Fully-constrained weak-sparse metal powder explosive compaction and powder plate explosion cladding method

A metal plate and metal powder technology, which is applied in the field of explosive composites, can solve the problems of inability to prepare composite materials by plate-to-board, the difficulty of combining metal powder and plates, and the high equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

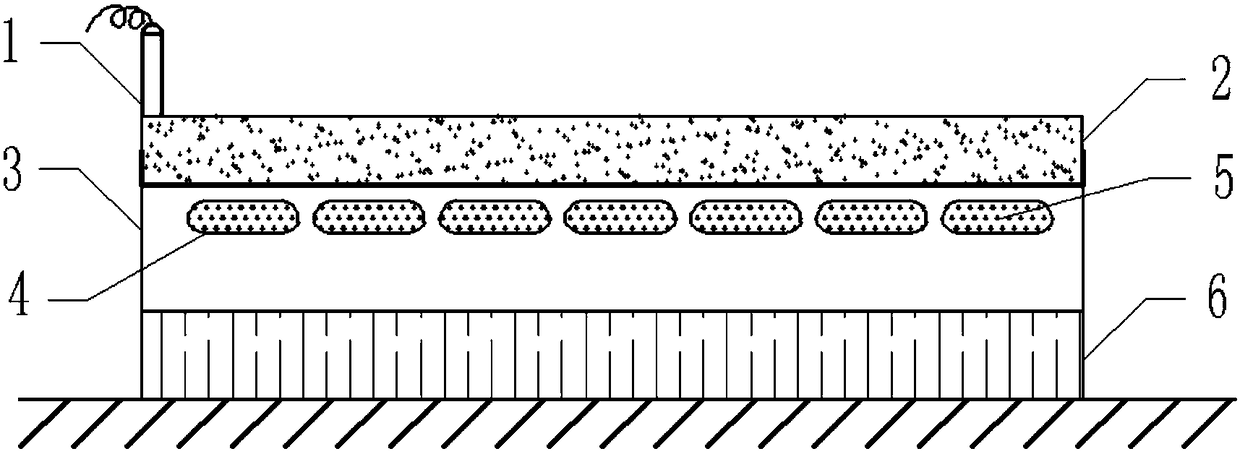

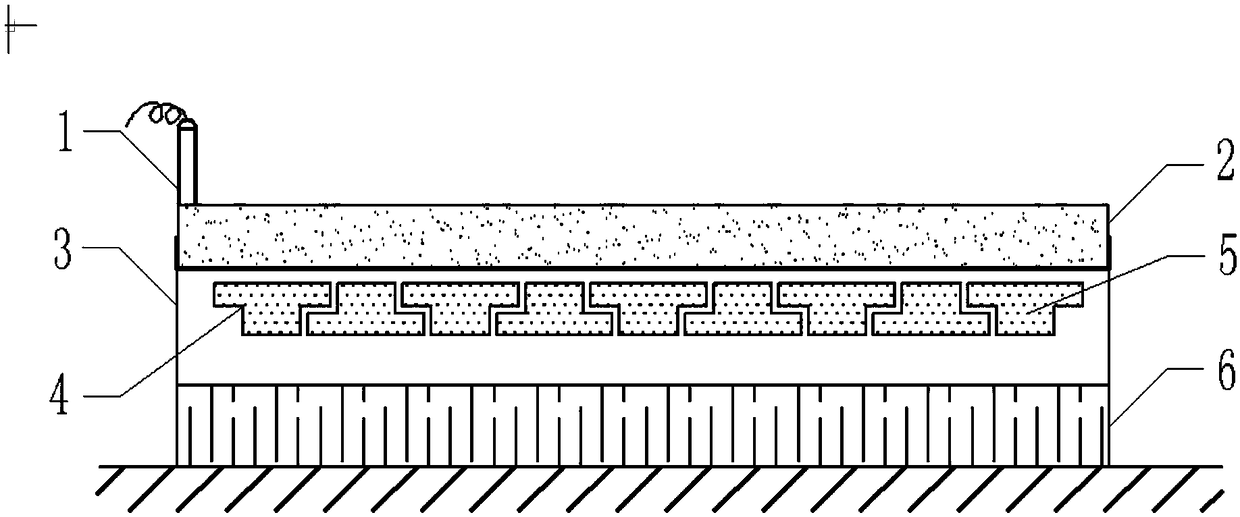

example 1

[0028] Explosive 2 adopts industrial emulsion explosive with a density of 1.1g / cm 3 , dosage is 150g. Metal plate 3 is made of T2 red copper, with a size of 80×100×12mm 3 , the shape of opening 4 is figure 1 As shown, the specific size is the middle rectangle 10×4mm 2 , both ends are a semicircle of φ4mm, the distance between the centers of the two openings is 16mm, the upper end of the opening is 2mm from the upper surface of the metal plate, and the lower end of the opening is 6mm from the lower surface of the metal plate. The metal powder 5 is tungsten powder with a particle size of 1-3 μm, and the packing density is 5 g / cm 3 . Clean and polish the inner wall of the opening before filling the powder. After filling the metal powder 5 and sealing it, if figure 1 Place all the components, place the backing plate 6, the metal plate 3, and the explosive 2 horizontally from bottom to top in order, and use edge detonation, and the detonator 1 is located at the midpoint of th...

