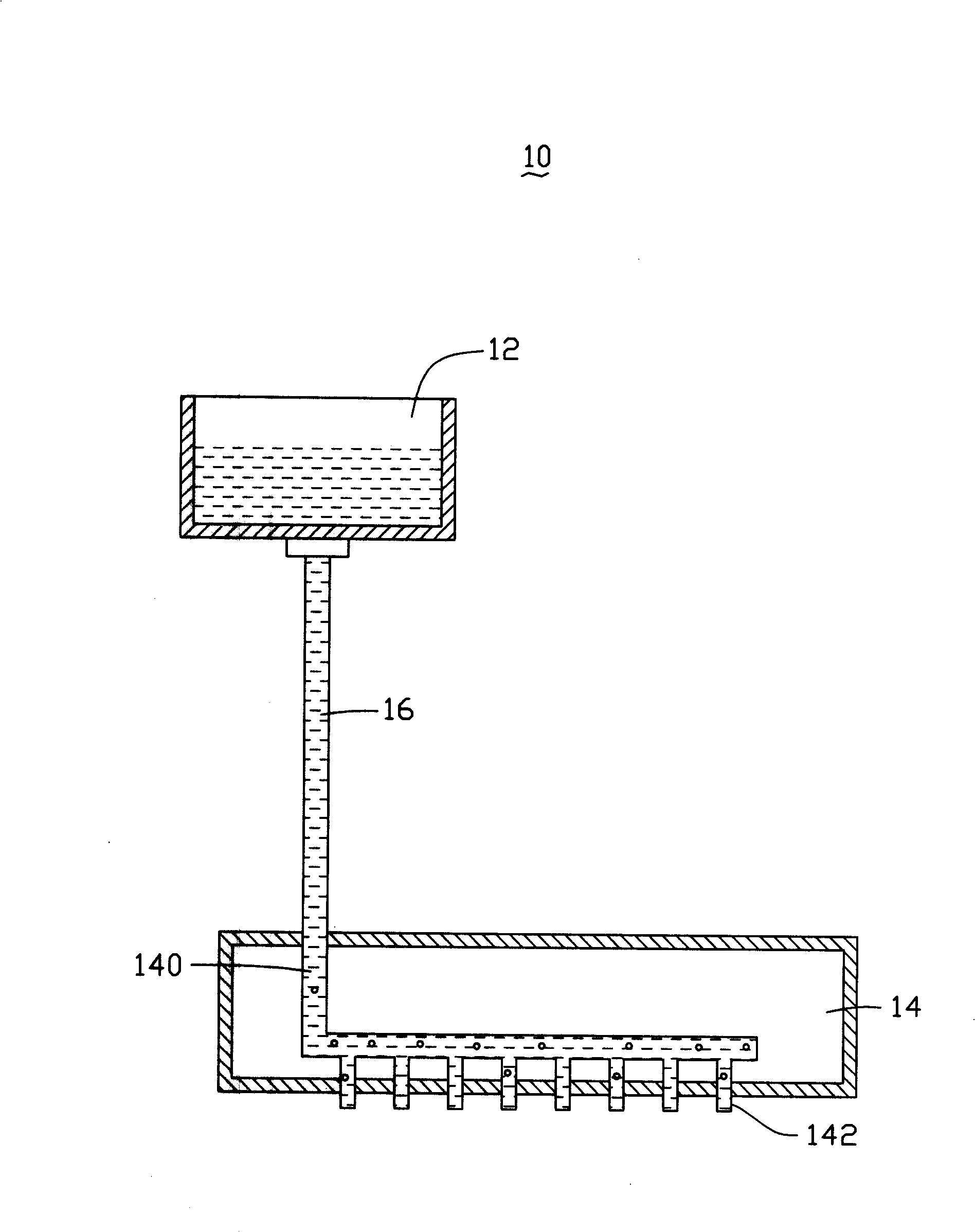

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

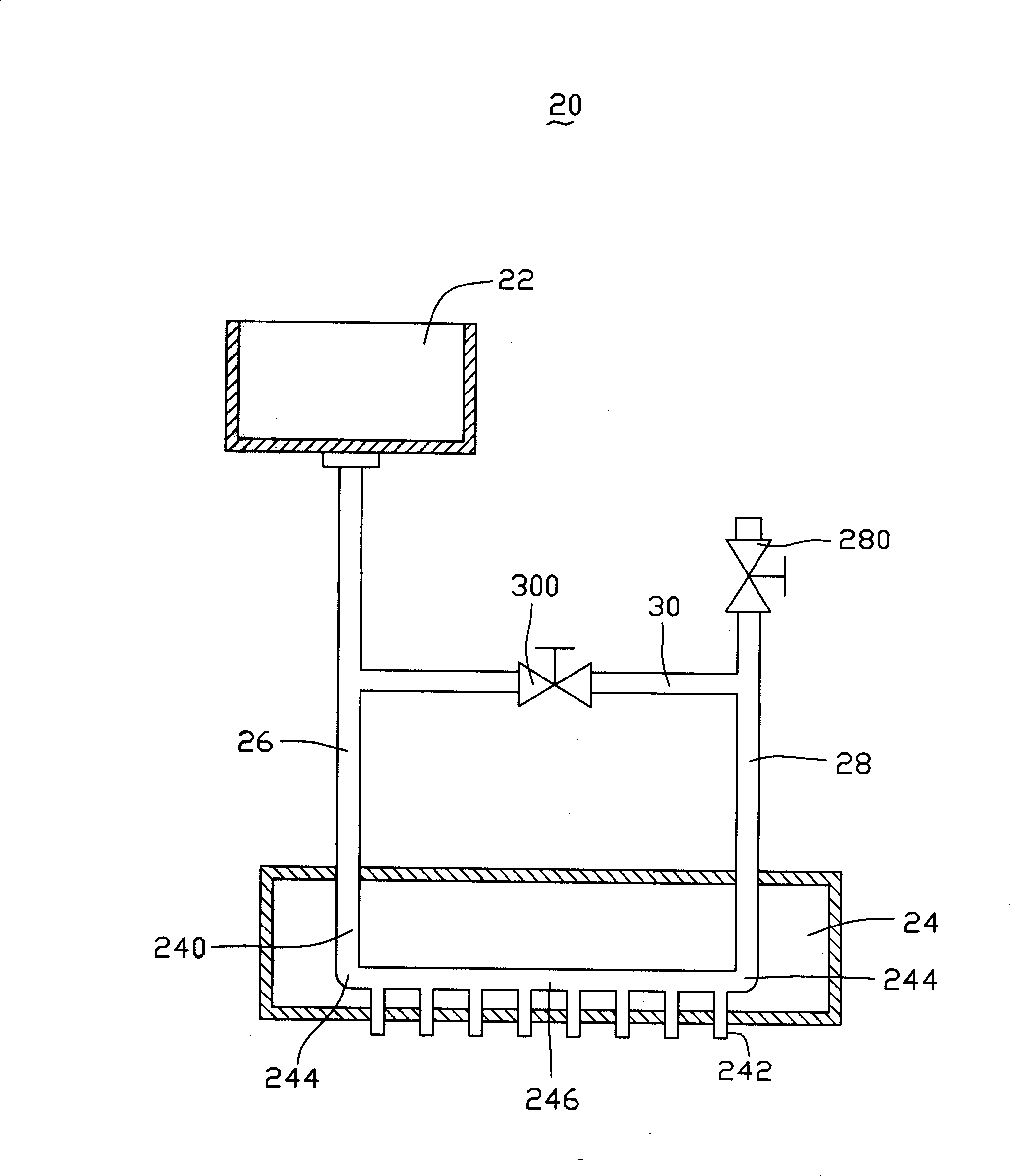

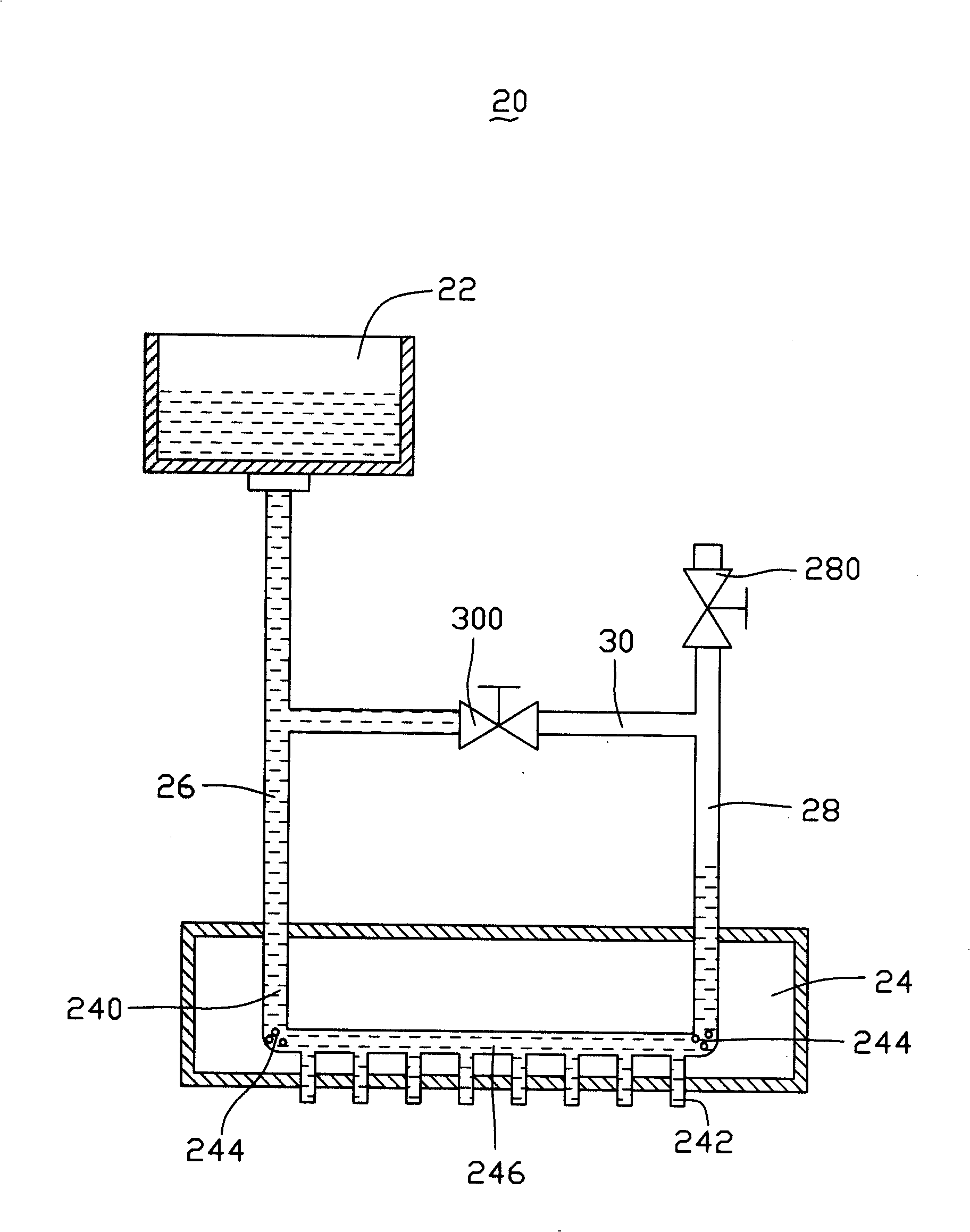

[0013] The invention provides an inkjet device. The device is between the ink supply tank and the inkjet head, plus an exhaust pipe and a balance pipe with a valve. Pressure balance between individual pipes. The type of ink used in the above-mentioned process is not limited, and inks using water, xylene, toluene and anisole as solvents are preferred.

[0014] See figure 2 , the embodiment of the present invention provides an inkjet device 20 . The inkjet device 20 includes an ink supply tank 22 and at least one inkjet head 24 . At least one input tube 26 is connected between the ink supply tank 22 and the at least one inkjet head 24 . The inkjet device 20 further includes at least one exhaust pipe 28 and at least one balance pipe 30 . The exhaust pipe 28 is used to connect the inkjet head 24 and the atmosphere, and the balance pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com