Method for controlling twist redistribution

A re-distribution and bearding technology, applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of inconvenient system installation, unfavorable large drafting, complex structure of the rear area, etc., to achieve increased compactness, Prevent twist redistribution and maintain uniform drafting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

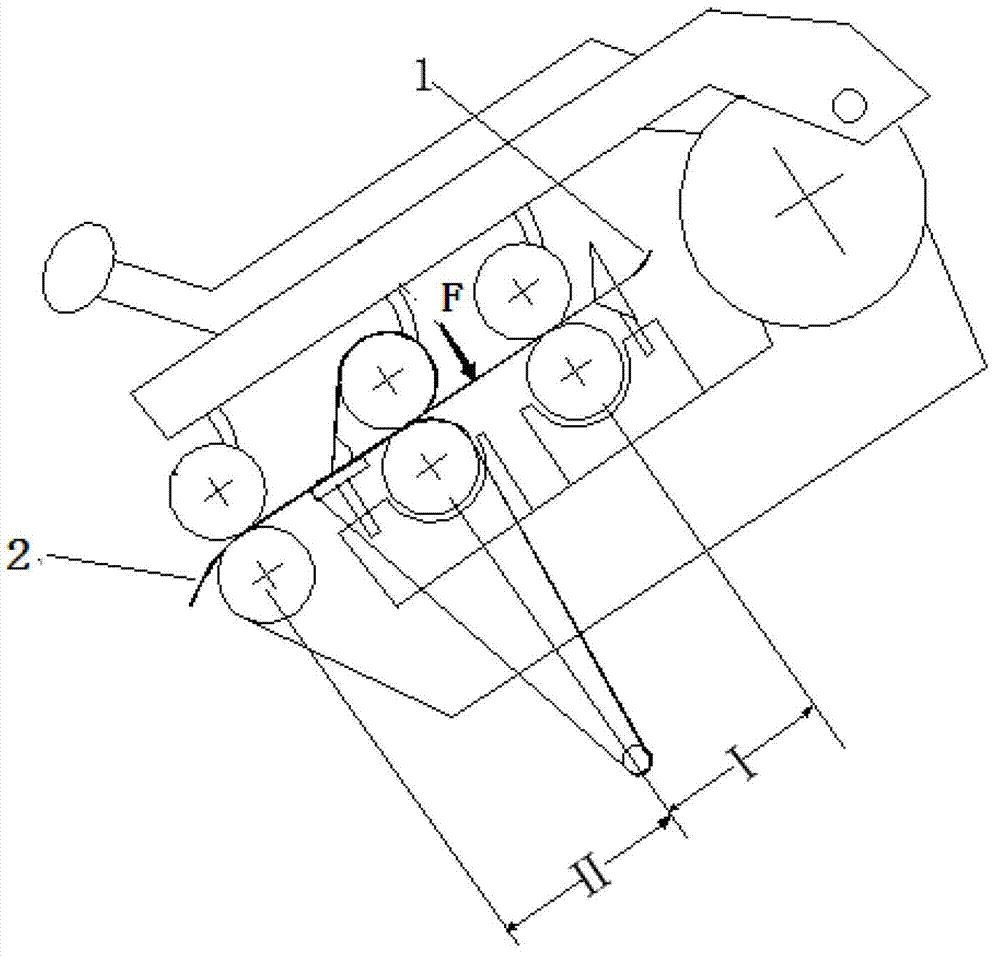

[0024] Taking pure cotton combed 14.6tex yarn spun by EJM128K spinning frame as an example, the roving strand 1 with a basis weight of 4.83g / ·10m and a twist coefficient of 144 is fed from the bell mouth, and the twist coefficient of the spun yarn is set at 380. The stretch ratio is set to 1.88, the total draft ratio is set to 33.03, no pressure is applied, and after the drafting effect of the rear draft zone I and the front draft zone II, it is twisted into a spun yarn 3, and the yarn quality is as shown in Table 1. Show.

Embodiment 2

[0026] Taking pure cotton combed 14.6tex yarn spun by EJM128K spinning frame as an example, the roving sliver 1 with a basis weight of 4.83g / ·10m and a twist coefficient of 144 is fed from the bell mouth, and the twist coefficient of the spun yarn is set at 380, and is pulled In stretch zone II, the positioning guide wheel driven by rolling bearings installed on the cradle exerts a positive pressure downward, the pressure is 10N / spindle, the draft ratio of the rear zone is set to 1.88, and the total draft ratio is set to 33.03. After the drafting in the rear drafting zone I and the front drafting zone II, the spun yarn 3 is twisted, and the yarn quality is shown in Table 1.

