Automatic testing method of wire line coring drilling hoisting-free pressurized water test

A wireline coring and automatic testing technology, which is applied in the field of engineering survey, can solve the problems that the pressure of the pressurized water test section cannot be accurately reflected, the wireline core drilling technology has not been well promoted, and the advantages of difficult wireline core drilling, etc. , to achieve the effect of improving exploration quality and efficiency, strong practicability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

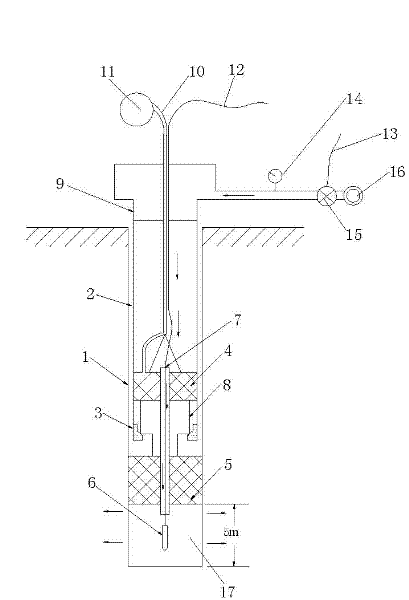

[0011] Depend on figure 1 Provide, the present invention is realized by the following steps in concrete implementation:

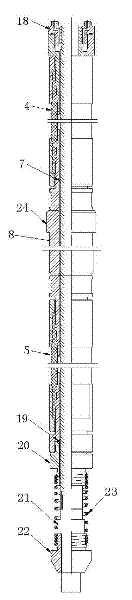

[0012] A. Design the water pressure test plug, see the structure figure 2 As shown, the plug is installed on the core pipe 7 by the upper capsule 4 and the lower capsule 5, and is connected together by a steel sleeve 8. After the upper capsule expands, it is used to close the inner hole of the drill pipe of the drilling tool. In the expanded state, the diameter is smaller than the inner diameter of the drill bit 3, which can pass through the drill bit smoothly and be placed in the drill hole 1, and the drill hole can be closed after expansion;

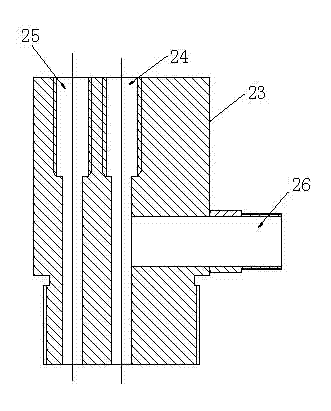

[0013] B. Design the orifice sealer (device), its structure see image 3 As shown, its structure is a body 23, there are parallel inflatable hose passages 25 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com