Patents

Literature

59results about How to "Meet material needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shaddock whole-fruit beer and its production process

The invention provides a method for preparing beer by using pomelo. It comprises following steps: washing pomelo, removing epiderm (or not) and bad part, separating pulp from peel, cleaning peel, cutting peel, adding water and grinding, controlling temperature, adding proper amount of acid and stirring evenly, adding enzyme and getting peel enzyme reaction liquid, beating pulp, removing seed and getting pulp slurry, adding proper amount of acid and stirring, adding enzyme and getting pulp enzyme reaction liquid; mixing peel enzyme reaction liquid with pulp enzyme reaction liquid according to a certain proportion, stirring evenly and getting pulp slurry enzyme reaction liquid, filtering and getting pomelo clear juice; mixing filtered pomelo clear juice with brewed beer, loading, sealing, disinfecting, cooling, packing and getting pomelo beer; or mixing pomelo enzyme reaction liquid with prepared cereal mash, boiling, cooling, injecting yeast and preparing with beer processing steps and getting fermented pomelo beer.

Owner:林伟锋 +3

Chinese truffle and India truffle mycorrhiza fungi seeding cultivating method

InactiveCN101061781AHigh infection rateRelieve the aftermath of extinctionFungiCultivating equipmentsMycorrhizaMushroom

The invention discloses a mycorrhizomata fostering method of Chinese and Indian mushroom, which comprises the following steps: collecting mushroom bacteria; gathering host plant seed such as Yunnan pine, mountain Hua pine and chestnut; disposing the host plant seed; breeding the host plant; inoculating the bacteria; cultivating the bacteria; detecting. The invention reduces the infectious rate of bacteria, which satisfies the living need with wide market prospect.

Owner:攀枝花市农林科学研究院

Novel method for extracting oryzanol from crude rice bran oil

The invention discloses a novel method for extracting oryzanol from crude rice bran oil. The crude rice bran oil is subjected to counter-current extraction through an ether nonpolar solvent and a polar alcohol solvent, the pH value of the solution is adjusted according to the solubility difference of the oryzanol in different solvents so as to separate the oryzanol from rice bran oil and fatty acid, the oryzanol is subjected to secondary extraction through the ether nonpolar solvent and is adjusted through an acid to obtain a rough oryzanol product. The rough product is refined and decolorized to obtain a finished oryzanol product. The novel method is high in oryzanol yield, little in oil loss and is capable of avoiding environmental pollution caused by nigre and saving the production cost, thereby having an excellent economic benefit.

Owner:ZHEJIANG DELEKANG FOOD CO LTD

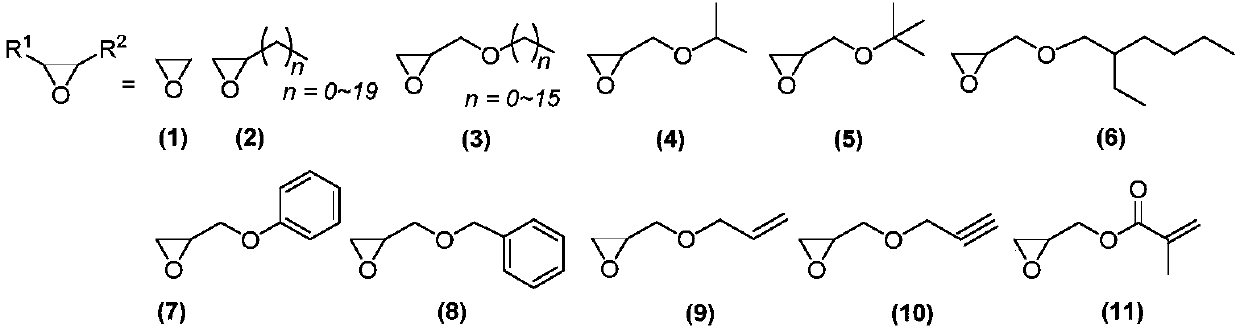

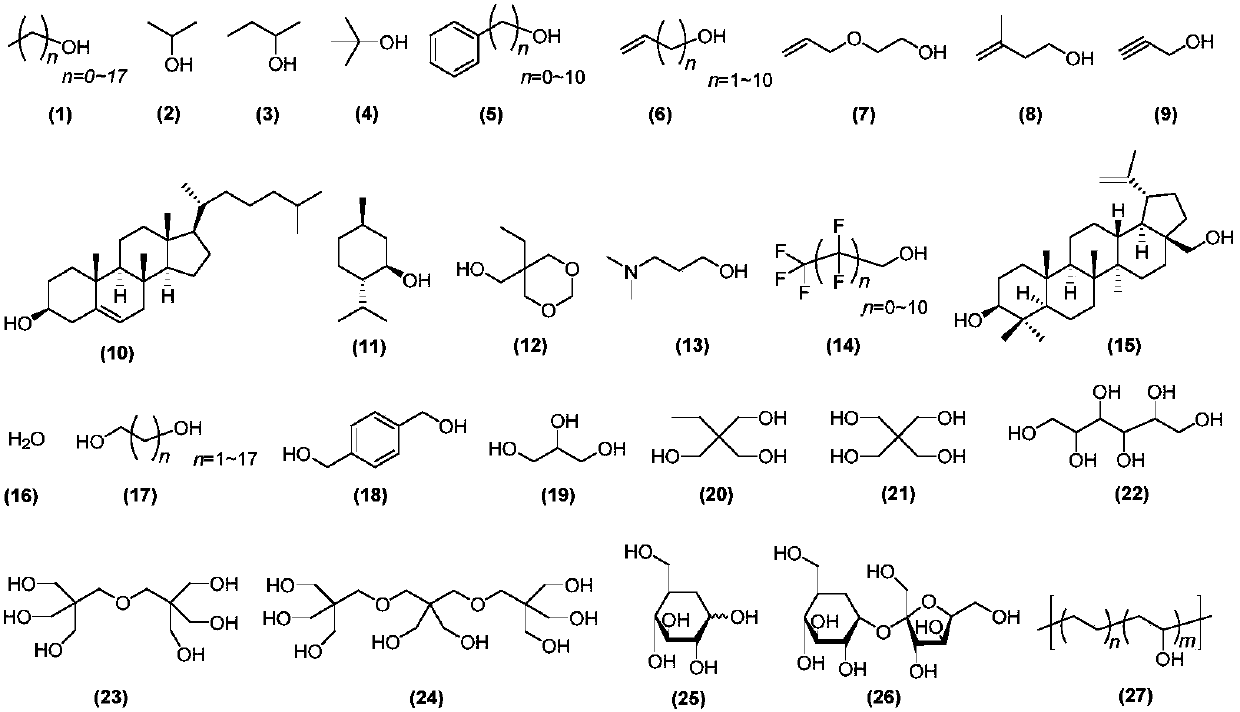

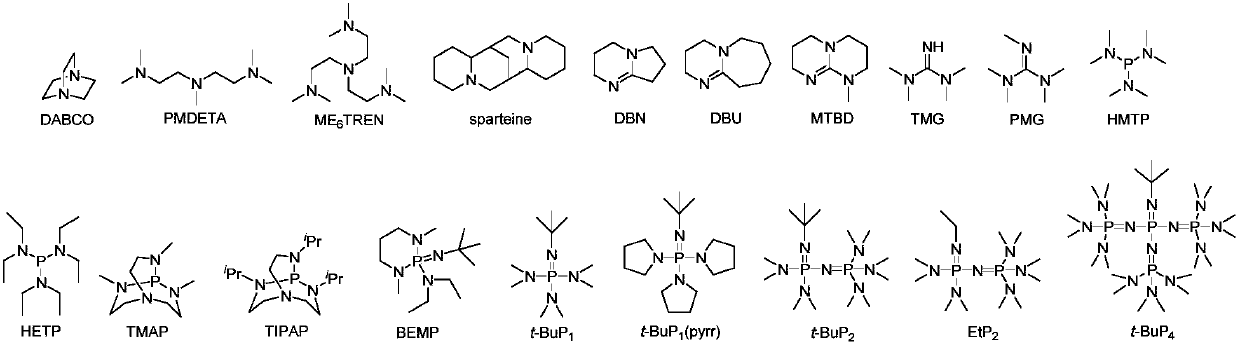

Method for preparing polyether based on three-component metal-free catalytic initiation system

The invention discloses a method for preparing polyether based on a three-component metal-free catalytic initiation system. The method comprises the steps of adding an epoxy monomer into a three-component metal-free catalytic initiation system containing hydroxy compounds, organic alkali and boron alkyl to react to obtain the polyether. The method is a currently known ethylene oxide room-temperature open-ring polymerization method with highest catalytic activity since the usage of organic alkali can be reduced to 40ppm and the conversion frequency can be 6000h / l. The polyether has the advantages of no metal residue and no cytotoxicity. The three-component catalytic initiation system adopts ethylene oxide open-ring polymerization, the chain transfer reaction toward the monomer and solvent can be completely avoided while the conversion frequency of 2720h / l can be obtained, and the polyether has the molecular weight of 0.1-400kg / mol, which can be accurately controlled. Furthermore, by utilizing the catalytic initiation system, the (poly) block polyether with controllable molecular weight, block sequence, block proportion and side base combination can be conveniently prepared by continuously adding materials.

Owner:SOUTH CHINA UNIV OF TECH

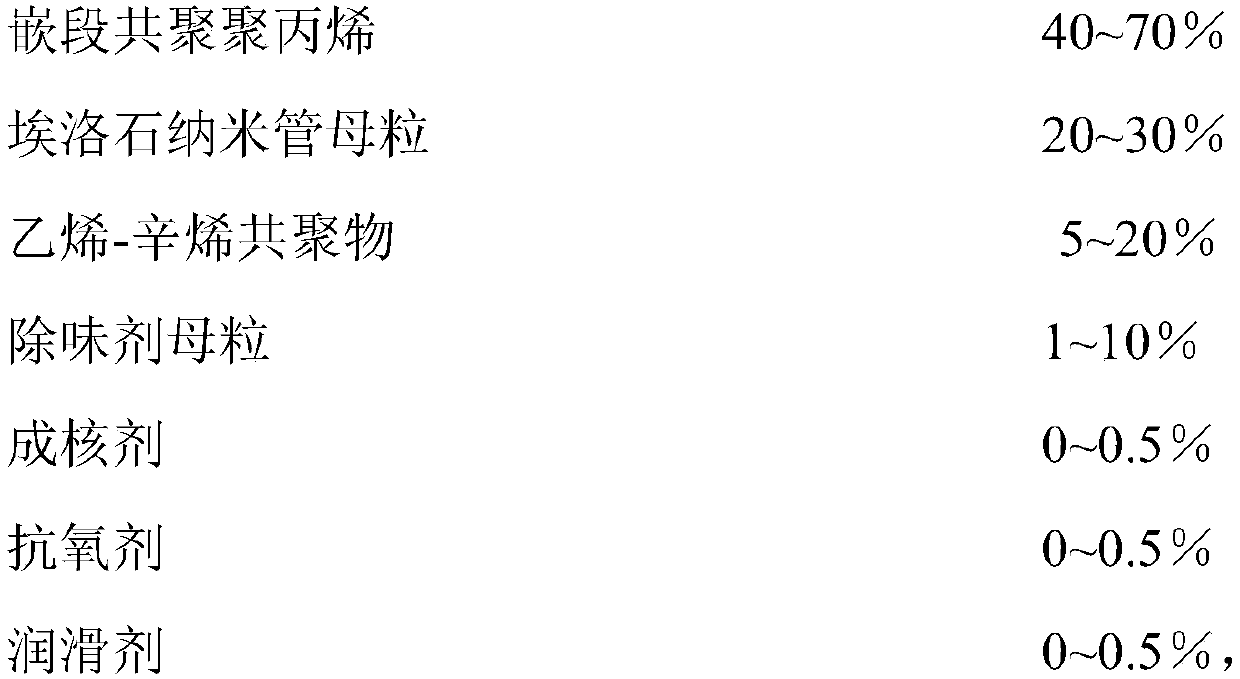

Low-odor polypropylene material for automobile interior decoration and preparation method and application thereof

