protective device and a protective method for anti-explosion and anti-shock of a T-beam connecting member

A technology for connecting components and protective devices, applied in bridge parts, bridges, bridge construction, etc., can solve the problems affecting the overall service performance of bridges, damage of T beams and connecting components, and instability of bridge structures, so as to improve the resistance to explosion shock waves and The ability of bulletproof and anti-fragmentation, good energy absorption and buffering effect, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

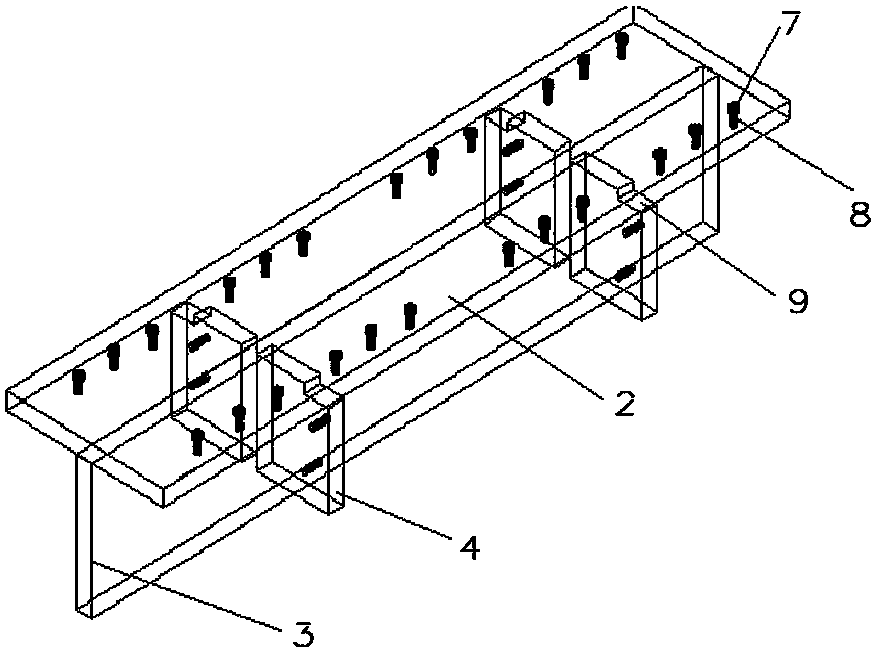

[0034] Such as Figure 1-7 as shown,

[0035] The anti-explosion and anti-shock protection device for T-beam connection components includes T-beam flange plate 2, web plate 3 and diaphragm 4, and is characterized in that the lower part of the flange plate 2 is provided with a first anti-shock Explosion components 5, the second anti-explosion components 6 are arranged on the diaphragm 4;

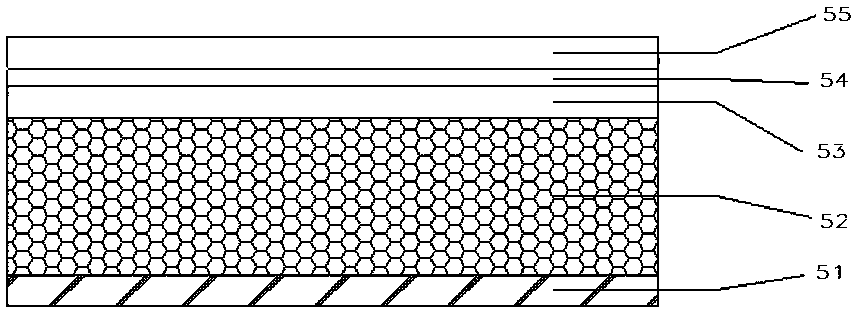

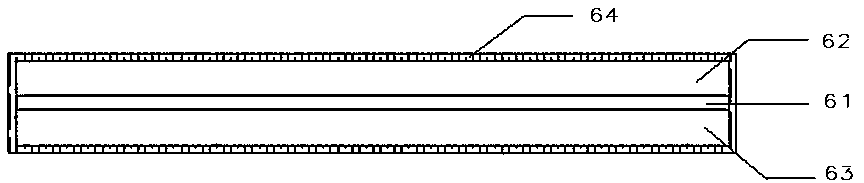

[0036] The flange plates 2 on both sides of the web 3 are provided with several high-strength bolt holes 7, and the high-strength bolt holes 7 are symmetrically distributed on both sides of the diaphragm 4, and the high-strength bolt holes 7 are fixed with high-strength steel pipes 8 ; The first anti-explosion member 5 includes a high-elastic steel plate 51, a foamed aluminum plate 52, a common steel plate 53, a first carbon fiber plate 54 and a first ceramic plate 55 arranged from top to bottom; the first anti-explosion member 5 is set There are several bolt through holes 10, which are set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com