Sinker control device for straight-bar machines

A technology of control device and sinker, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of complex transmission, reduced transmission reliability, and high manufacturing cost, and achieve high movement reliability, low cost, and simple manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention and its advantages will be further described below in conjunction with the accompanying drawings.

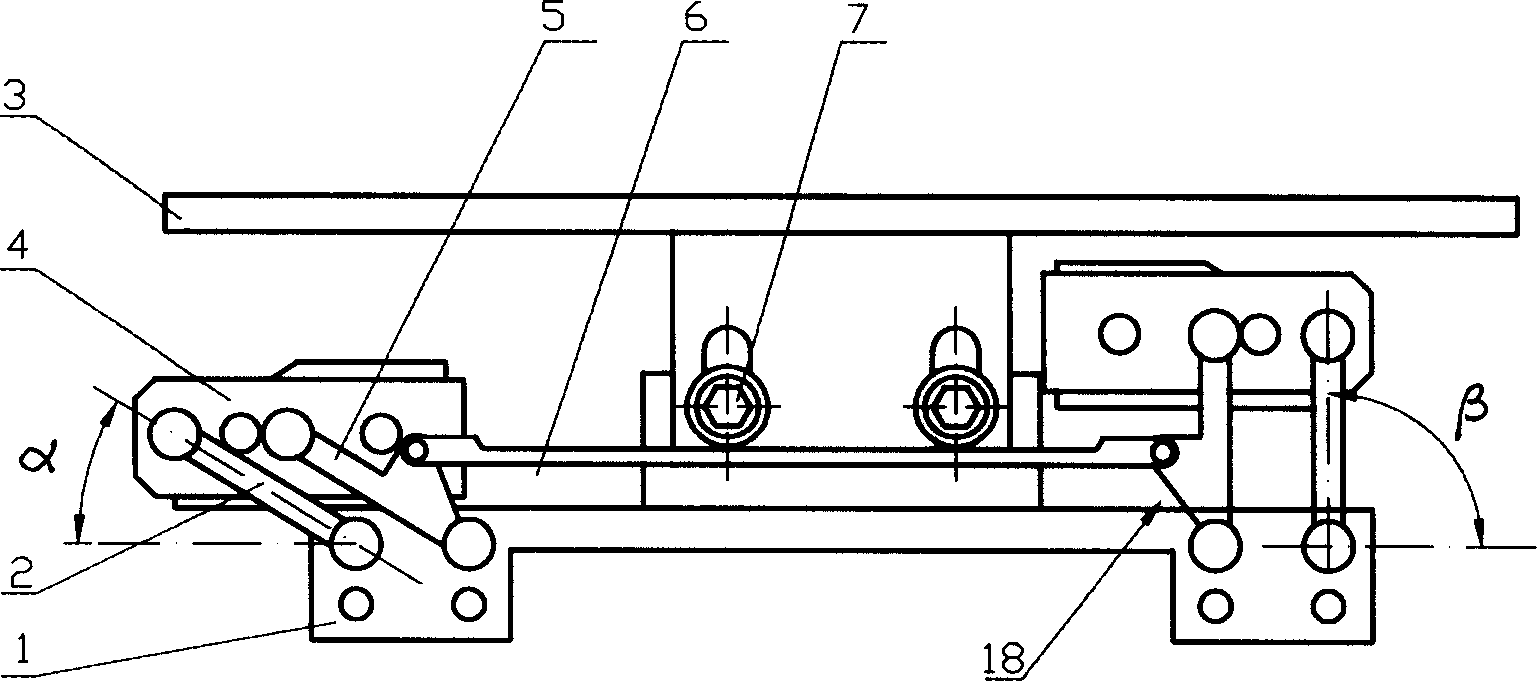