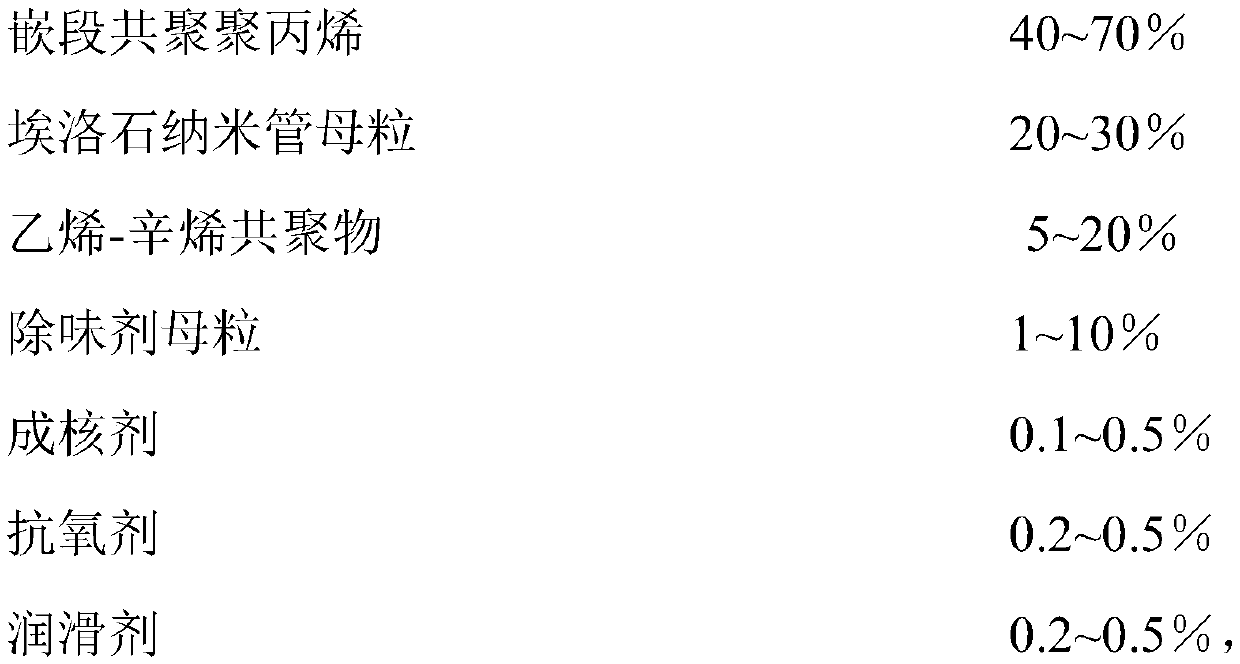

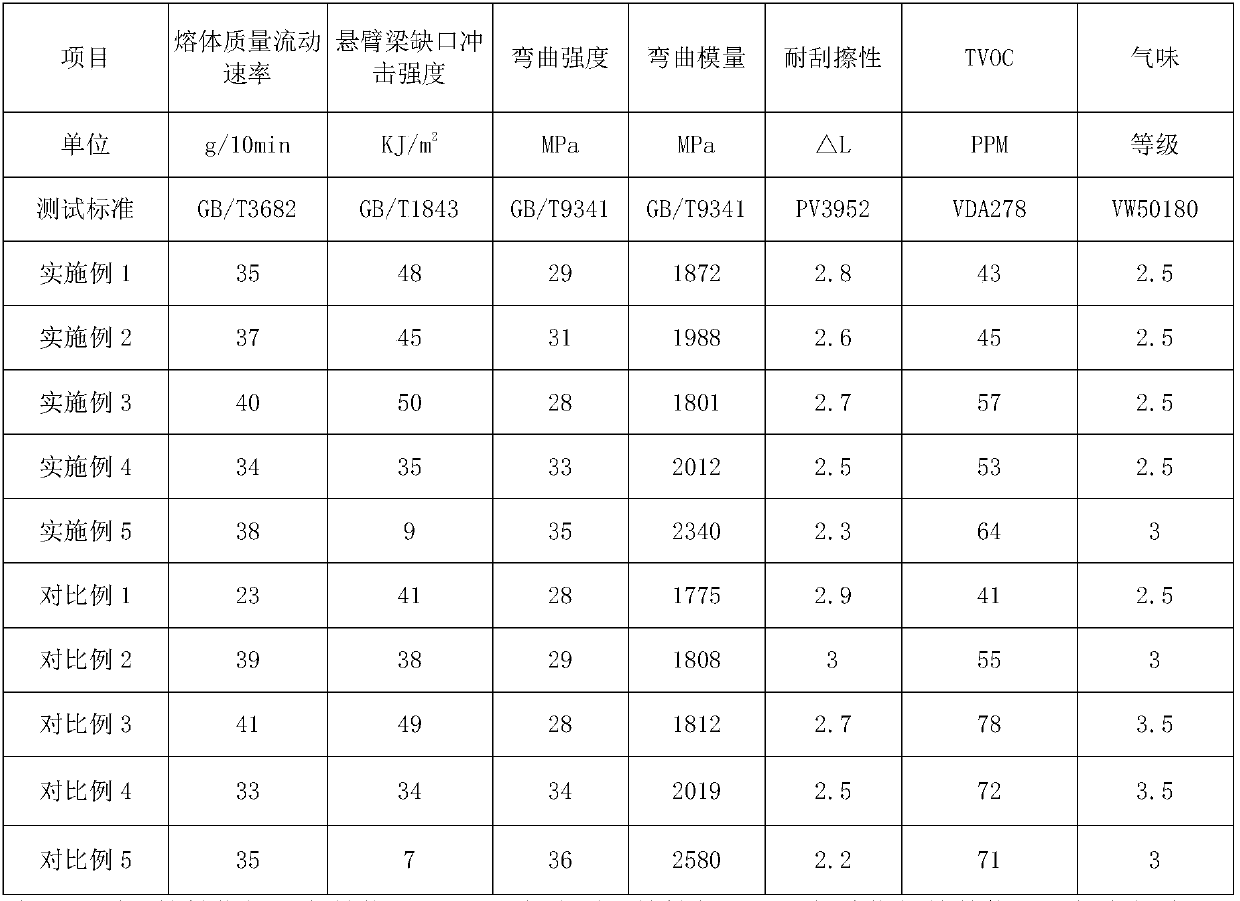

The invention discloses a low-odor polypropylene material for automobile interior decoration and a preparation method and application thereof. The low-odor polypropylene material for automobile interior decoration is prepared from the following components in percentage by mass: 40 to 70 percent of block copolymer polypropylene, 20 to 30 percent of halloysite nanotube masterbatch, 5 to 20 percent of an ethylene octene copolymer, 1 to 10 percent of deodorant masterbatch, 0 to 0.5 percent of a nucleating agent, 0 to 0.5 percent of an antioxidant and 0 to 0.5 percent of a lubricant. According to the low-odor polypropylene material for automobile interior decoration, block copolymerized polypropylene is used as a resin base material, and is modified by adding the halloysite nanotube masterbatchand the deodorant masterbatch, thereby improving the scratch resistance of the polypropylene material and reducing the volatility and odor. The low-odor polypropylene produced by the invention can bewidely used in the automobile field.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

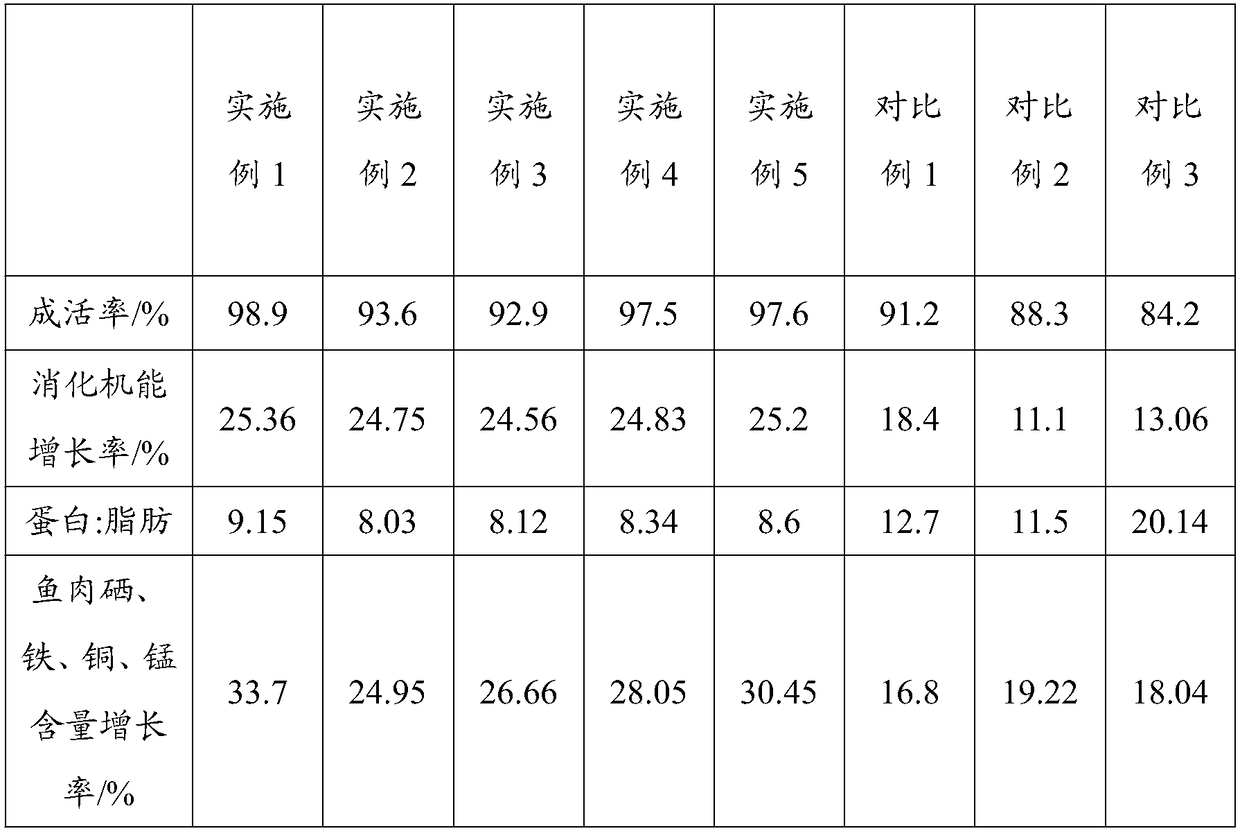

Ecologic fish culture method

InactiveCN107494340AAvoid wastingReduce dosageFood processingClimate change adaptationDiseaseMixed culture

The invention discloses an ecologic fish culture method. The method comprises the steps of (1) site selection and building of a fish pond, (2) preparation before stocking, (3) treatments before fry release, (4) feeding and management, (5) water quality management, (6) disease prevention and control, and (7) periodic fishing. The ecologic fish culture method disclosed by the invention is characterized in that mixed culture of carp, grass carp and figured chub is achieved; according to growth features of the three types of fishes, fodder can be eaten by various types of fishes from the upper layer to the bottom layer during fodder release, so fodder waste and worsening of water quality are avoided; the bred fries have a high survival rate and high disease resistance; and the fishes grow quickly, taste delicious and have a high yield.

Owner:开县永珍养鱼场

Organic rice solid type full-fertilizing of biogas manure

InactiveCN101041594ASolve pollutionSolve the ecological environmentBio-organic fraction processingClimate change adaptationEcological environmentRice grain

The invention discloses a stereo-typed full-fertilizing method of organic rice, which comprises the following steps: building standard rice field; designing line and row of rice field; building mechanical plowing channel and draining groove; setting methane tank; saving energy without polluting environment.

Owner:吴三友

High-property long glass fiber reinforced nylon 66 composite material and preparation process thereof

The invention relates to a high-property long glass fiber reinforced nylon 66 composite material and a preparation process thereof. The high-property long glass fiber reinforced nylon 66 composite material is prepared from the following raw materials by mass percent: 66.50%-80% of low-viscosity nylon, 20%-50% of special long glass fibers, 5%-8% of a compatilizer, 0.3%-1.0% of a special nylon 66 rheology modifier, 0.3%-0.5% of silicone powder and 0.3%-0.5% of calcium stearate. The preparation process comprises the main steps: manufacturing a special die and a special drying box; selecting liquid glue to bind glass fibers; weighing the nylon 66, the special nylon 66 rheology modifier, the silicone powder and calcium stearate; uniformly mixing; realizing a molten state under the effect of a single-screw extruder; feeding the molten mixture into a cavity of a die special for long glass production at a constant speed; immersing together with the long glass fibers which are dried and pulled into the cavity of the die; pulling out the immersed glass fibers under the traction of a tractor at the regular speed; feeding into a special granulator for granulation.

