Leak detection device for U-shaped waste heat boiler pipe column

A technology of waste heat boiler and leak detection, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problem of short holding time of the system and insufficient observation of the leakage point of the tube sheet and tube bundle. Easy and other problems, to achieve the effect of accurate and convenient leak detection, and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

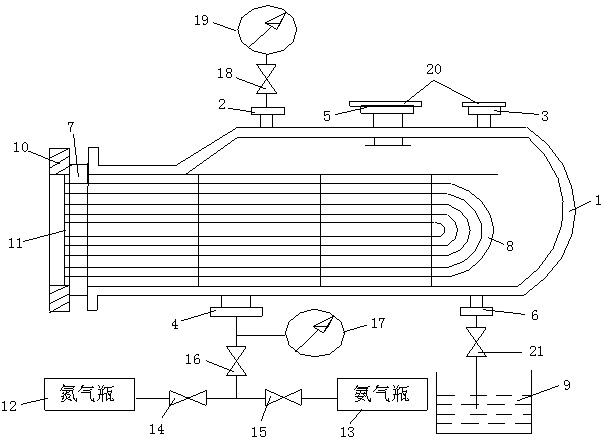

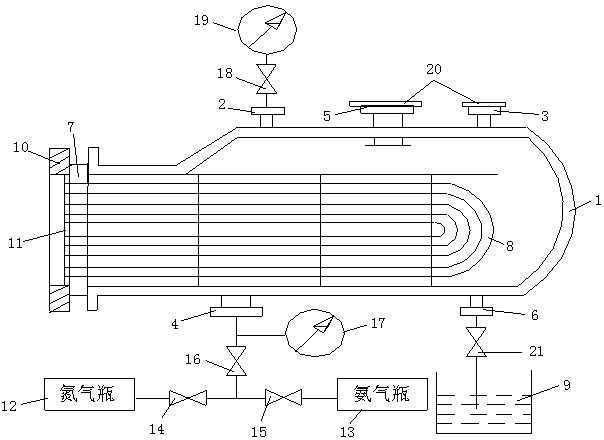

[0027] like figure 1 A U-shaped waste heat boiler tube bundle leak detection device shown in the figure includes a housing 1 on which a first interface 2, a second interface 3, a water inlet 4, a steam outlet 5 and a discharge port 6 are provided. 1 is provided with a tube plate 7 matching the opening of the shell 1, and a U-shaped tube bundle is arranged inside the shell 1, and the two ends of each U-shaped tube 8 in the U-shaped tube bundle are respectively fixed on the tube plate 7, and the tube plate 7 A pressure ring 10 is provided on the side away from the opening of the shell 1, and the pressure ring 10 is connected with the shell 1 by bolts, and the end surface of the tube plate 7 close to the pressure ring 10 and the two ports of each U-shaped tube 8 are attached with test paper 11 , the water inlet port 4 is respectively connected with a nitrogen cylinder 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com