Fluid leakage online supervision and locating system and method

A fluid leakage and positioning system technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as difficult detection, large fluctuations, false positives or missed positives, etc., to achieve easy identification and improve The effect of the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

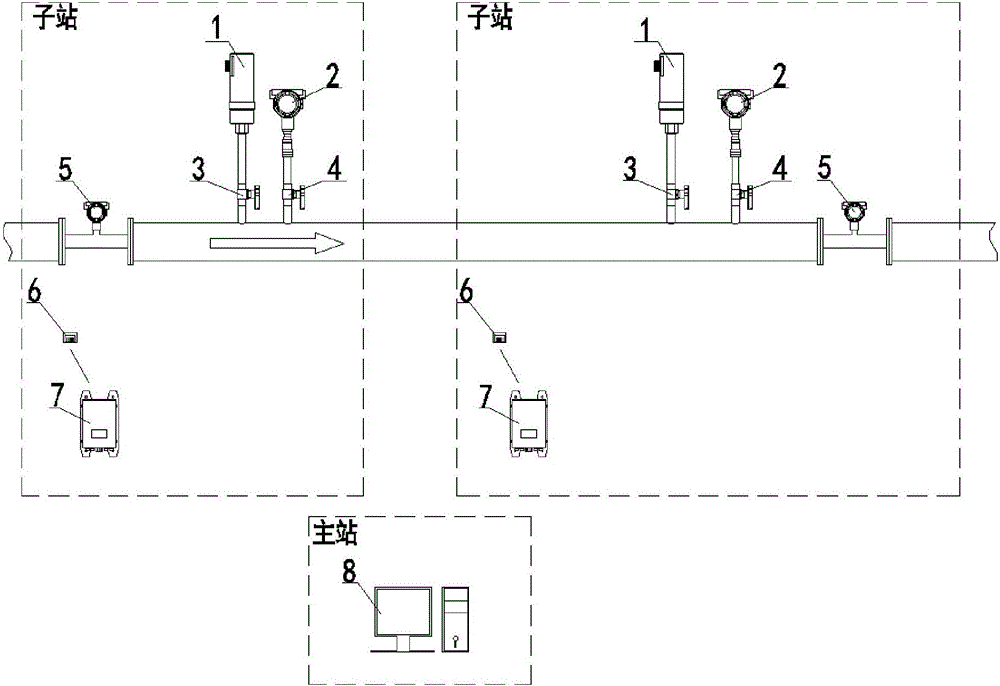

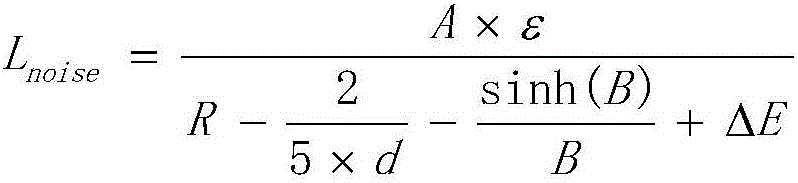

[0025] When the system is running normally, the digitizer 7 collects the pressure data p in the pipeline through the pressure transmitter 2, collects the flow data Q of the fluid in the pipeline through the flowmeter 5, and collects the infrasonic data in the pipeline through the infrasonic wave sensor 1, and then the collected Pressure data p, flow data Q, and infrasound wave data are added to the Global Positioning System (GPS) time tag to eliminate the impact of network link delay on positioning, and then transmitted to the host through Ethernet or 3G / 4G using TCP / IP protocol. After receiving the data, the station system 8 and the master station system 8 calculate the L noise , through the infrasonic sensor gain adjustment formula, the infrasonic sensor gain Z=5×L noise , and transmit the gain Z to the infrasonic sensor through the digitizer, and the infrasonic sensor adjusts the gain according to the Z value.

[0026] When the sonic characteristic level L noise L , the s...

Embodiment 2

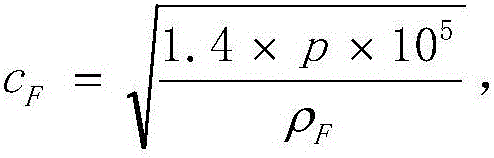

[0028] When the system is running normally, the digitizer 7 collects the pressure data p in the pipeline through the pressure transmitter 2, collects the flow data Q of the fluid in the pipeline through the flowmeter 5, and collects the infrasonic data in the pipeline through the infrasonic wave sensor 1, and then the collected Pressure data p, flow data Q, and infrasound wave data are added to the Global Positioning System (GPS) time tag to eliminate the impact of network link delay on positioning, and then transmitted to the host through Ethernet or 3G / 4G using TCP / IP protocol. After receiving the data, the station system 8 and the master station system 8 calculate the L noise , through the infrasonic sensor gain adjustment formula, the infrasonic sensor gain Z=5×L noise , and transmit the gain Z to the infrasonic sensor through the digitizer, and the infrasonic sensor adjusts the gain according to the Z value.

[0029] When L L ≤ L noise ≤ L H ,The system selects both t...

Embodiment 3

[0031] When the system is running normally, the digitizer 7 collects the pressure data p in the pipeline through the pressure transmitter 2, collects the flow data Q of the fluid in the pipeline through the flowmeter 5, and collects the infrasonic data in the pipeline through the infrasonic wave sensor 1, and then the collected Pressure data p, flow data Q, and infrasound wave data are added to the Global Positioning System (GPS) time tag to eliminate the impact of network link delay on positioning, and then transmitted to the host through Ethernet or 3G / 4G using TCP / IP protocol. After receiving the data, the station system 8 and the master station system 8 calculate the L noise , through the infrasonic sensor gain adjustment formula, the infrasonic sensor gain Z=5×L noise , and transmit the gain Z to the infrasonic sensor through the digitizer, and the infrasonic sensor adjusts the gain according to the Z value.

[0032] When the sonic characteristic level L noise >L H , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com