Testing device for high-temperature pressure sensor

A technology of pressure sensor and test device, applied in the direction of measuring device, measuring fluid pressure, instrument, etc., can solve the problems of test failure, loss of sealing of insulating glass, etc., to achieve the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

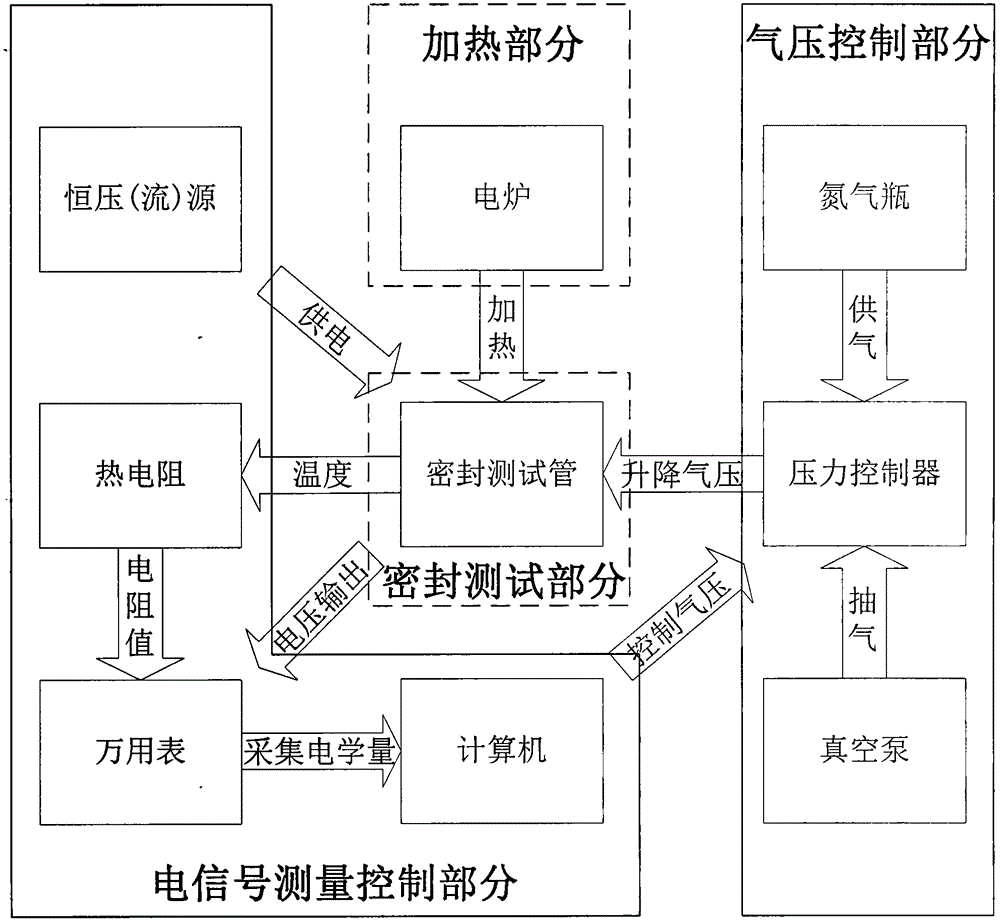

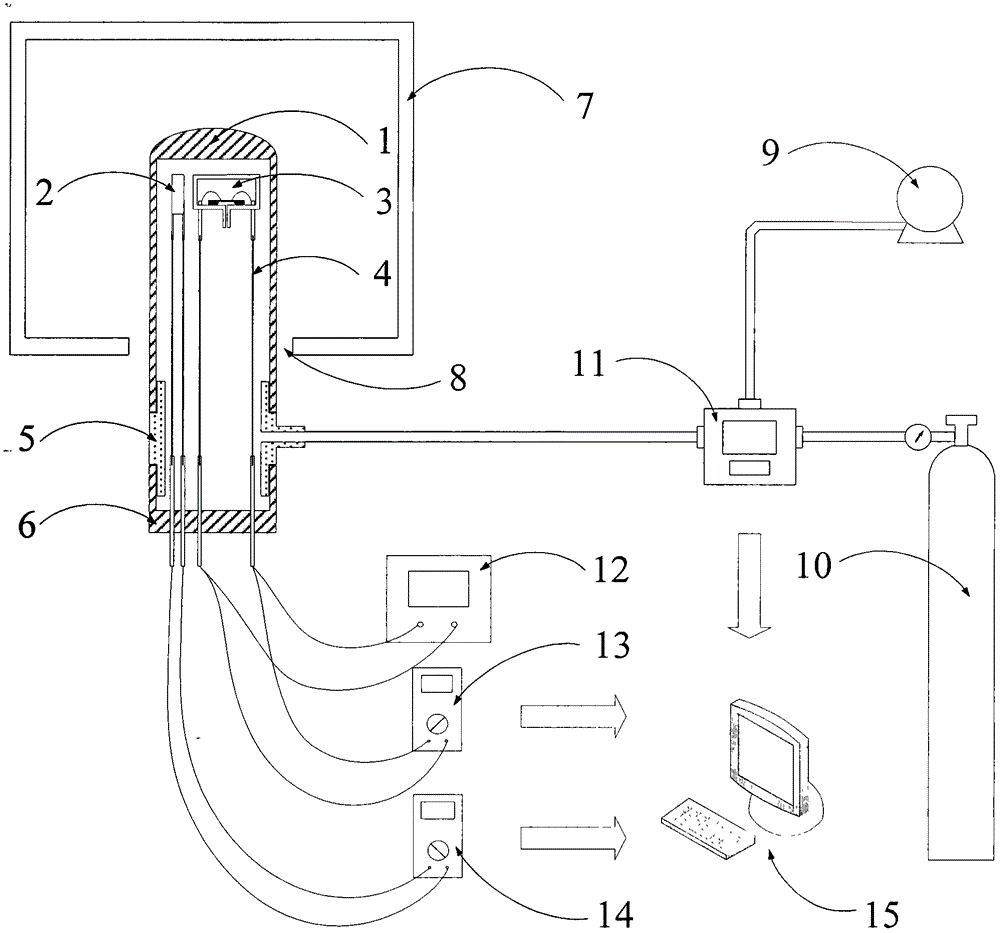

[0017] figure 1 It is a structural block diagram of the high-temperature pressure sensor testing device in the present invention, and the structural block diagram reflects the composition and interrelationship of each part in the device. As can be seen from the structural block diagram, the whole device is divided into four parts: 1. The sealing test part provides the sealing environment required for the high-temperature pressure sensor test. The tube body of the test tube is a metal tube with one end closed, and the other end Composed of three-way joints and aviation plugs, the pressure sensor to be tested is placed at the blind end of the test tube, and is inserted into the furnace from the test hole of the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com