Embodiment 3

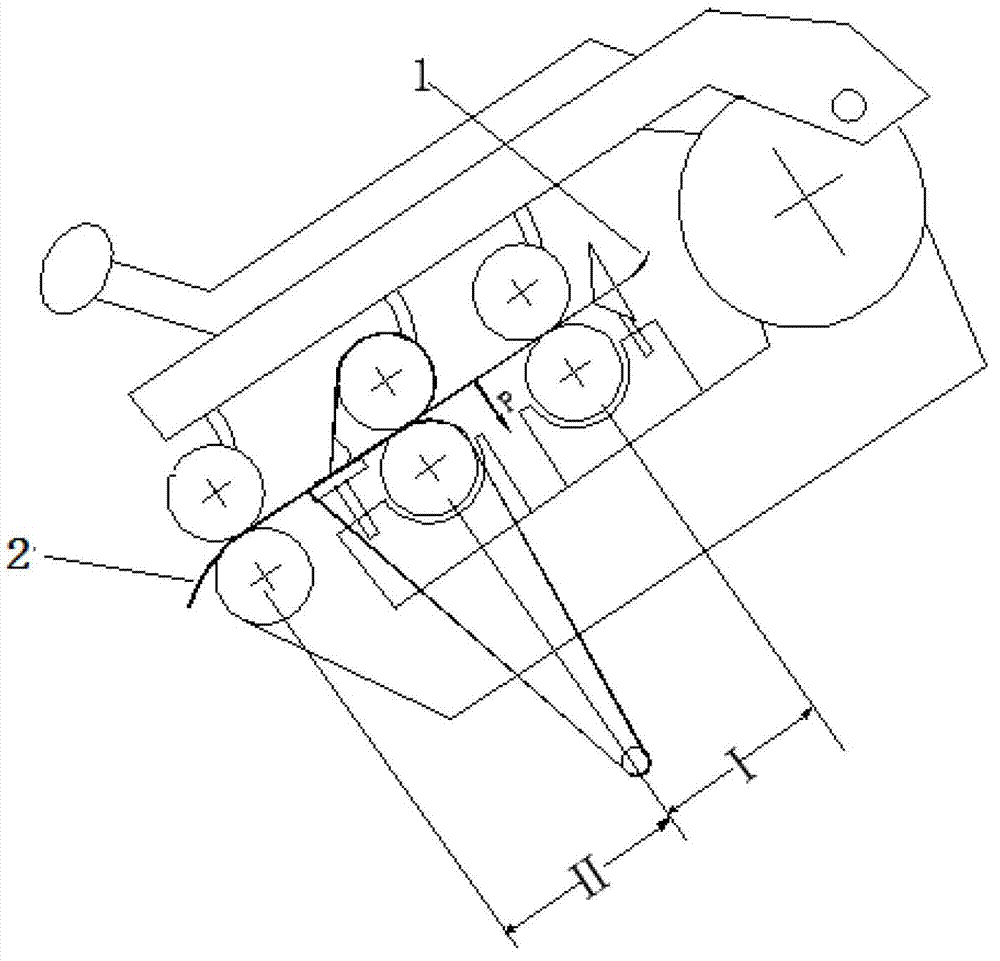

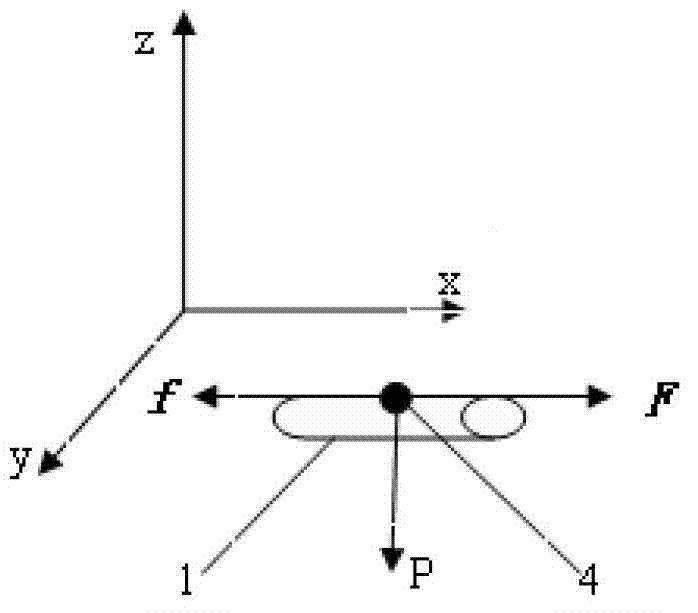

[0028] Still using the EJM128K spinning frame to spin pure cotton combed 14.6tex yarn, the roving sliver 1 with a basis weight of 4.83g / 10m and a twist coefficient of 144 is fed from the bell mouth, and the twist coefficient of the spun yarn is set at 380. The perforated upper apron is used on the roller to cooperate with the upper pin with a hollow structure, and the bottom plane of the lower pin contains air outlet holes, and the corresponding lower pin is added to the rear end of the middle roller to form the jaw in the rear area. The upper part of the hollow lower pin contains negative pressure suction Channel, the negative pressure airflow applied is 3000Pa, the negative pressure airflow acts on the whiskers at the jaws through the air outlet hole of the hollow lower pin and the hole on the perforated upper apron, and then generates reverse pressure on the whiskers passing through the force application point 4 P , the reverse pressure P Frictional resistance to moving whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com