Damping energy dissipation assembling node of precast column and integrated precast beam panel, and construction method thereof

A technology for assembling nodes and prefabricated columns, applied in building components, earthquake resistance, building types, etc., can solve problems such as the need to improve seismic energy consumption capacity, unfavorable construction efficiency and construction quality, and structural system integrity. The degree of design, construction quality and effect are improved, and the effect of reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

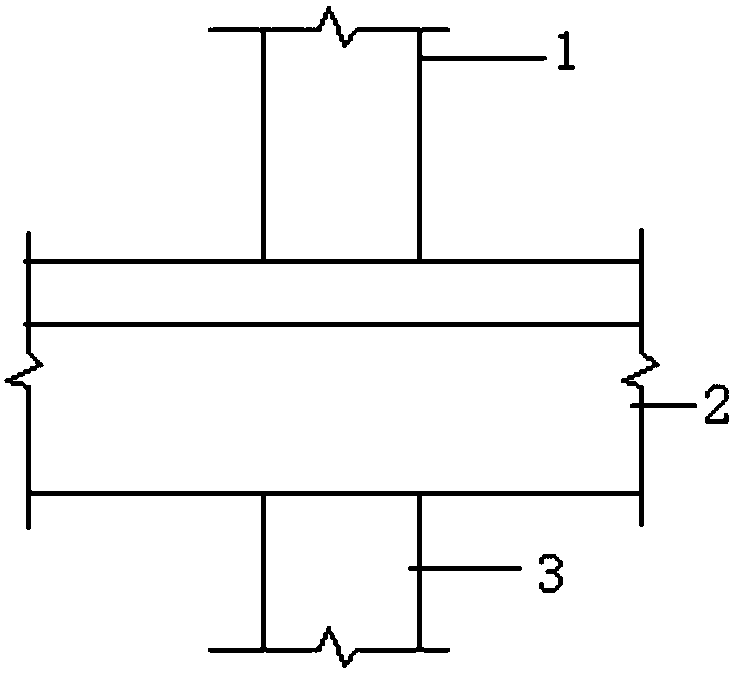

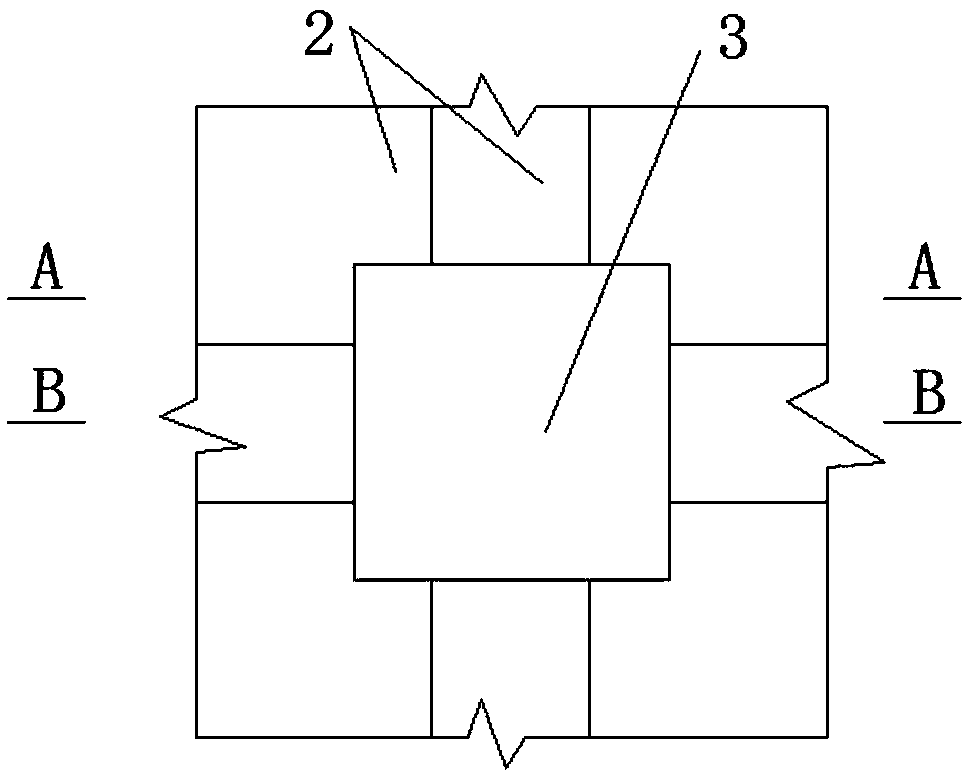

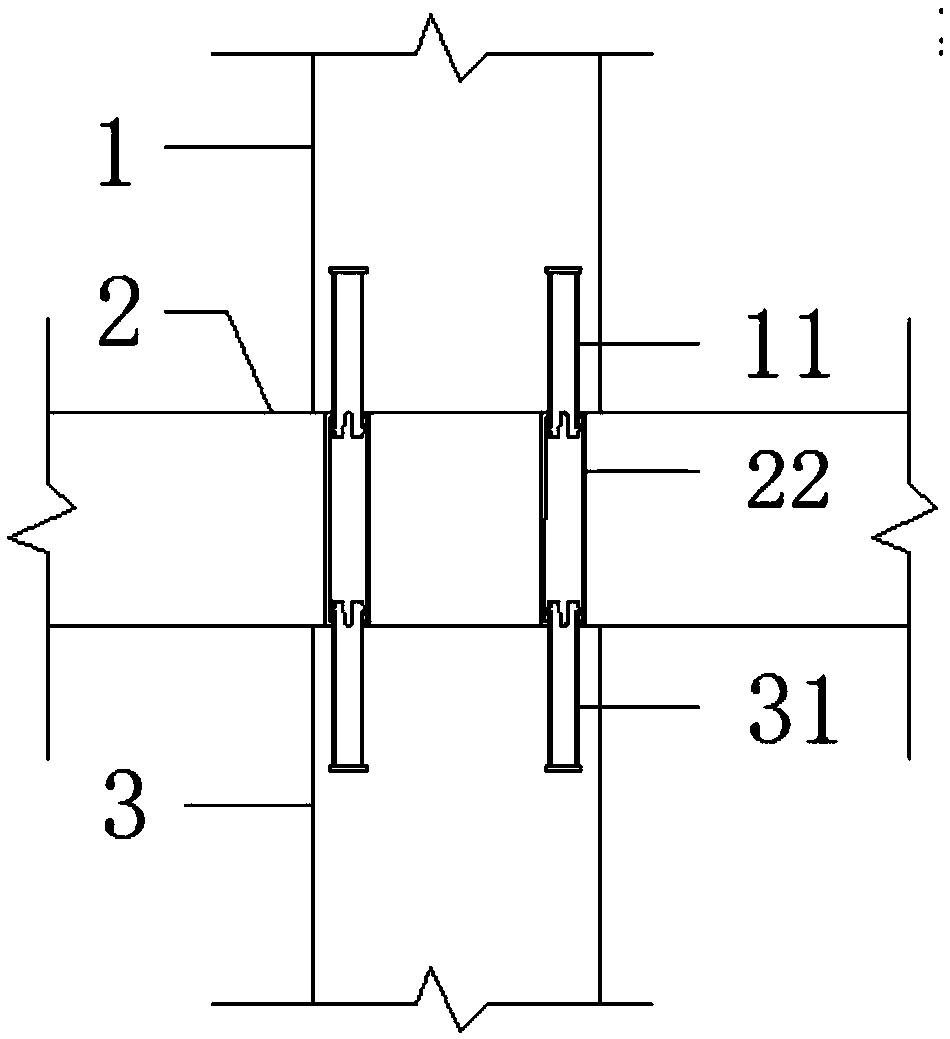

[0051] see Figure 1-4 , Figure 10 , 11 , the damping energy-dissipating assembly node of the prefabricated column and the integrated prefabricated beam slab of the specific embodiment includes a horizontal integrated prefabricated beam slab 2 and a vertical prefabricated column; the prefabricated column includes a lower prefabricated column 3 and an upper prefabricated column 1; The upper surface of the lower prefabricated column 3 is pre-embedded with connecting section steel 32 extending vertically upward and several flared steel pipes I31; the lower prefabricated column 3 of the embodiment is a square column, and the connecting section steel 32 is arranged At the geometric center of the upper surface, flared steel pipes I31 are arranged at intervals along the outer edge of the upper surface of the lower precast column 3, and the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com