High pressure nitrogen storage bottle made of kevlar fiber and carbon fiber mixed composite material and its preparation method

A fiber composite material and composite material technology, applied in the field of composite high-pressure nitrogen storage cylinder and preparation, can solve the problems of low tensile strength and tensile modulus of glass fiber, low compressive performance of organic fiber, poor safety and reliability, etc. The molding process is easy to operate, the structure is optimized, and the comprehensive performance is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

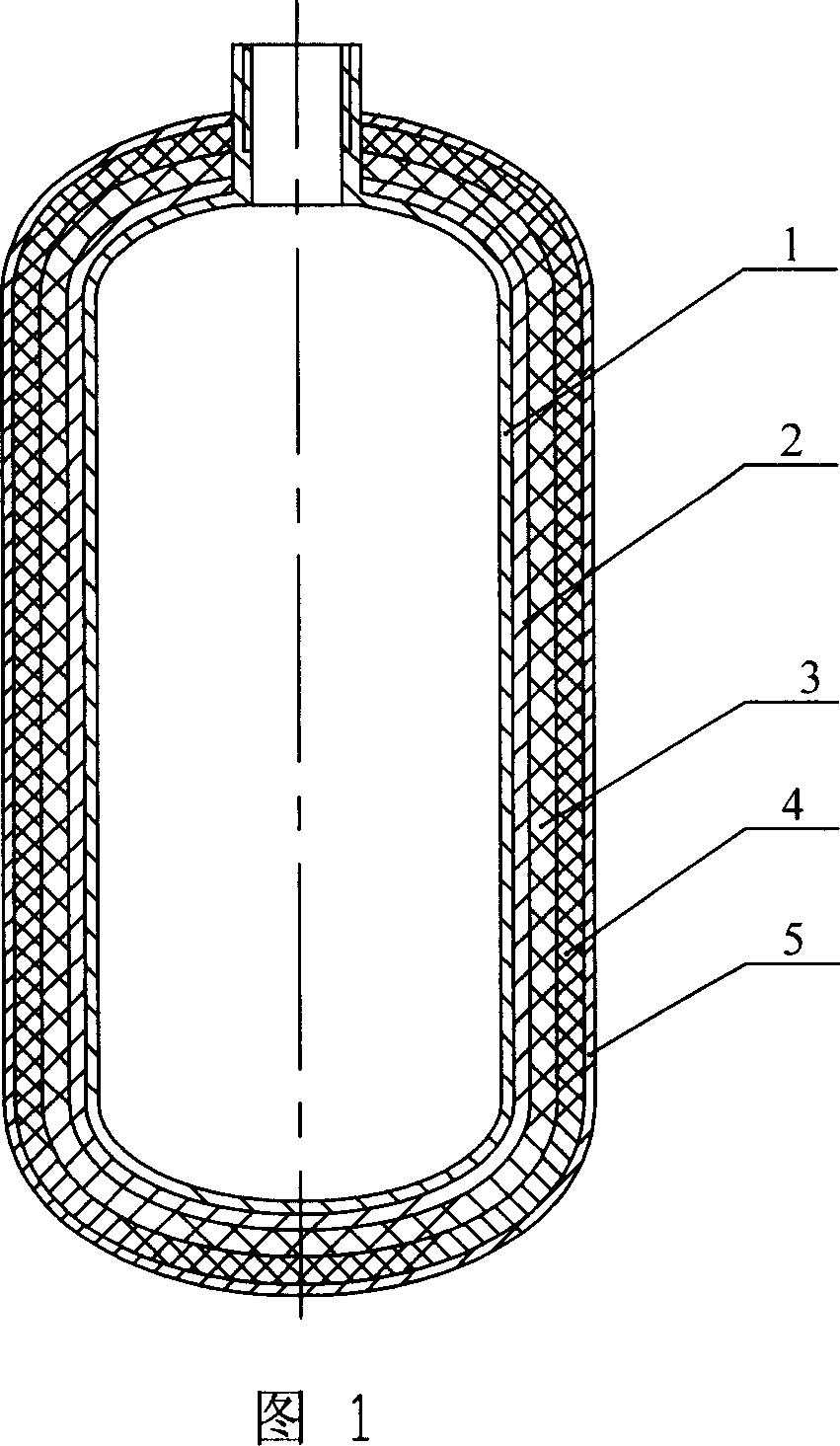

[0014] Embodiment 1: This embodiment is described with reference to FIG. 1 . This embodiment is composed of an inner lining layer 1, an adhesive layer 2, a fiber composite material layer and an outer protective layer 5 of glass fiber composite material. The fiber composite material layer is composed of a carbon fiber composite material inner structure layer 3 and a Kevlar fiber composite material outer structure layer. 4, the inner lining layer 1 is made of aluminum alloy, the outer surface of the aluminum alloy inner lining layer 1 is bonded to the adhesive layer 2, and the outer surface of the adhesive layer 2 is bonded to the inner surface of the carbon fiber composite material inner structural layer 3. , the inner surface of the Kevlar fiber composite material outer structure layer 4 is wound on the outer surface of the carbon fiber composite material inner structure layer 3, and the outer surface of the Kevlar fiber composite material outer structure layer 4 is wound with ...

specific Embodiment approach 2

[0015] Specific embodiment two: the preparation method of this embodiment adopts the following steps:

[0016] Step 1: First, evenly coat an elastic adhesive layer 2 with a thickness of 0.6 mm to 0.7 mm on the outer surface of the aluminum alloy inner lining layer 1;

[0017] In step 2, the inner structure layer 3 of carbon fiber composite material is formed by a wet method (impregnated epoxy resin) winding process on the outer surface of the elastic adhesive layer 2. Three layers of hoop winding, two to four layers of helical winding and two to three layers of hoop winding. The thickness of the inner structure layer 3 is 4.8mm-9.6mm, forming the inner structure layer 3 of the carbon fiber composite material;

[0018] In step 3, the outer surface of the carbon fiber composite material inner structure layer 3 made in step 2 is wound with the outer structure layer 4 of the Kevlar fiber composite material, and the winding adopts one to two layers of helical winding, two layers o...

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the thickness of the elastic adhesive layer 2 in step 1 is 0.6 mm; in step 2, two layers of helical winding and two layers of hoop winding are performed in sequence. , two-layer helical winding and two-layer hoop winding, the winding angle of the helical winding is 15.5°, the thickness of each winding layer is 0.6mm, and the winding thickness of the inner structural layer 3 of the carbon fiber hybrid composite material is 4.8mm; step three; One layer of helical winding, two layers of hoop winding, one layer of helical winding, and one layer of hoop winding are adopted in sequence. The winding thickness of the structural layer 4 is 2.5mm; in step 4, the two layers of glass fiber composite materials are spirally wound and two layers are circumferentially wound, and the helical winding angle is 25°, and the thickness of each winding layer is 0.5 mm. The winding thickness of the outer protective l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com