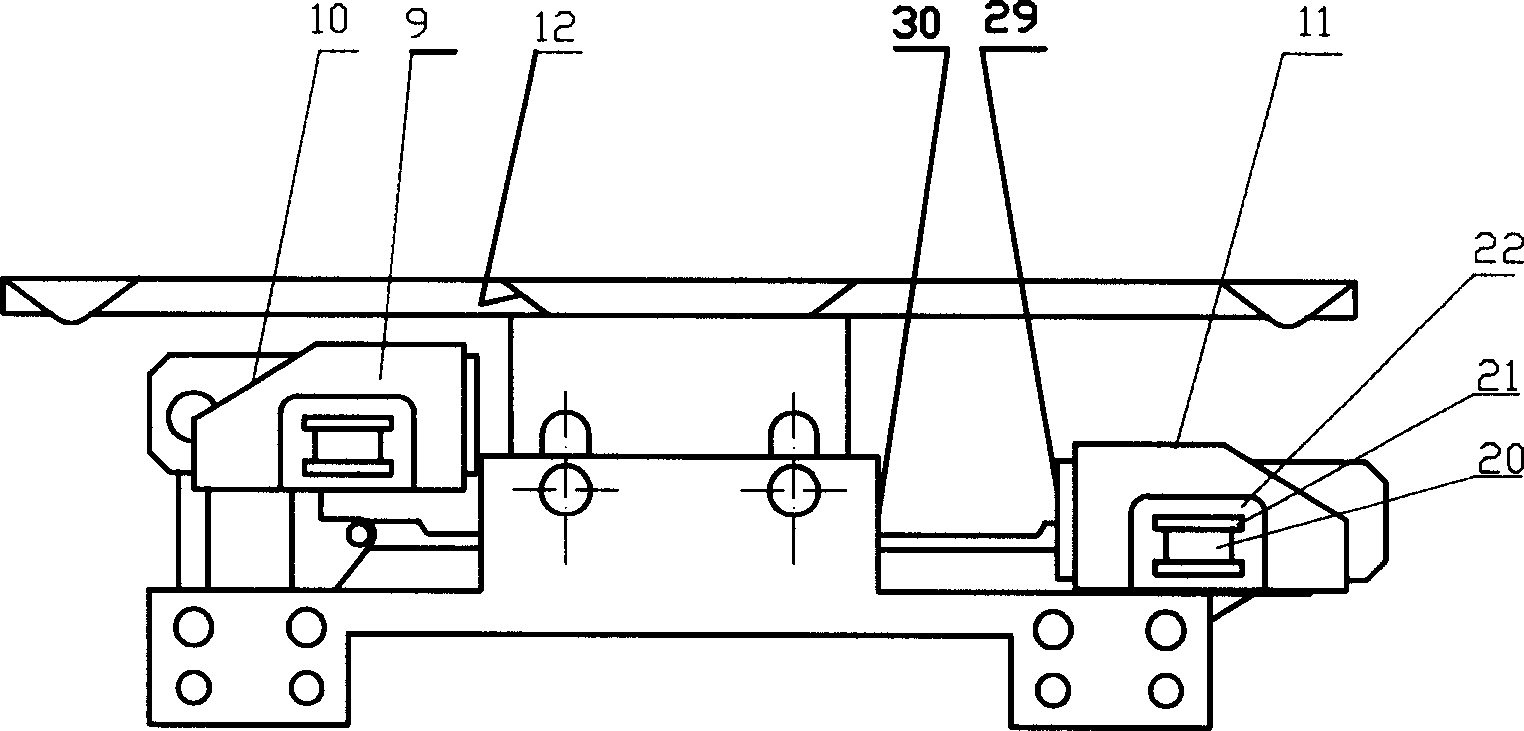

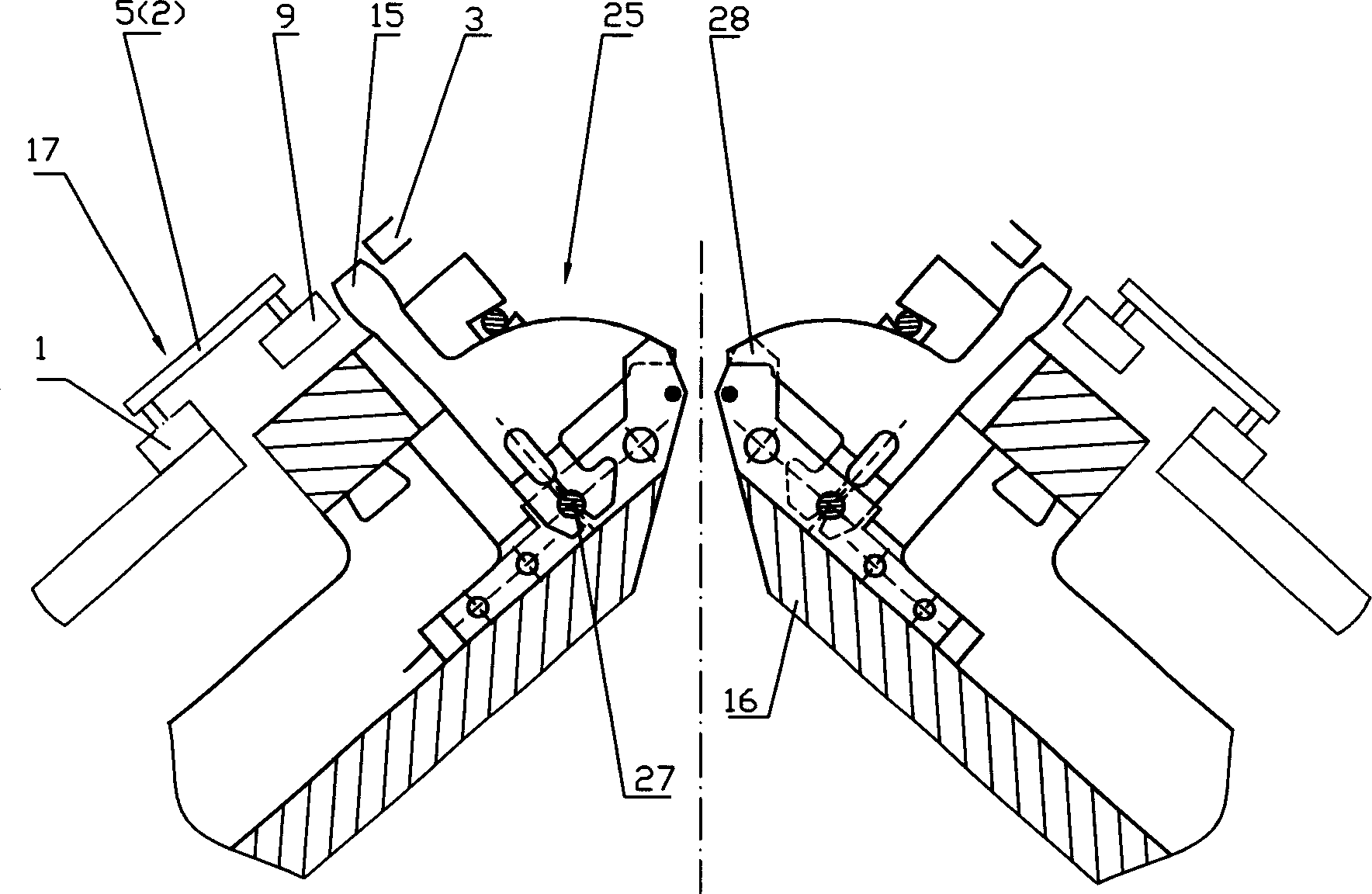

[0017] figure 1 , figure 2 It is the structural diagram of this embodiment, the reset triangle 3 is T-shaped, the base 1 is approximately inverted T-shaped, the reset triangle 3 is placed above the base 1, and the middle parts of the two are superimposed and connected by screws 7 . The left and right ends of the frame 1 are respectively hinged with the lower ends of the two swing rods 2 and 5 in the first and second parallel four-bar linkage mechanisms 17 and 18, and the upper ends of the swing rods 2 and 5 are respectively hinged with the two ends of the translation rod 4 , the needle-starting triangle 9 is installed on one side of the translation bar 5 by the screw 7, the needle-starting slope 10 and the vertical surface 24 are connected by the horizontal upper end surface 11, the needle-starting slope 10 and the reset slope 12 form the control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com