Automatic infrasonic wave non-pressure oil well liquid level monitoring instrument

An automatic monitoring and infrasonic technology, which is applied in measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems of inconvenient operation and carrying, potential safety hazards of gunpowder and sound bombs, and high indirect costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

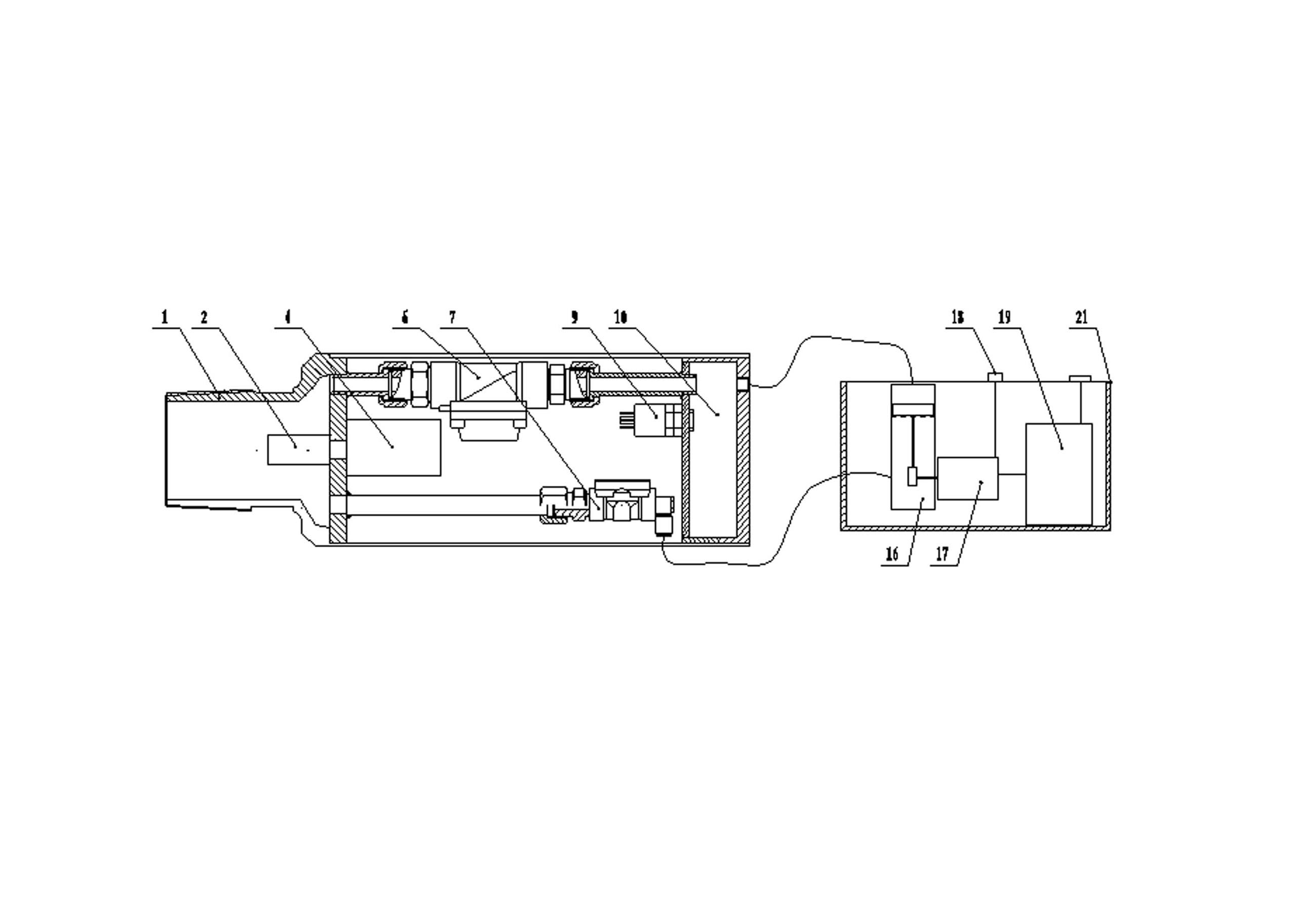

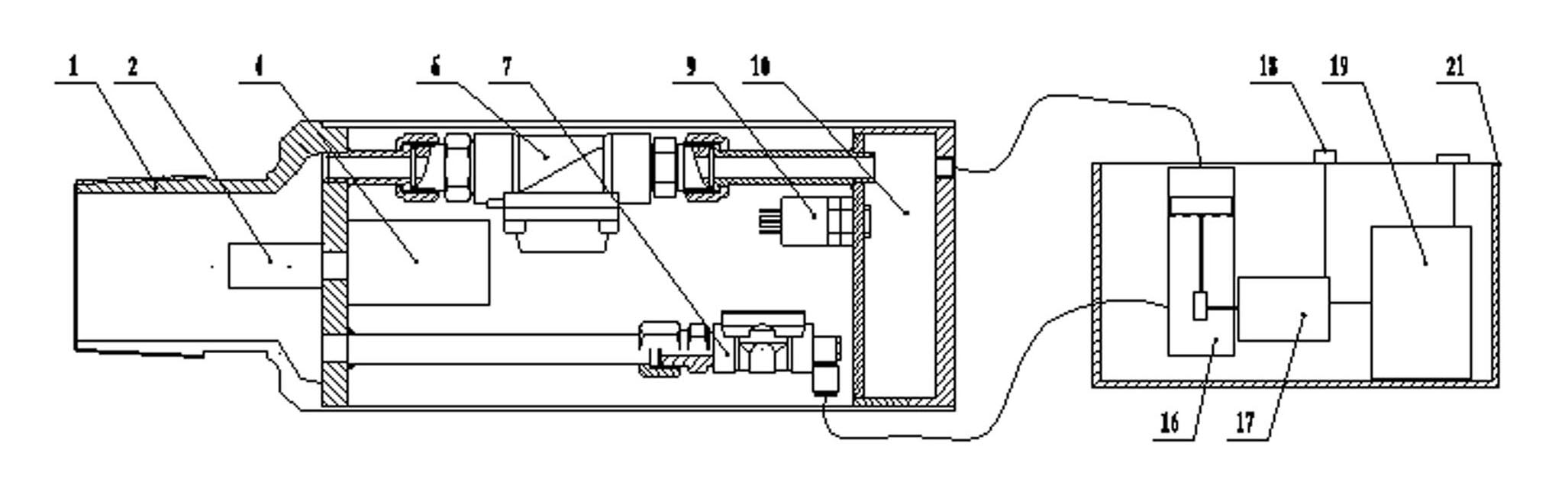

[0013] Such as figure 1 As shown, an automatic infrasonic wave non-pressure oil well liquid level monitor has the following structure: a gas storage chamber 10, a gas chamber pressure sensor 9 connected to the gas storage chamber, a gas emitting device, and an infrasonic wave receiver are arranged in the casing of the monitor. The processing device, the gas collection device, and the monitor are also provided with a gas generating device 21, the gas inlet of the gas generating device 21 is connected to the gas collecting device through a pipeline, and the gas outlet of the gas generating device 21 is connected to the gas storage chamber 10 through a pipeline .

[0014] The structure of the gas generating device is as follows: a control box 21 is provided outside the housing of the automatic monitor, and a rechargeable backup battery 19, a DC brushless motor 17, a piston cylinder 16, and a power charging socket 20 are arranged in the control box 21. and the control signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com