Patents

Literature

82 results about "Stretch zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

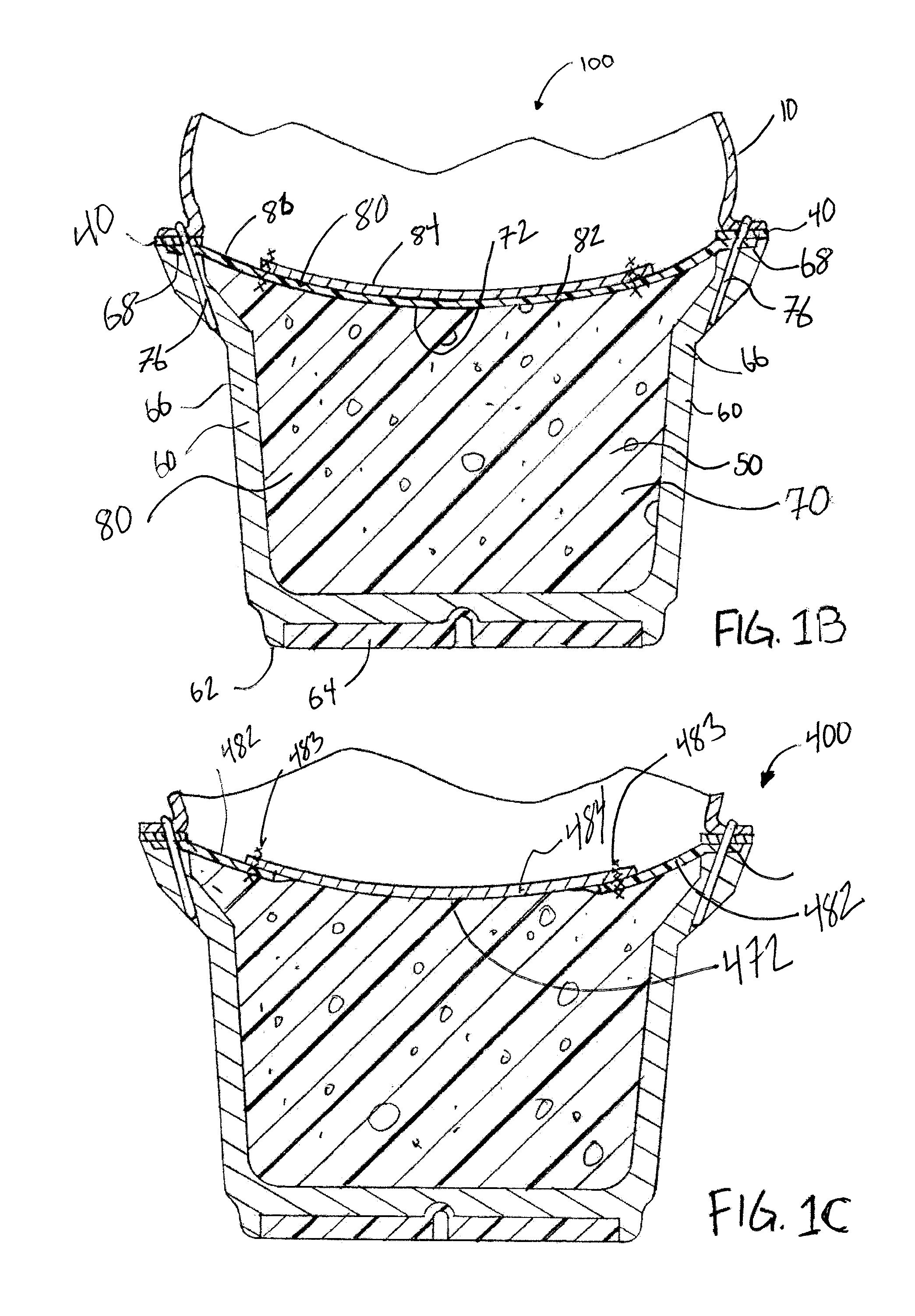

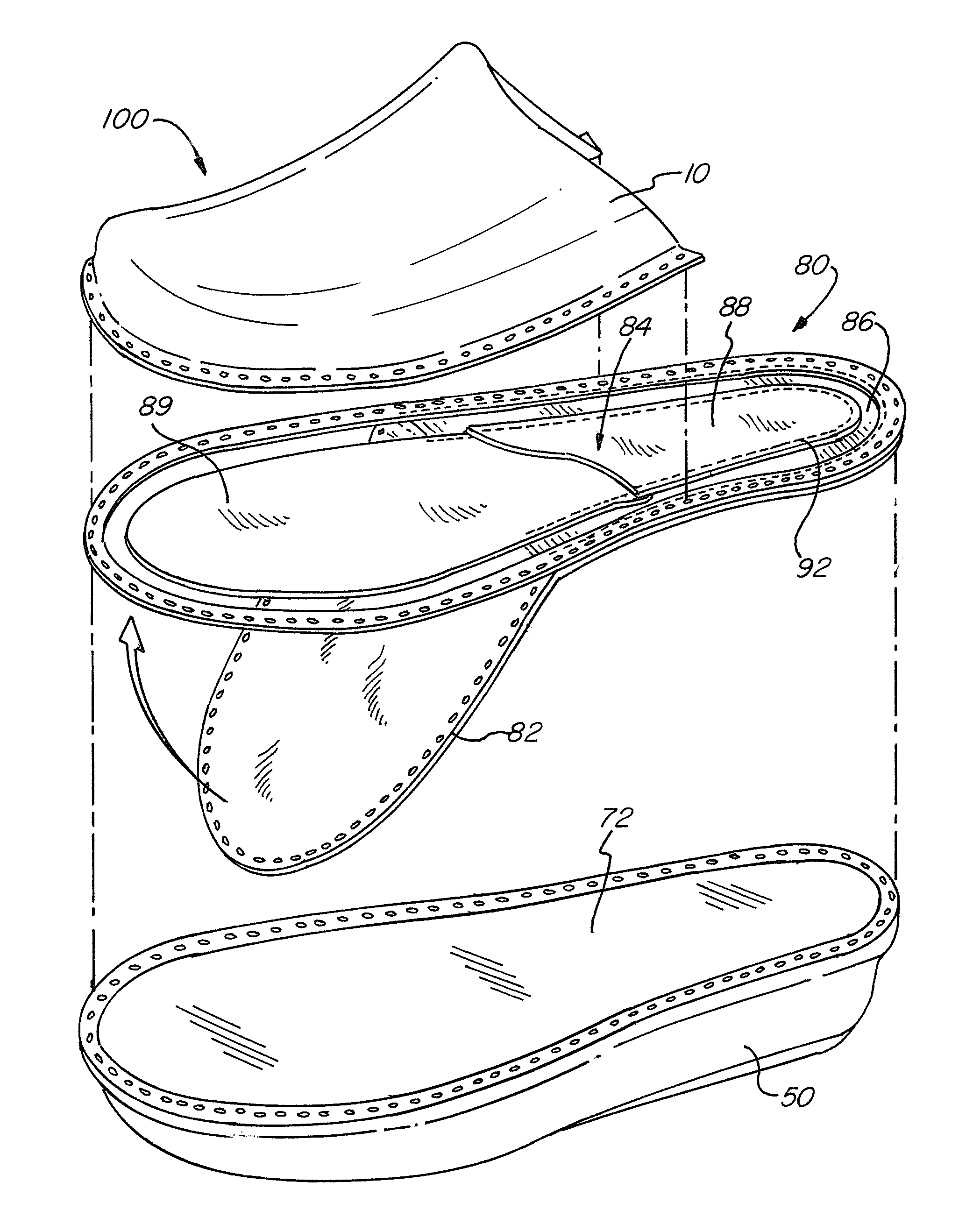

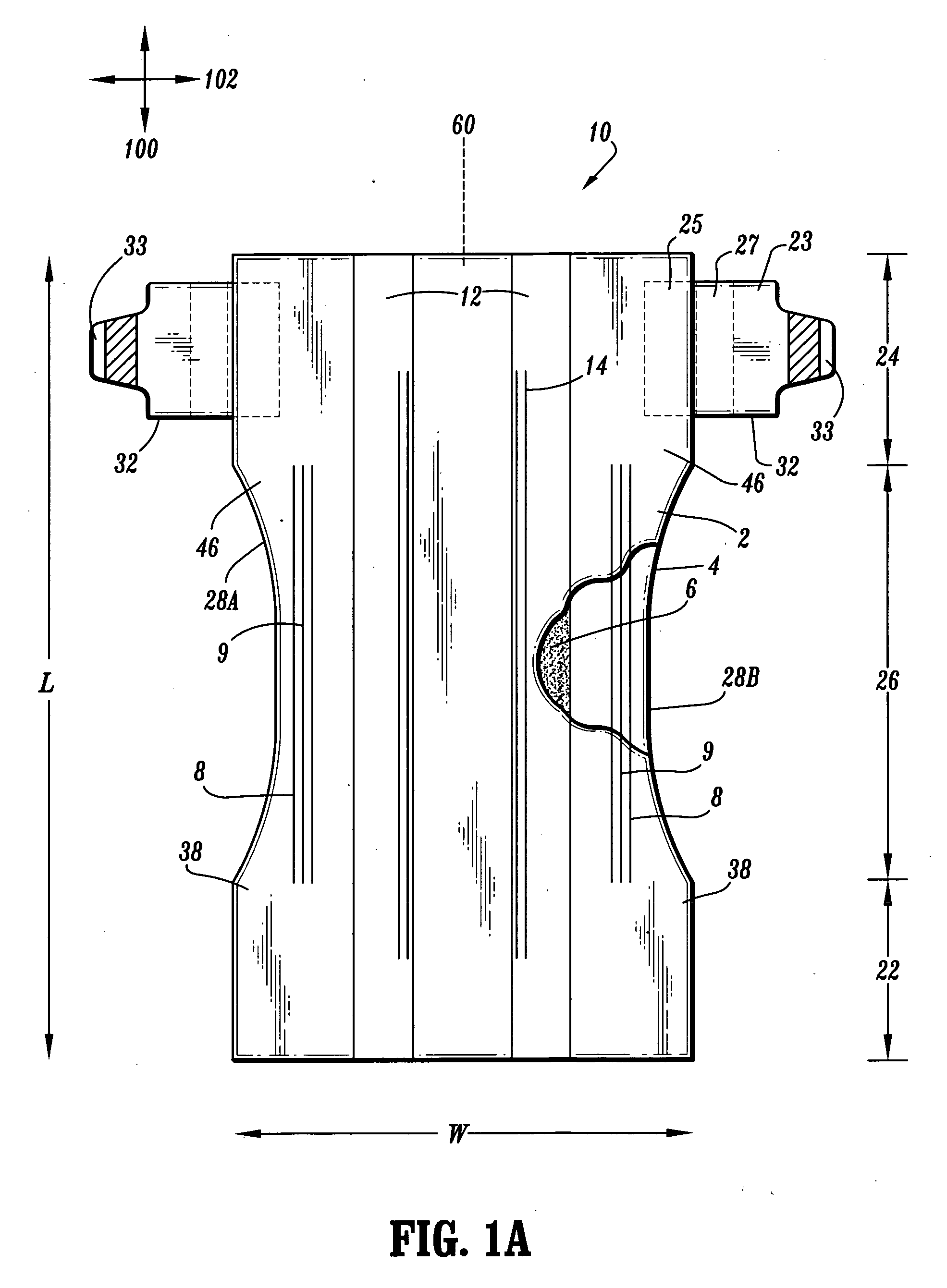

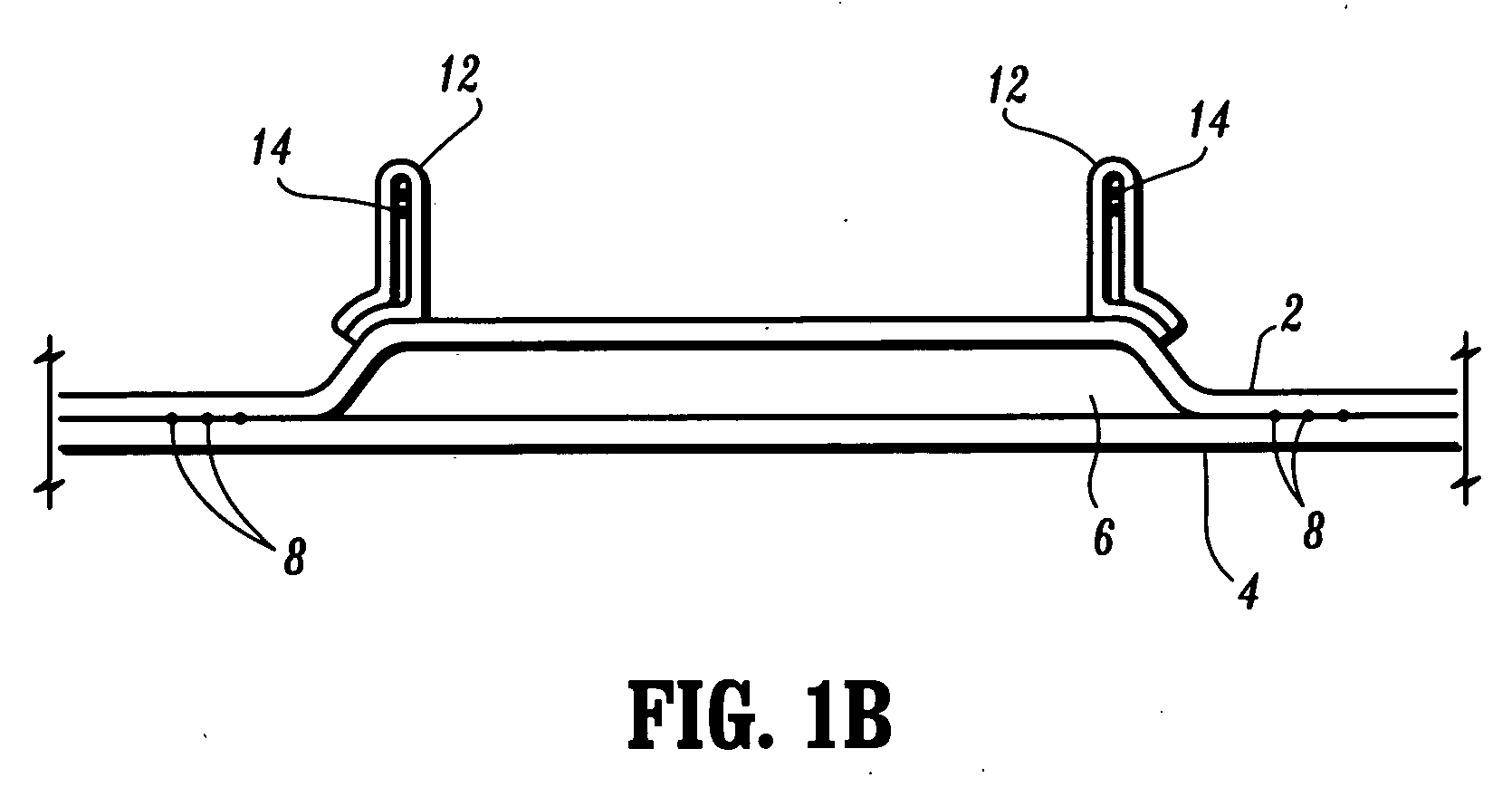

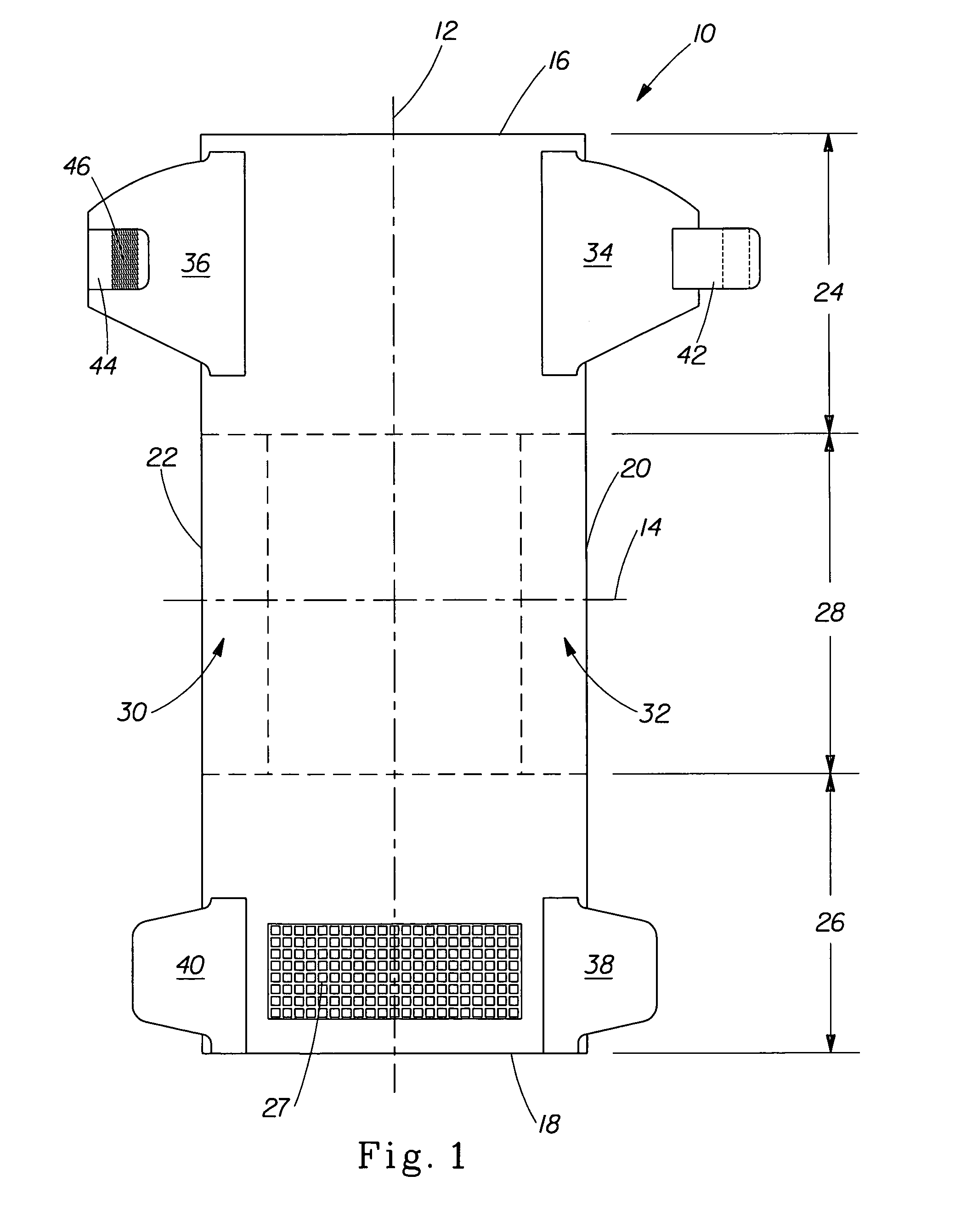

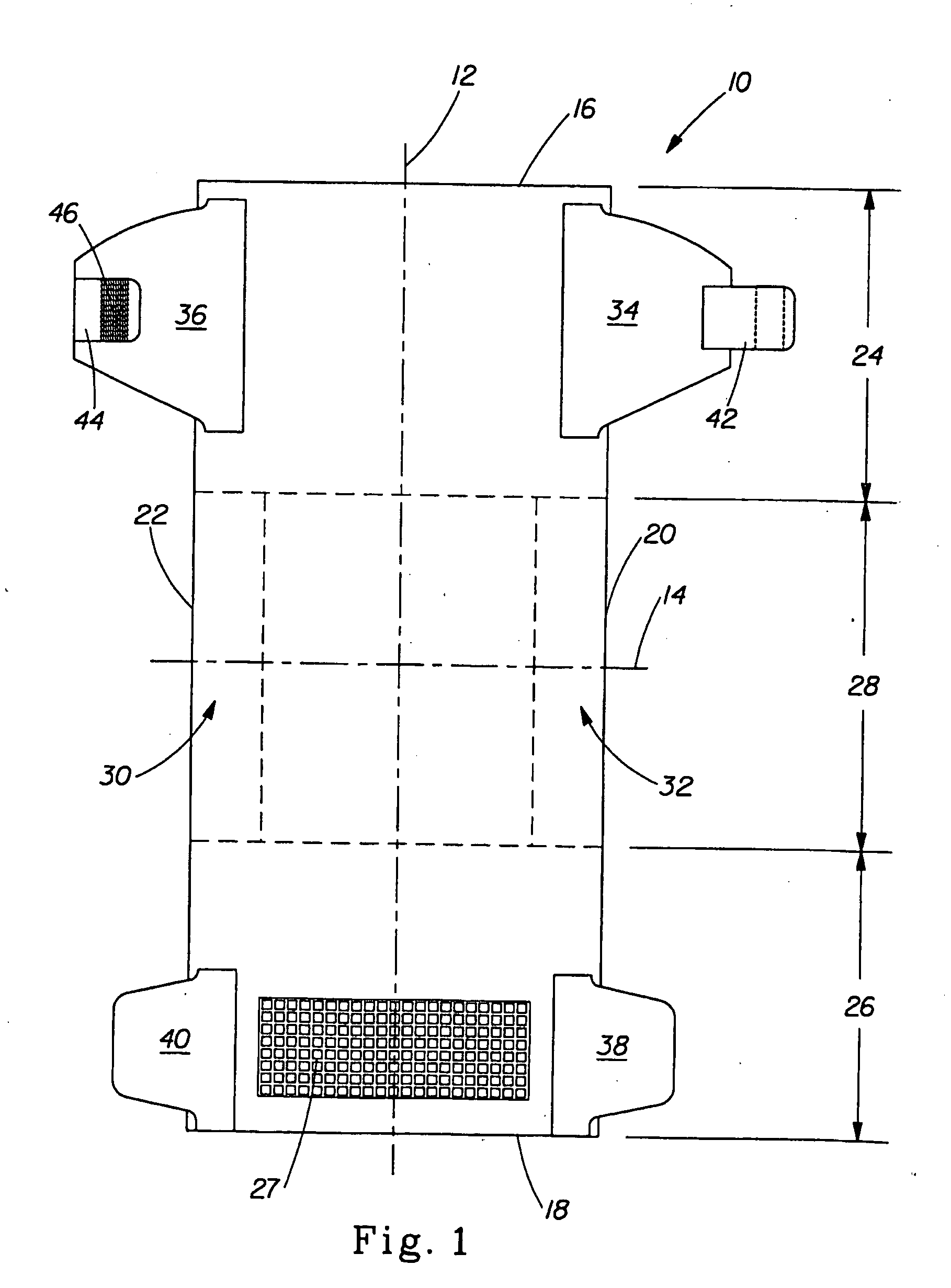

Disposable absorbent articles with zones comprising elastomeric components

Absorbent articles having a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core disposed between said topsheet and said backsheet are disclosed. The absorbent articles include a thermoplastic elastomer joined to or disposed in a stretch zone on at least one component or region of the absorbent article to impart an elastic resistance that provides sizing or shaping capabilities to the article. The absorbent article can be in the form of diapers, pull-on diapers, training pants, sanitary napkins, wipes, bibs, incontinence briefs or inserts.

Owner:THE PROCTER & GAMBLE COMPANY

Disposable absorbent articles with zones comprising elastomeric components

Absorbent articles having a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core disposed between said topsheet and said backsheet are disclosed. The absorbent articles include a thermoplastic elastomer joined to or disposed in a stretch zone on at least one component or region of the absorbent article to impart an elastic resistance that provides sizing or shaping capabilities to the article. The absorbent article can be in the form of diapers, pull-on diapers, training pants, sanitary napkins, wipes, bibs, incontinence briefs or inserts.