Owner:MIANYANG PENGYANG POLYMER MATERIAL

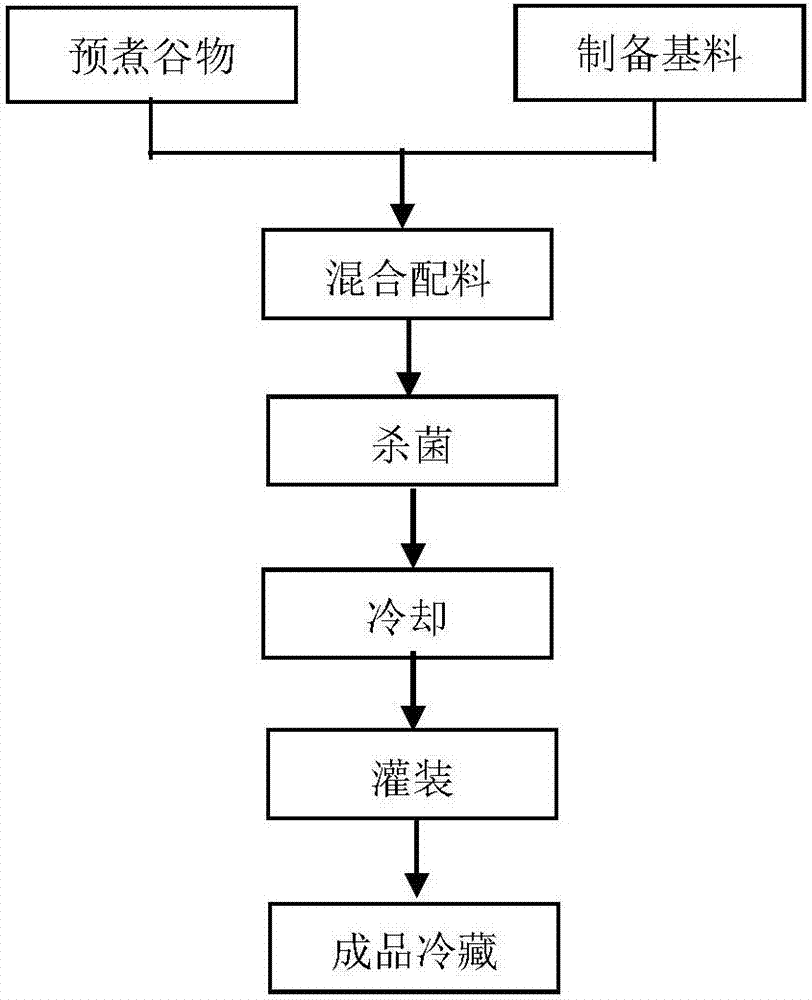

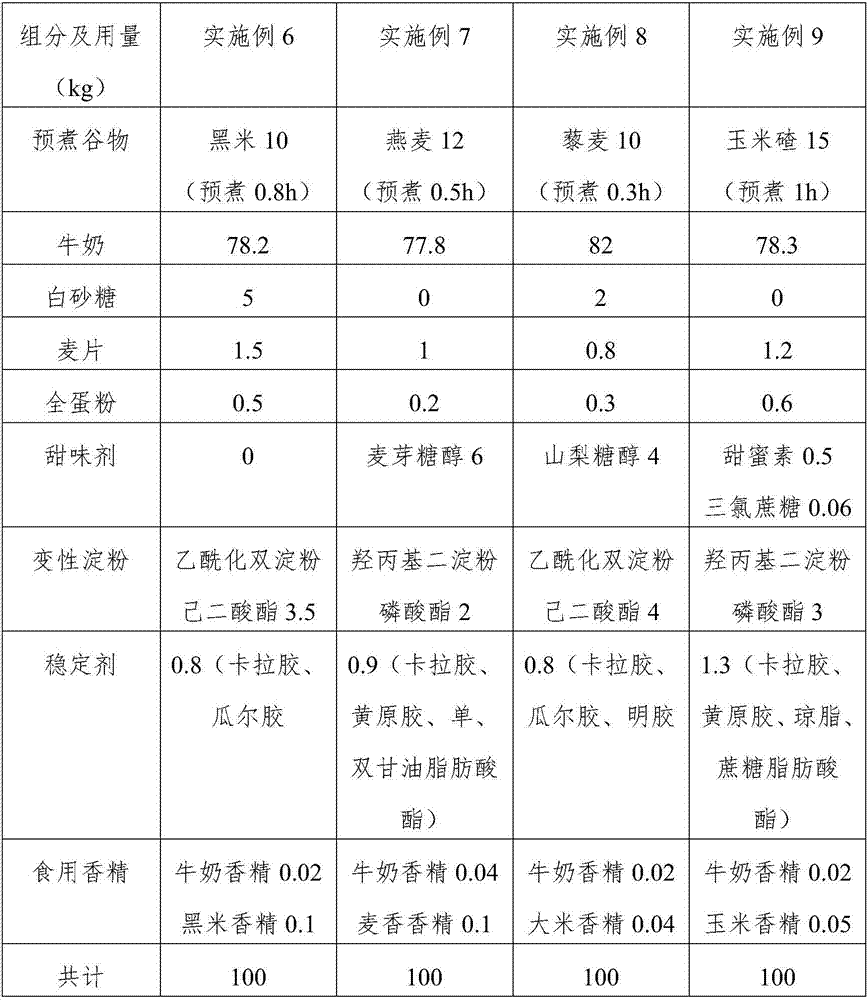

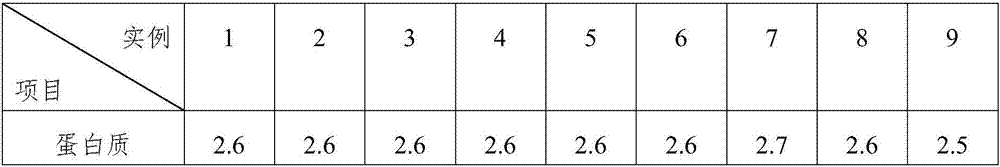

Grain egg milk pudding and preparation method thereof

InactiveCN106954796AInhibition of grain retrogradationKeep the tasteFood scienceMarket needsDietary fiber

The invention relates to a grain egg milk pudding which is prepared from the following raw materials in parts by weight: 30-85 parts of milk, 1-25 parts of grains, 0.01-2 parts of whole egg powder, 0.1-3 parts of oatmeal, 0.5-5 parts of modified starch, 0.1-2 parts of stabilizer, 0.01-5 parts of prebiotics, 0.01-5 parts of dietary fiber and 0-8 parts of white granulated sugar. The invention also provides a method of preparing the grain egg milk pudding, wherein the method comprises the following steps: pre-cooking the grain into cooked grain; uniformly mixing the rest raw materials to obtain a base material; and uniformly mixing the cooked grain with the base material to obtain the grain egg milk pudding. In the invention, the product is of rational nutrition arrangement and unique mouthfeel and meets existing market needs.

