Dry coal pressure closed phase conveyer with several discharge branches

A technology of dense phase conveying and dry coal powder, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of unstable operation and easy blockage, and achieve the effect of uniform distribution, not easy to block, and uniform conveying volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

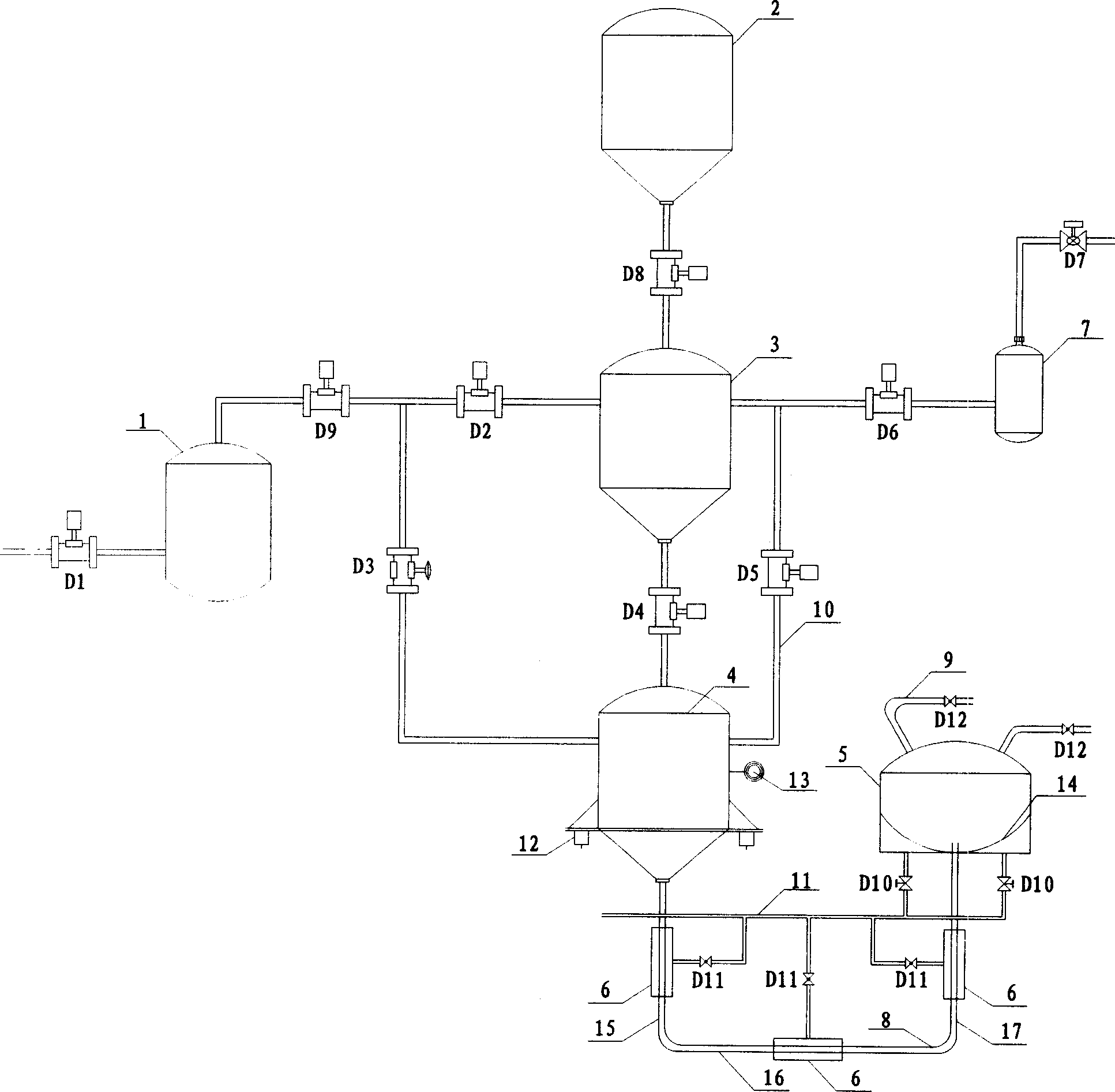

[0013] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

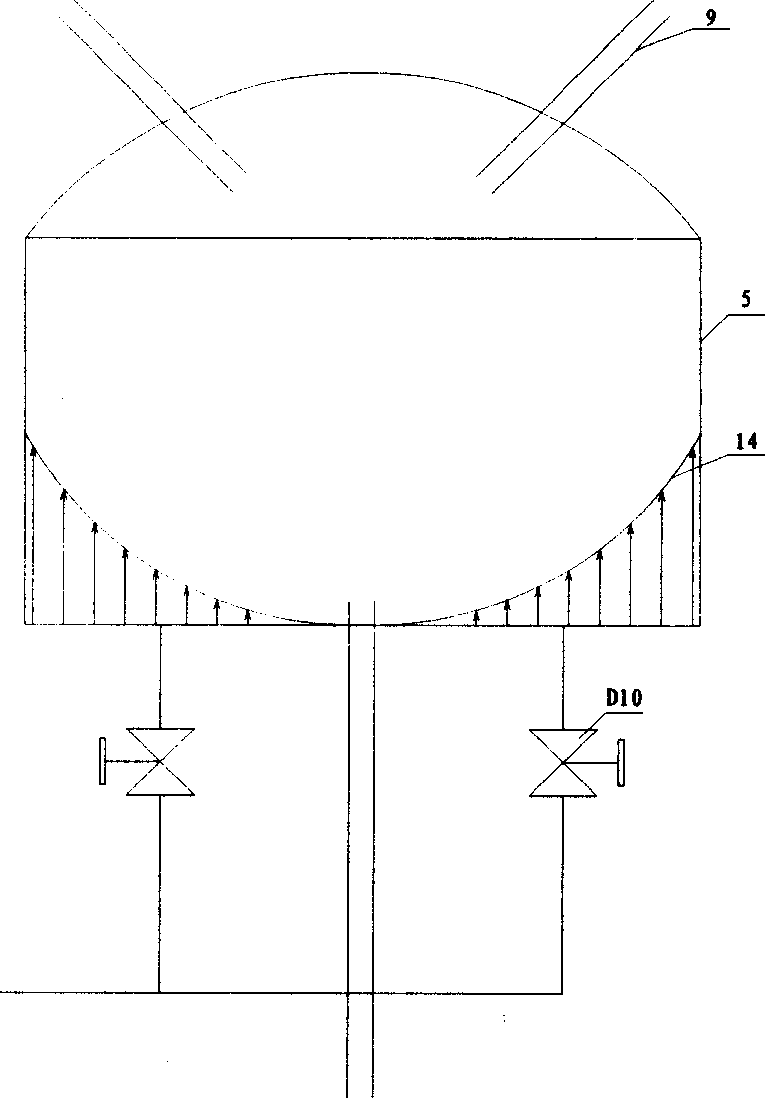

[0014] see figure 1 , 2, the present invention comprises the normal pressure pulverized coal bin 2 and the variable pressure bin 3 which is connected with the pulverized coal outlet of the normal pressure pulverized coal bin 2 through the normal pressure pulverized coal control valve D8, and the gas inlet of the variable pressure bin 3 passes through the pipeline And the ramming nitrogen outlet control valve D9 and the variable pressure chamber nitrogen inlet valve D2 arranged on this pipeline are connected with the ramming nitrogen tank 1. The pulverized coal outlet is connected to the pressurization chamber 4 through the pipeline and the pressure change chamber pressurization chamber control valve D4 set on this pipeline, and the gas outlet of the pressure transformation chamber 3 also passes through the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com