Owner:THE PROCTER & GAMBLE COMPANY

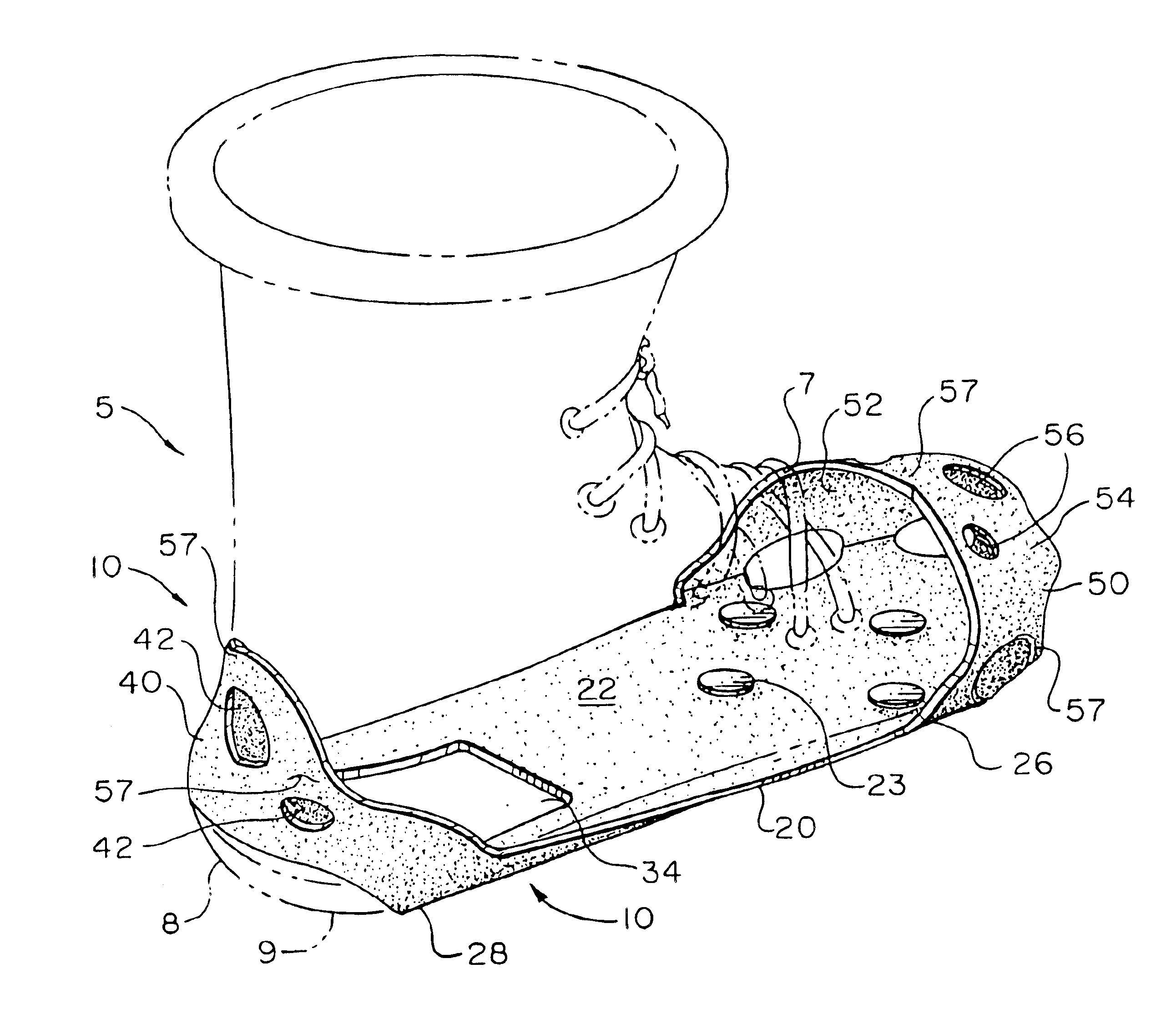

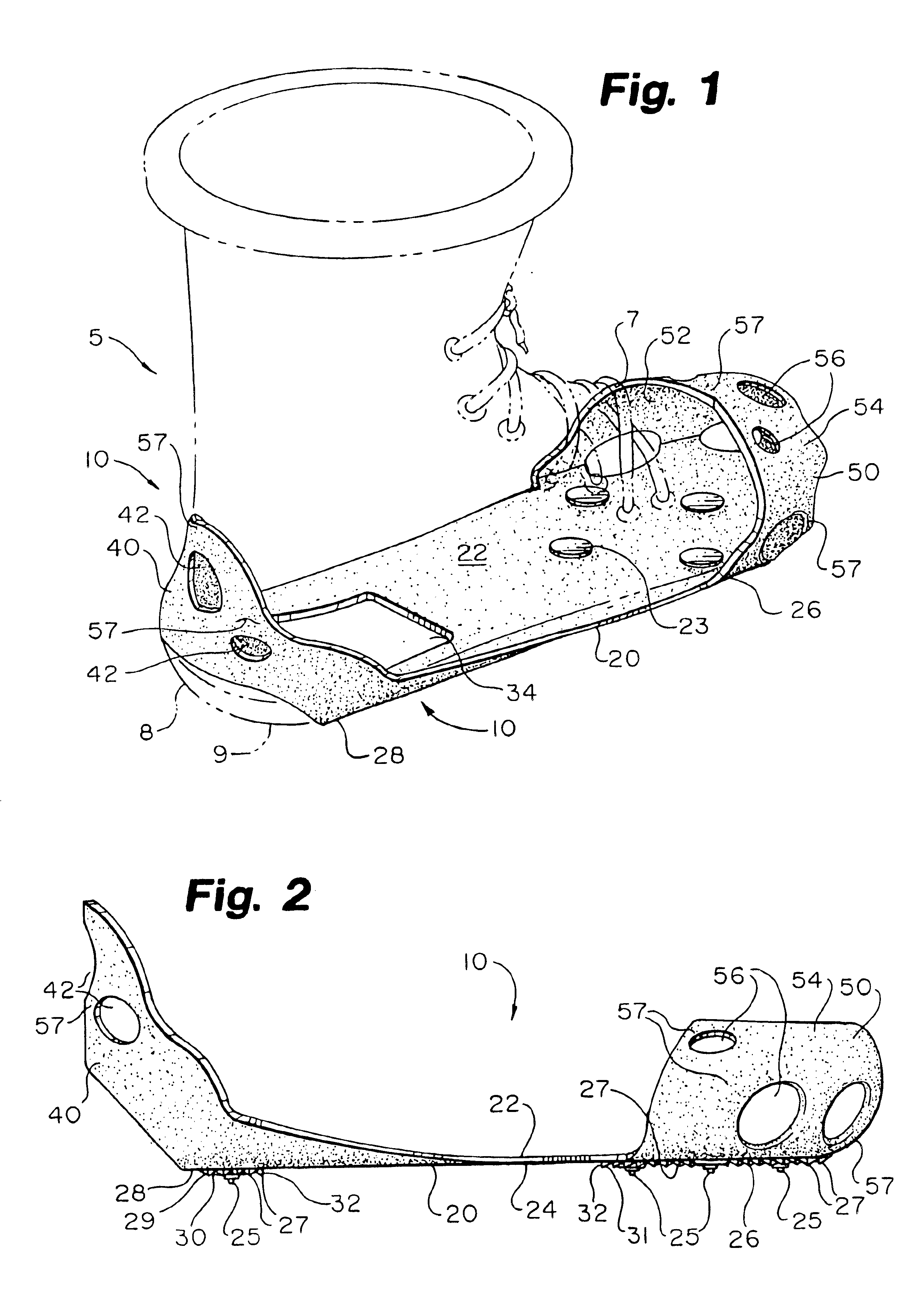

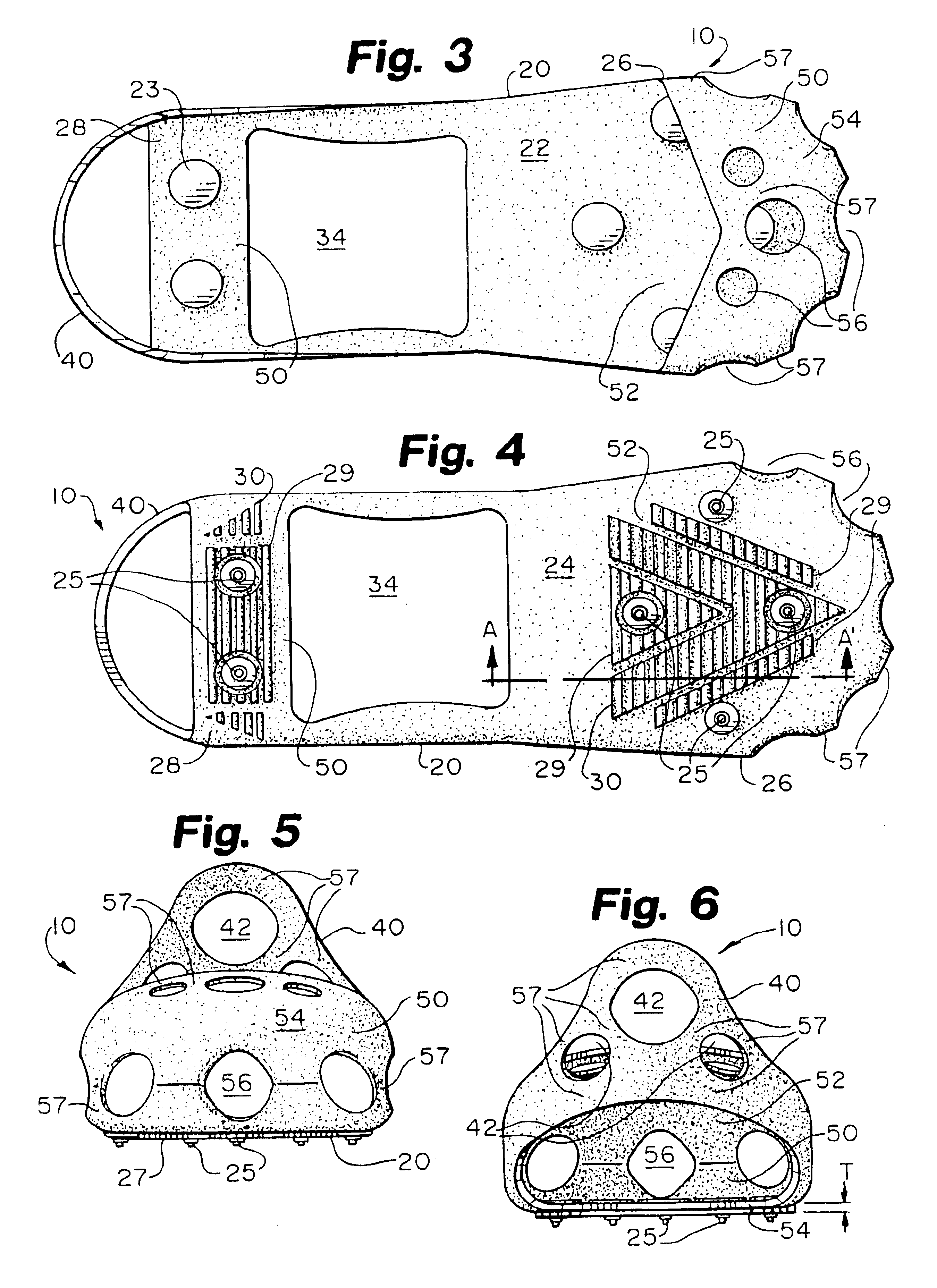

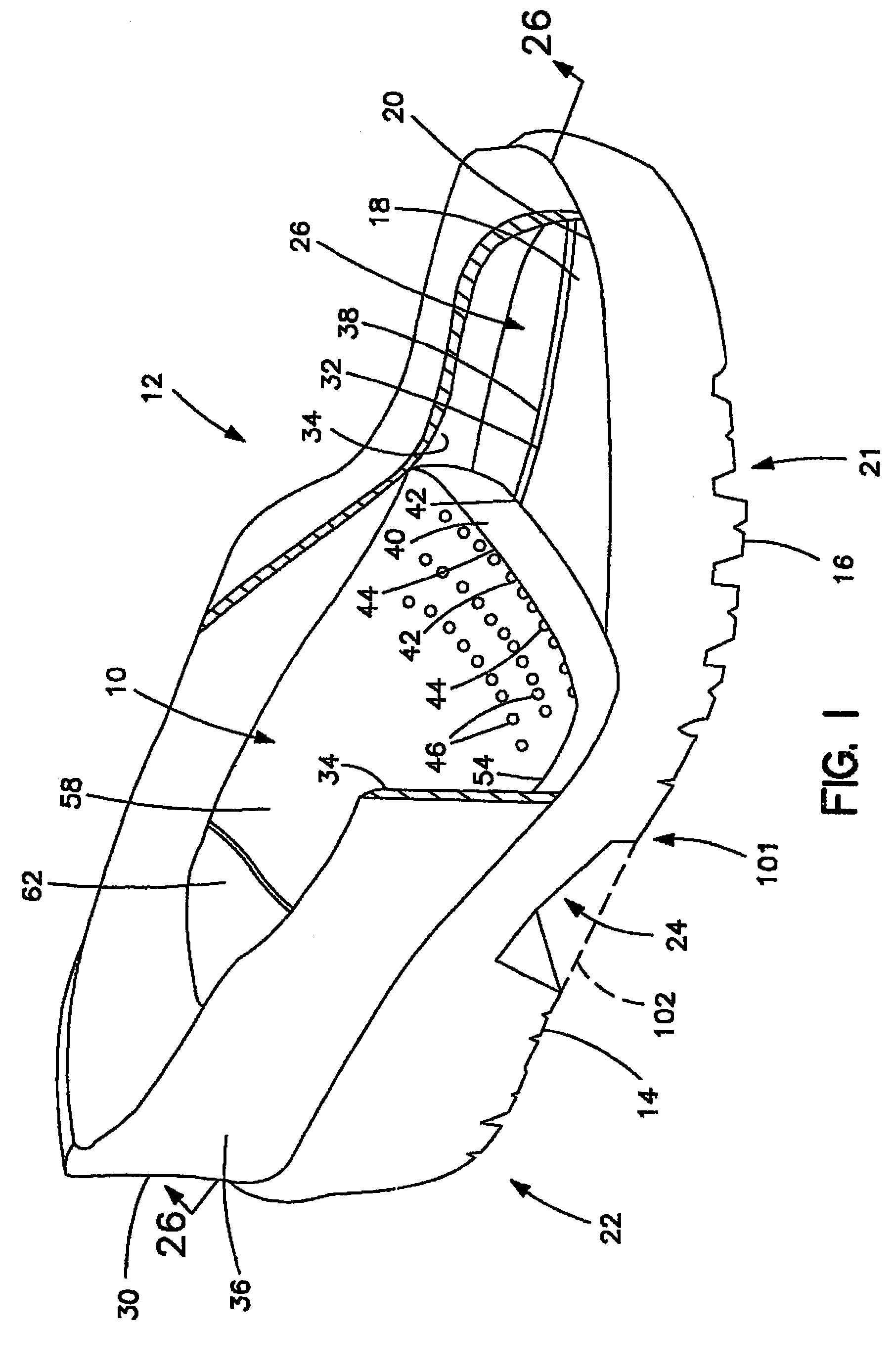

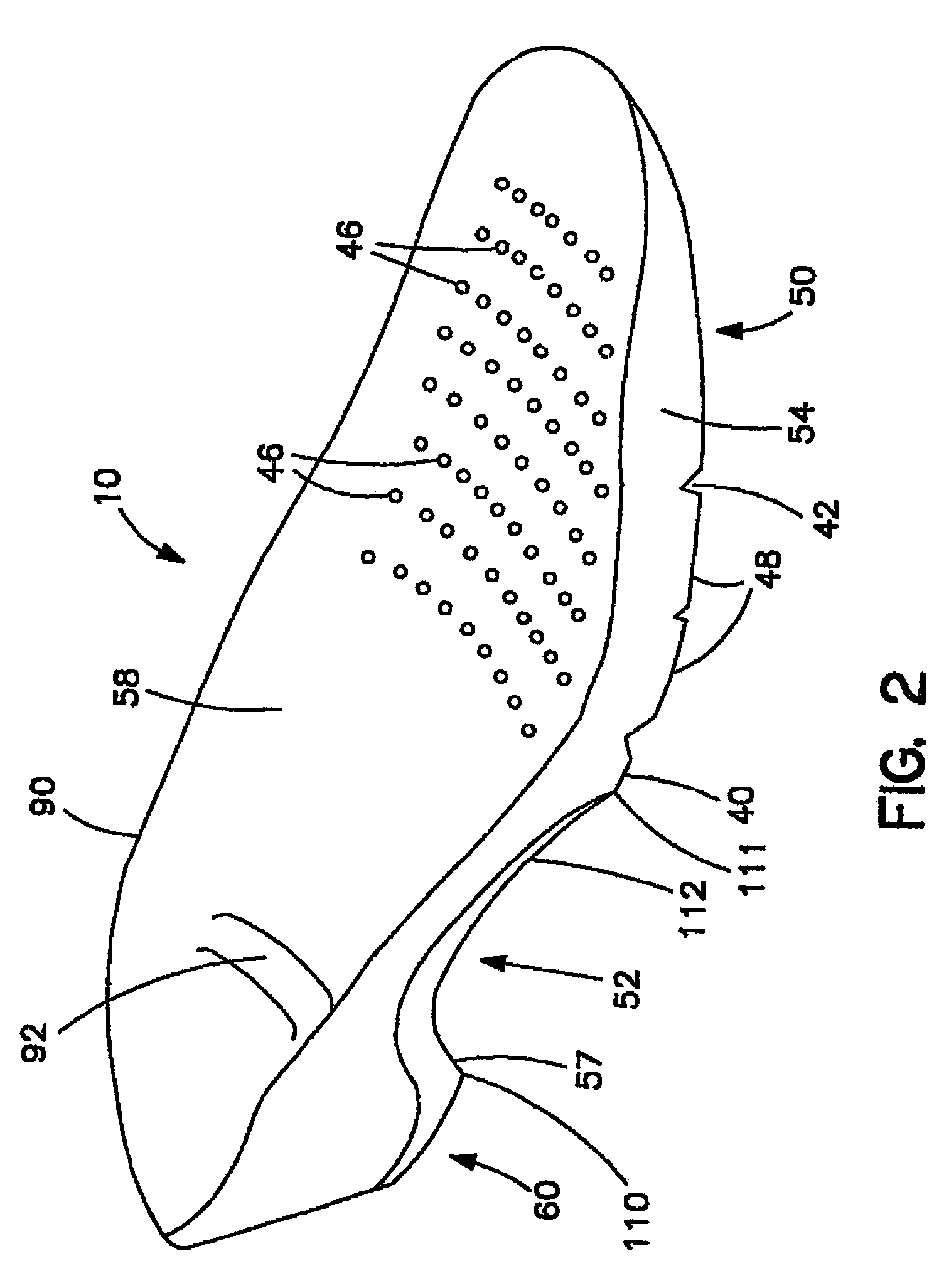

Anti-slip overshoe

An overshoe that is removably disposable on a user's shoe and provides a tread surface that enhances the user's footing on slippery surfaces. The tread surface has removable spikes that penetrate surfaces and forward-oriented and rearwards-oriented gripping ridges that grip the surface. The ease of pulling on and removing the overshoe is enhanced by using stretch zones that are placed to allow stretching of the overshoe to fit over a shoe or the like without compromising the snugness of the overshoe fit. A spike assembly for use with an overshoe that fits over a person's shoe and enhances a person's contact with the ground, includes a spike having a head operably coupled to a shank; and a button overmolded on the spike and having a neck for removable engagement in a bore defined in the overshoe. A method of minimizing slippage on a ground surface is further included.

