Shale gas well simulated reservoir fracture fracturing liquid flowback rate experimental measurement device and method

A technology for shale gas wells and volume fracturing, which is applied to measurement devices, soil material testing, material inspection products, etc., can solve the dynamic process without simulating shale self-priming and flowback, and the formation temperature is not considered, and there is no comprehensive consideration. shale flowback rate and other issues, to achieve the true and reliable experimental results and the optimization of the flowback system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The specific embodiment of the present invention will be described in detail below according to the accompanying drawings and a well in Sichuan area as an example. details as follows:

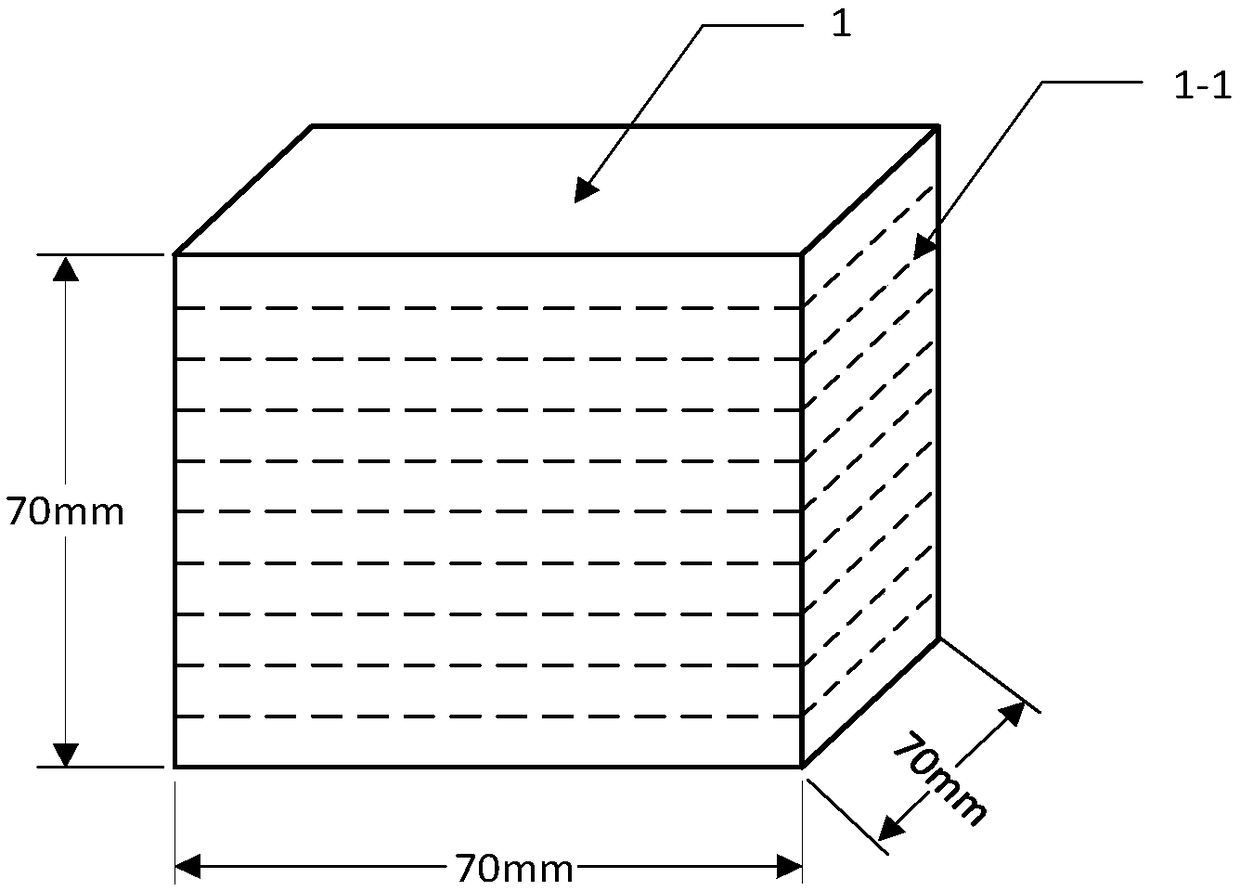

[0037] ①. Rock sample preparation: Take the actual downhole core from the 2015-2060m reservoir section of Well W1, process the core into a cubic rock sample with a side length of 7cm±1mm, and place the rock sample in an oven at 100°C to dry to constant weight. And weigh the mass m 0 It is 850.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com