Owner:BEIJING SANYUAN FOOD

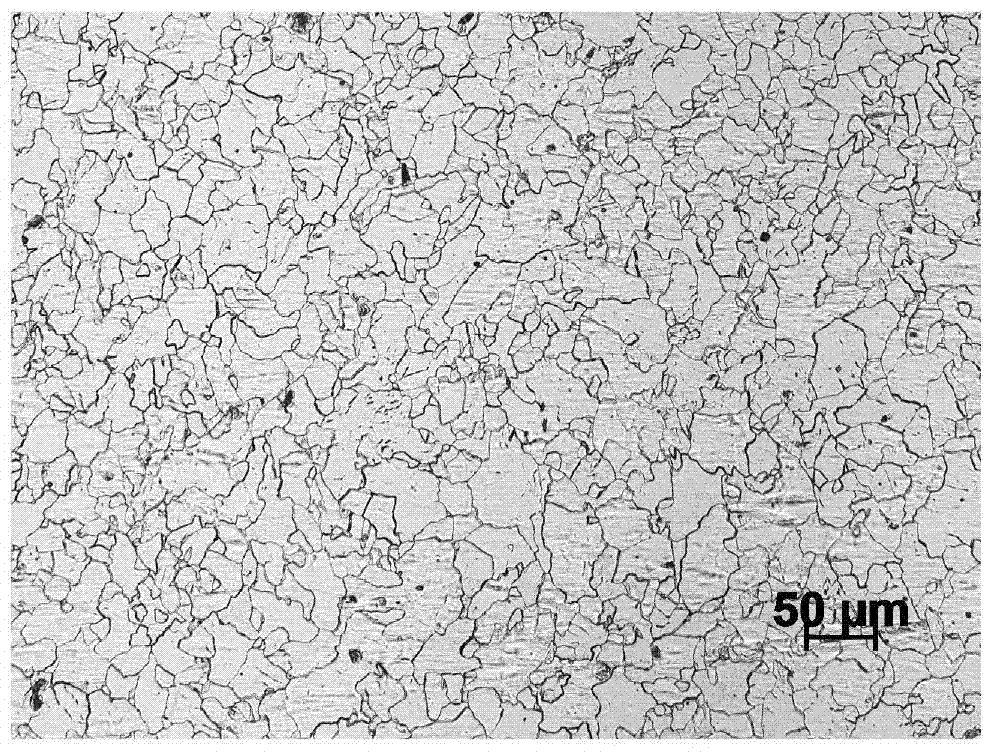

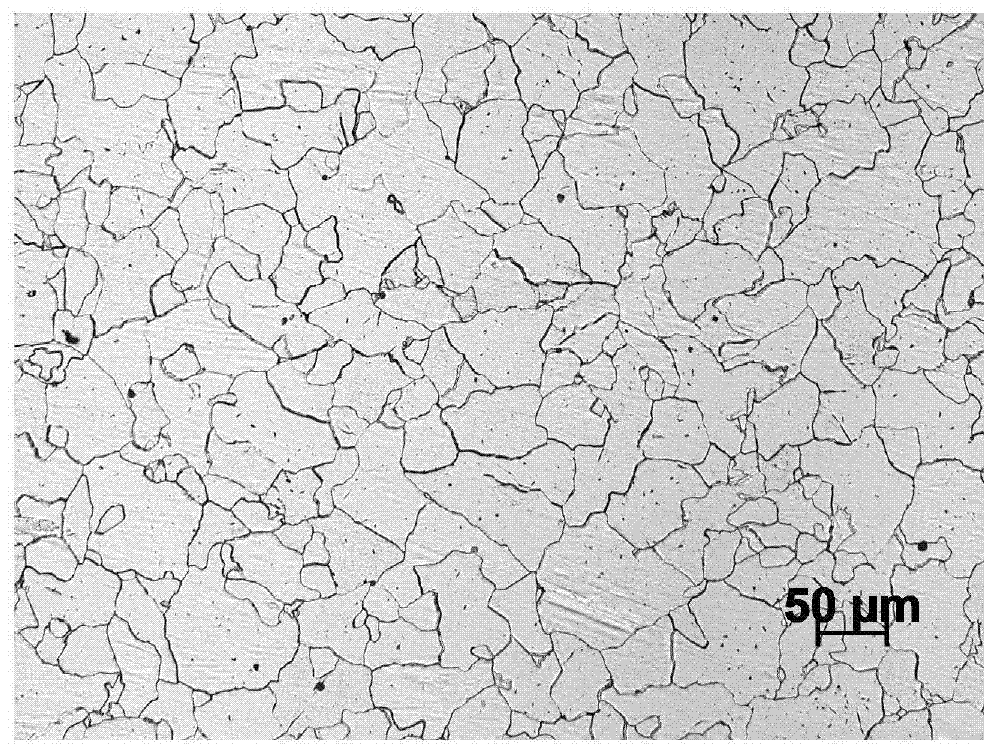

Low-temperature low-yield steel and manufacturing method thereof

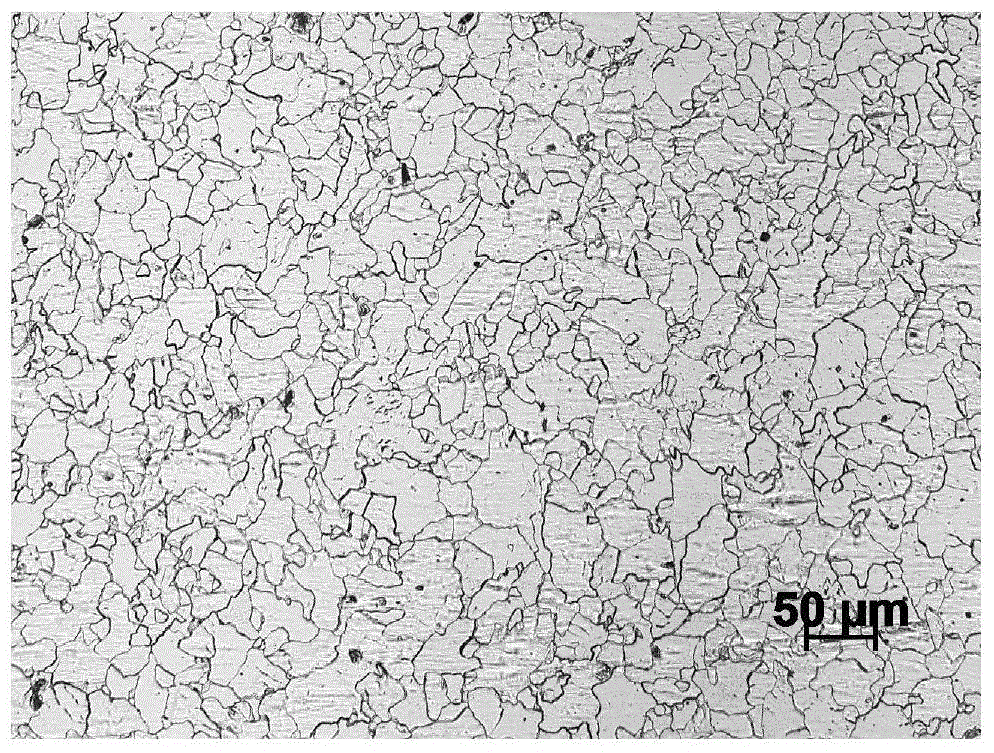

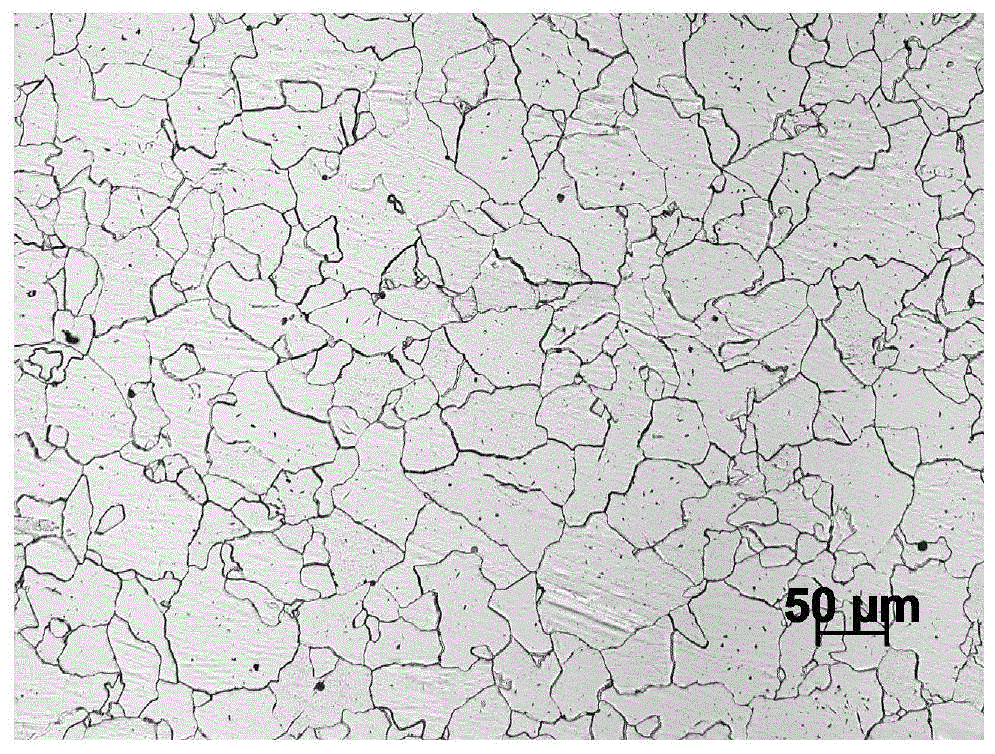

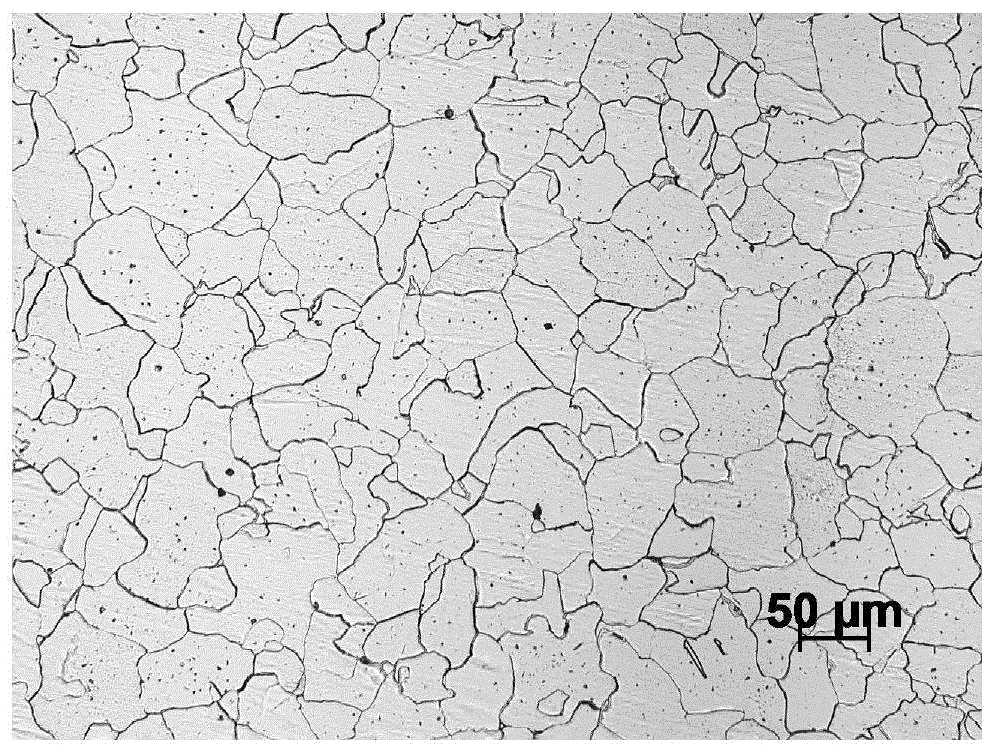

The invention relates to a low-temperature low-yield steel and a manufacturing method thereof, wherein the steel is prepared by the following chemical components according to the weight percentage: 0.01-0.04% C, 0.14-0.3% Si, 0.3-0.5% Mn, no more than 0.013% P, no more than 0.005% S, and 0.01-0.035% Nb, and the steel is designed by adopting ultra-low carbon and micro niobium alloy to ensure its low-temperature impact toughness under a low-yield condition. The manufacturing method of the hot-rolling low-temperature low-yield steel is characterized by adopting ultra-low carbon and niobium alloy, and combining a reasonable controlled rolling and cooling process to manufacture the low-temperature low-yield anti-seismic steel, wherein the hot rolling mechanical property can reach requirements, the yield strength is less than 225MPa, the elongation reaches 40%, and the impact energy is no less than 250 J at -40 degrees centigrade. The method can successfully solve the technical difficulty that the low-temperature low-yield steel is easy to mix crystals, narrow in rolling temperature windows and low roll force.

Owner:NANJING IRON & STEEL CO LTD

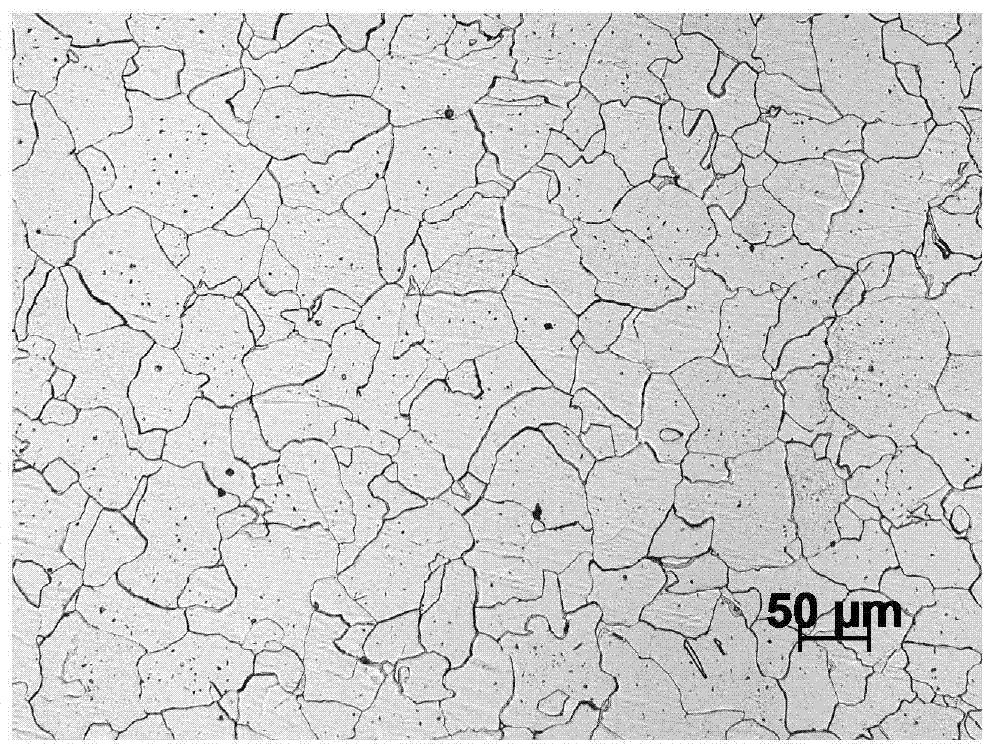

Special material for high-toughness and high-water pressure resistance polypropylene randon copolymer (PPR) pipe material and preparation process thereof

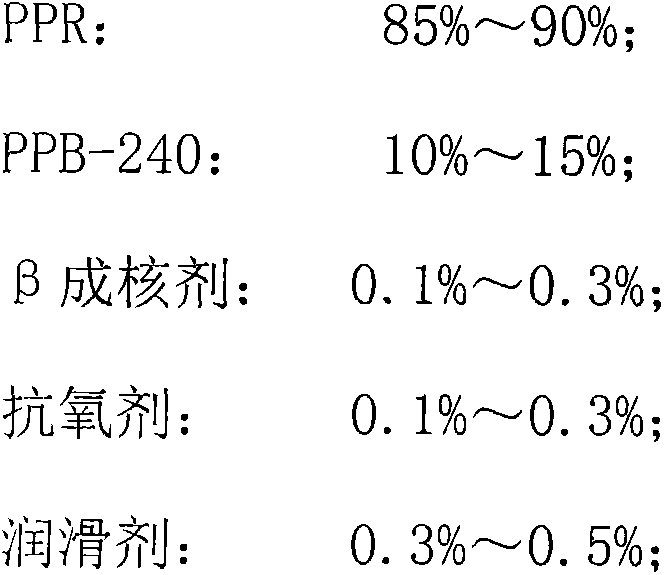

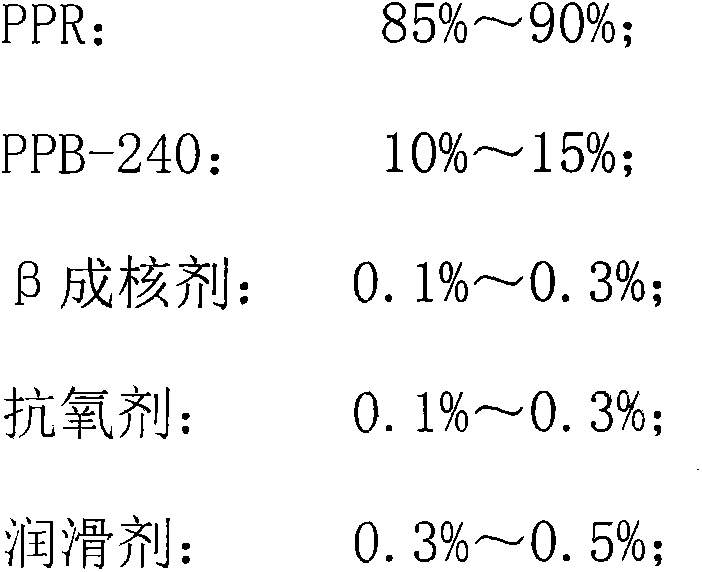

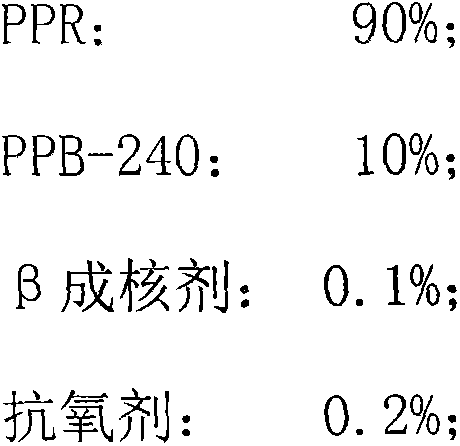

The invention relates to a special material for a high-toughness and high-water pressure resistance polypropylene randon copolymer (PPR) pipe material and a preparation process of the special material. The special material is prepared from the following raw materials in percentage by mass: 85-90% of PPR, 10-15% of PPB-240, 0.1-0.3% of a beta-nucleating agent, 0.1-0.3% of an antioxidant and 0.3-0.5% of a lubricant. The preparation process mainly comprises the steps of weighing proper amounts of PPR, PPB, a beta-nucleating agent, an antioxidant and a lubricant according to the prescription, and mixing the materials in a low-speed mixer according to an order from higher proportion to lower proportion; setting a corresponding thread combination; setting heating temperature of various sections of charging barrels of a dual-screw extruder; adding mixed raw and auxiliary materials to a storage hopper of the dual-screw extruder set; starting a lubricating oil pump, a cooling fan, a grain cutting machine, cooling water, a main motor and a feeding motor, and regulating rotating speeds of the main motor and the feeding motor; drawing the extruded materials to the grain cutting machine through a cooling water bath and a blow drying machine, regulating rotating speed of the grain cutting machine, so that the cut materials are 3 in granularity and 3mm long; and detecting various physical indicators of the produced materials in real time.