Owner:SUREWERX USA INC

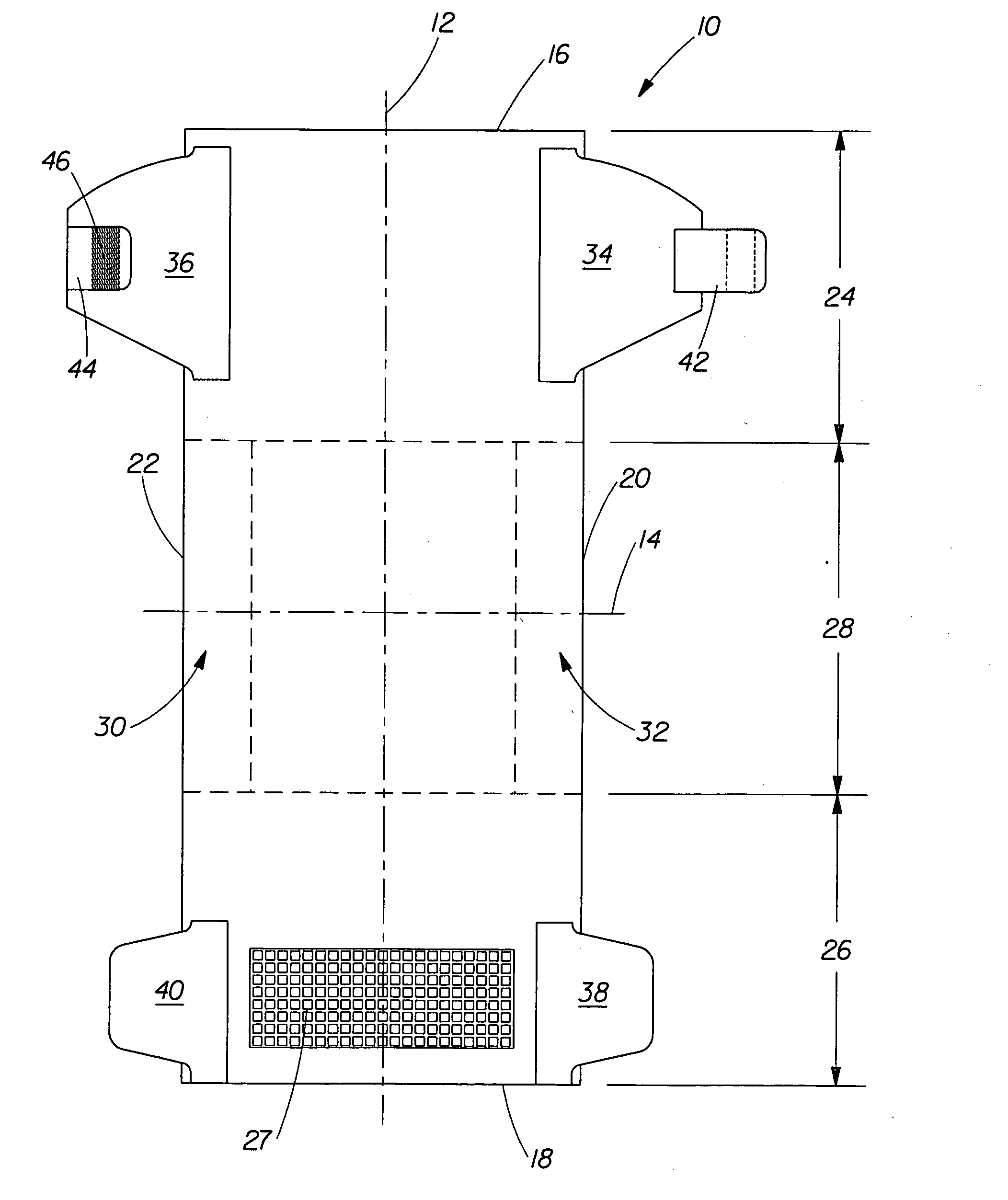

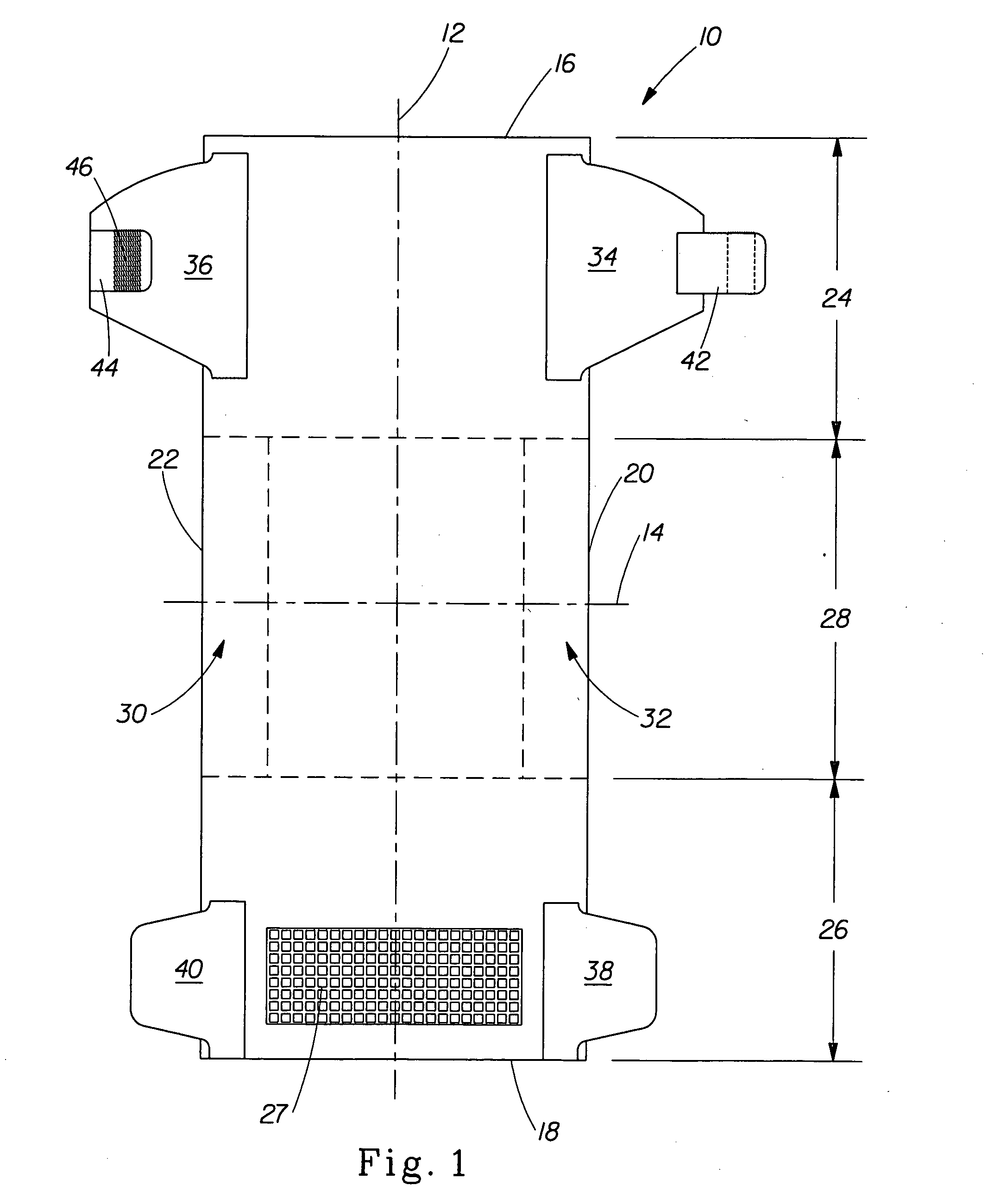

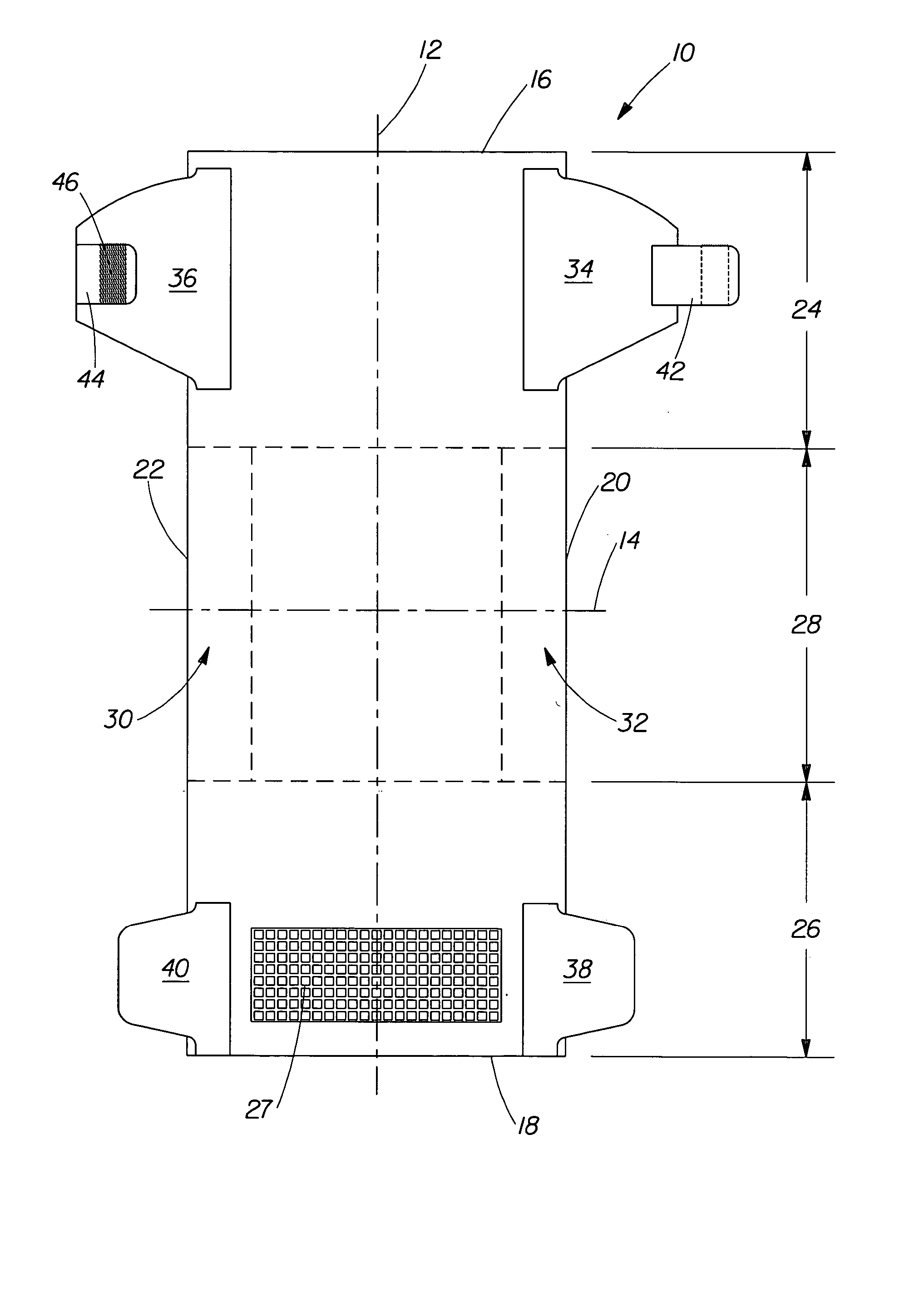

Absorbent articles with stretch zones comprising slow recovery elastic materials

An absorbent article having at least one stretch zone comprising a slow recovery elastomer wherein said slow recovery elastomer exhibits a normalized unload force of greater than about 0.04 N / mm2 at 37° C.; and said slow recovery elastomer exhibits at least about 20% post elongation strain at 22° C. after 15 seconds of recovery from a 400% strain. The absorbent article may additionally comprises at least one feature selected from the group consisting of a liquid permeable topsheet, a liquid impermeable backsheet, an absorbent core, an ear, a side panel, a waist feature, a fastener component, a leg cuff, a gasketing cuff, a barrier cuff, and combinations thereof; wherein the feature comprises at least a part of the stretch zone.

