Rigid servo-actuated loading frame structure

A technology of dynamic loading, frame structure, applied in the direction of strength characteristics, using stable tension/compression test material strength, measuring device, etc., can solve test failure, rock sample geometric center deviation, rock sample geometric center Invariant and other problems, to achieve the effect of reducing manufacturing costs, meeting high stiffness and large load output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

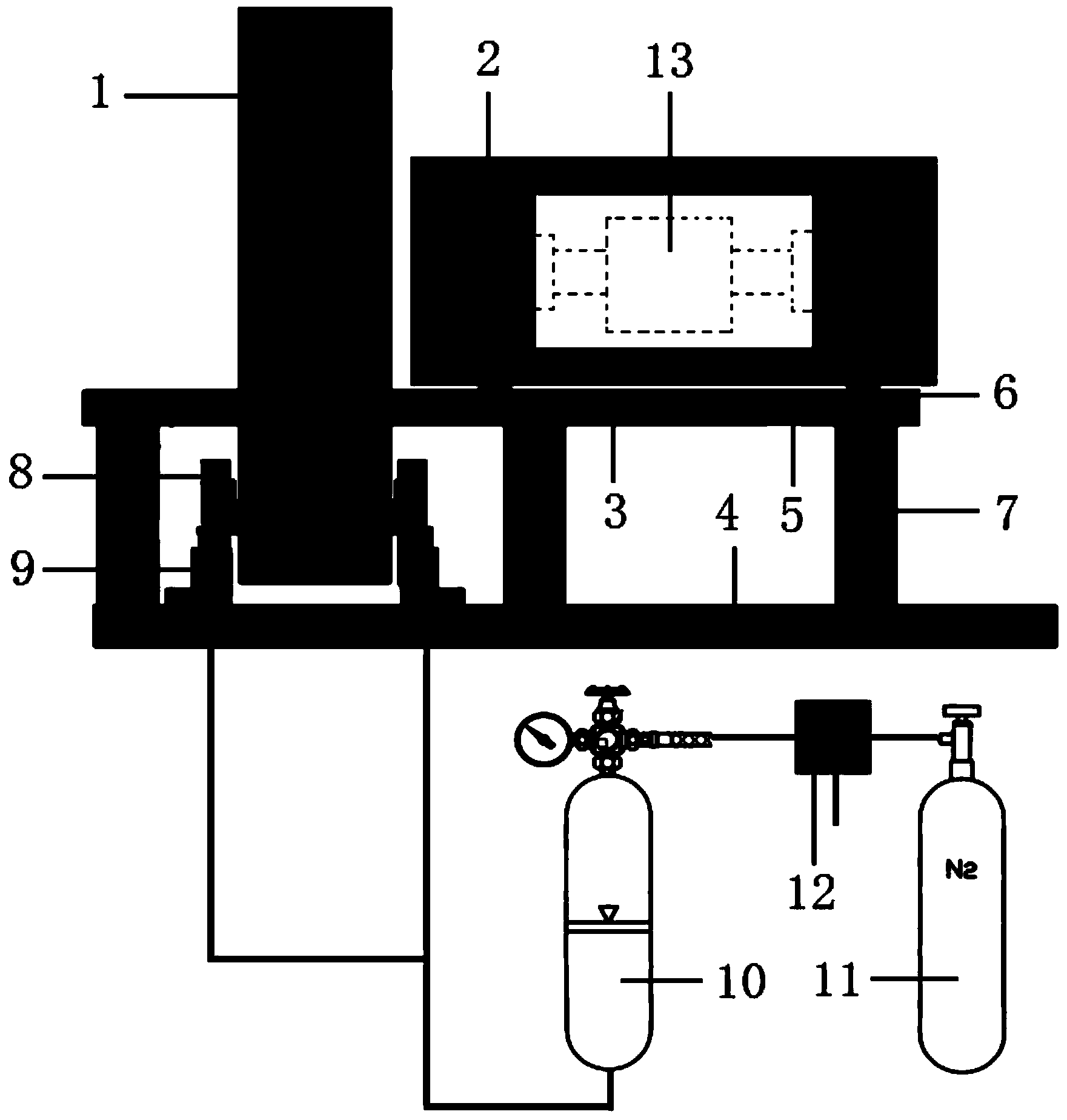

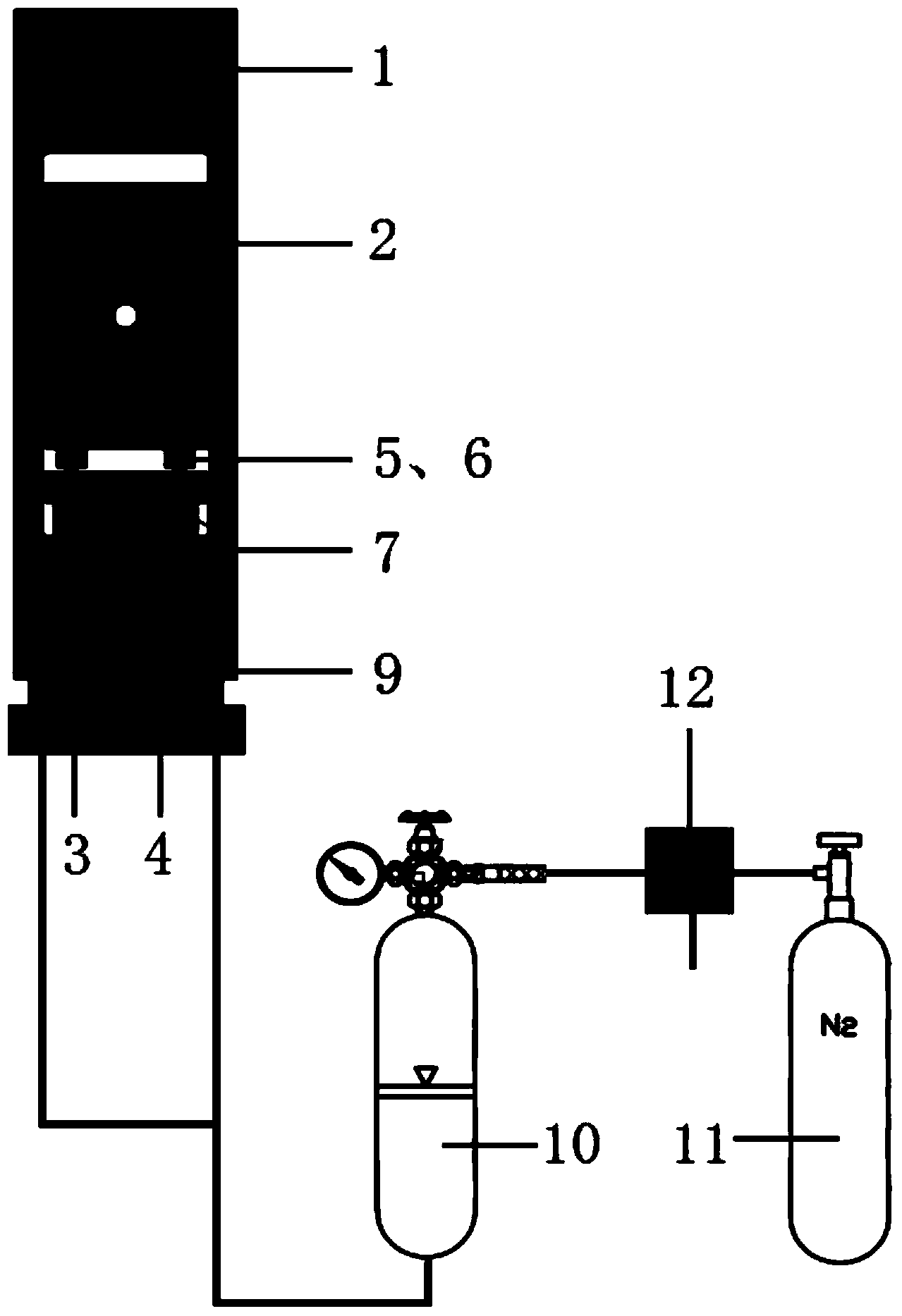

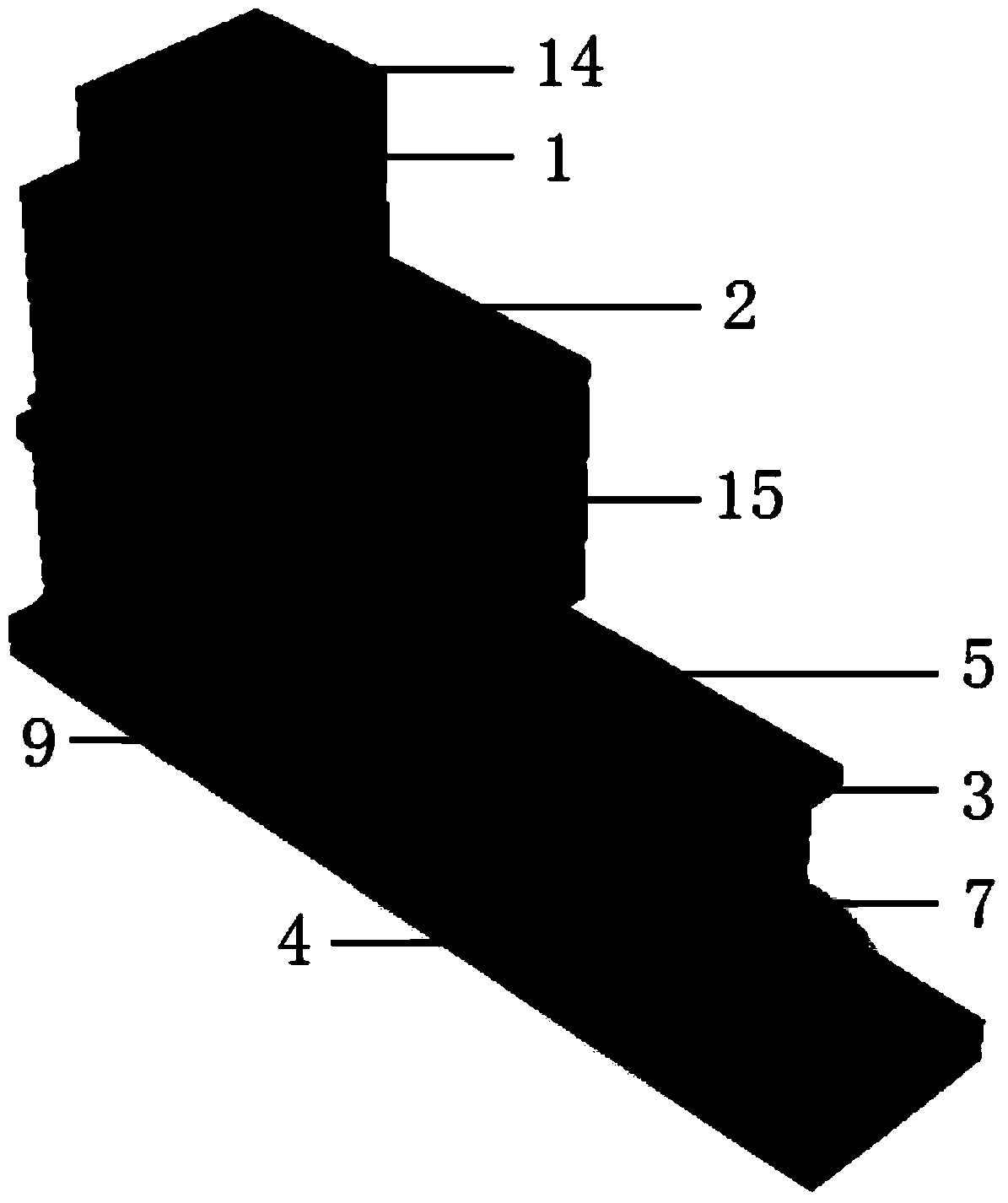

[0024] Such as figure 1 , 2 , shown in 3, a kind of rigid follow-up loading frame structure, comprises frame unit and pneumatic hydraulic balance unit, and described frame unit comprises vertical frame 1, horizontal frame 2, upper support platform 3, lower support platform 4 and support between platforms Column 7, the pneumatic hydraulic balance unit includes a support cylinder 9, an accumulator 10, a nitrogen cylinder 11 and an electronic pressure regulating valve 12;

[0025] The horizontal frame 2 is arranged above the upper support platform 3, and the horizontal frame 2 and the upper support platform 3 are in a sliding fit; the upper support platform 3 is fixed on the lower support platform 4 through support columns 7 (the number is three) between platforms Above, the lower support platform 4 is fixed on the ground (specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com