Owner:MIANYANG PENGYANG POLYMER MATERIAL

Feed for improving raised fish quality

InactiveCN108522897AImprove gastrointestinal immune functionEnhance immune functionFood processingClimate change adaptationAquaculture industryFish quality

The invention discloses feed for improving raised fish quality. According to preparation method by reasonably formulating bio-fermented feed and grass feed, nutritional ingredients essential to growthof aquatic products can be provided, nutrient elements of the whole aquatic product fertilizer are uniform and balanced, health and sustainable development of environment-friendly aquaculture industry can be improved, and demand for animal growing materials in the aquaculture process can be met.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

Biological nutrient and preparing method thereof and product made therefrom

InactiveCN1488292AEasy to takeMeet material needsFood preservationFood preparationBacterial strainSugar

The invention discloses an organic bio-nutrient, making method and the product. The nutrient contains the elements in the following preparing ratio: organic Ca : Zn : Fe : Se : folacin : Vitamin B1 : Vitamin B2 : total sugar = (180-240) : (3-6) : (7-9) : (0.02-0.05) : (0.0002-0.0003) : (0.6-0.8) : (0.6-0.8) : (4-6). The making method includes the steps: mixing the above matters except total sugar in the preparing ratio: (800-1200) : (30-50) : (10-20) : (3-9) : (1.5-2) : (5-11) : (5-11), to develop nutrient source; taking bacterial strain, culture medium and water to make mixed inoculation, to make terminal culture medium; mix the terminal, the nutrient source and water in preparing ratio: (0.5-1.5) : (8-12) : (80-120), and then sending to reaction kettle to produce bio-nutrient liquid; making solid-liquid separation on the bio-nutrient liquid to develop solid bio-nutrient and liquid bio-nutrient. It mixes the bio-nutrient with beer, drink and flour in the proportion of (0.5-1.5) : (8-12) : (80-120) to make the product.

Owner:韩家宣

Processing process of high-strength high-stretchability chinlon industrial yarn

InactiveCN106987913AMeet material needsMeet needsArtificial filament heat treatmentDry spinning methodsYarnThree level

The invention discloses a processing process of high-strength high-stretchability chinlon industrial yarn. The processing process includes the following steps of 1, preparation of a spinning solution; 2, spinning forming; 3, cooling; 4, drafting setting, wherein drafting setting is carried out on primary cellosilk beams, three-level hot drafting is adopted for drafting, the first-level hot drafting multiple ranges from 2 to 2.1, the second-level hot drafting multiple ranges from 1.8 to 1.9, the third-level hot drafting multiple ranges from 1.5 to 1.7, and tension hot setting is adopted for setting; 5, winding. In this way, the process is simple and easy to control, and the prepared chinlon industrial yarn is high in breaking strength and low in dry heat shrinkage rate, further has the advantages of being excellent in abrasion resistance, fatigue resistance, impact resistance and the like, and can meet the requirements of safety air bag materials.

Owner:CHANGSHU POLYESTER

Aglaia odorata tea fragrant mulberry silk quilt

InactiveCN107595025AHigh oil contentImprove qualityBed-coversSleep/relaxation inducing devicesWire gauzeBombyx mori

A Milanese scented mulberry silk quilt, the production steps of which are: (1) putting cooked silkworms on a silk spinning net; (2) stripping off wool sheets; (3) degumming treatment of the wool sheets; (4) washing and dehydrating; ( 5) Drying of cotton sheets; (6) Weighing of cotton sheets; (7) Cutting of cotton sheets; Put anti-running silk gauze on the top and bottom of the sheet; (10) Cover the two cotton sheets with a layer of tire cover, sew them on three sides, and leave an opening on one side to form a tire core bag; (11) Prepare Milan flower tea granules; (12) Milan flower tea granules Coating; (13) Preparing non-woven bags; (14) Preparing Milanese scented tea granules; (15) Finally, fixing Milanese scented tea granules in the fetal heart bag, and then placing the fetal heart bag in the quilt cover. The mulberry silk quilt is of good quality, can emit the fragrance of Milan flower tea, and the fragrance is released slowly, and the fragrance can be maintained for a long time.

Owner:GUANGXI GUIHUA SILK CO LTD

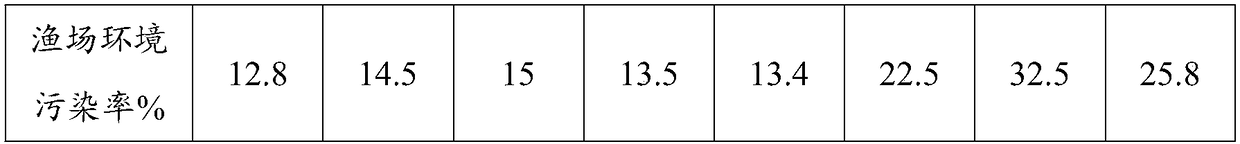

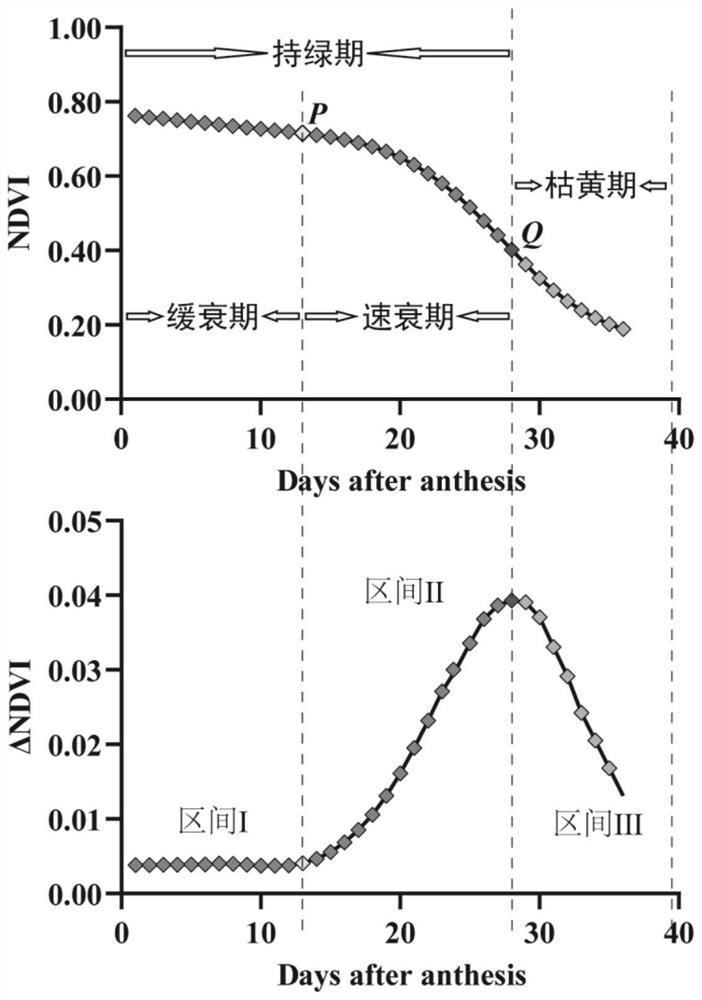

Method for dynamically analyzing canopy aging progress of cereal crops by using post-flowering NDVI (normalized difference vegetation index)

PendingCN112750048AEasy to operateLow costData processing applicationsScattering properties measurementsGenetic stockNormalized Difference Vegetation Index

The invention discloses a method for dynamically analyzing the canopy aging progress of cereal crops by using post-flowering NDVI (normalized difference vegetation index). The method comprises the following steps: acquiring a post-flowering NDVI dynamic state and carrying out data smoothing, acquiring a post-flowering delta NDVI dynamic state and carrying out Gauss fitting, correspondingly dividing each aging stage and calculating each aging related index. According to the method, the aging progress of different varieties is analyzed by acquiring the NDVI information of canopies of different varieties and constructing the related aging indexes, so that the purpose of identifying and selecting the varieties is achieved. The new method overcomes the defects of time consumption, low efficiency and the like in the traditional measurement based on chemical components or physiological indexes of leaf organs, does not set mathematical limitation for the aging process, fully considers the regular change of growth and development of crops, and can quickly and nondestructively meet the requirements of aging process evaluation of cereal crops.

Owner:CHINA AGRI UNIV

Preparation method of mosquito-repellent jasmine tea baby pillow

InactiveCN107456021ADimensions neat and beautifulEasy to preparePillowsNervous disorderWoven fabricPorous starch

A method for preparing a mosquito-proof jasmine tea baby pillow, the process steps are as follows: (1) tea base treatment; (2) jasmine flower picking; (3) jasmine flower maintenance; (4) scenting; (5) adding Drying of raw materials; (6) crushing and screening; (7) preparation of coating agent from corn porous starch; (8) coating; (9) selection of pure cotton fabrics to prepare jasmine tea baby pillow jacket; (10) selection of white non-woven (11) Put the coated jasmine tea into a non-woven bag to become the jasmine tea baby pillow liner; (12) Put the jasmine tea baby pillow liner into the jasmine tea baby pillow coat , that is, the anti-mosquito jasmine tea baby pillow. The anti-mosquito jasmine tea baby pillow of the present invention has a unique fragrance that makes people feel comfortable, and also has the effects of anti-mosquito and mosquito repellent, calming the nerves and helping sleep, clearing away heat and detoxification, reducing phlegm and relieving cough, and preventing cold and fever. long lasting.

Owner:广西巧恩茶业有限公司

Fully-constrained weak-sparse metal powder explosive compaction and powder plate explosion cladding method

The invention discloses a fully-constrained weak-sparse metal powder explosive compaction and powder plate explosion cladding method. The method comprises the following steps: (1) processing a metal plate: forming openings in the side surface of the metal plate, and cleaning the inner walls of the openings, wherein the shapes and sizes of the openings can be designed and adjusted according to therequirements; (2) filling metal powder: sealing one opened side of the metal plate, pouring the metal powder into the openings step by step, compacting the metal powder to the greatest extent, after all the openings are compactly filled, sealing the other side, wherein the filling density is relevant with the materials of the metal powder; and (3) putting the metal plate filled with the metal powder on a cushion plate, putting an explosive on the metal plate, firing the explosive through a detonator so as to drive the upper part of the metal plate to downwards compact the metal powder to enable the metal powder to be closely combined with the metal plate, so as to finish the cladding between the metal powder and the plate. Compared with traditional explosion cladding techniques, the methodhas the advantages that by fully constraining the metal powder, sparse waves are weakened, and the compaction of the metal powder and the cladding of the powder plate material can both be realized.

Owner:UNIV OF SCI & TECH OF CHINA

Biological processing method of grains

ActiveCN104560521APure tasteAdd flavorAlcoholic beverage preparationMicroorganism based processesFiberAmylase

The invention relates to a biological processing method of grains. The method provided by the invention comprises the following steps: with the grains as a raw material, sequentially carrying out enzymolysis with amylase and protease, and then carrying out inoculating fermentation with a yeast, so as to obtain a fermentation liquor and a solid matter; centrifuging the solid matter to obtain yeast paste and grain fibers; and respectively processing the fermentation liquor, the yeast paste and the grain fibers into fermentation wine, biological soy sauce and cooking wine. According to the method provided by the invention, the fermentation wine, the biological soy sauce and the cooking wine can be simultaneously prepared by feeding once, so that the method has relatively high economic benefits and social benefits, and has the profound practical significance and social values in improvement of efficient comprehensive utilization of resources, emission of relatively few wastes and environment protection; simultaneously the method can be used for achieving industrialization production by combining an existing beer brewing process and can be as an example for transformation of a development mode of a company.

