Production method of aluminum alloy base material for 5052 alloy door plate

A production method and aluminum alloy-based technology, applied in the field of aluminum alloy production, can solve problems such as wrinkling on the board surface, achieve high R value, improve melt quality, and stabilize yield ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

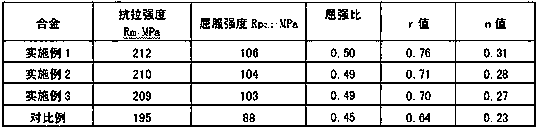

Examples

Embodiment 1

[0018] The steps of the production method of the aluminum alloy base material for the 5052 alloy door panel of the present embodiment include:

[0019] Step 1: Manufacturing aluminum alloy finished products.

[0020] 101. Ingredients.

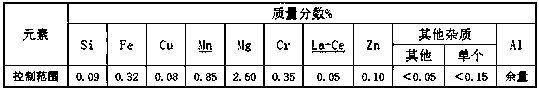

[0021] On the basis of 5052 aluminum alloy, the chemical composition ratio is readjusted. According to metal mass percentage Si <0.10%, Fe <0.35%, Cu<0.10%, Mn <0.10%, Mg is 2.30~2.60%, Cr is 0.15~0.35%, La+Ce is 0.01~0.05%, Zn<0.10 %, the balance is Al.

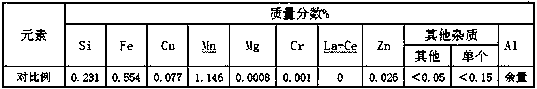

[0022] The composition ratios of the aluminum alloy raw materials in this embodiment are shown in the table below.

[0023]

[0024] It should be pointed out that Table 1 also indicates that the aluminum alloy raw materials contain a small amount of other impurities. The total content of these other impurities is below 0.15%, which is an impurity that cannot be removed in actual production and has no effect on the overall performance of the aluminum alloy base material. will have a sub...

Embodiment 2

[0044] The composition ratios of the aluminum alloy raw materials in this embodiment are shown in the table below.

[0045]

[0046] In this example, La is 0.005%, Ce is 0.005%, and La+Ce is 0.01%; the melting temperature is 730°C; during smelting and heat preservation, 28 minutes of electromagnetic stirring refining and 14 minutes of manual stirring refining are carried out; the casting temperature is 740°C; The temperature of the homogenization treatment is 540°C, and the holding time is 10 hours; the finishing temperature of the hot continuous rolling is 300°C, and the average pass reduction is 20mm; the cleaning parameters before annealing: the cleaning water temperature is 85°C, the cleaning The water pressure is 52mpa, and the cleaning speed is controlled to be 95m / min; in the annealing step, the annealing temperature is 300°C, the holding time is 4 hours, and then the furnace is cooled at a rate of 30°C per hour; the elongation rate is set during straightening 0.9%, ...

Embodiment 3

[0048] The composition ratios of the aluminum alloy raw materials in this embodiment are shown in the table below.

[0049]

[0050] In this example, La is 0.012%, Ce is 0.015%, and La+Ce is 0.027%; the melting temperature is 735°C; during smelting and heat preservation, 28 minutes of electromagnetic stirring refining and 15 minutes of manual stirring refining are carried out; the casting temperature is 735°C; The temperature of the homogenization treatment is 542°C, and the holding time is 12 hours; the finishing temperature of hot continuous rolling is 326°C, and the average pass reduction is 22mm; the cleaning parameters before annealing: the cleaning water temperature is 80°C, the cleaning water The pressure is 50mpa, and the cleaning speed is controlled to be 85m / min; in the annealing step, the annealing temperature is 310°C, the holding time is 4 hours, and then the furnace is cooled at a speed of 40°C per hour; the elongation rate is set to 1.0%, the flatness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com