Drive system of 8-cylinder hot-air engine

A technology of transmission system and hot air engine, which is applied in the direction of hot air variable capacity engine device, machine/engine, mechanical equipment, etc. High reliability, compact structure, low bearing load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

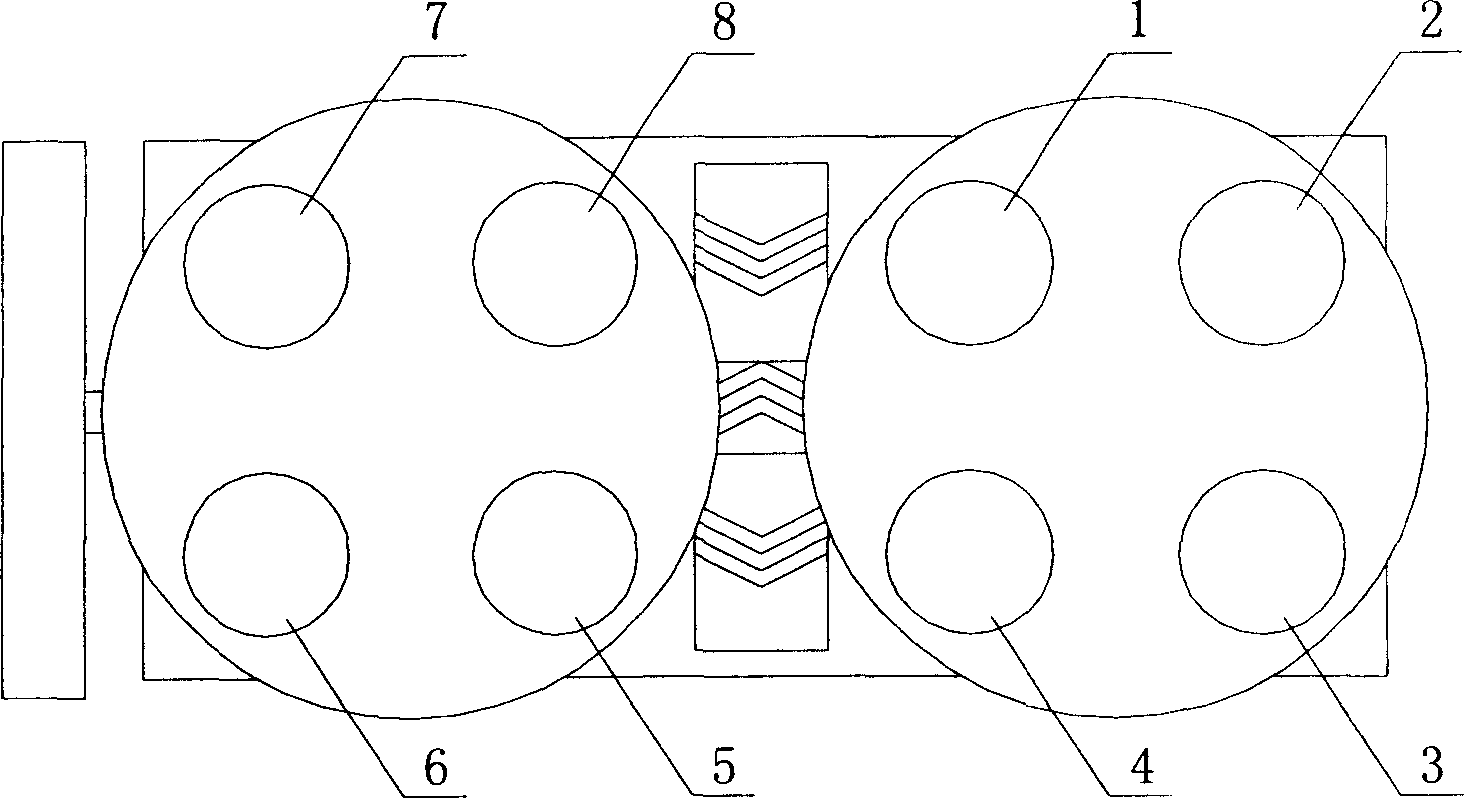

[0030] figure 1 Shown is a schematic diagram of the cylinder arrangement of an eight-cylinder heat engine, cylinder one 1, cylinder two 2, cylinder seven 7, cylinder eight 8 are arranged on the left crankshaft, cylinder three 3, cylinder four 4, cylinder five 5 are arranged on the right crankshaft , Cylinder six 6, Cylinder one 1, Cylinder two 2, Cylinder three 3, Cylinder four 4 are arranged in a square, forming the first four-cylinder double-acting heat engine unit, Cylinder five 5, Cylinder six 6, Cylinder seven 7, Cylinder The eight eights are also arranged in a square shape to form a second four-cylinder double-acting heat engine unit, and the two four-cylinder heat engine units are connected in series to form an eight-cylinder heat engine.