Owner:滕传文

Preparation method of dragon fruit beer

The invention discloses a preparation method of dragon fruit beer. The preparation method of the invention comprises the following steps: raw material preparation mainly includes the following raw materials: barley malt, sorghum and rice, the weight ratio of which is 10:2:1; Step 1 is to prepare malt juice, step 2 prepares pitaya fruit juice, step 3 secondary fermentation, low-temperature wine storage, and then filtration, high magnetic field magnetization sterilization to obtain the described dragon fruit beer; the preparation method of the present invention adopts high magnetic field magnetization sterilization, which can effectively kill Harmful microorganisms, there is no chemical residue problem, and the damage to the nutritional components and original flavor of beer itself is small. Magnetized dragon fruit wine is obtained after magnetization by a high magnetic field. The nutrients in dragon fruit beer are easily absorbed by the human body, especially trace elements are easily absorbed. absorbed by the body.

Owner:钦州市钦南区科学技术情报研究所

A kind of low-temperature low-yield steel and its production method

The invention relates to a low-temperature low-yield steel and a production method thereof, the chemical composition of which is calculated by weight percentage, including: C: 0.01-0.04, Si: 0.14-0.3, Mn: 0.3-0.5, P≤0.013, S≤0.005, Nb: 0.01‑0.035, designed with ultra-low carbon and micro-niobium alloying components to ensure low-temperature impact toughness under low-yield conditions. The production method of the hot-rolled low-temperature and low-yield steel provided is through the composition design of ultra-low carbon and niobium alloying, combined with a reasonable controlled rolling and controlled cooling process to produce low-temperature, low-yield anti-seismic steel with a thickness of 70mm, and hot-rolled The dynamic mechanical properties meet the requirements, the yield strength is less than 225MPa, the elongation reaches 40%, and the impact energy at ‑40°C is ≥250J. This method successfully solves the technical difficulties of low-temperature, low-yield steel prone to mixed crystals, narrow rolling temperature window, and low rolling force.

