Industrial code-spraying equipment

A coding and equipment technology, applied in power transmission devices, printing, transfer materials, etc., can solve problems such as nozzle vibration, unusable, ink loss, etc., to reduce starting friction resistance, reduce dynamic friction resistance, and reduce friction The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

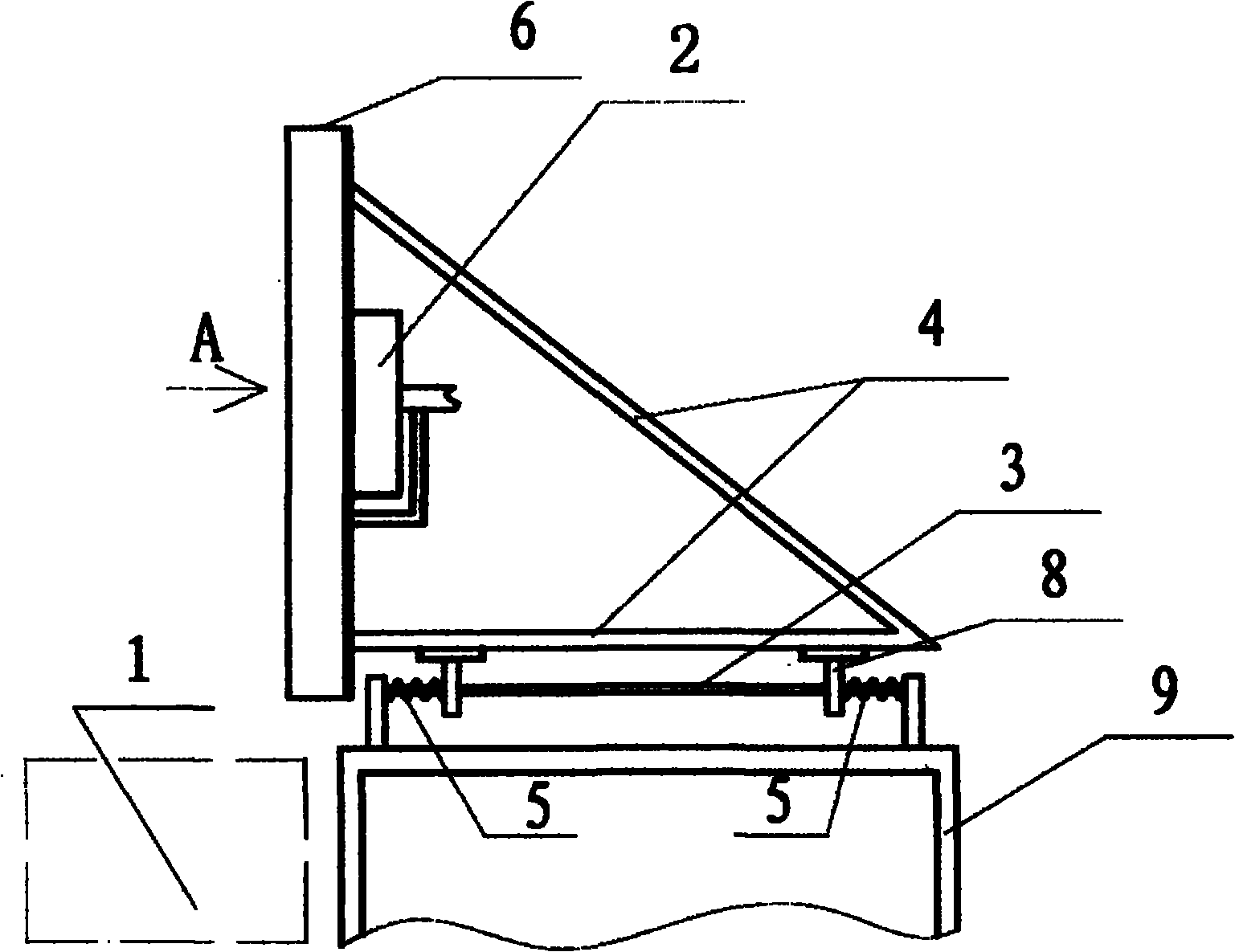

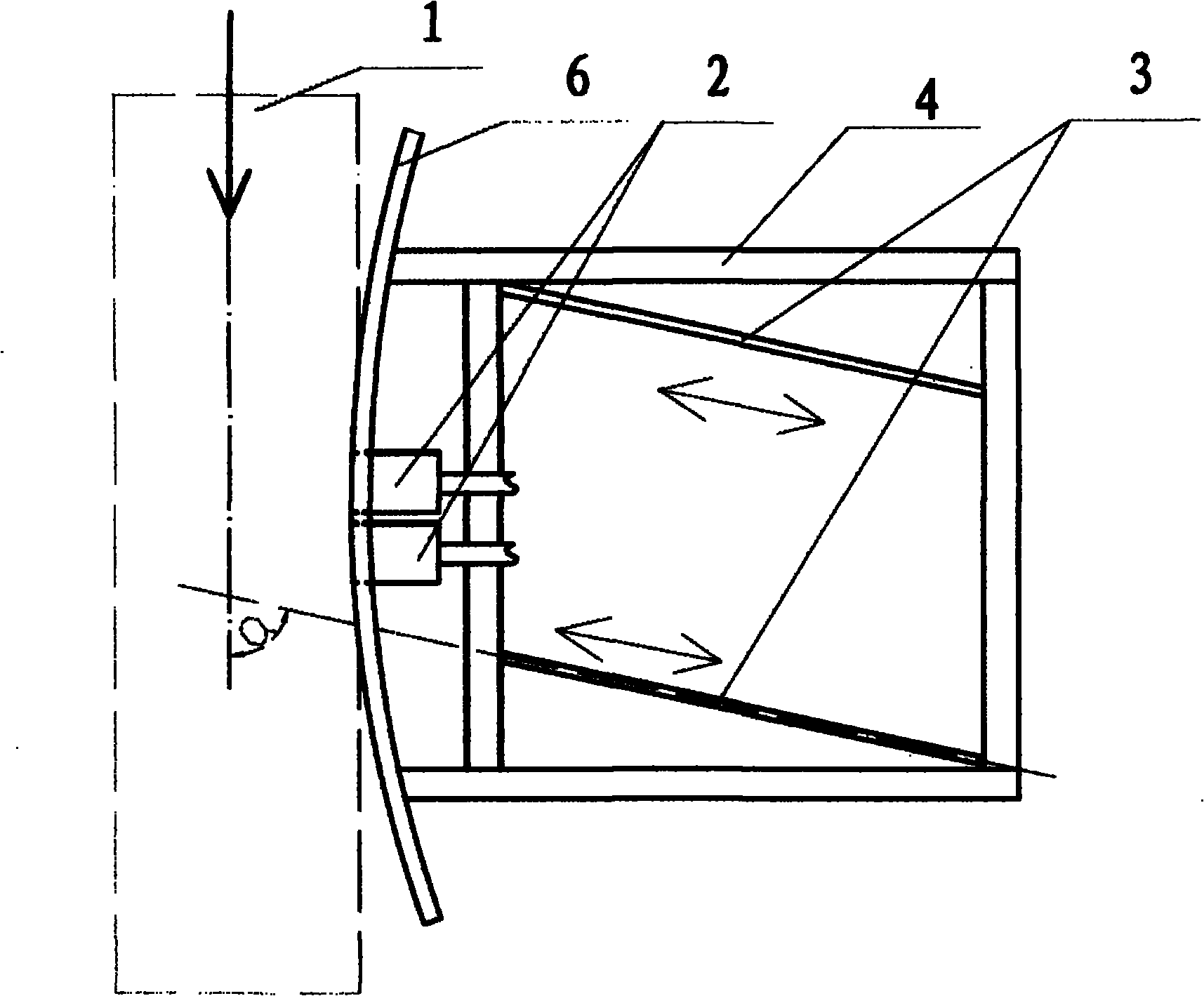

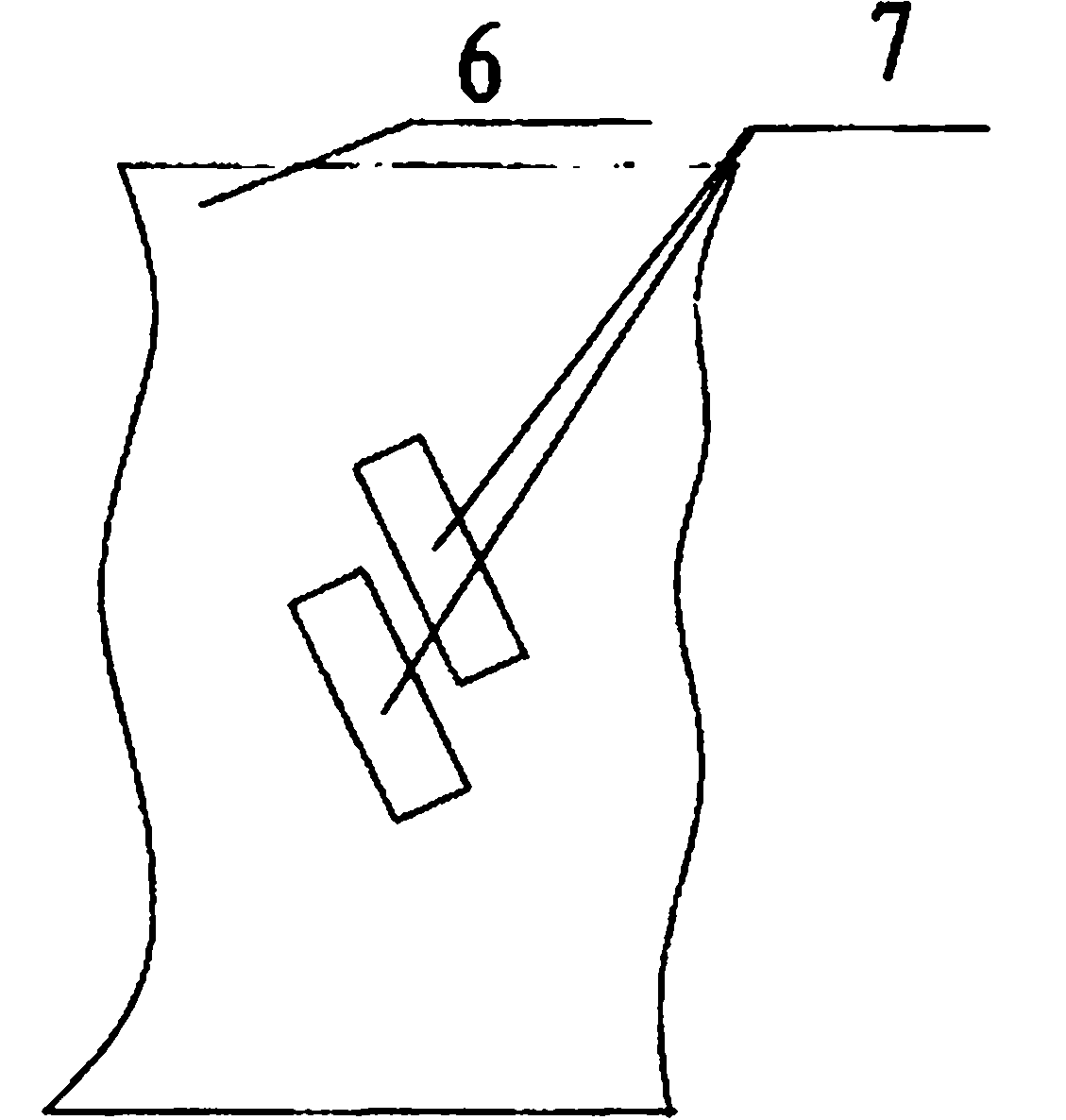

[0017] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, the present invention is installed on one side of the conveyor belt 1, and its fixing method can be directly installed on one side of the conveyor belt, or a fixed bracket 9 can be installed on the side of the conveyor belt 1, and a guide rail 3 is connected on the fixed bracket 9. The guide rail 3 used is a linear bearing guide rail, and the angle a between the linear bearing guide rail and the forward direction of the conveyor belt 1 is less than 90° during installation. The bearing 8 is matched with the guide rail 3, and two support return springs 5 of the same type are installed at the contact position between the arc plate support 4 and the guide rail 3. The support return spring 5 is sleeved on the linear bearing guide rail, and is located on the two side and in the compression deformation position (such as figure 1 ); the arc plate 6 is connected to the arc plate support 4, and the arc of the arc p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com