A Three-way Motion Decoupled Periodic Structure for Shaker Model Box

A technology of periodic structure and vibrating table, which is applied in the field of civil engineering, can solve the problems of difficult control of precision, impossibility of realization, horizontal hardening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

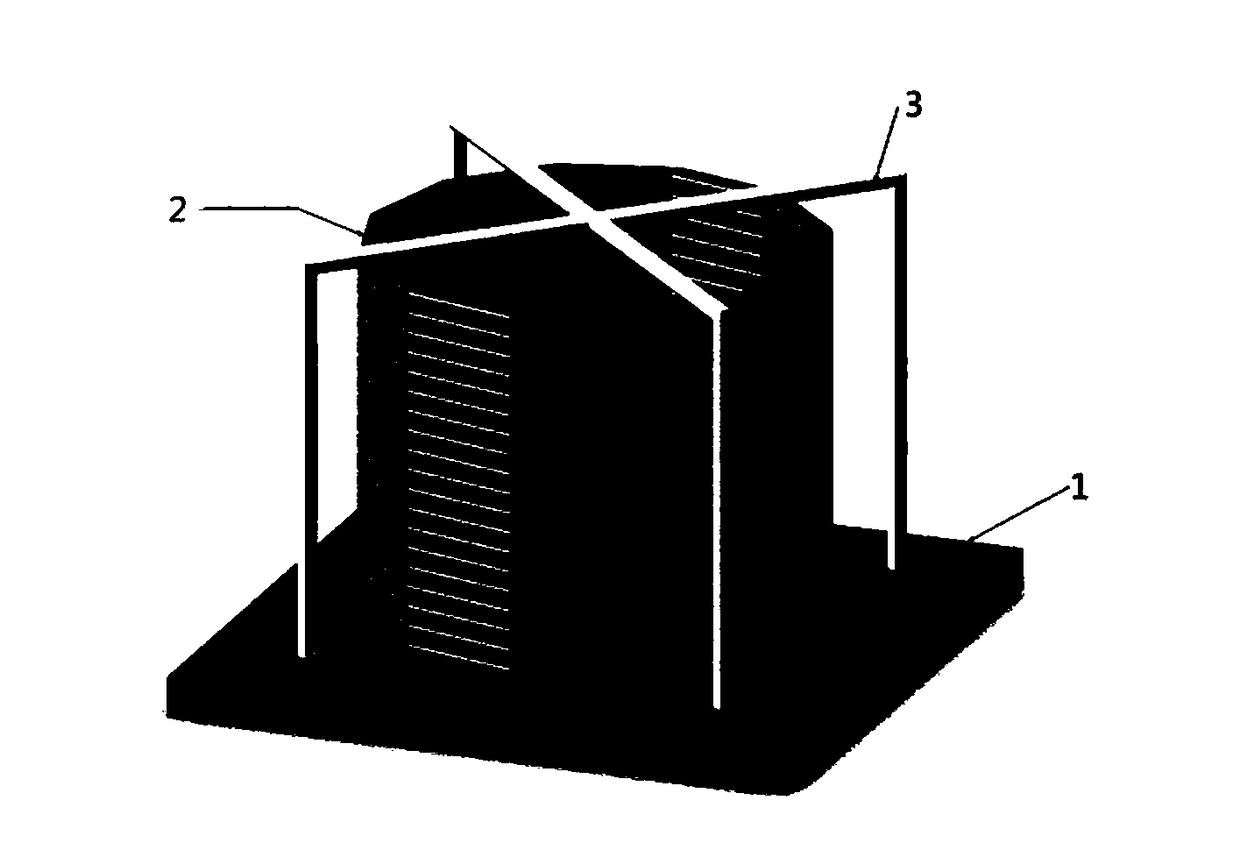

Embodiment 1

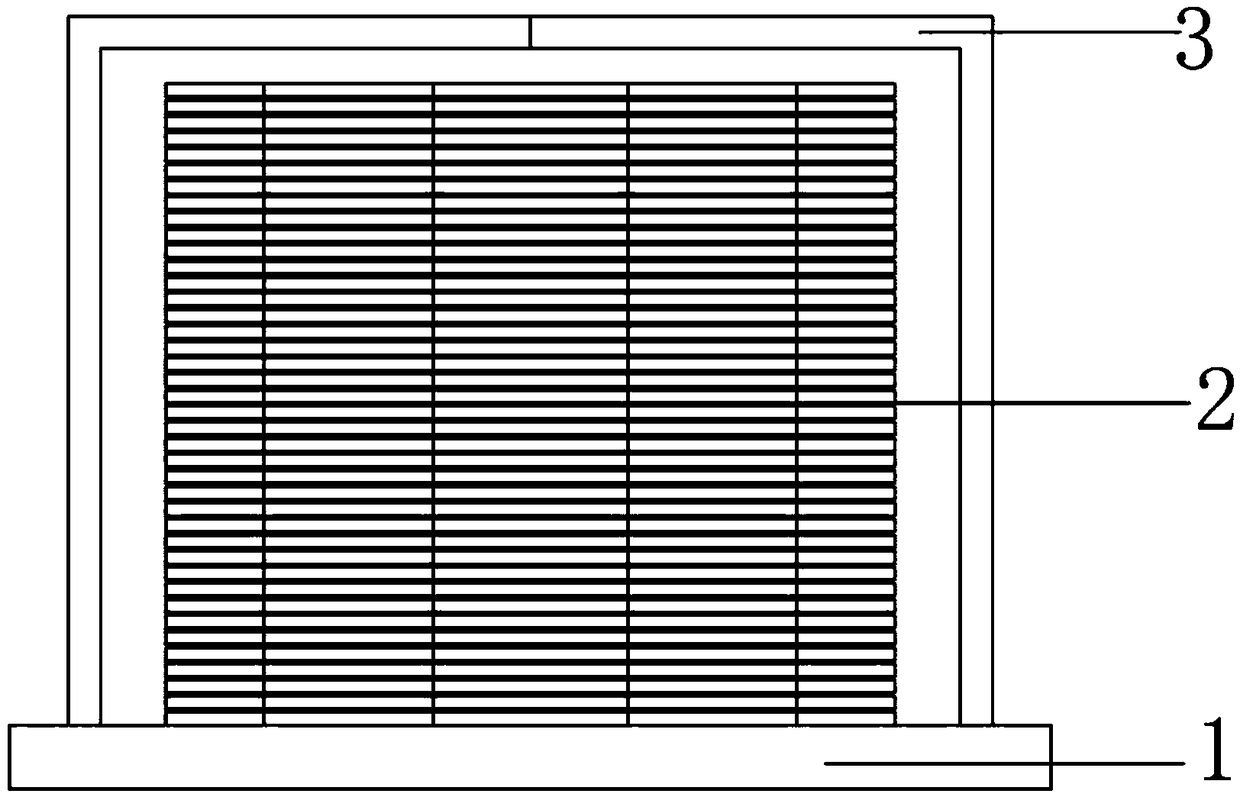

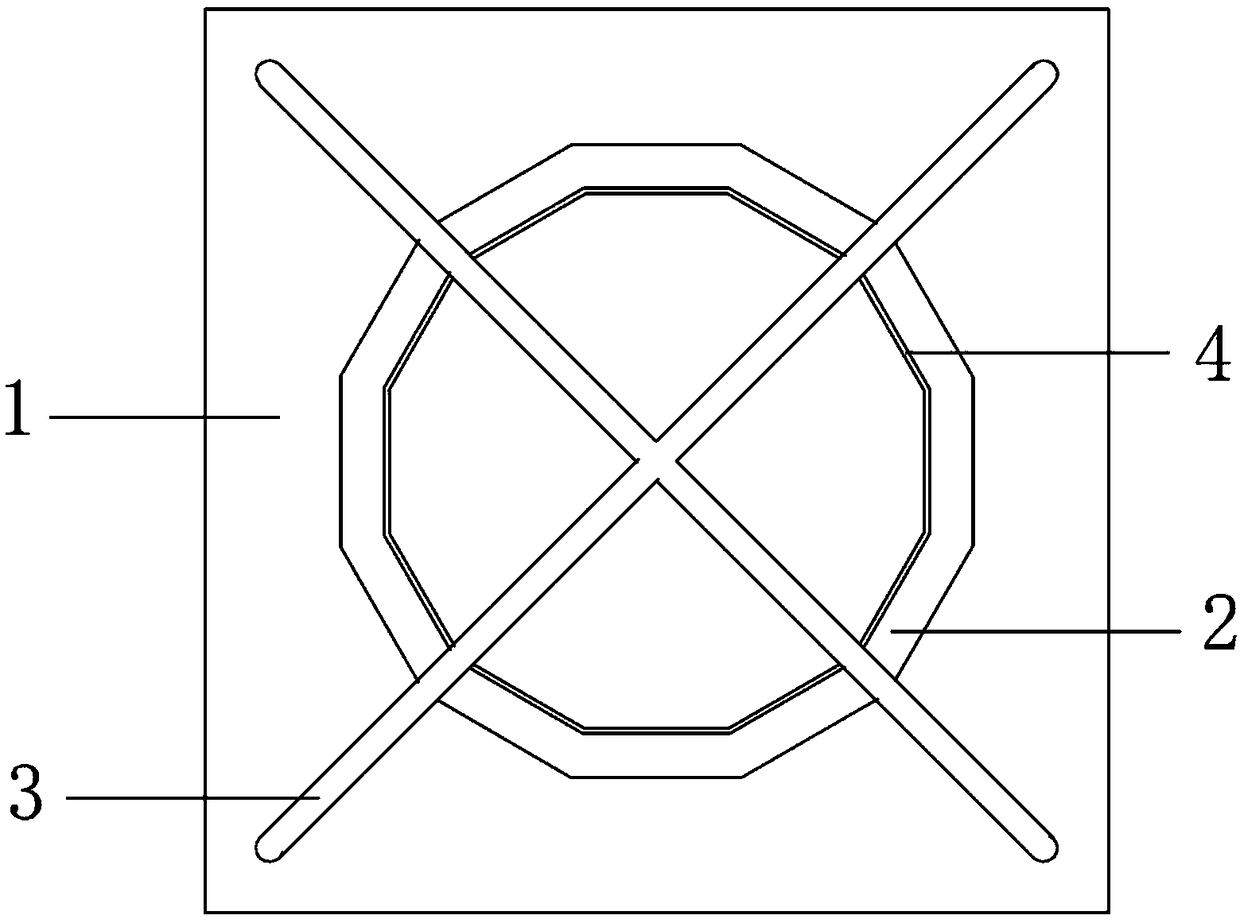

[0104] The shearing model box 1 is formed by stacking regular dodecagonal stacked ring periodic structures. The length of each side on the periphery of the periodic structure is 13.1 cm, and the radius of the inscribed circle is 50 cm. The periodic structure of each layer is made of high-strength lightweight aluminum-magnesium alloy, and the overall height of the model box is 61cm. The model box of the three-way vibration table has a total of 10 periodic structures. The regular dodecagonal aluminum-magnesium alloy ring is 25mm high per layer. Adjacent periodic structures are connected by 10mm thick special rubber and pressed into shape. The regular dodecagonal aluminum alloy ring The width