Owner:THE PROCTER & GAMBLE COMPANY

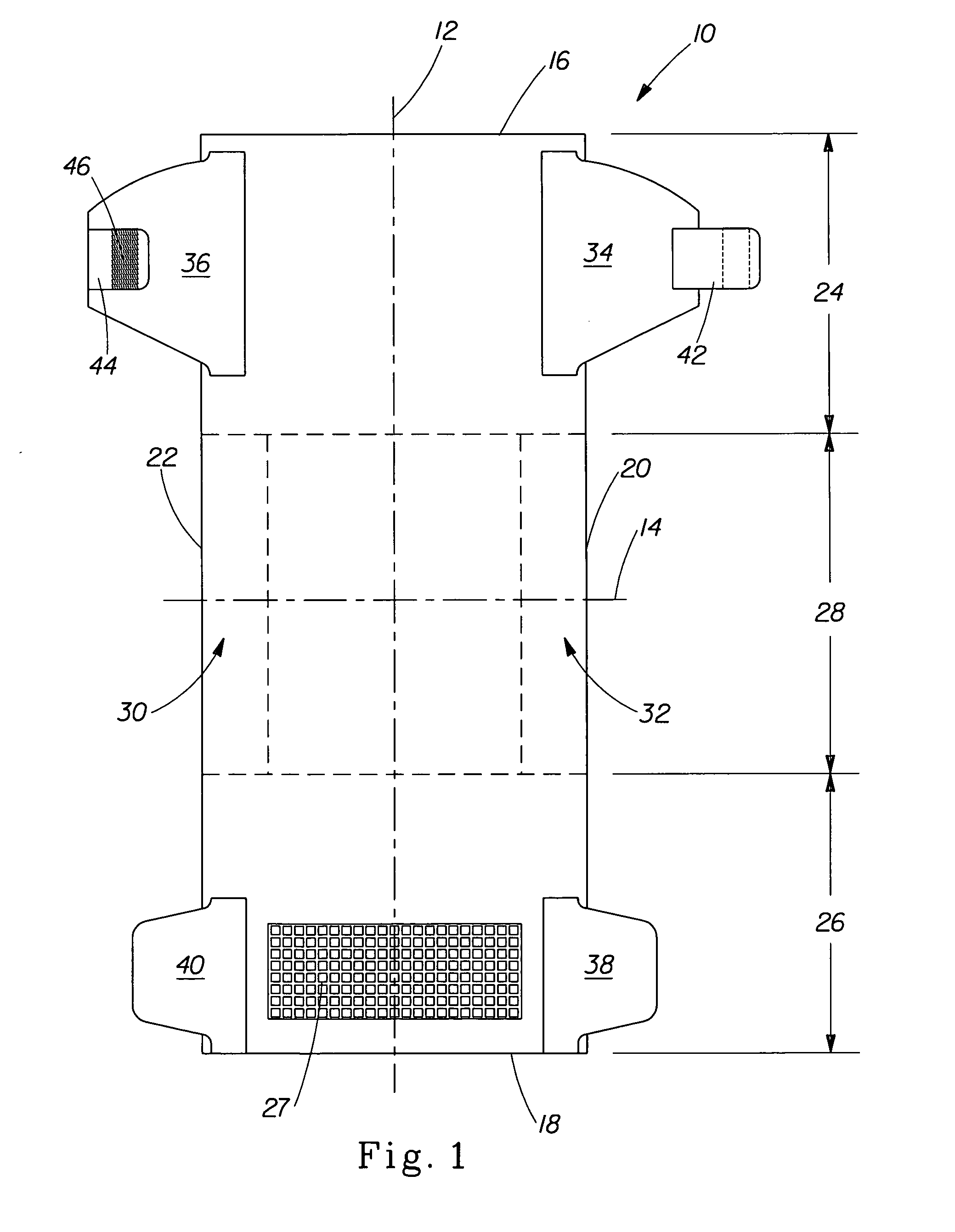

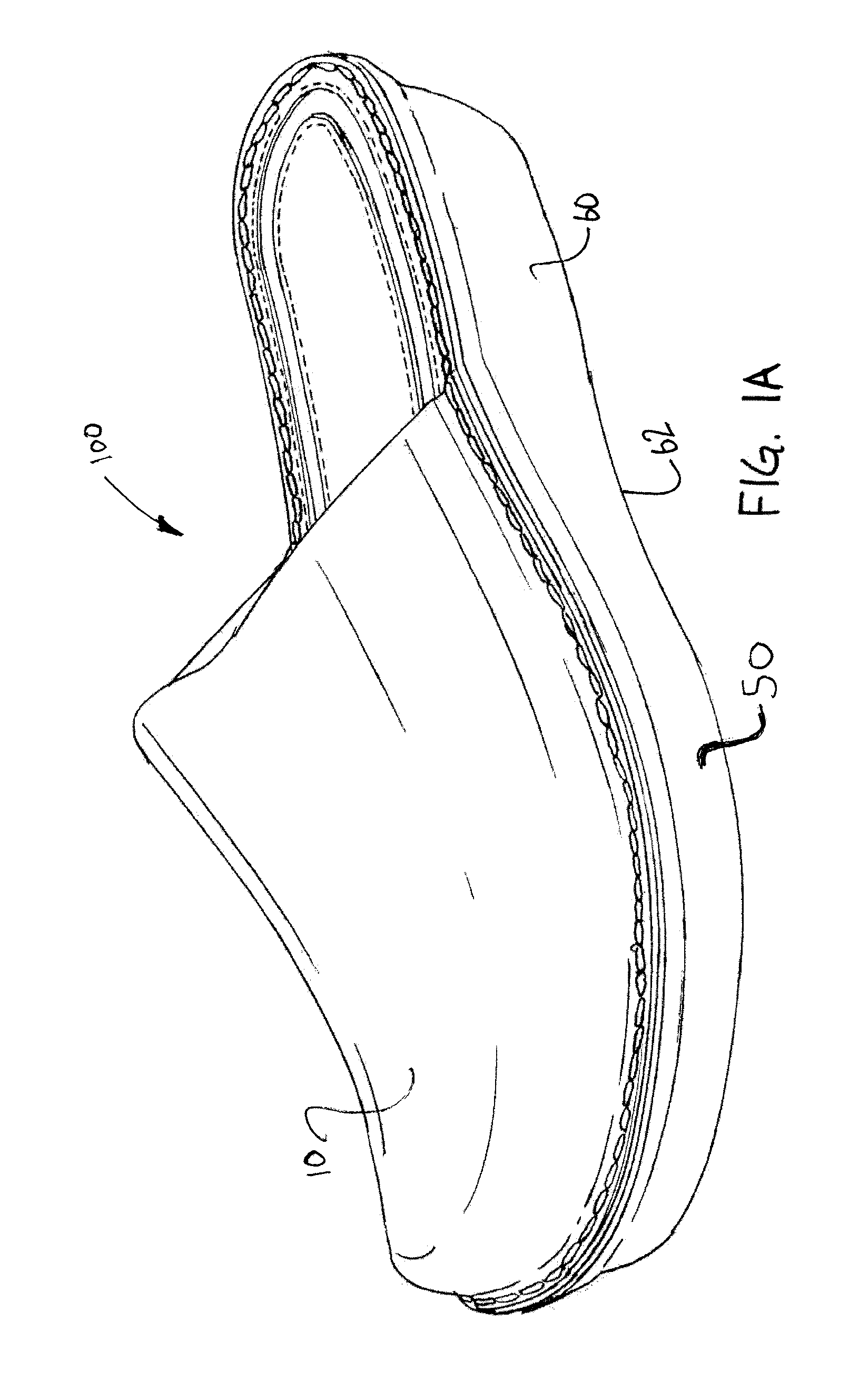

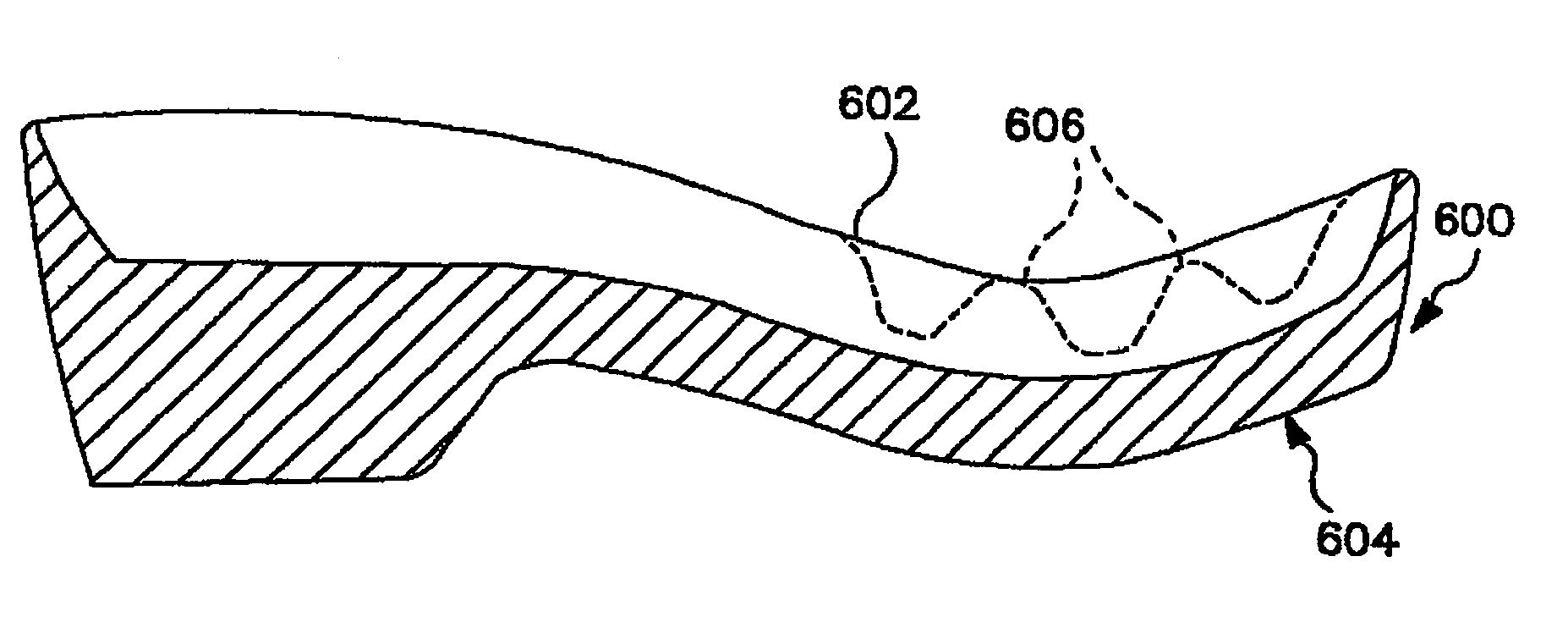

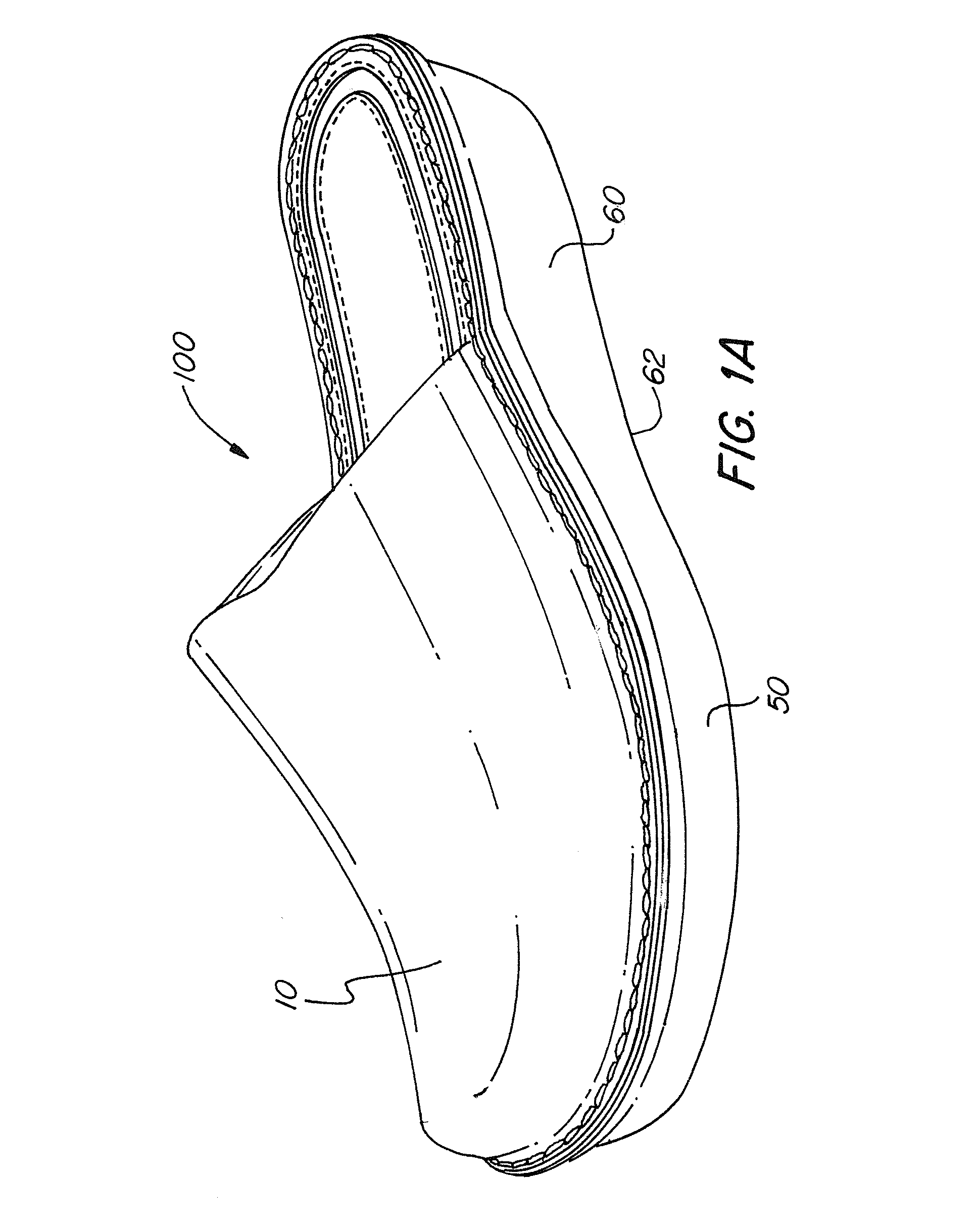

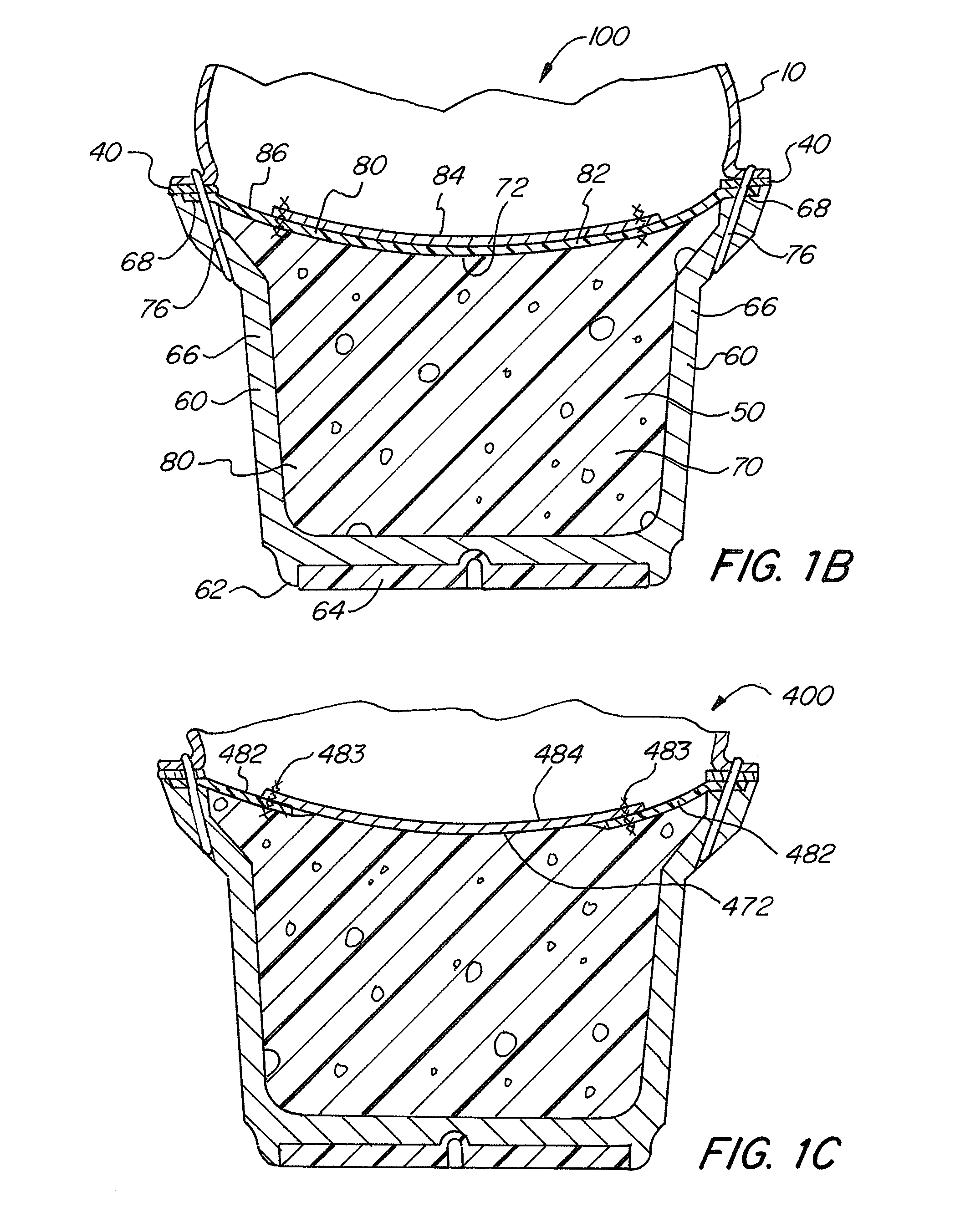

Footwear With Elastic Footbed Cover And Soft Foam Footbed

An article of footwear has a molded outsole which contains a resilient midsole located in the cavity of the outsole and a footbed cover which has a stretch material layer affixed to the outsole and provides a stretch zone. The stretch zone allows the footbed cover to work in conjunction with the resilient midsole to absorb shock upon heel strike or other compression of the midsole to increase comfort. Preferably, the midsole has sections of different hardness in the heel area and the forefoot area.