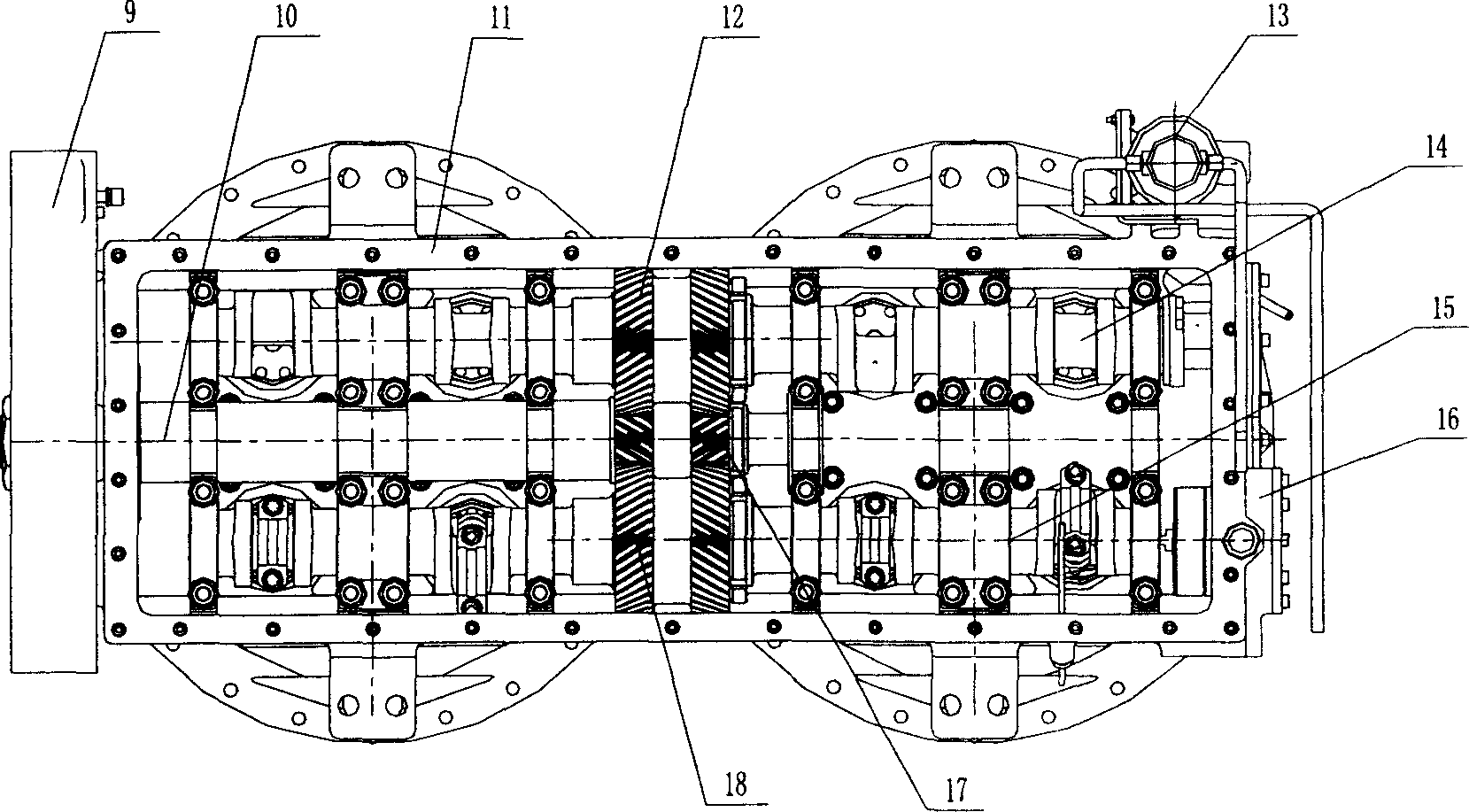

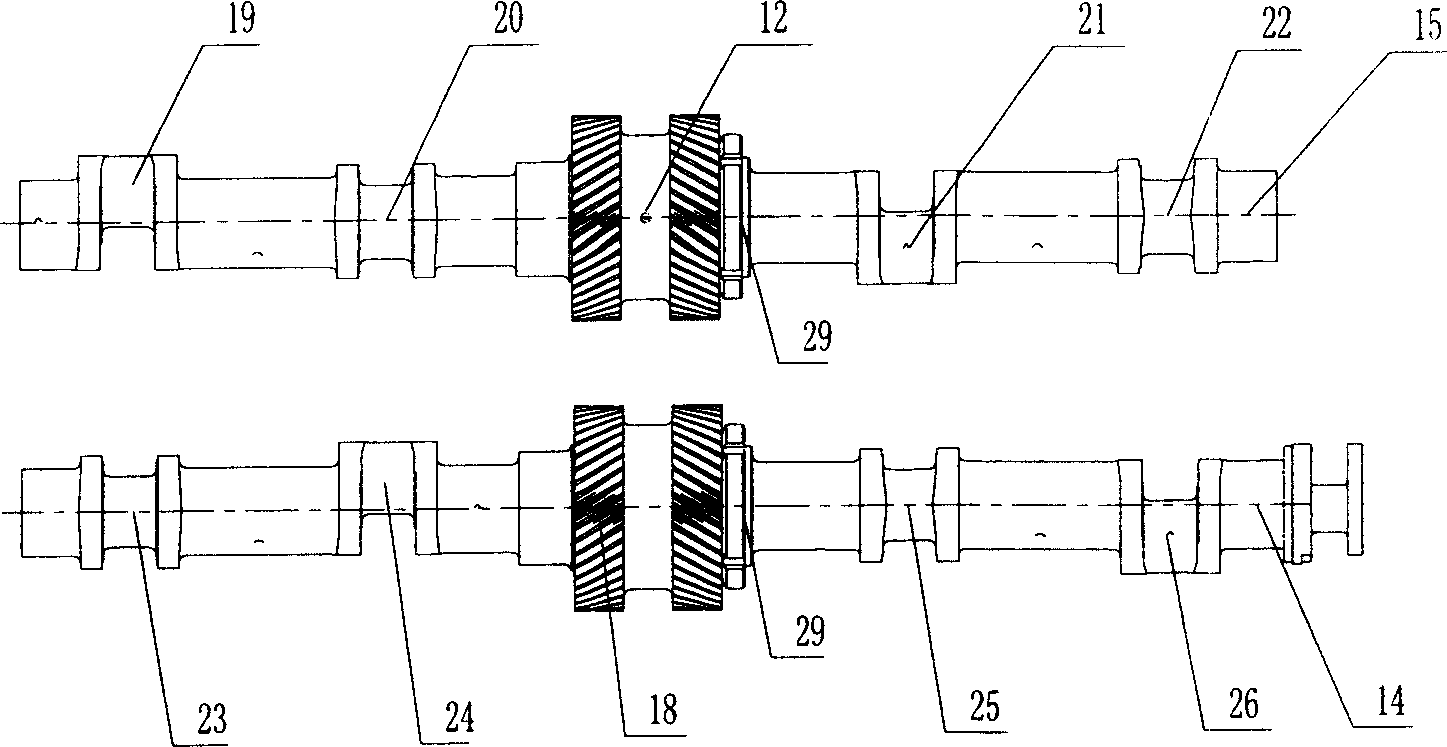

[0031] Such as figure 2 , image 3 and Figure 4 As shown, the eight-cylinder machine transmission system of the present invention includes a left crankshaft 15, a right crankshaft 14, an output shaft 10, a crankcase 11 and a gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com