example 2

[0030] Explosive 2 adopts industrial emulsion explosive with a density of 1.1g / cm 3 , dosage is 150g. Metal plate 3 is made of T2 red copper, with a size of 80×100×12mm 3 , the shape of opening 4 is figure 1 As shown, the specific size is the middle rectangle 10×4mm 2 , both ends are a semicircle of φ4mm, the distance between the centers of the two openings is 16mm, the upper end of the opening is 2mm from the upper surface of the metal plate, and the lower end of the opening is 6mm from the lower surface of the metal plate. Metal powder 5 is tungsten powder with a particle size of 45 μm and a packing density of 4.5 g / cm 3 . Clean and polish the inner wall of the opening before filling the powder. After filling the metal powder 5 and sealing it, if figure 1 Place all the components, place the backing plate 6, the metal plate 3, and the explosive 2 horizontally from bottom to top in order, and use edge detonation, and the detonator 1 is located at the midpoint of the side...

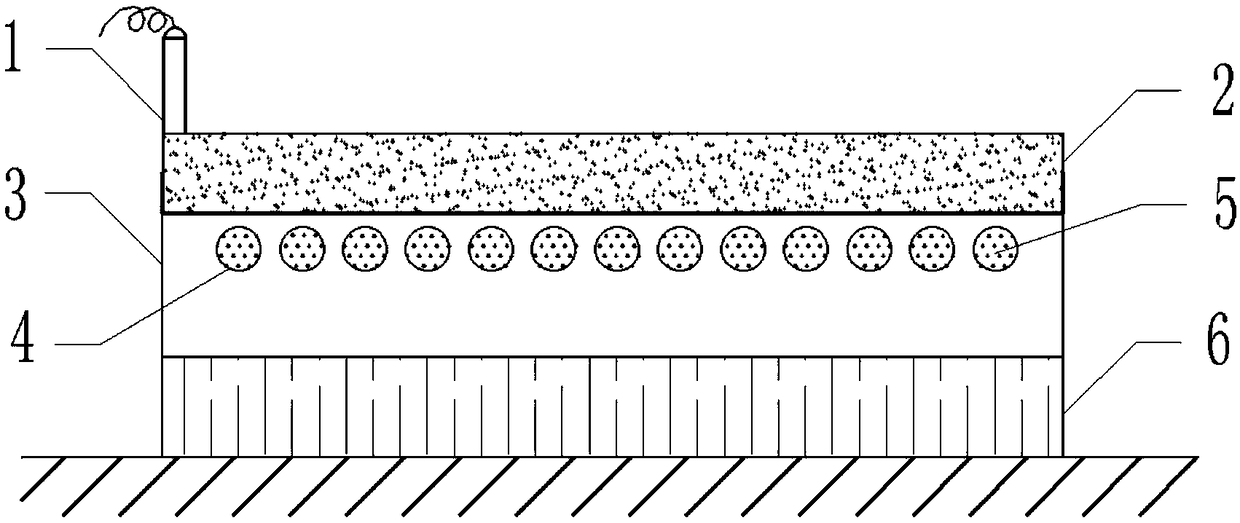

example 3

[0032] Explosive 2 adopts industrial emulsion explosive with a density of 1.1g / cm 3 , dosage is 150g. Metal plate 3 is made of T2 red copper, with a size of 80×100×12mm 3 , the shape of opening 4 is figure 2As shown, it is a round hole of φ5mm, the distance between the centers of the two openings is 12mm, the upper end of the opening is 2mm from the upper surface of the metal plate, and the lower end of the opening is 5mm from the lower surface of the metal plate. Metal powder 5 is tungsten powder with a particle size of 45 μm and a packing density of 4.6 g / cm 3 . Clean and polish the inner wall of the opening before filling the powder. After filling the metal powder 5 and sealing it, if figure 1 Place all the components, place the backing plate 6, the metal plate 3, and the explosive 2 horizontally from bottom to top in order, and use edge detonation, and the detonator 1 is located at the midpoint of the side of the explosive 2 perpendicular to the opening direction. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com