Slip sheet control device of rotary compressor

A technology of rotary compressor and control device, which is applied to the combination of elastic fluid rotary piston/oscillating piston pump, mechanical equipment, machine/engine, etc., can solve the problems of vane and piston damage, etc. The effect of improving the control effect, prolonging the service life and improving the reliability of the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

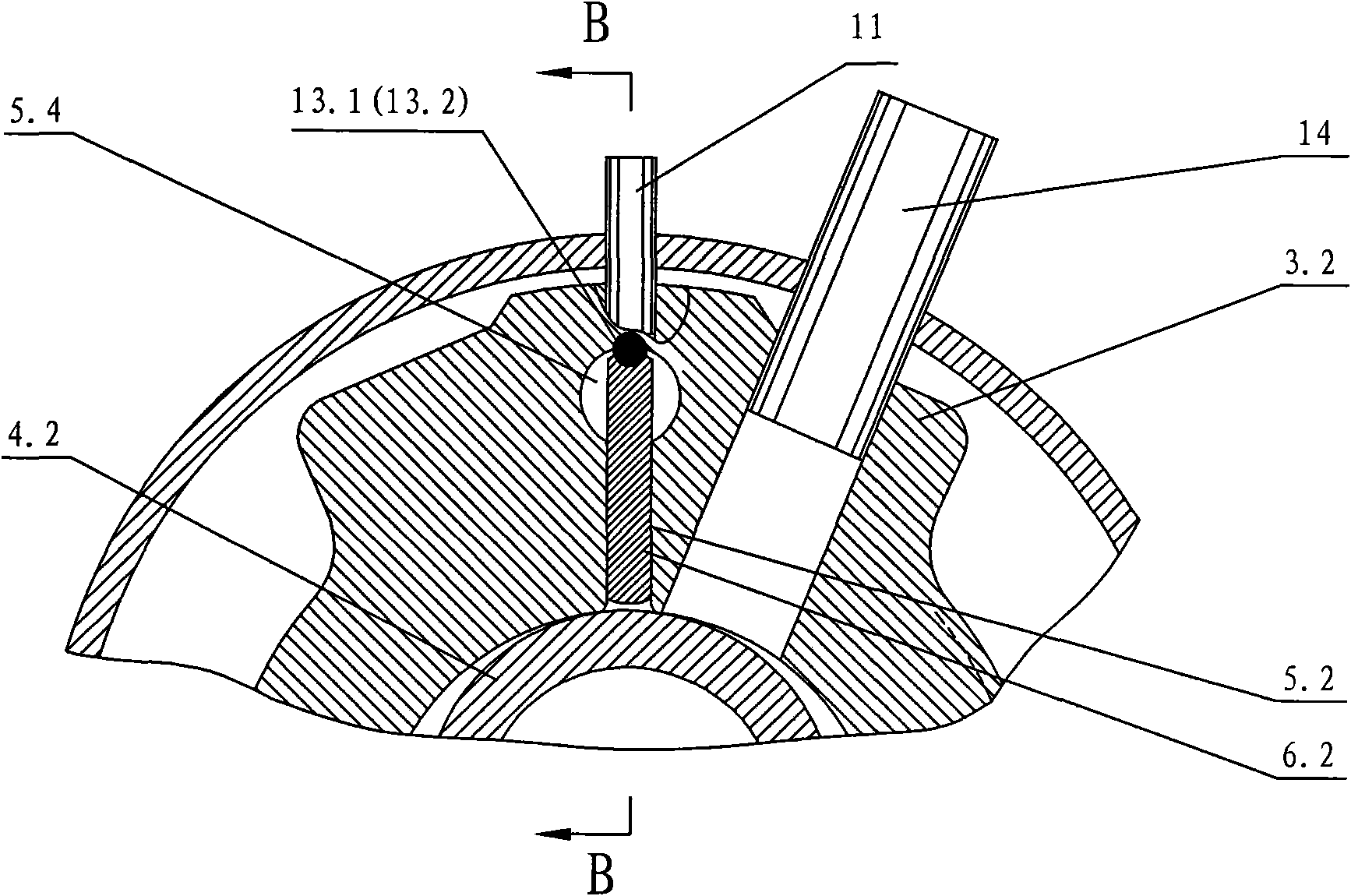

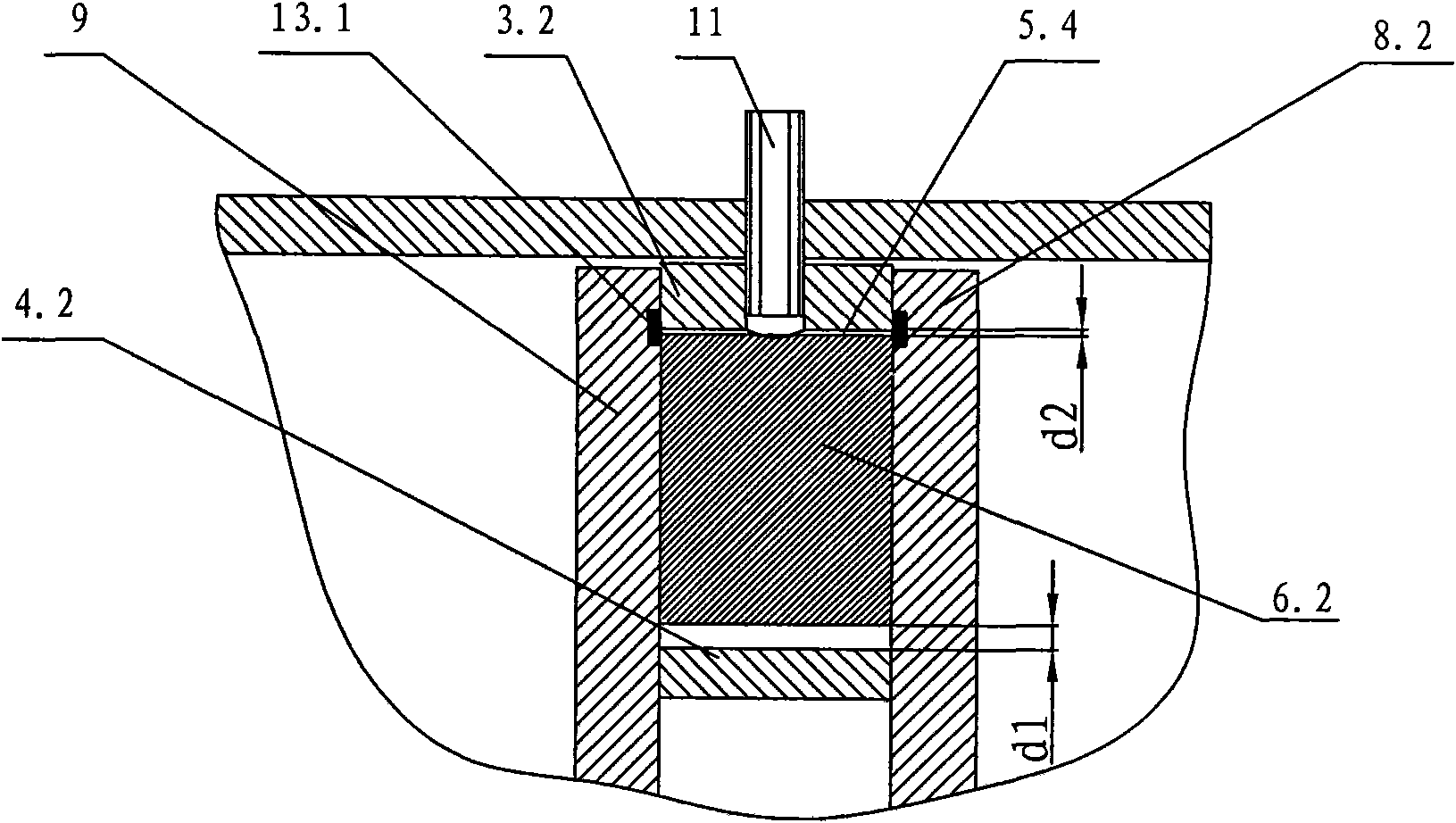

[0034] see Figure 5 , Figure 6 and Figure 9 A small head that moves in the same direction as the second slide 6.2 and improves its movement reliability is provided on the back of the second slide 6.2, and a space is provided on the side of the small head facing the magnet. The purpose of setting the space is to meet the requirements of the above scheme. The simple method is to open two straight cuts between the backs of the second slide 6.2, and design the back section of the second slide 6.2 into a convex shape, that is, the side shape of the small head in the circumferential direction of the second cylinder 3.2 is square , Or, it can also be understood as follows: the section of the small head along the moving direction of the second sliding piece 6.2 is square.

[0035] Figure 5 Among them, when the second sliding piece 6.2 stops working and is at the position that just withdraws from the inner wall of the second cylinder 3.2, the back of the second sliding piece 6....

no. 2 example

[0040] see Figure 7 and Figure 9 , set two oblique cuts on the back of the second sliding plate 6.2, that is, when the side shape of the small head in the circumferential direction of the second cylinder 3.2 is trapezoidal, its implementation effect is the same as that of the first embodiment, but the processing performance of the sliding plate is improved. That is, the processing cost is low and the processing efficiency is high.

[0041] Of course, concave arc-shaped grooves can also be provided on the upper and lower sides of the back of the second sliding piece 6.2, and the same effect as that of the first embodiment can also be achieved.

[0042] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com