Owner:NANJING IRON & STEEL CO LTD

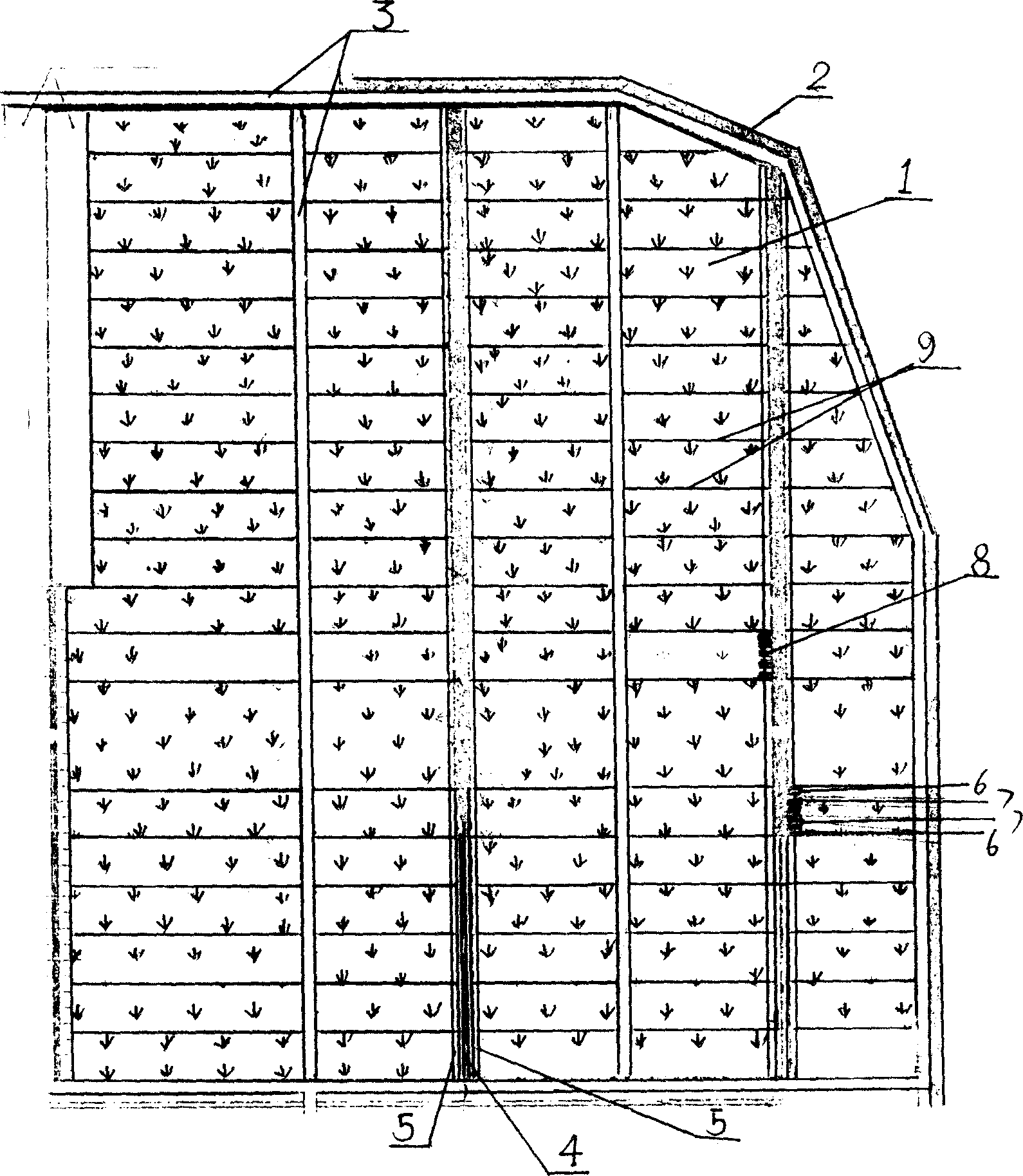

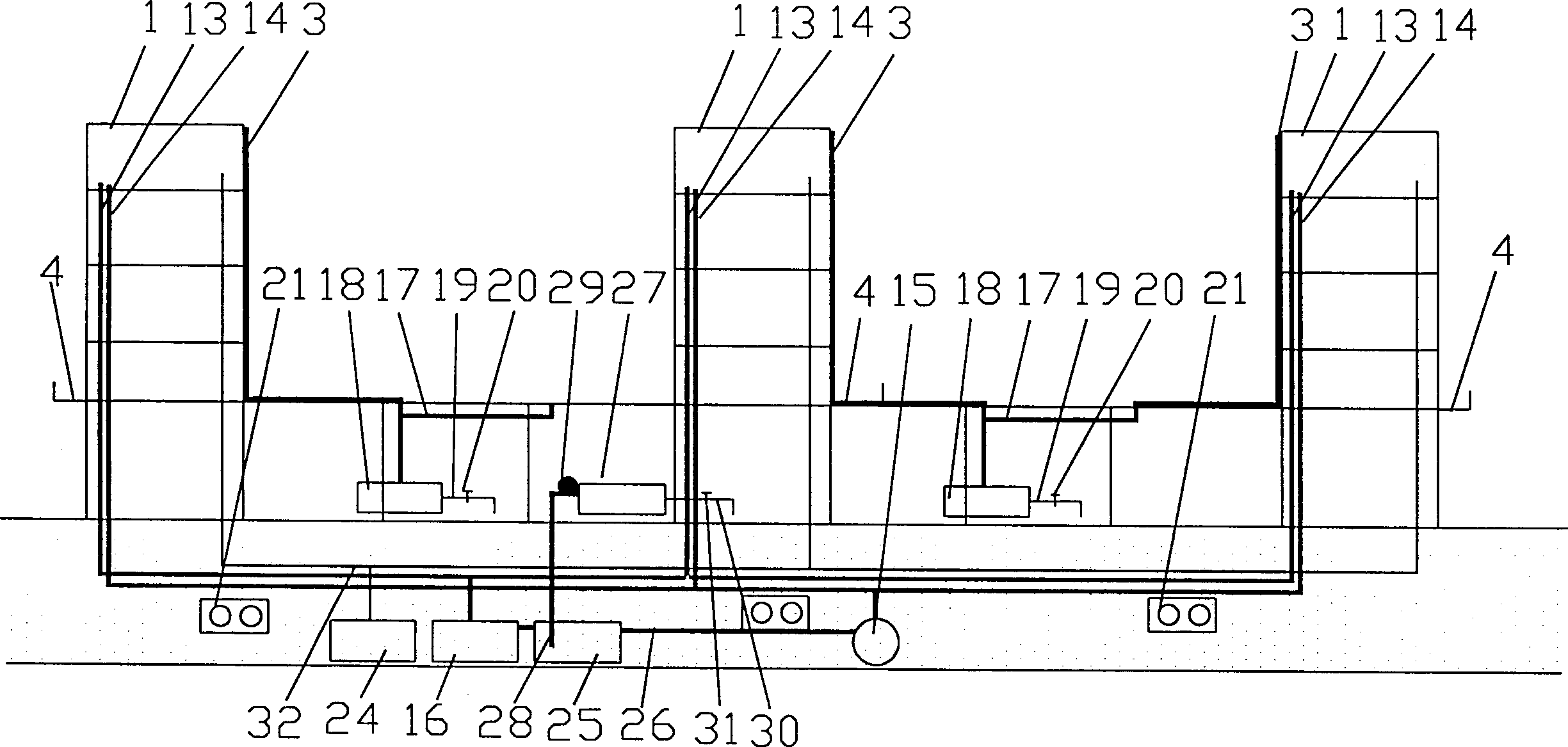

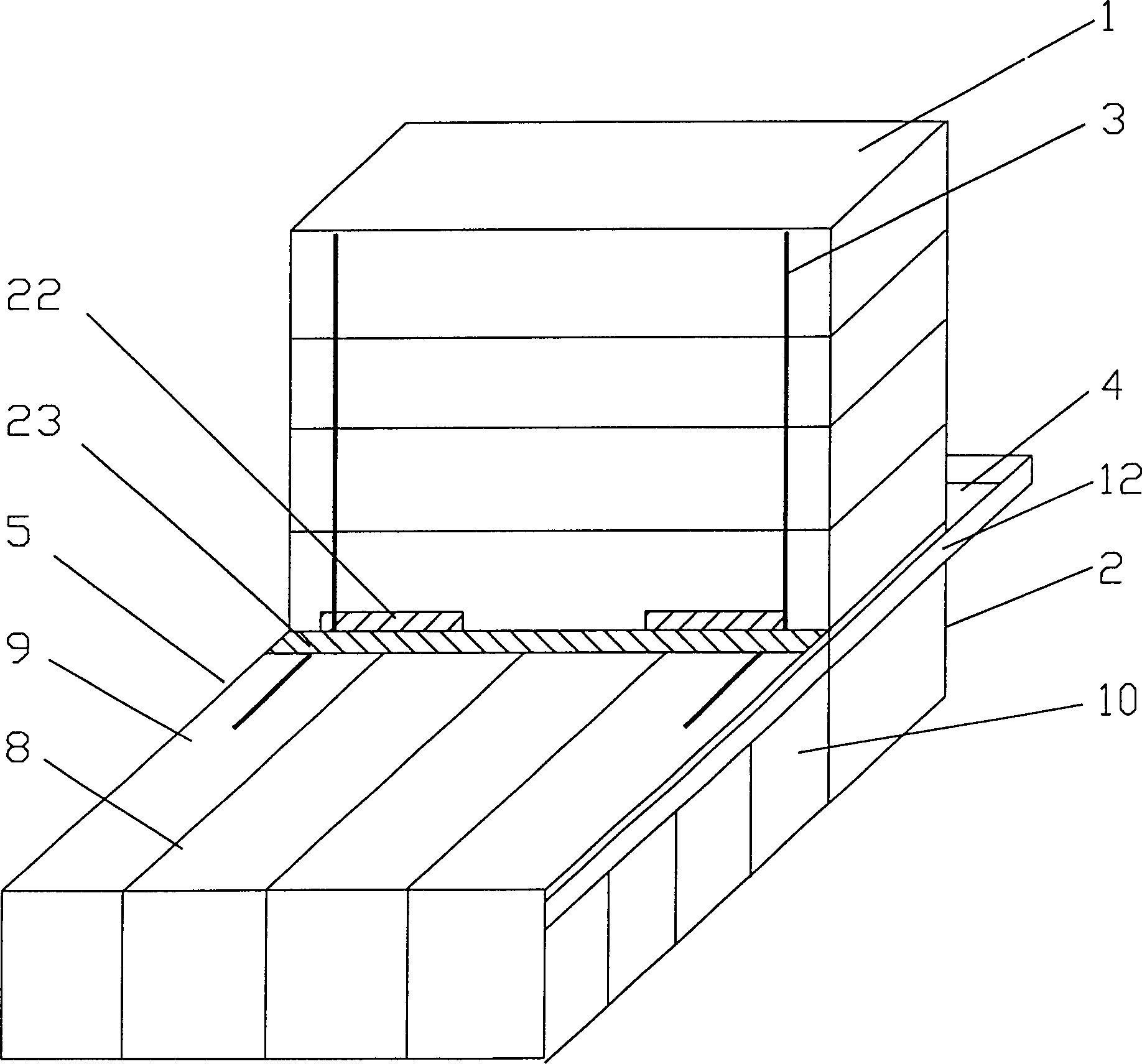

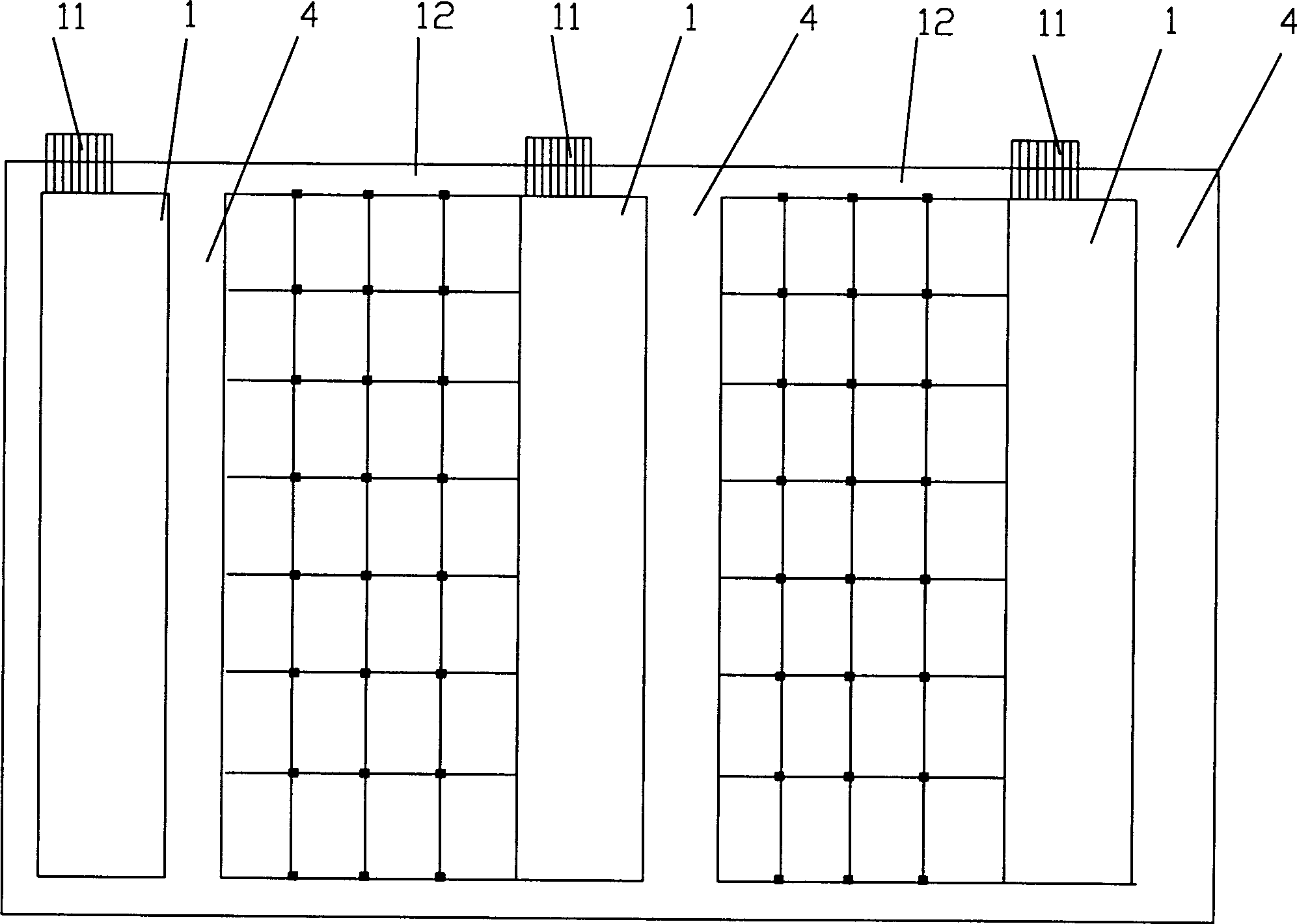

High-efficacy building

InactiveCN1119479CLow costImprove efficiencyClimate change adaptationSpecial buildingEngineeringEfficacy

Owner:张文举

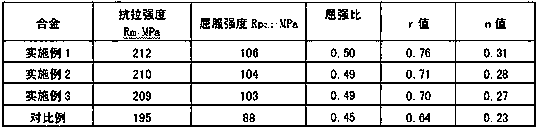

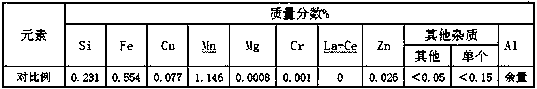

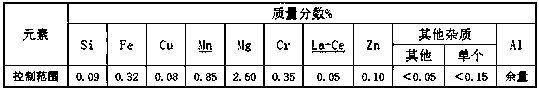

Production method of aluminum alloy base material for 5052 alloy door plate

ActiveCN109487131AGuaranteed flatnessStable yield ratioCasting cleaning apparatusAluminium alloyRaw material

The invention discloses a production method of an aluminum alloy base material for a 5052 alloy door plate, and relates to the technical field of aluminum alloy production. The method comprises the following steps that an aluminum alloy finished product is prepared from the following raw materials, by mass, less than 0.10% of Si, less than 0.35 of Fe, less than 0.10% of Cu, less than 0.10% of Mn,2.30-2.60% of Mg, 0.15-0.35% of Cr, 0.01-0.05% of La+Ce, less than 0.10% of Zn, the total content of impurities is below 0.15%, and the balance is Al; the aluminum alloy finished product is subject toannealing treatment, under the protection of inert gas, the temperature is controlled to be 300-320 DEG C in a box-type furnace, and the aluminum alloy finished product keeps warm for 2-4 hours and then cooled with the furnace at the speed of 20-40 DEG C per hour; and the aluminum alloy finished product is subject to stretching bending straightening treatment. According to the production method,the problem that an existing door-used aluminum alloy base material is prone to wrinkling after stamping is solved.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

A new method for extracting oryzanol from crude rice bran oil

The invention discloses a novel method for extracting oryzanol from crude rice bran oil. The crude rice bran oil is subjected to counter-current extraction through an ether nonpolar solvent and a polar alcohol solvent, the pH value of the solution is adjusted according to the solubility difference of the oryzanol in different solvents so as to separate the oryzanol from rice bran oil and fatty acid, the oryzanol is subjected to secondary extraction through the ether nonpolar solvent and is adjusted through an acid to obtain a rough oryzanol product. The rough product is refined and decolorized to obtain a finished oryzanol product. The novel method is high in oryzanol yield, little in oil loss and is capable of avoiding environmental pollution caused by nigre and saving the production cost, thereby having an excellent economic benefit.