Owner:C & J CLARK INT

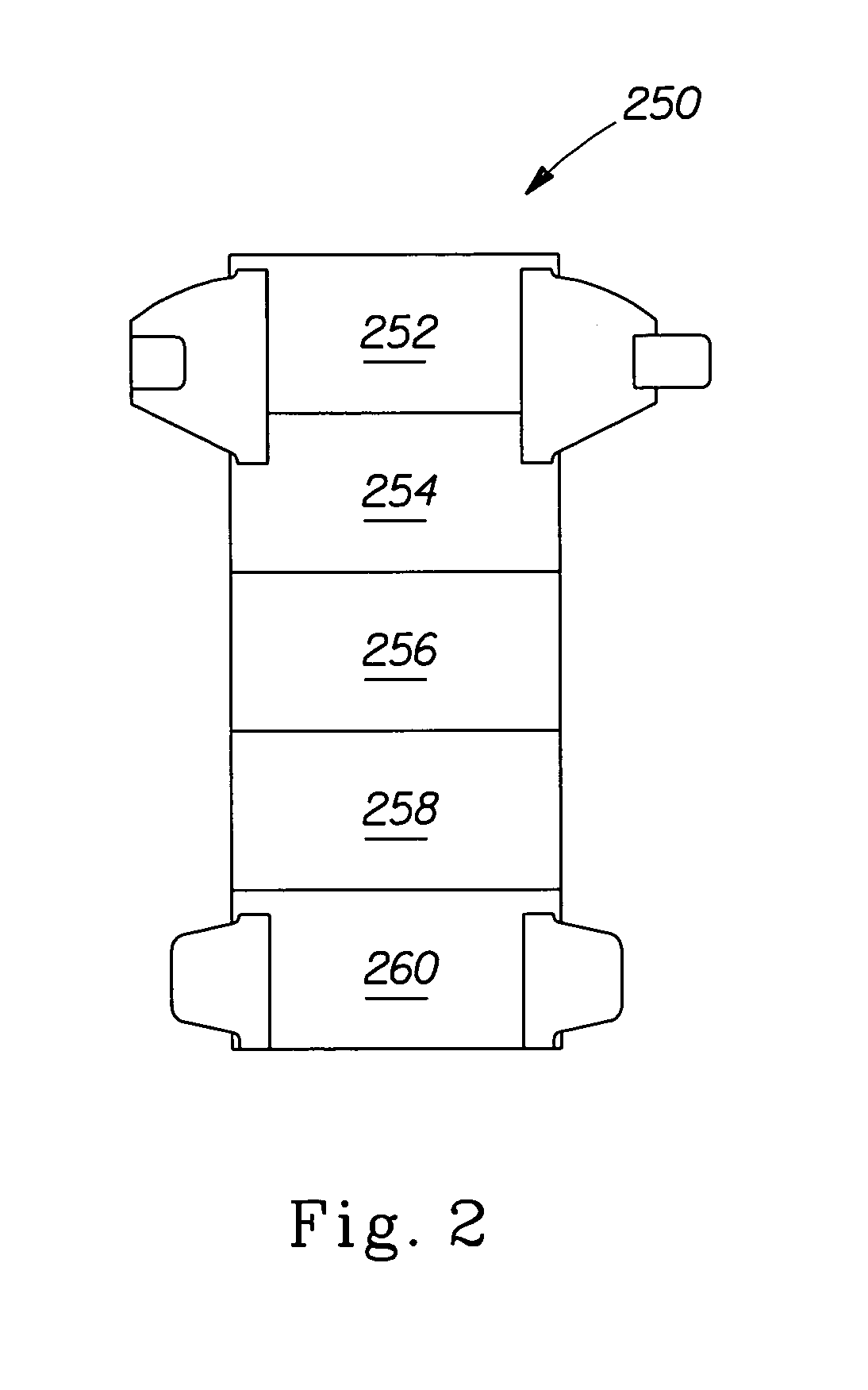

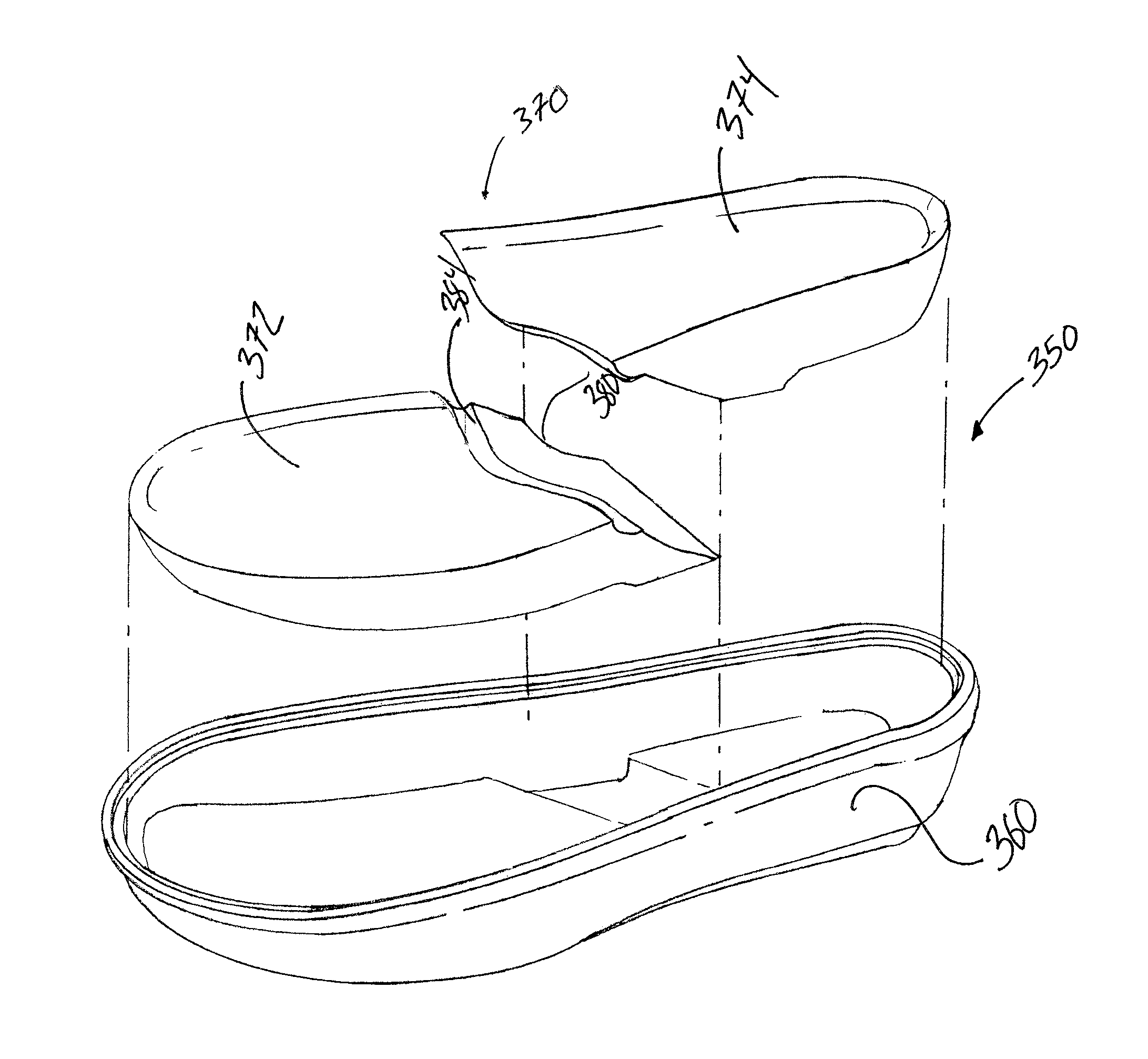

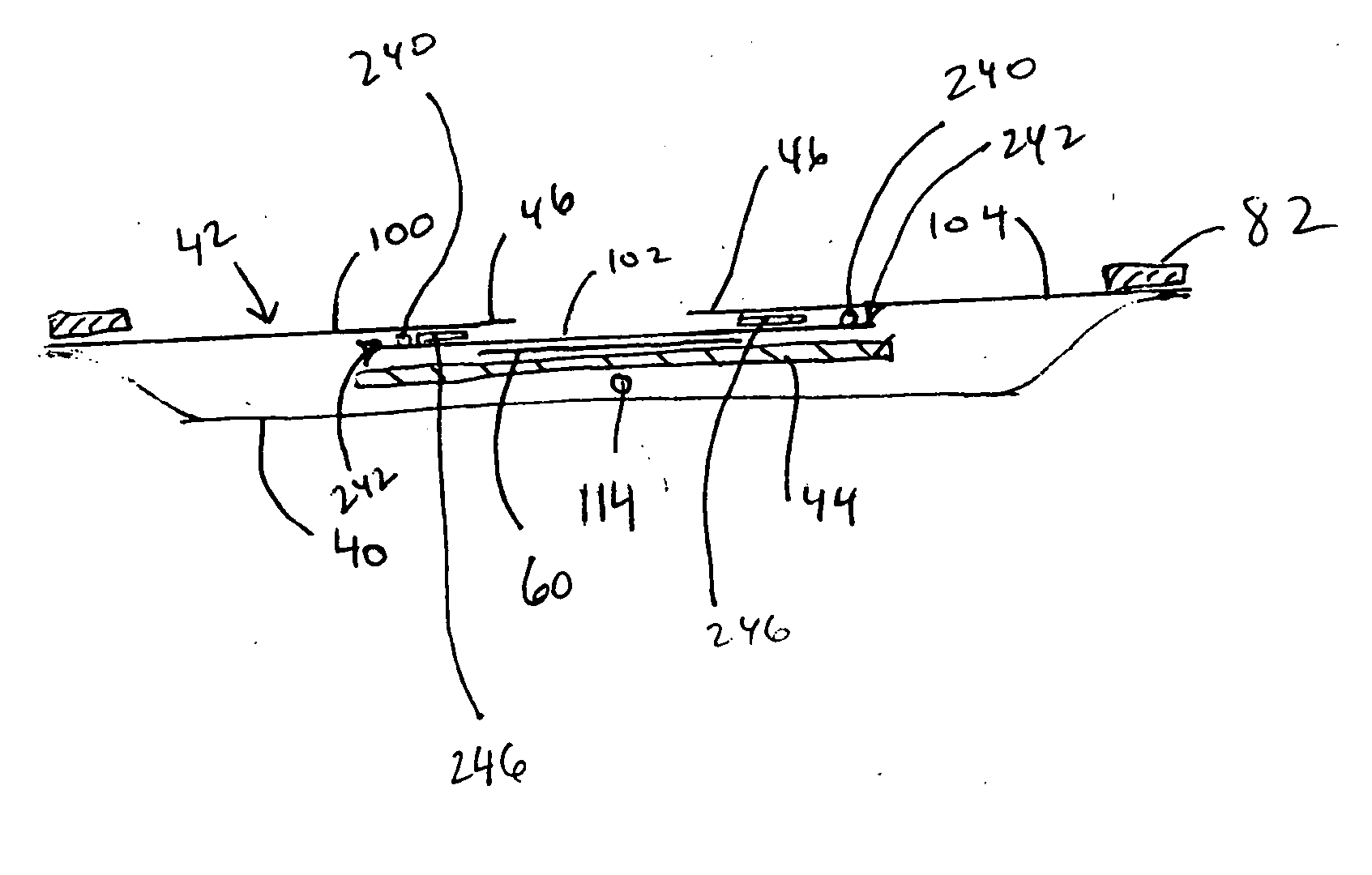

Footwear structure and method of forming the same

A footwear structure including an outsole, an upper and a midsole. The outsole may include at least one stretch zone for allowing expansion and contraction of the outsole, e.g. corresponding to expansion and contraction of a user's foot during wear. The upper may include stretch zones for allowing expansion of the upper, and the midsole may include varying regions of rigidity.

