Stabilized-pressure oil supply system of high-pressure direct-injection injector and control method thereof

A fuel supply system and fuel injector technology, applied in the directions of fuel injection control, electrical control, charging system, etc., can solve problems such as energy waste, preparation difficulties, and difficulty in sealing between fuel injectors and high-pressure fuel rails, and improve safety. performance, reducing oil pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

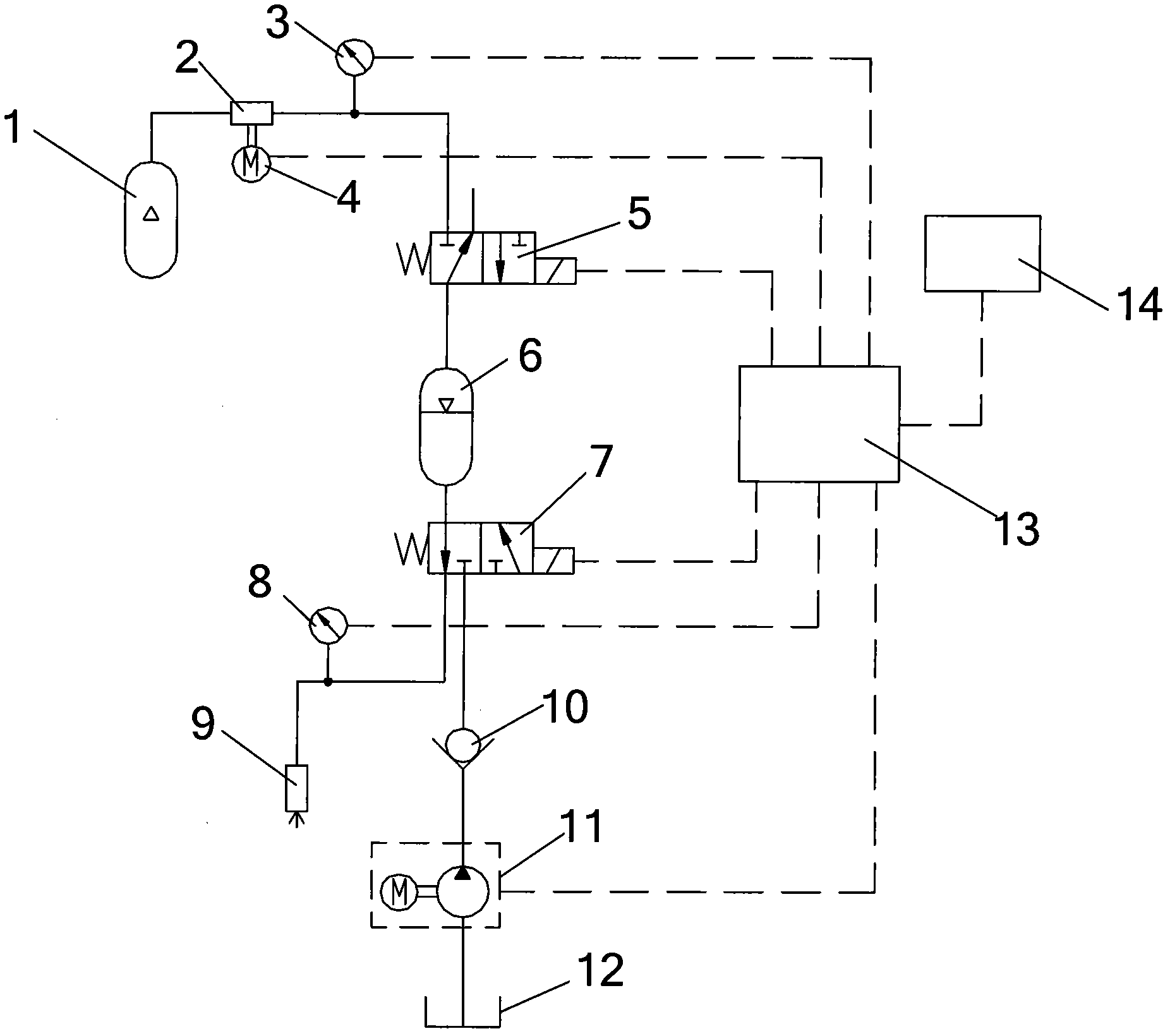

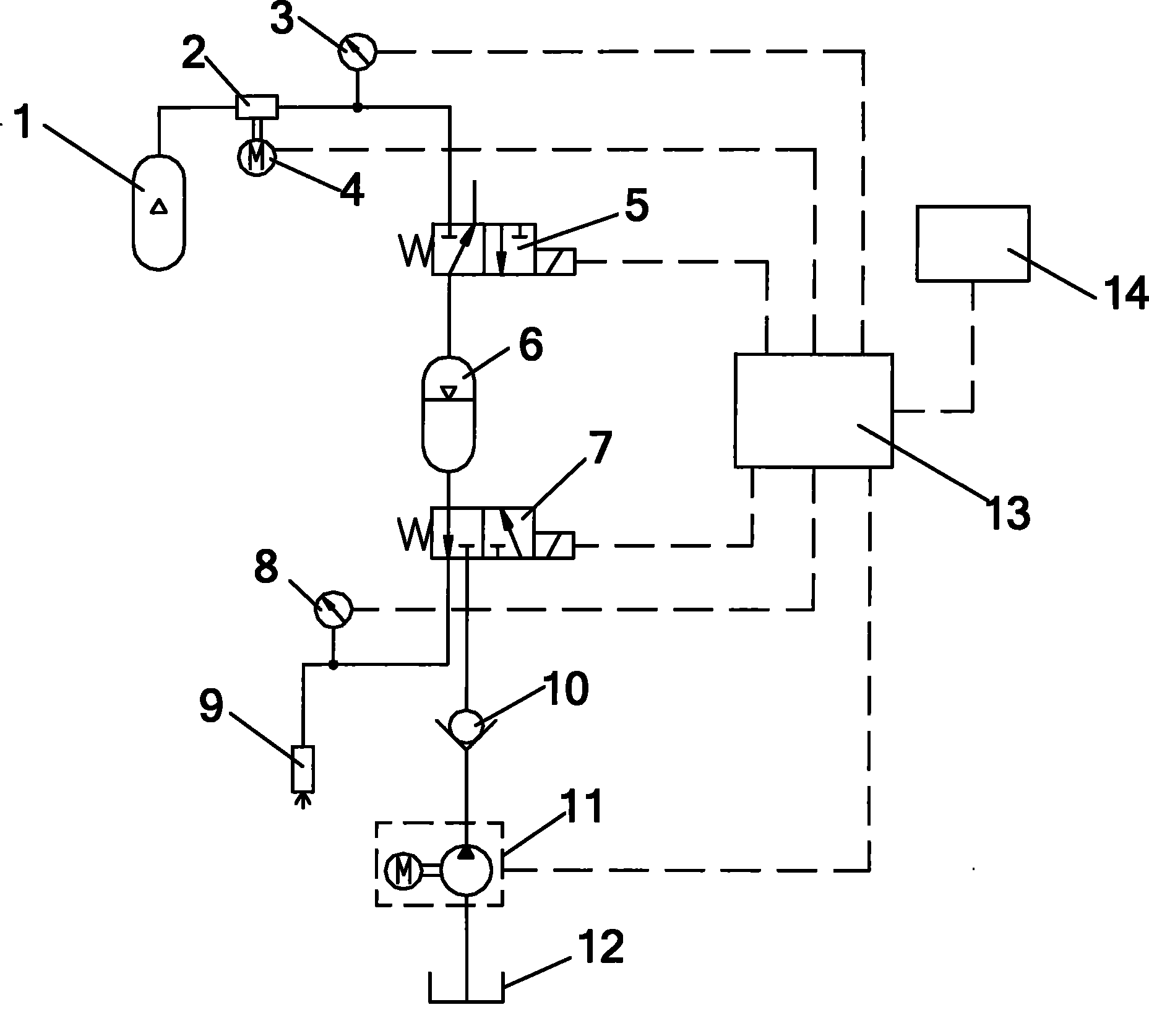

[0040] The stabilized oil supply system of the high-pressure direct injection fuel injector provided by the present invention, such as figure 1As shown, it mainly includes: high-pressure nitrogen cylinder 1, pressure reducer 2, stepping motor 4, pressure sensor A3, two-position three-way solenoid valve A5, accumulator 6, two-position three-way solenoid valve B7, pressure sensor B8, Fuel injector 9, check valve 10, fuel pump 11, fuel tank 12, controller 13 and display screen 14.

[0041] The high-pressure nitrogen cylinder 1 is used to inflate the accumulator 6, and the high-pressure nitrogen cylinder 1 and the accumulator 6 are sequentially connected with a pressure reducer 2 and a two-position three-way solenoid valve A5 through a pipeline to form a gas passage; The other end of the accumulator 6 is connected to the inlet of the two-position three-way solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com