Owner:ZHEJIANG DELEKANG FOOD CO LTD

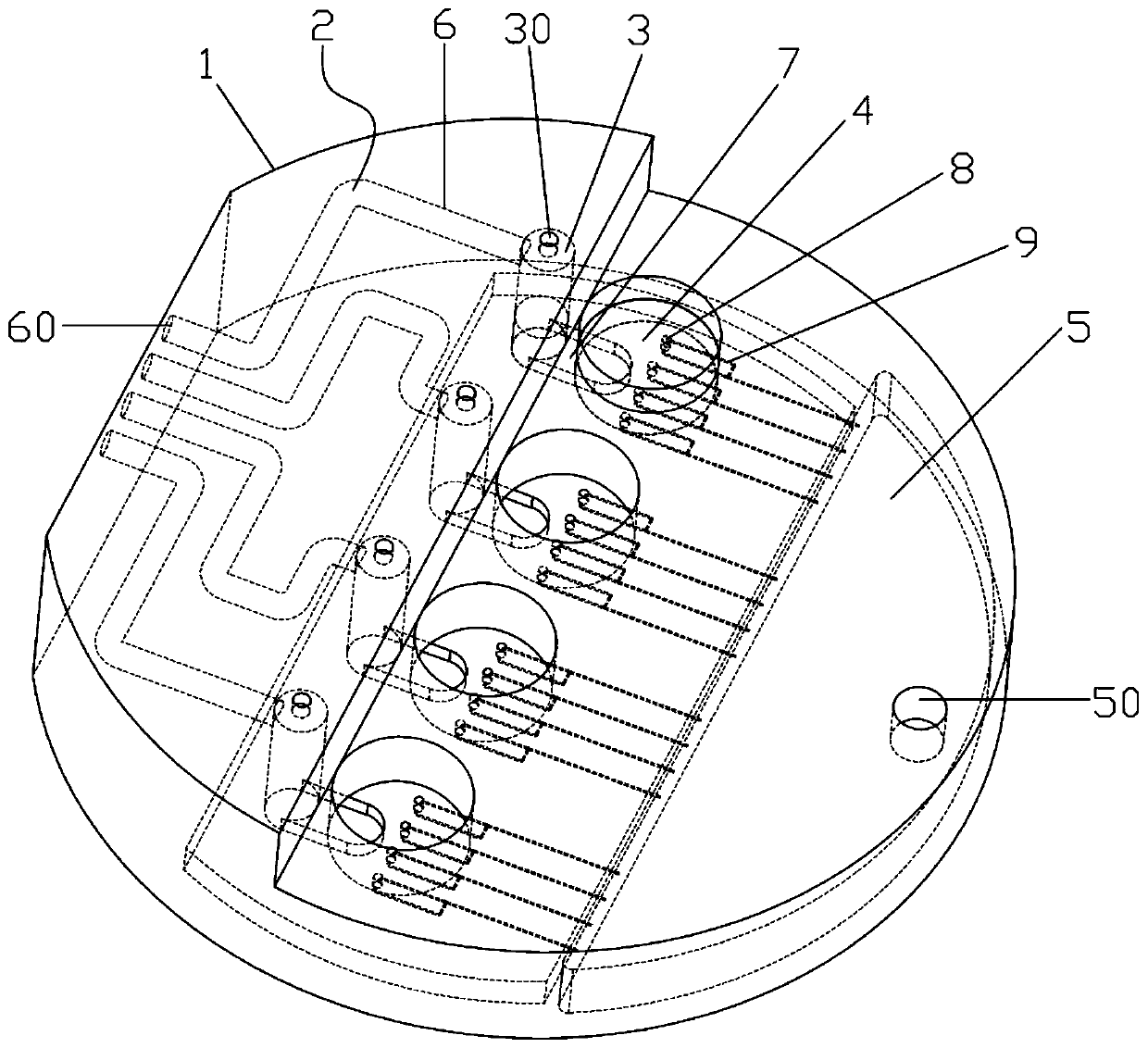

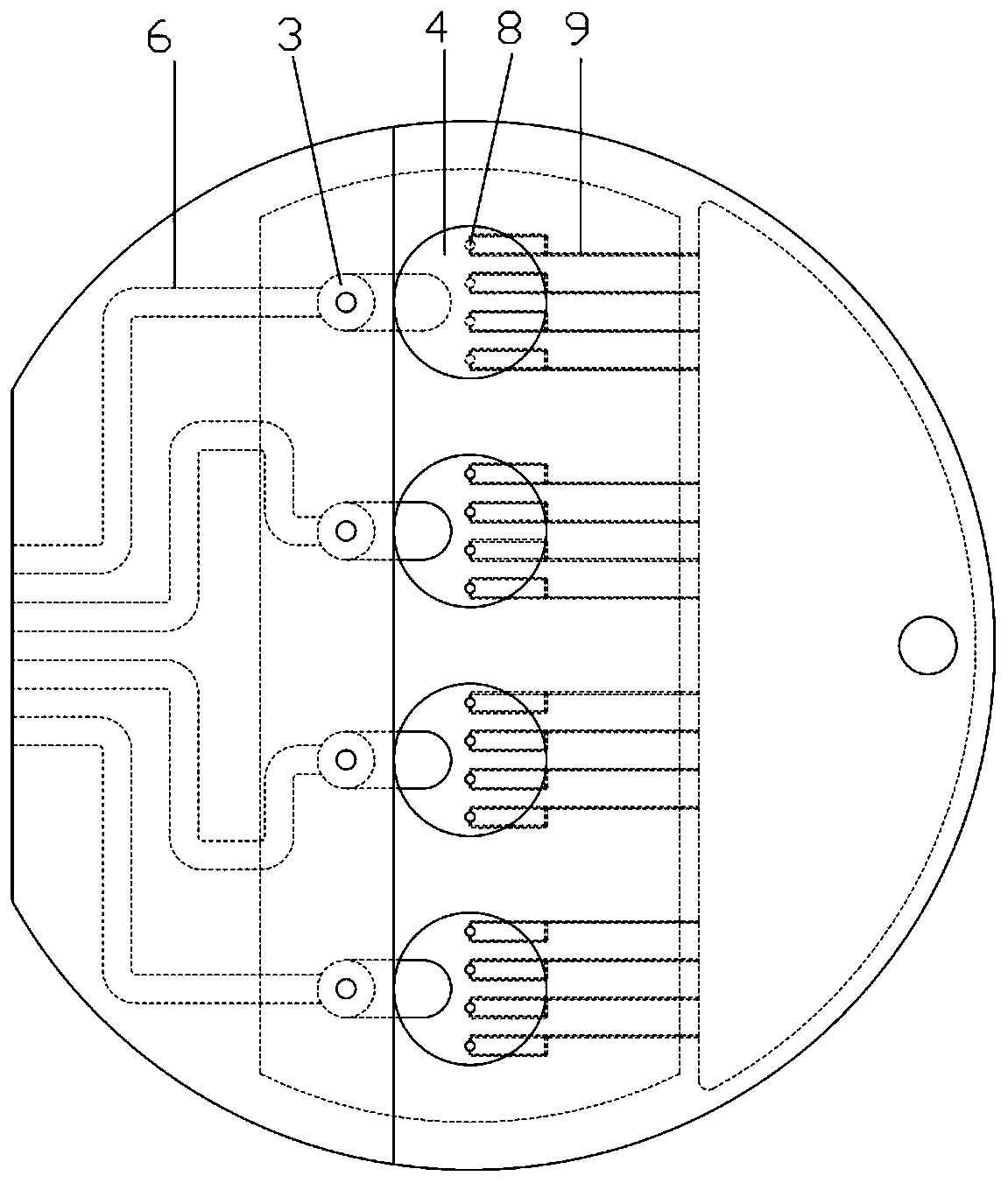

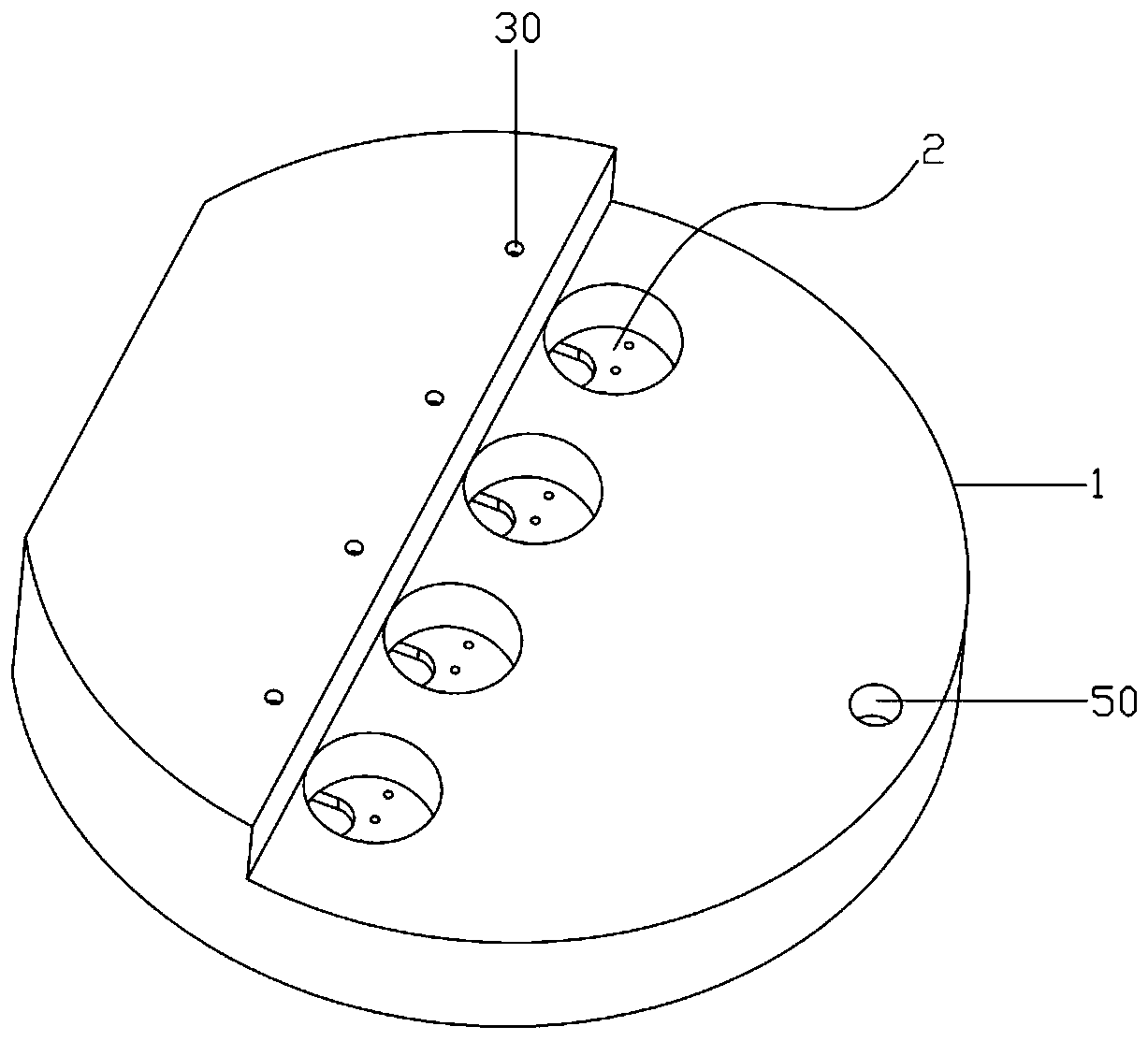

Embryo automatic liquid change culture dish

PendingCN110408540AMeet material needsAvoid harmBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid ChangeInlet channel

The invention discloses an embryo automatic liquid change culture dish including at least one group of culture unit; the culture unit includes a liquid injection pool, a culture pool and a waste liquid chamber which communicate with each other in turn; the upper part of the liquid injection pool communicates with a liquid inlet channel, and the bottom of the liquid injection pool communicates withthe bottom of the culture pool through an overflow channel; the bottom of the culture pool is provided with at least one embryo micropore, and the bottom of the embryo micropore communicates with thewaste liquid cavity through a waste liquid flow channel. The embryo automatic liquid change culture dish can realize complete liquid exchange and effectively meet material requirements required in each development stage of an embryo; through automatic liquid exchange, the damage of repeated manual intervention operation to an embryo culture environment and the damage of the embryo are avoided, the stability of the embryo culture and the quality of a blastocyst can be improved, and the clinical pregnancy rate and the live yield are effectively increased.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Easily dissolved slow release aquaculture feed

InactiveCN106578666APromote growthPromote reproductionFodderClimate change adaptationAquaculture industryPeat

The present invention discloses an easily dissolved slow release aquaculture feed. The feed is characterized by comprising the following raw materials: active peat, zinc fulvic acid, chicken manures, soybean cake, fish meal, sodium alginate and starch. The slow release aquaculture feed comprises the following raw materials in parts by weight: 20-30 parts of active peat, 2-5 parts of zinc fulvic acid, 12-15 parts of chicken manures, 10-20 parts of soybean cake, 15-30 parts of fish meal, 2-5 parts of sodium alginate, and 10-12 parts of starch. The aquaculture feed is safe and environmentally friendly, and free of pollution, and can make use of wastes and realize the natural circulation of the substances. The active peats are added into the aquaculture feed and the feed is more conducive to the growth of aquatic products, can ensure the balance of feed nutrients in the aquatic products, promotes the healthy and sustainable developments of green aquaculture industry, and meets people's needs for the green aquatic products.

Owner:营口富里泥炭科技有限公司

Preparation method of jasmine tea baby sleeping pillow

InactiveCN107411465AEasy to prepareAvoid cold and feverSenses disorderNervous disorderToxic materialParticle coating

A method for preparing a jasmine tea baby sleeping pillow, the process steps are: (1) processing tea dregs; (2) picking jasmine flowers; (3) maintaining jasmine flowers; (4) scenting; (5) baking scented tea; (6) Add traditional Chinese medicine to make granules; (7) Prepare jasmine tea granule coating agent; (8) Coat jasmine tea granules; (9) Select pure cotton fabric to prepare baby sleeping pillow jacket; (10) Prepare non-woven (11) Put the coated jasmine tea into a non-woven bag to become an inner liner; (12) Put the inner liner of the jasmine tea baby sleeping pillow into the jasmine tea baby sleeping pillow jacket, and you can get the jasmine tea baby sleeping pillow pillow. The jasmine tea baby sleeping pillow of the present invention has a unique fragrance that makes people feel comfortable, and also has the effects of nourishing the heart and calming the nerves, clearing heat and detoxifying, clearing the liver and improving eyesight, moistening the intestines and laxatives, reducing phlegm and relieving cough, preventing cold, fever and anorexia. The floral scent is slow released and the pillow has a long lifespan.

Owner:广西巧恩茶业有限公司

Compound meat product quality modifier

InactiveCN111165792AAchieving strong alkaline taste and poor tasteThe defect of realizing the distortion of adding colloidal tasteFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentBiotechnologySODIUM METAPHOSPHATE

The invention discloses a compound meat product quality modifier. The compound meat product quality modifier is characterized by being prepared from the following components in percentage by weight: 1-30 parts of transglutaminase, 1-30 parts of collagen, 5-50 parts of sodium tripolyphosphate, 5-50 parts of sodium pyrophosphate and 5-35 parts of sodium hexametaphosphate. By utilizing the unique function of protein cross-linking of the transglutaminase, the natural collagen is used as a substrate of reaction of the transglutaminase, and the sodium tripolyphosphate, the sodium pyrophosphate and the sodium hexametaphosphate are used for effectively extracting functions of actin and myosin in a meat product. The meat product quality improver is compounded by adding the components with differentfunctions. In addition, trehalose can also be comprised to provide unique water retention and freshness locking functions.

Owner:福建正味生物科技有限公司

Silk quilt with gardenia fragrance

A gardenia-scented mulberry silk quilt, the production steps of which are: (1) placing cooked silkworms on a silk spinning net; (2) stripping off wool sheets; (3) degumming treatment of the wool sheets; (4) washing and dehydrating; 5) Drying of cotton sheets; (6) Weighing of cotton sheets; (7) Cutting of cotton sheets; Put anti-running silk gauze on the top and bottom of the sheet; (10) Cover the two cotton sheets with a layer of tire cover, sew them on three sides, and leave an opening on one side to form a tire core bag; (11) Select gardenia flower buds; (12) Dry Gardenia flower buds; (13) Prepare mixed granules; (14) Coat and dry mixed granules; (15) Prepare non-woven bags; (16) Prepare mixed granules; (17) Finally, fix the mixed granules on core bag, and then place the core bag in the quilt cover. The mulberry silk quilt has good quality, can emit the fragrance of gardenia, releases the fragrance slowly, and can maintain the fragrance for a long time.

Owner:GUANGXI GUIHUA SILK CO LTD

Method for manufacturing jasmine tea old people health care pillow

InactiveCN107692718ADimensions neat and beautifulEasy to preparePillowsNervous disorderOlder peopleBlood circulation

A method for manufacturing a jasmine tea old people health care pillow includes the following steps: (1) processing tea bases; (2) picking up jasmine fresh flower; (3) nursing jasmine fresh flowers; (4) performing scenting; (5) baking flower tea; (6) adding traditional Chinese medicine and manufacturing particles; (7) preparing a jasmine flower particle coating material; (8) coating jasmine flowerparticles; (9) selecting a pure cotton fabric to produce a casing of the old people health care pillow; (10) producing a non-woven bag; (11) putting the coated jasmine flower particles in the non-woven bag to form a liner; and (12) putting the liner of the jasmine tea old people health care pillow in the casing of the jasmine tea old people health care pillow to acquire the jasmine tea old peoplehealth care pillow. The jasmine tea old people health care pillow has unique fragrance, makes people comfortable, can promote blood circulation to arrest pain, can expel wind and remove cold, can slowly release fragrance, and is long in service life.

Owner:广西巧恩茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com