Owner:GEER KENTON D

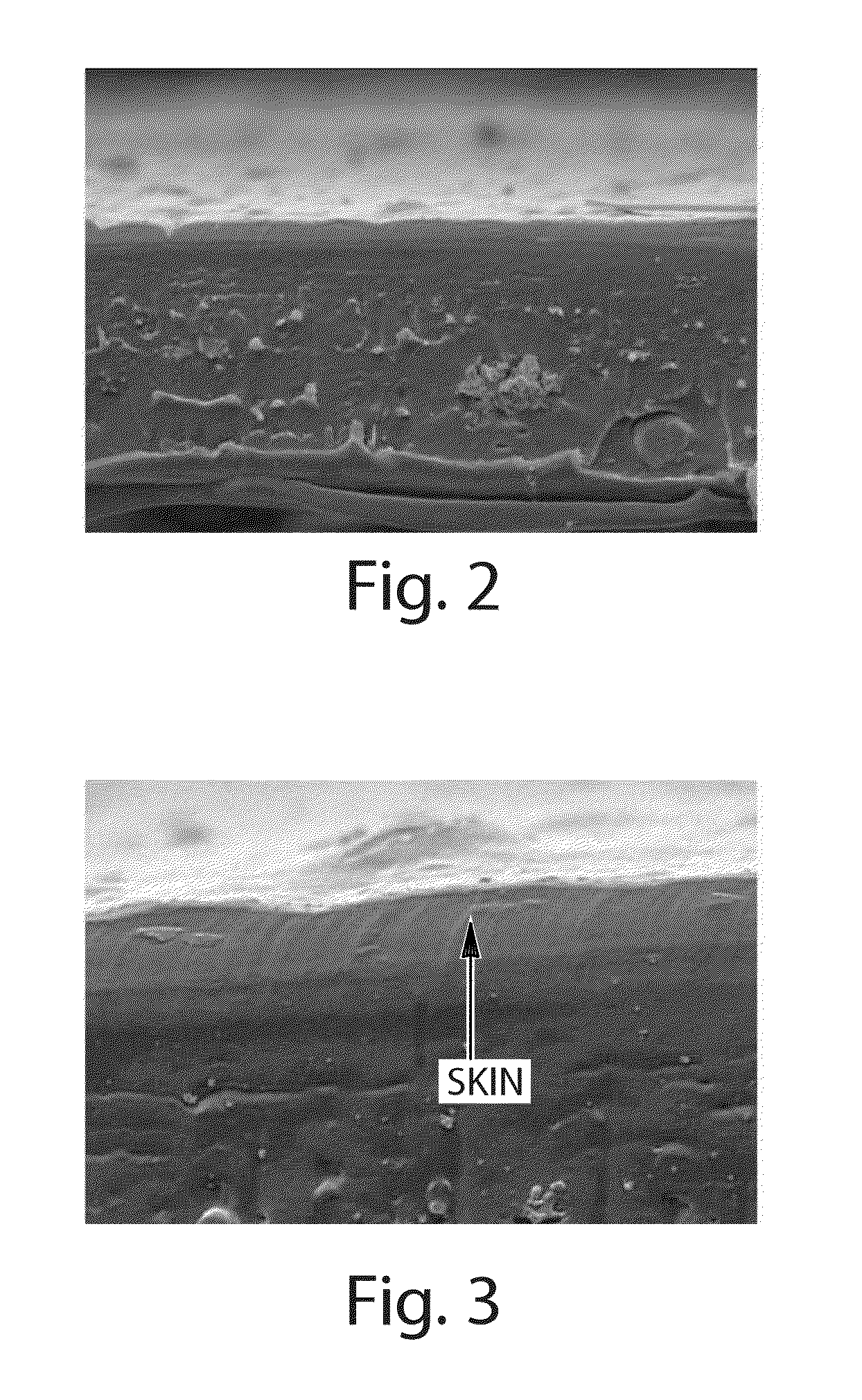

Absorbent articles comprising stretch laminates

An absorbent article includes a chassis comprising a topsheet, a backsheet, and an absorbent core disposed between the topsheet and the backsheet, and at least one elastically elongatable panel joined to the chassis. The elastically elongatable panel includes a stretch laminate that has at least one cover layer, an elastomeric film attached to the cover layer, the elastomeric film having two surfaces and a skin on at least one of the surfaces, and an adhesive disposed between the skin and the cover layer. The stretch laminate has at least one anchoring zone and at least one stretch zone, the skin that is located in the anchoring zone has a plurality of wrinkles, and the wrinkles have furrows, and at least some of the adhesive is disposed in at least some of the furrows. An absorbent article including the stretch laminate is also provided.

Owner:THE PROCTER & GAMBLE COMPANY

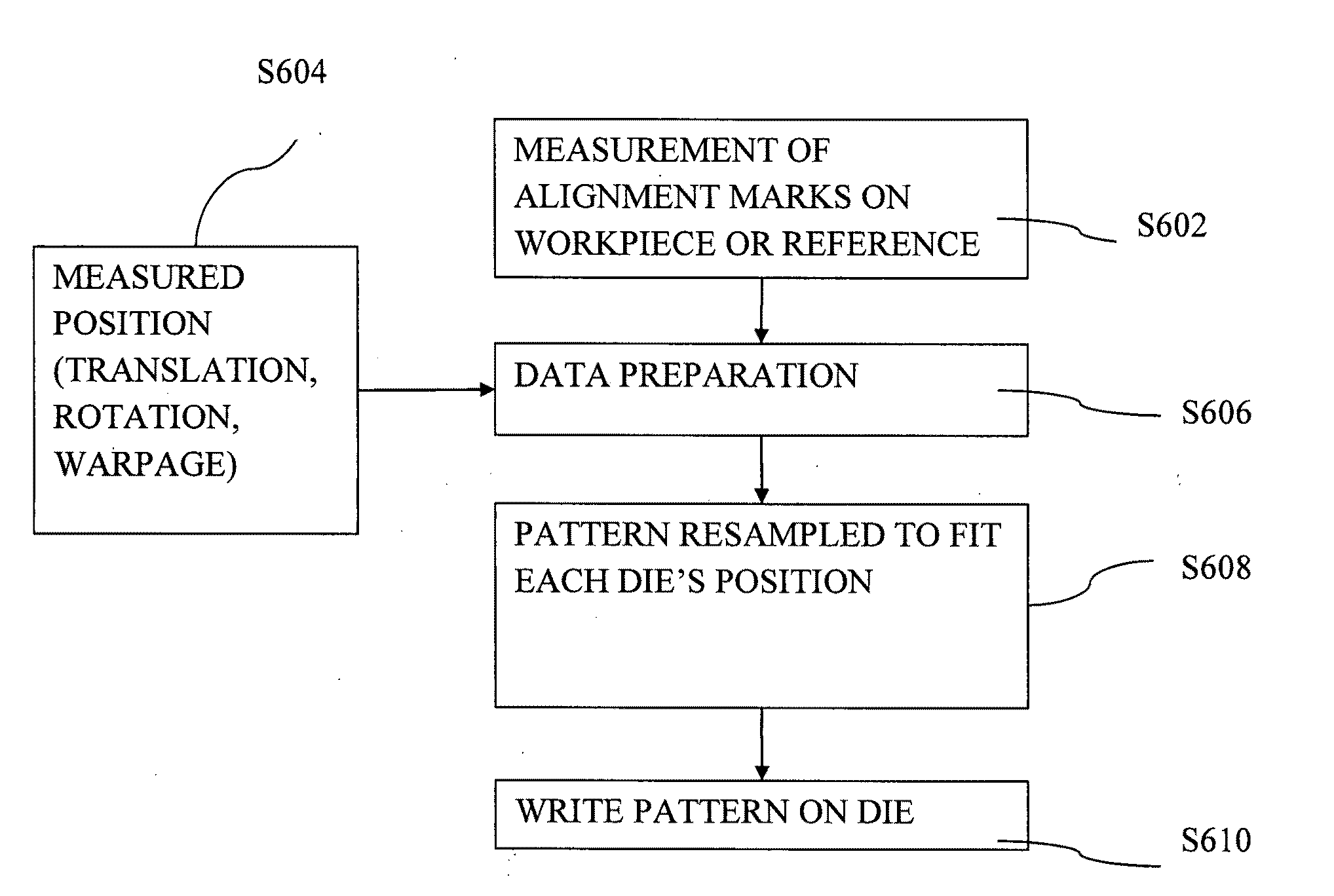

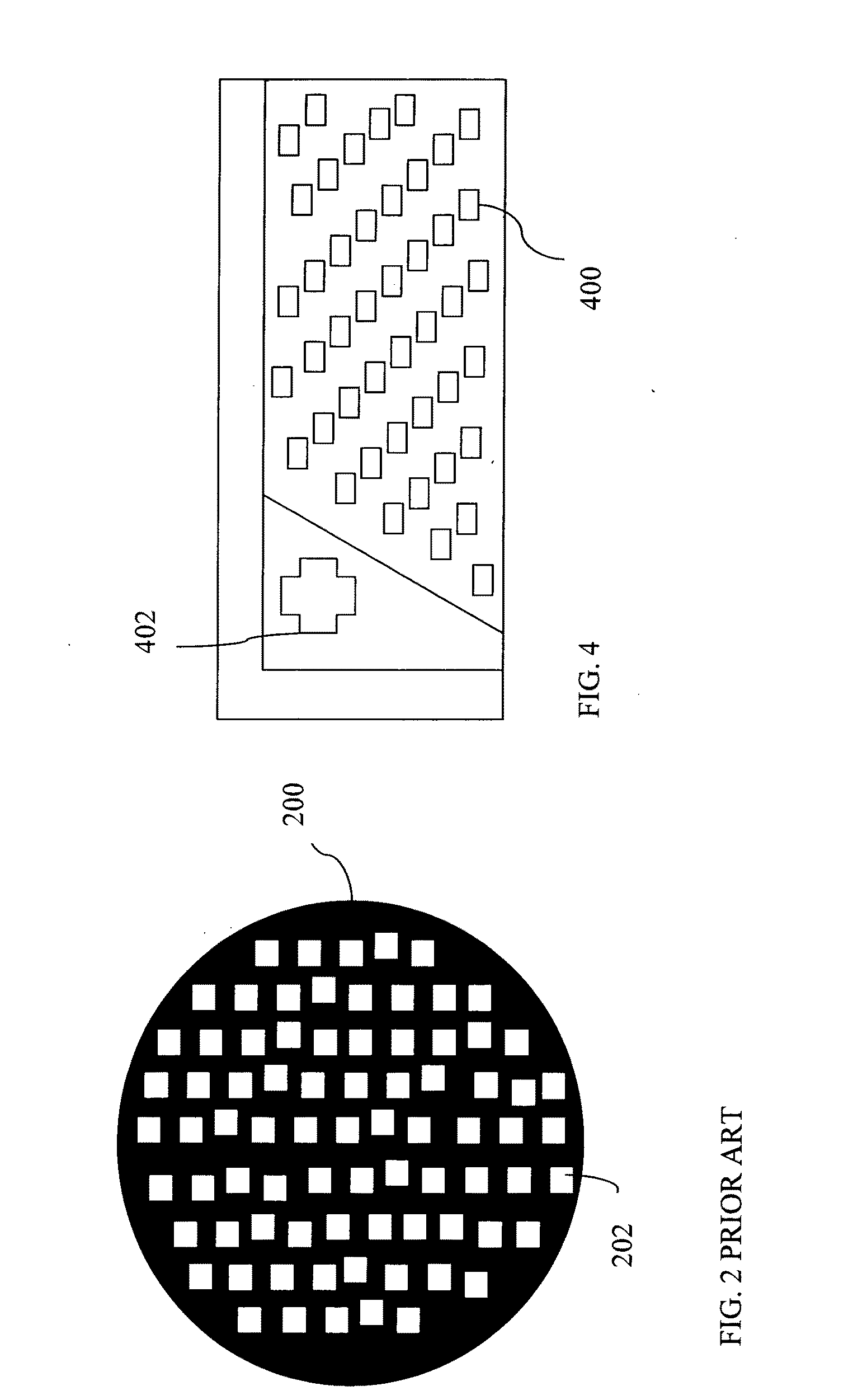

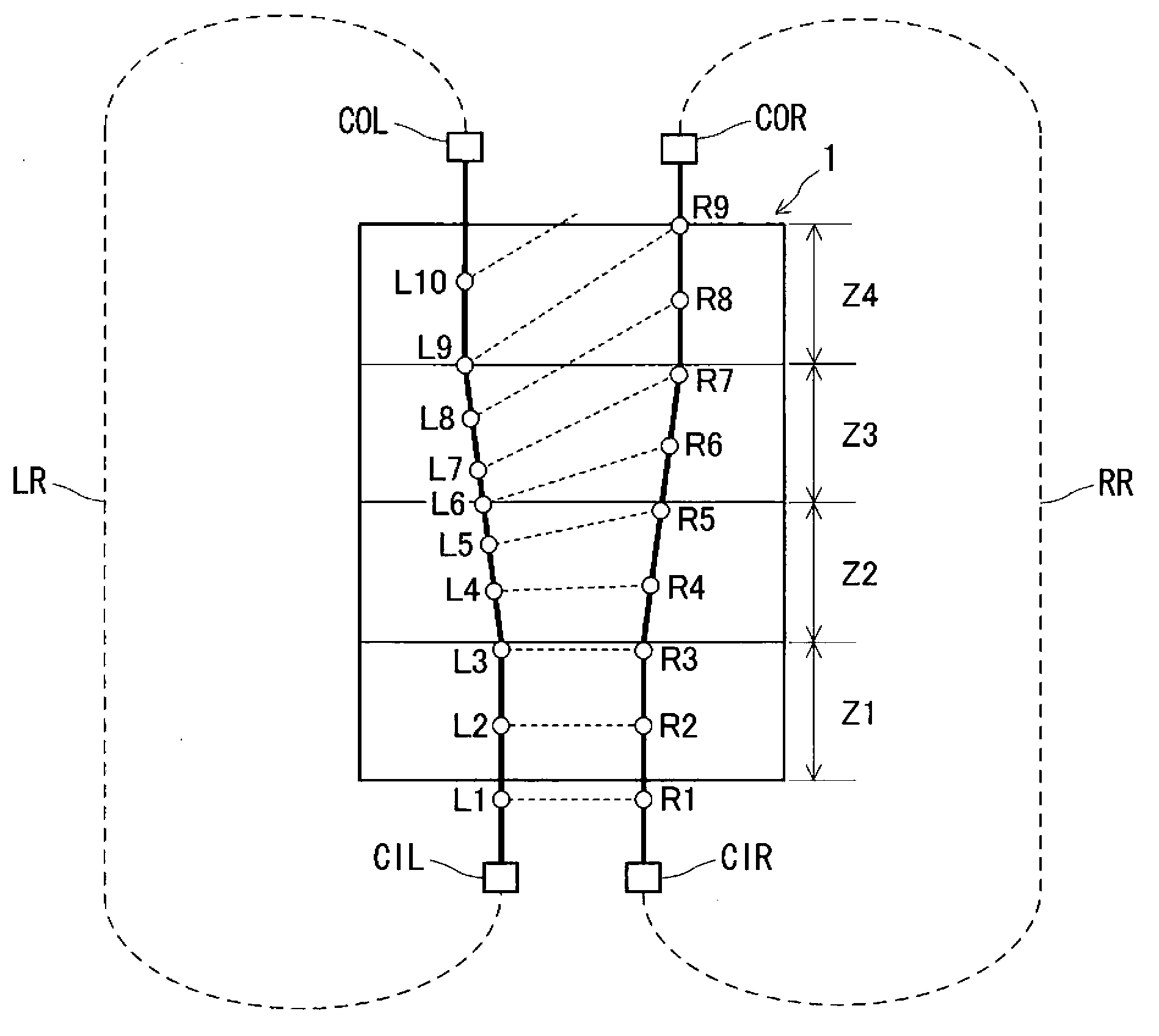

Method and apparatus for performing pattern reconnection after individual or multipart alignment

ActiveUS20110257777A1Avoid connectionAvoid roughnessPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringSystem in package

