Electrical connection device

A technology for electrical connection devices and coils, applied in conductive connections, components of connection devices, connections, etc., can solve problems such as failure, affecting the maximum current value, large vibration, etc., achieve full and effective contact, and increase the number of contact points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

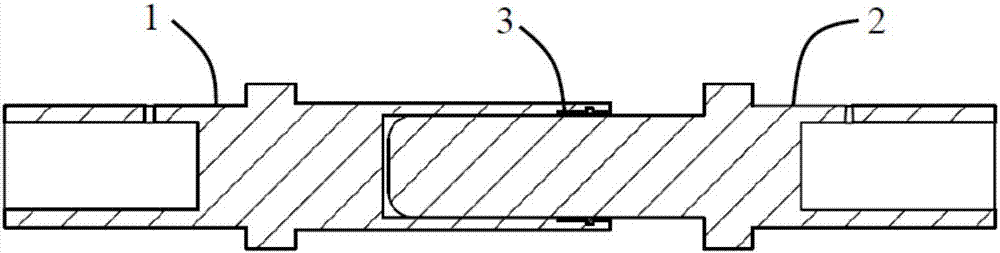

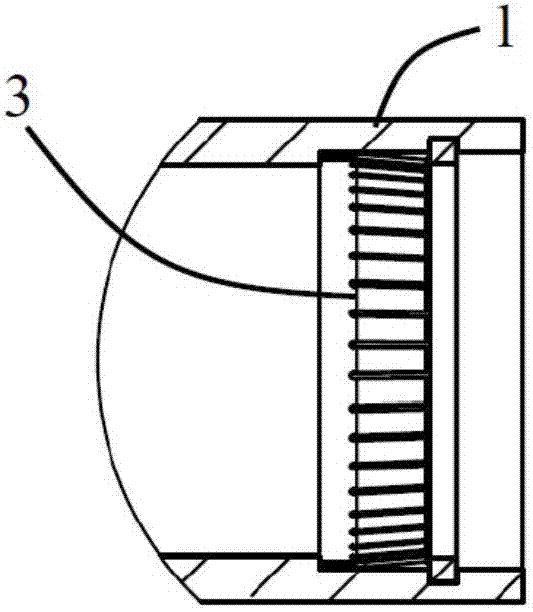

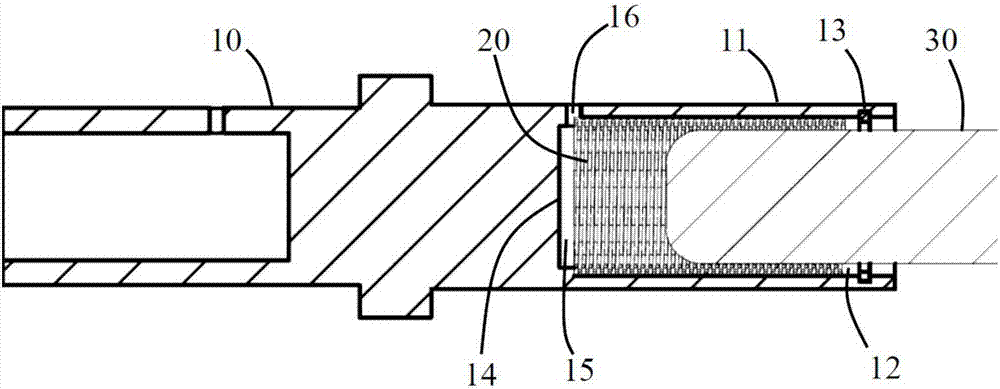

[0024] ginseng image 3 As shown, the present invention provides an electrical connection device, which is provided with a socket main body 10 and a spring member 20 located in the socket main body 10, the socket main body 10 and the spring member 20 are made of metal, The two are in contact with each other to realize conduction, and are used for electrical connection with a mating pin body 30. The pin body 30 is provided with an insertion end inserted into the inner side of the spring element 20, and the insertion end is inserted into the spring element. Conduction is realized under the clamping of 20.

[0025] Wherein, the jack body 10 is in the shape of a strip, and one end thereof is provided with a ring wall 11 , an accommodation cavity 12 inside the ring wall 11 , and a retaining ring 13 inside the accommodation cavity 12 . The accommodating chamber 12 is cylindrical and is surrounded by the ring wall 11 for accommodating the spring member 20 , and the bottom wall 14 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com