Robot bouncing mechanism based on hydraulic drive

A robot and hydraulic technology, applied in the field of robot bouncing mechanism, can solve the problems of low power/mass ratio of motor drive device, low energy utilization rate of robot, inability to adjust jump height, etc., so as to improve obstacle-surmounting ability and range of activities, and has a compact structure. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a robot bounce mechanism based on hydraulic drive.

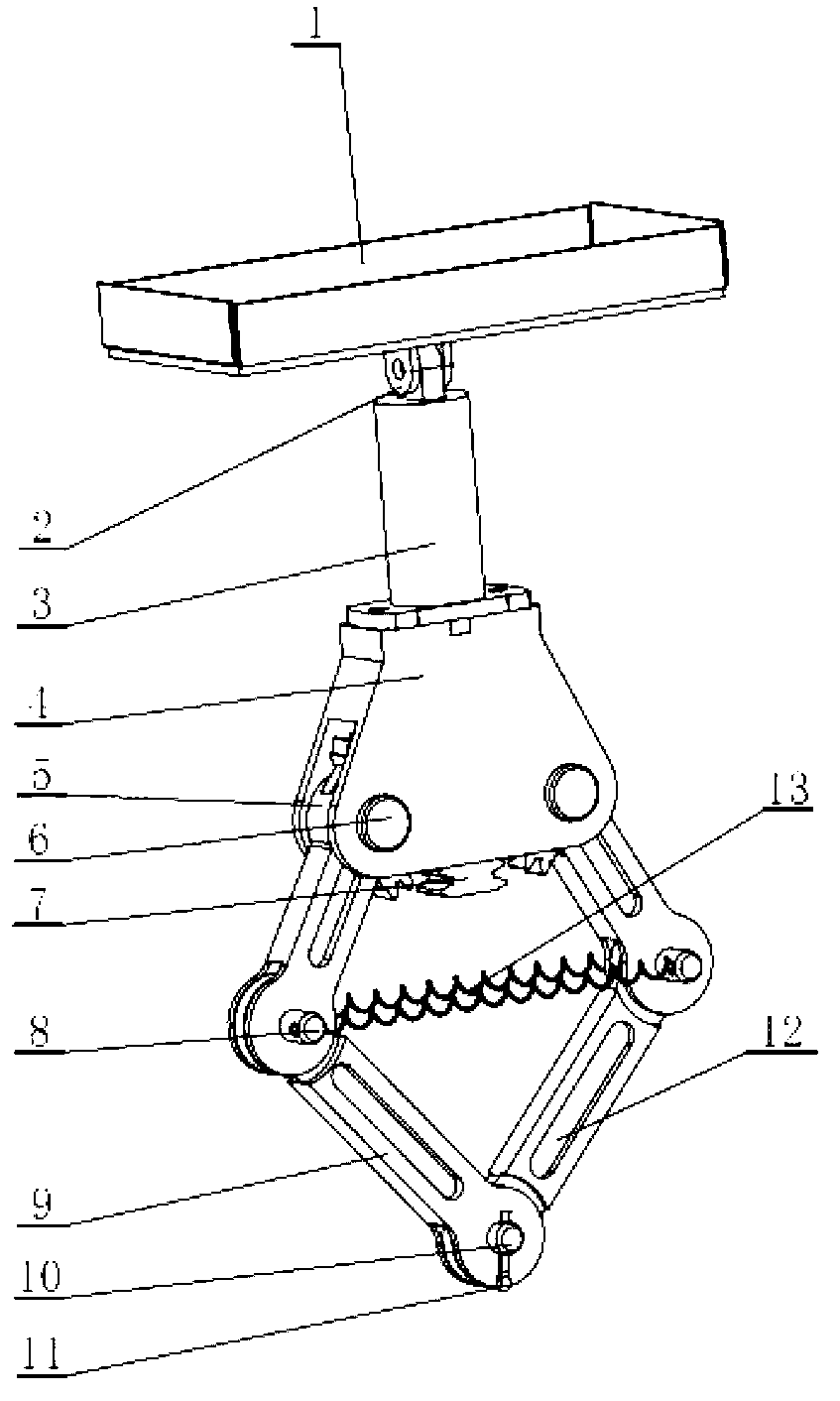

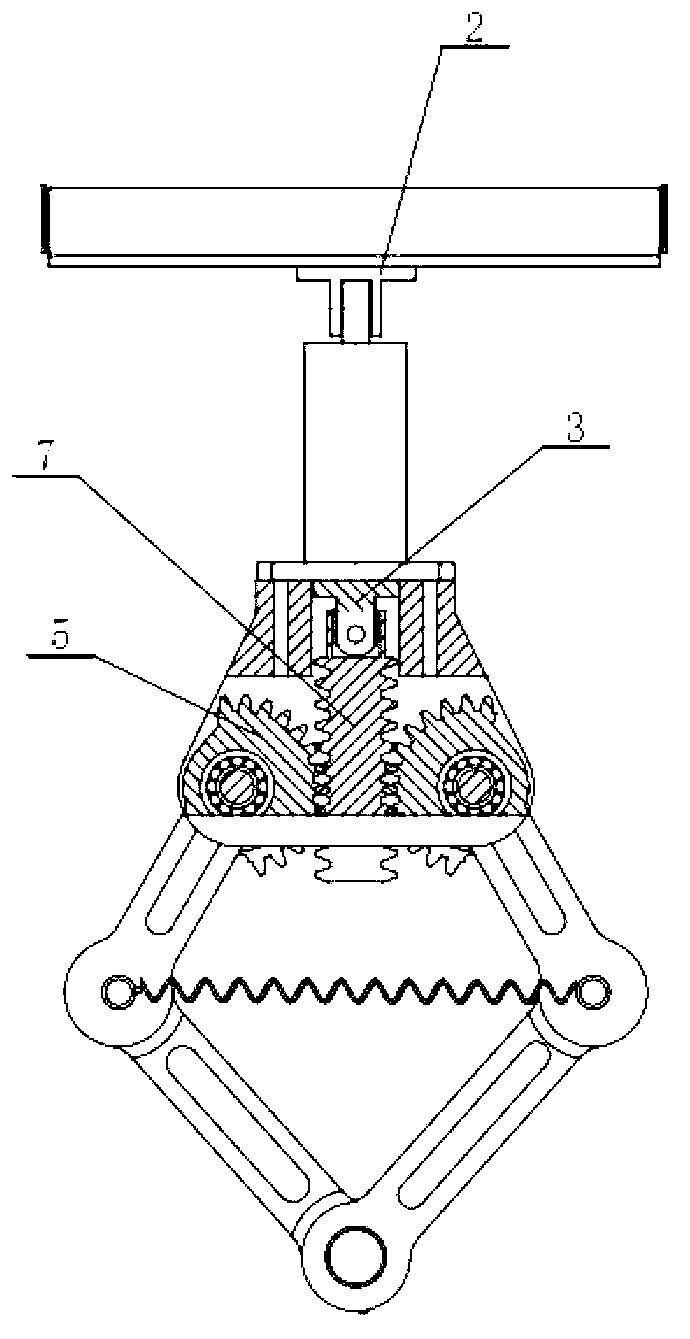

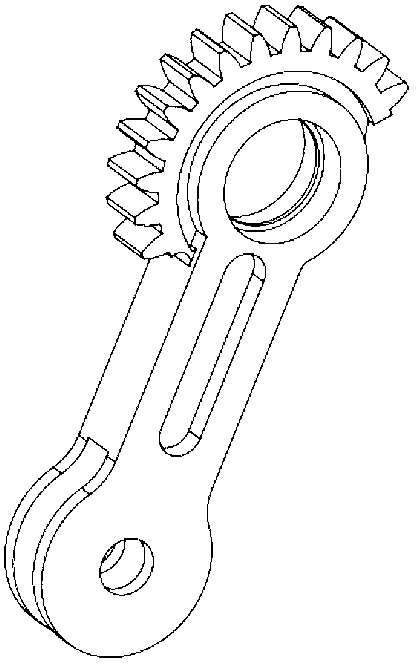

[0020] refer to figure 1 , figure 2 , the present invention is based on a hydraulically driven robot bounce mechanism, which consists of a hydraulic device 1, a hydraulic cylinder 3, a connecting seat 2, a connecting frame 4, a toothed connecting rod 5, a rotating shaft 6, a double-sided rack 7, a pin shaft 8, and a second connecting rod 9. The connecting shaft 10, the cotter pin 11, the third connecting rod 12, and the spring 13 are composed. The hydraulic device 1 is installed on the body of the robot, and the hydraulic cylinder 3 is installed under the hydraulic device 1 through the connecting seat and the lug on the top of the hydraulic cylinder. Connection, the connecting flange at the lower end of the hydraulic cylinder 3 is fixedly connected with the connecting frame 4 through bolts. The double-sided rack 7 is fixedly installed in the middle part of the connecting frame 4, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com