Low-temperature low-yield steel and manufacturing method thereof

A production method and low-yield technology, applied in the field of steelmaking, can solve the problems of small rolling force, prone to mixed crystals, narrow rolling temperature window, etc., and achieve the effect of low cost, meeting material requirements, and good material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

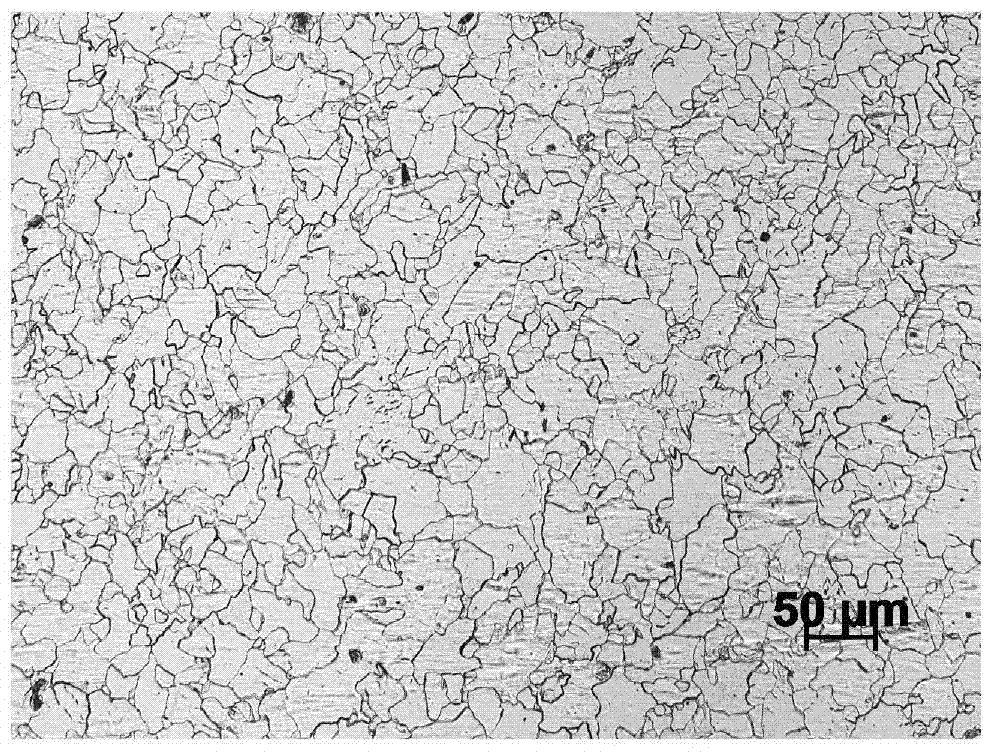

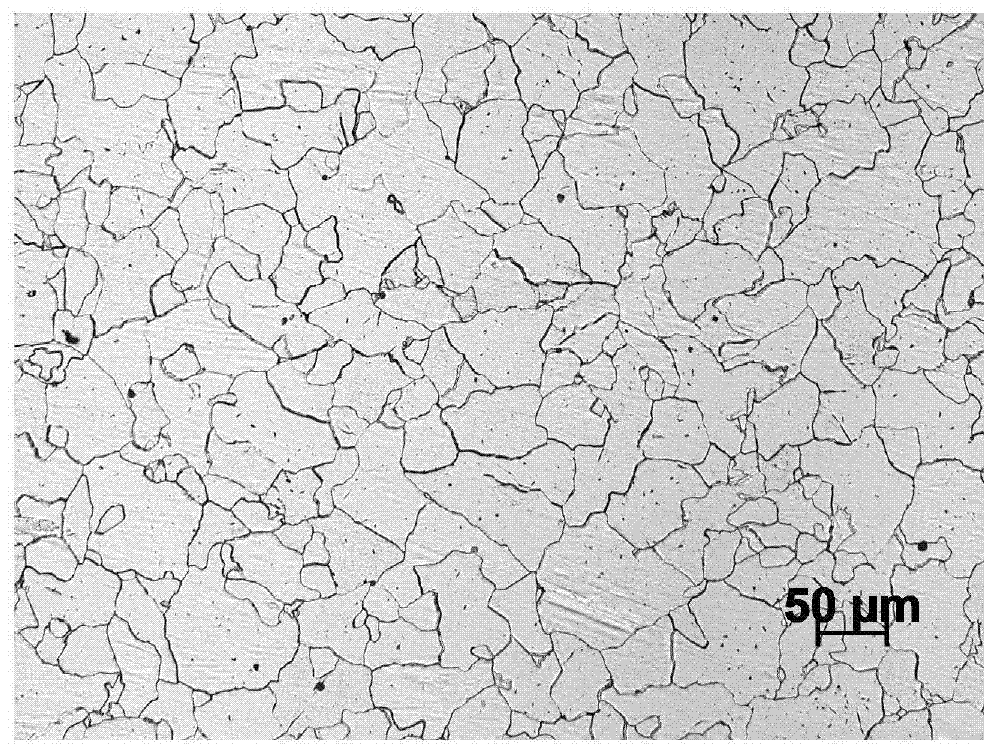

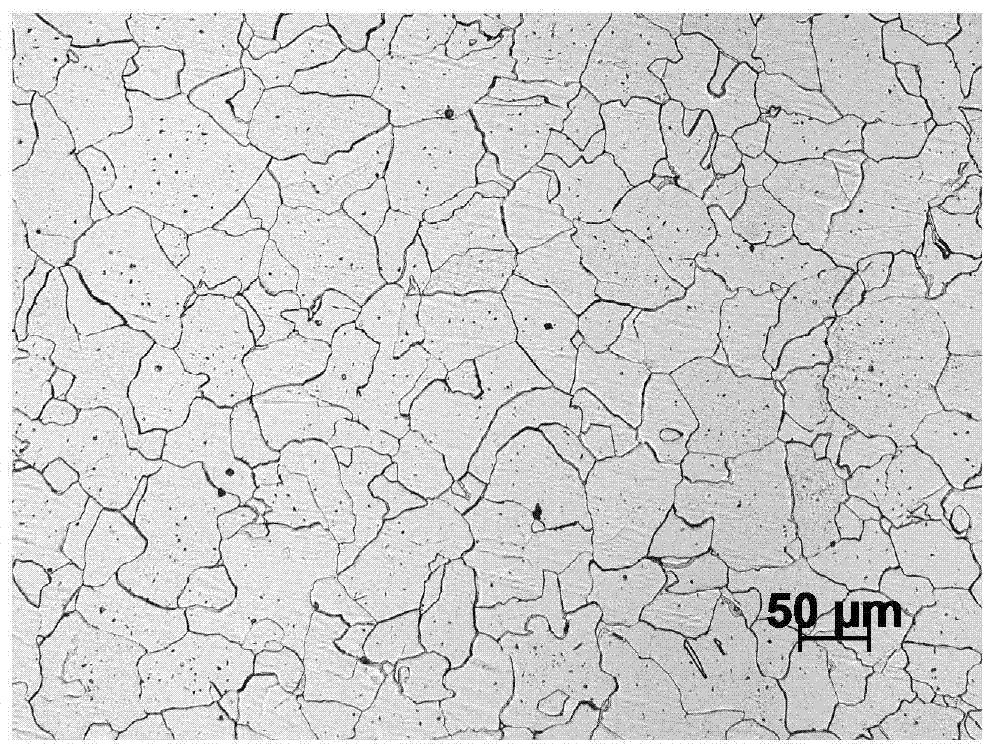

[0022] The production method of a low-temperature low-yield steel provided in this embodiment includes a smelting process, a continuous casting process, a rolling process, and a heat treatment process. Harmful gas N, H content, using LF refining for deoxidation, desulfurization, alloying, and finally slab continuous casting, the chemical composition of the cast slab meets: C: 0.01-0.04%, Si: 0.14-0.3%, Mn: 0.3-0.5%, P≤0.013%, S≤0.005%, Nb: 0.01-0.035%, and the balance is iron and unavoidable impurity elements.

[0023] (1) According to the production process of the present invention, considering the low strength requirements, the composition design adopts the addition of a small amount of Nb alloy elements in the near-pure iron composition to prevent the high temperature state from heating the original crystal so as to ensure its low temperature impact toughness under low yield conditions . The actual chemical composition of the steel grade of the present invention is as show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com