Mould with alterable brake bead resistance

A drawbead and resistance technology, which is applied in the field of variable drawbead height molds and variable drawbead resistance molds, can solve the problems that the variable drawbead resistance cannot be changed, achieve large adjustments, reduce production costs, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

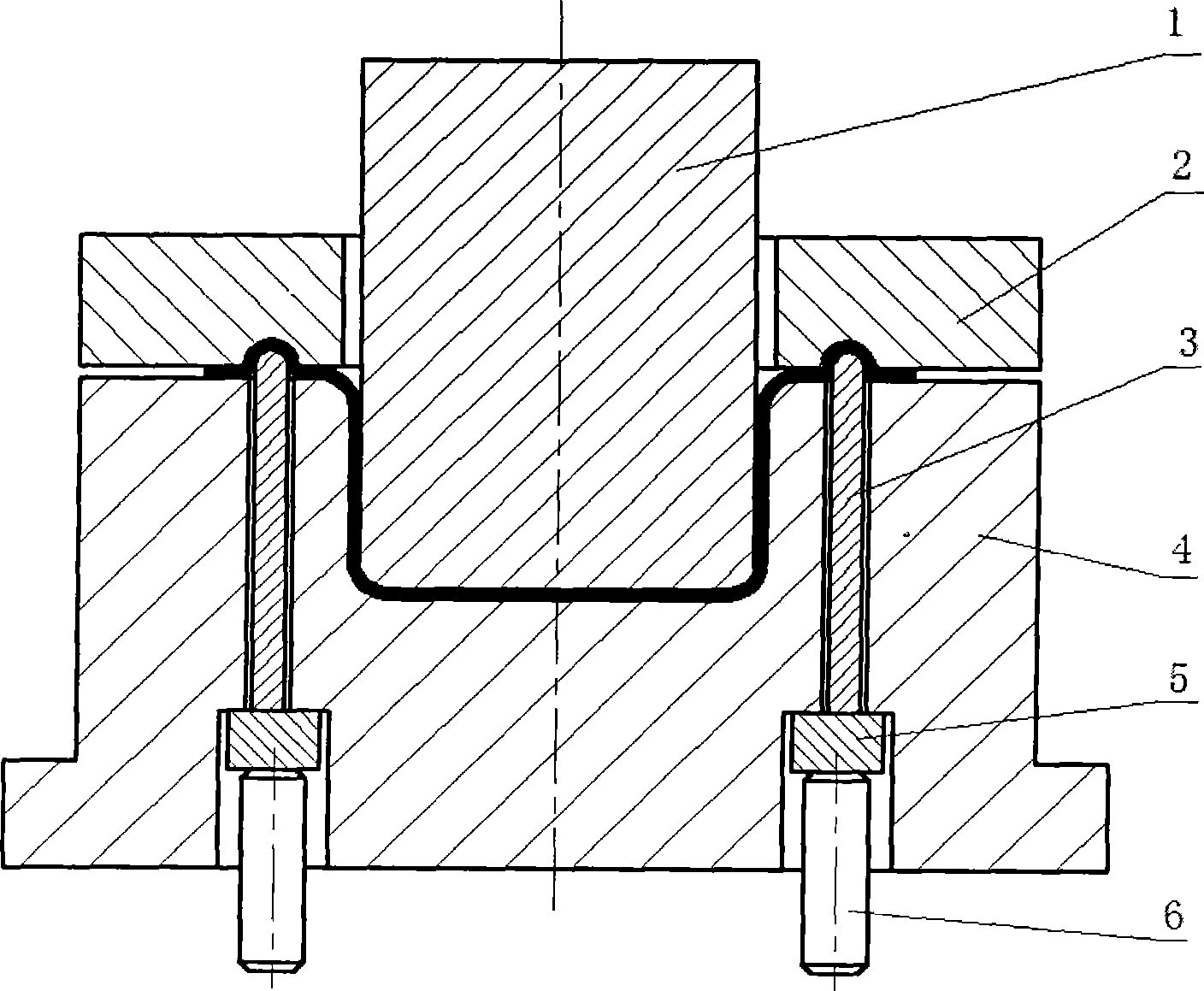

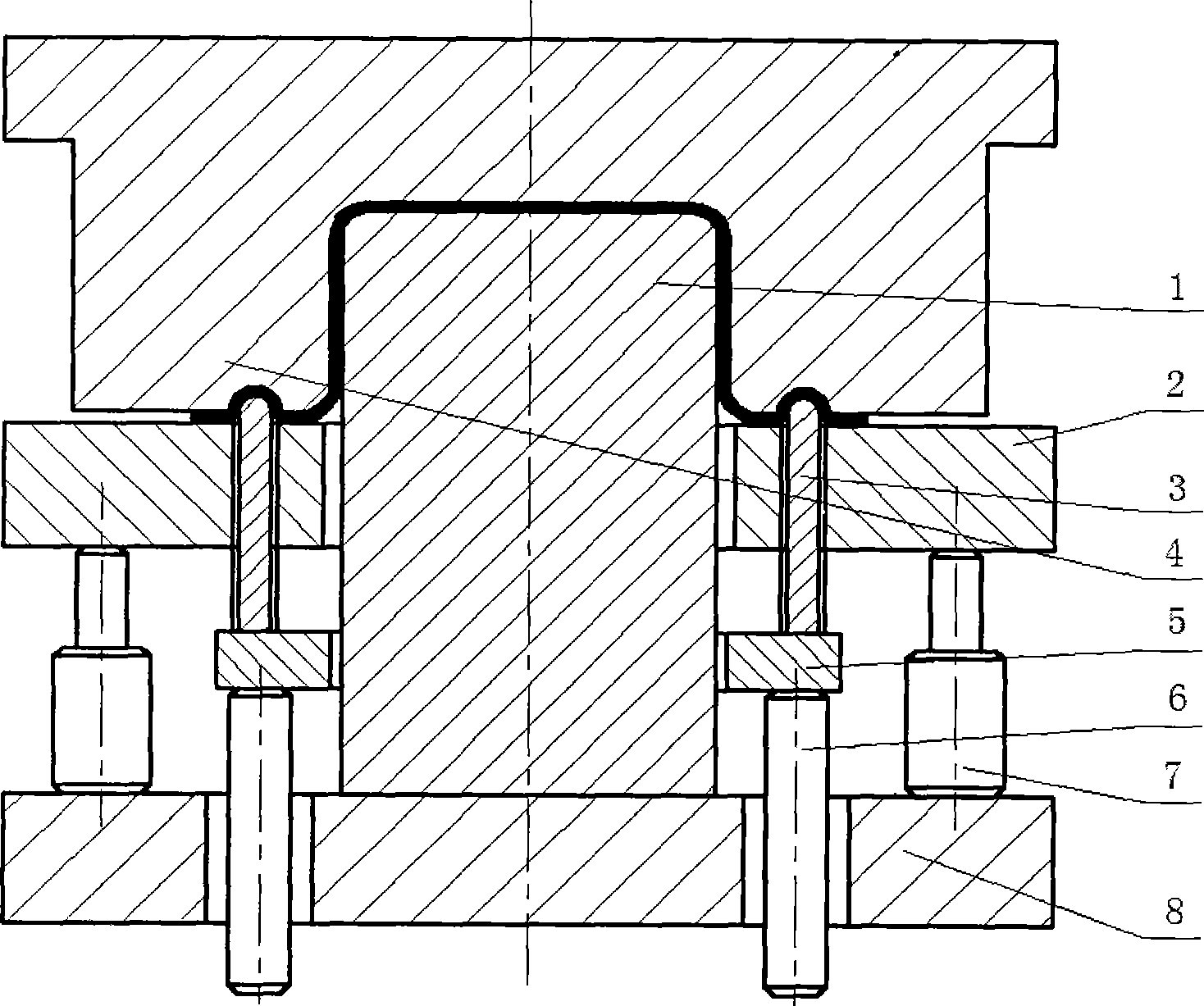

[0012] See figure 1 , Shown is the double-action press to change the drawbead resistance of the mold, including the punch 1, the die 4, the blank 2, the drawbead 3, the drawbead pad 5 and the ejector rod 6. The punch 1 is installed on the inner sliding block of the press, the pressing plate 2 is installed on the outer sliding block of the press, and the female mold 4 is installed on the worktable. At least one independent drawing bead 3 is also provided. The drawing bead 3 penetrates upward from the die 4, and the lower end is in contact with the upper end of the top rod 6 through the drawing bead pad 5. The ejector rod 6 pushes the drawbead pad 5 to move up and down, and the drawbead pad 5 pushes the drawbead 3 to move up and down synchronously to adjust the height of the drawbead 3 and adjust the height of the drawbead 3 to expose the die 4 (from The height of the die 4 penetrated upwards). The ejector rod 6 is connected with the air cushion, and the force provided by the eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com