Chip mounter for CSP LEDs, and processing process for chip mounter

A processing technology, LED chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low yield rate of finished products, difficulty in mass production, general stability and other problems, and achieve high yield rate of finished products and low production cost , The effect of ensuring the stability of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

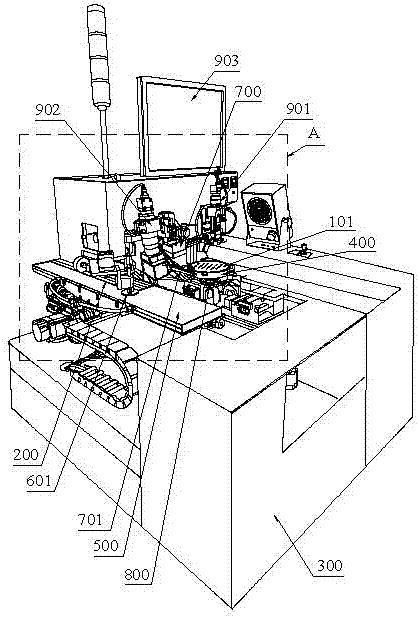

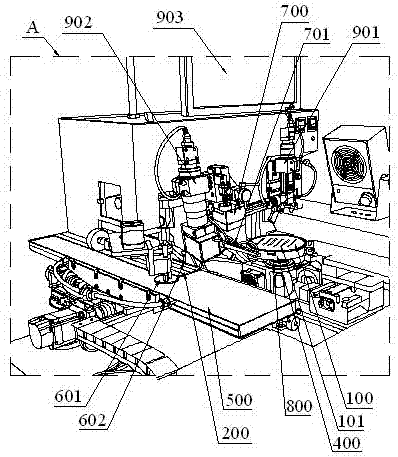

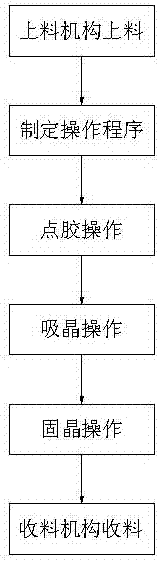

[0015] refer to Figure 1 to Figure 3 , an embodiment of a placement machine for CSP packaged LEDs and its processing technology of the present invention is proposed, the LED chips 101 attached to the blue film 100 arranged in an array can be directly welded and fixed to the substrate 200, and the placement machine includes The frame 300, the crystal suction table 400 which is set on the frame 300 and can be installed with the blue film 100 and makes the blue film 100 tight, and the movable crystal bonding for holding the substrate 200 which is set on the frame 300 Workbench 500 , a dispensing mechanism disposed above the die-bonding workbench 500 and capable of dispensing glue on corresponding pads of the substrate 200 .

[0016] The placement machine also includes a suction crystal with a swing arm 701 that can vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com