of the gap between them is 1mm; a circular groove is formed at the center of each side of the regular dodecagonal aluminum-magnesium alloy ring with a periodic structure, a total of 12 circular grooves; steel balls are placed in the circular grooves, A ball is placed in each circular groove;...

Embodiment 2

[0106] The shearing model box 2 is made of a circular stacked ring periodic structure, the radius of the inscribed circle is 60cm, and the radius of the circumscribed circle is 62cm. The periodic structure of each layer is made of high-strength and lightweight boron aluminum alloy, and the overall height of the model box is 51cm. The three-way vibration table model box has a total of 10 periodic structures. The regular dodecagonal aluminum alloy ring is 20mm high per layer. Adjacent periodic structures are connected by 10mm thick special rubber and pressed into shape. The gap between the circular boron aluminum alloy rings The width of the circular boron aluminum alloy ring is 1mm; circular grooves are evenly formed in the center of the periphery of the circular boron aluminum alloy ring with a periodic structure, a total of 16 circular grooves; steel balls are placed in the circular grooves, and each circular groove Place a ball; the maximum displacement between layers is 2.5...

Embodiment 3

[0108] The shearing model box 3 is formed by stacking regular octagonal stacked ring periodic structures. The length of each side on the periphery of the periodic structure is 14.2 cm, and the radius of the inscribed circle is 45 cm. The periodic structure of each layer is formed by high-strength carbon fiber filled with epoxy resin, and the overall height of the model box is 71cm. The three-way vibration table model box has a total of 10 periodic structures. The regular octagonal high-strength carbon fiber ring is 30mm high per layer. Adjacent periodic structures are connected with 10mm thick special rubber and pressed into shape. The gap between the regular octagonal high-strength carbon fiber rings The width is 1mm; a circular groove is formed at the center of each side of the regular octagonal high-strength carbon fiber ring of the periodic structure, a total of 8 circular grooves; steel balls are placed in the circular groove, and each circular groove A ball is placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com