Dynamic repulsion disk and repulsion mechanism using same

A technology of repulsion disk and repulsion coil, which is applied in the direction of contact operating mechanism, power device inside the switch, electrical components, etc., can solve the problems affecting the reliability of the movement of the repulsion mechanism and the low efficiency of the repulsion force, so as to improve the quality of power supply and increase The effect of overall mechanical strength, quick closing and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

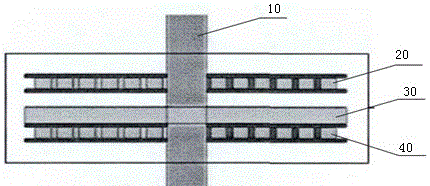

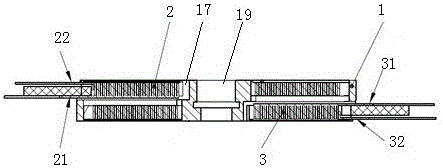

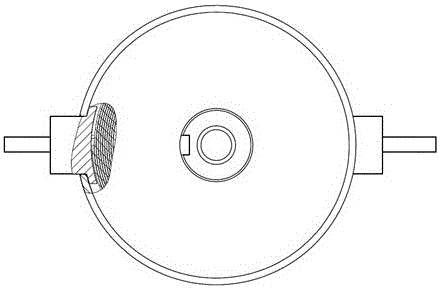

[0033] The specific embodiment of dynamic repulsion disc of the present invention, as Figures 2 to 5 As shown, the dynamic repulsion disk is provided with a central hole 19 extending along the up and down direction for the axis of the transmission rod to be installed. The dynamic repulsion disk includes a disk-shaped skeleton 1 and the first dynamic repulsion coil 2 and the second fixed on the upper and lower sides of the skeleton 1. Two dynamic repulsion coils 3. The skeleton 1 is a disc-shaped structure forged from 45# steel. The first dynamic repulsion coil 2 and the second dynamic repulsion coil 3 have the same structure, and the axes of the two coils coincide with the axes of the central hole 19 . The outer circumference of the center hole 19 on the skeleton 1 is provided with two installation ring grooves 18 for installing the first dynamic repulsion coil 2 and the second dynamic repulsion coil 3, and the two installation ring grooves 18 are distributed along the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com