Owner:MICRONIC LASER SYST AB

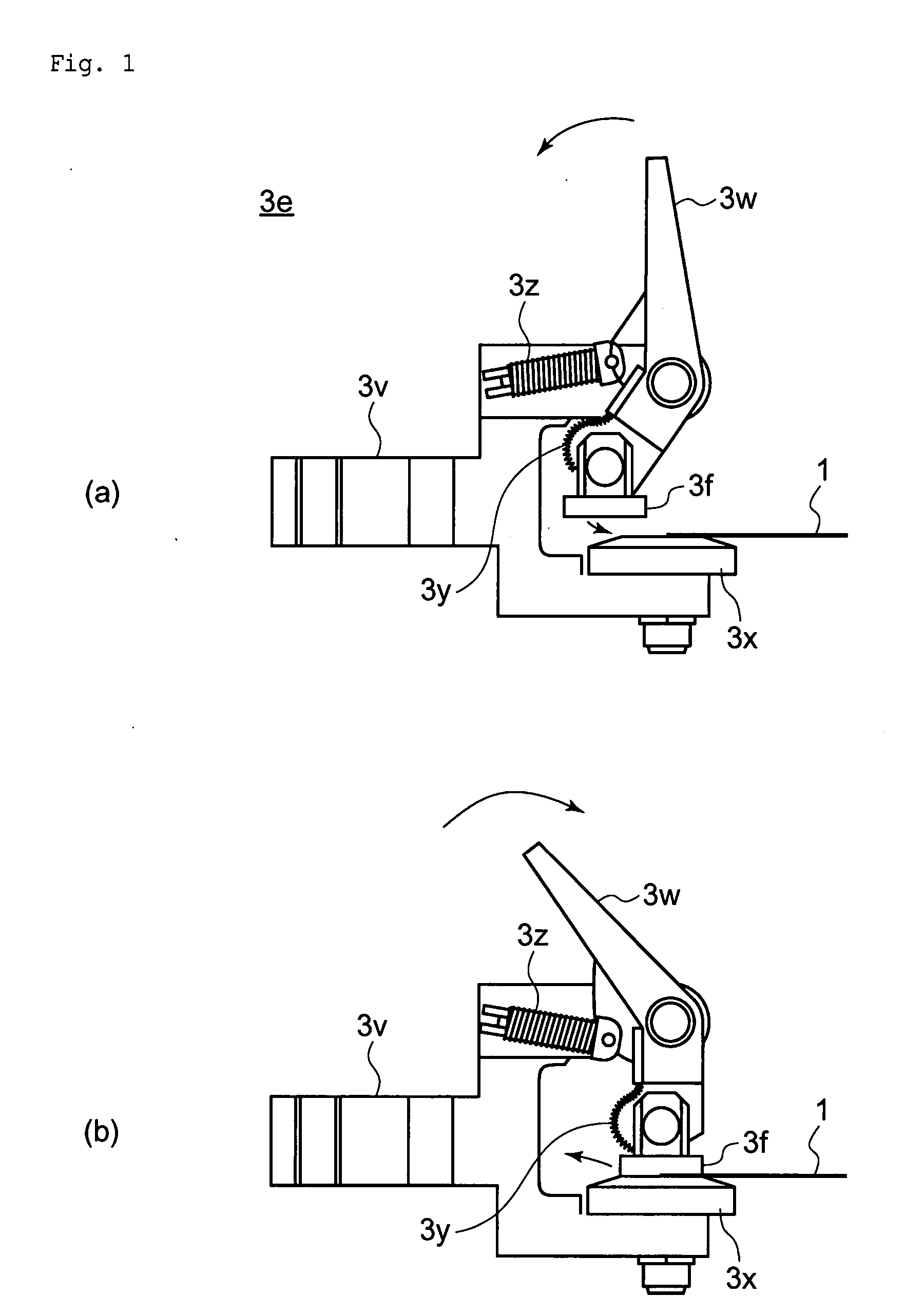

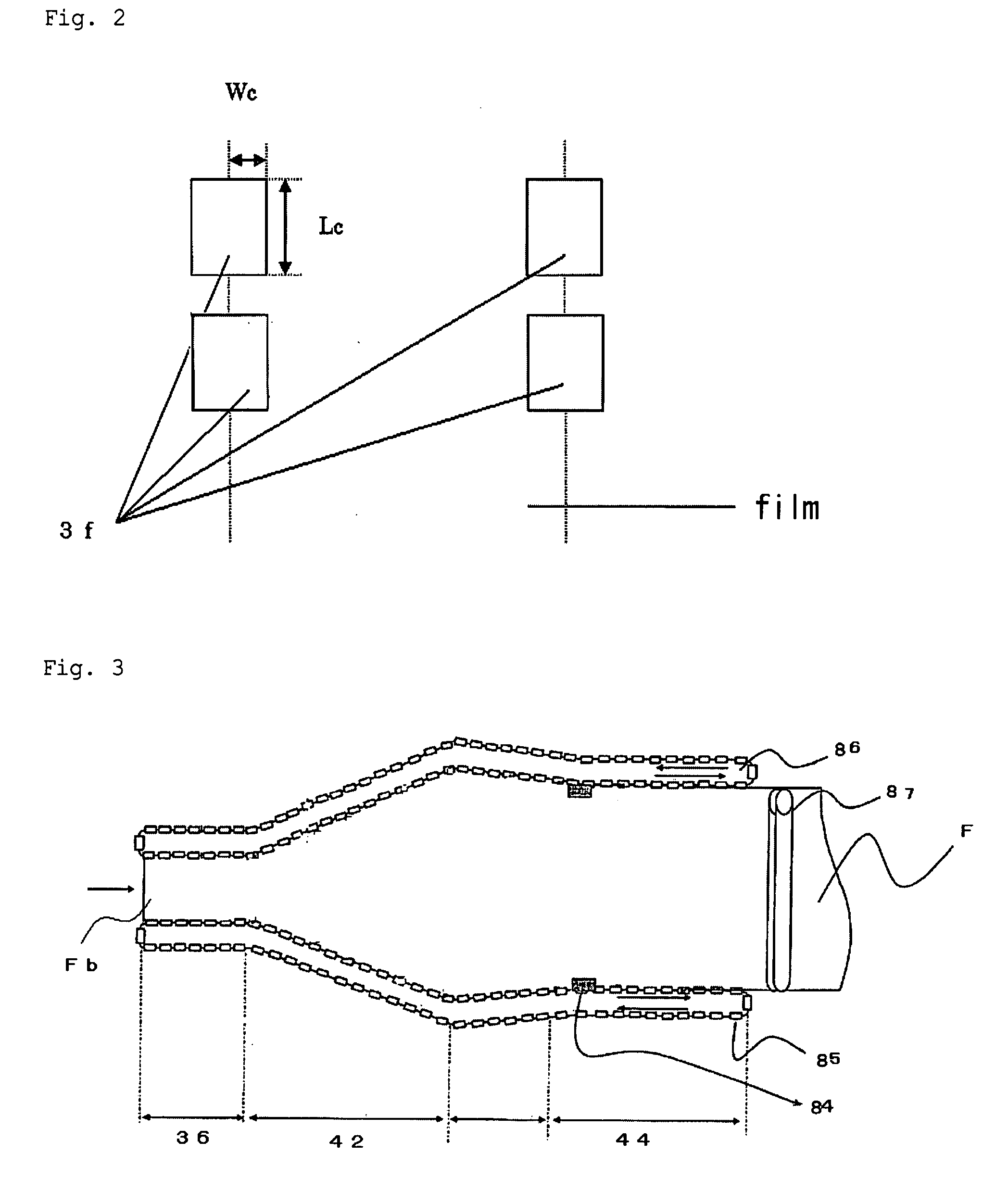

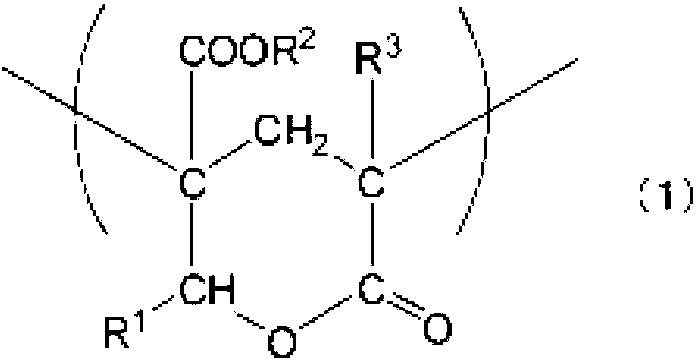

Transparent thermoplastic film and a method of producing the same

InactiveUS20070275183A1Liquid crystal compositionsCellulosic plastic layered productsEngineeringClutch

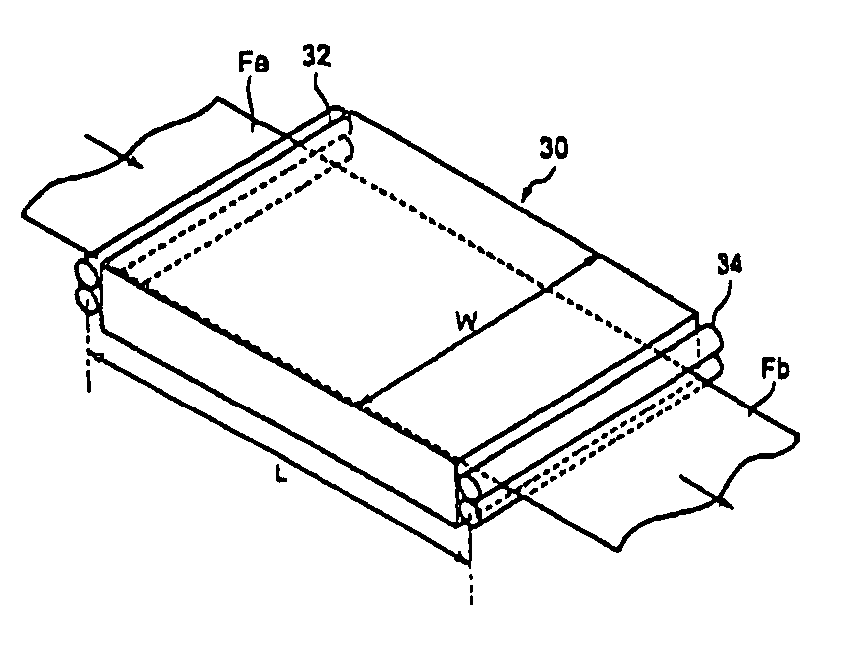

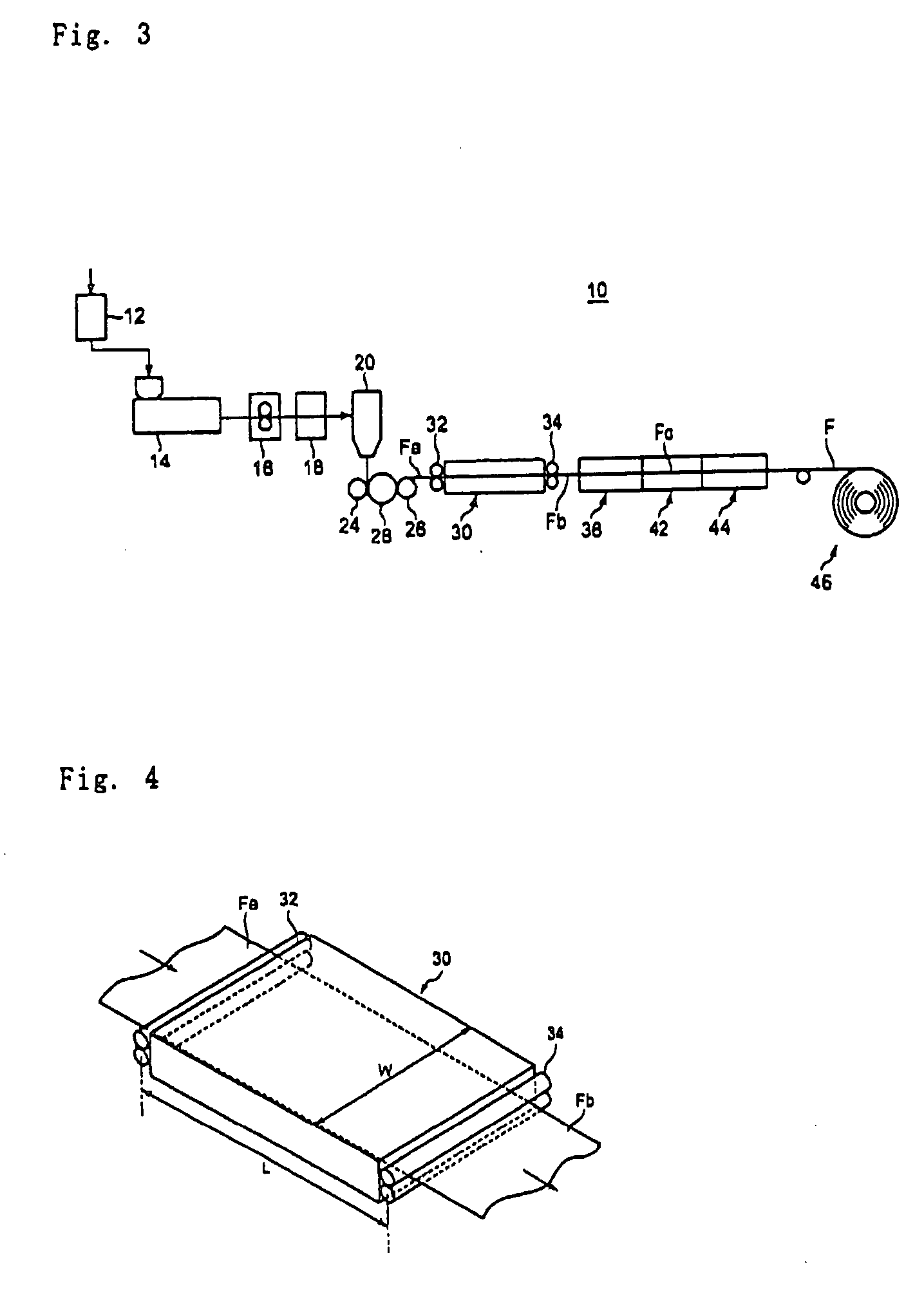

A method of producing a transparent thermoplastic film comprising transversely stretching a film by 1% to 200%, wherein a ratio (Lc / Wc) of a clutch length (Lc) of a chuck to a clutch depth (Wc) of the chuck in the transverse stretching zone is in the range of 3 to 50.

Owner:FUJIFILM CORP

Footwear with elastic footbed cover and soft foam footbed

An article of footwear has a molded outsole which contains a resilient midsole located in the cavity of the outsole and a footbed cover which has a stretch material layer affixed to the outsole and provides a stretch zone. The stretch zone allows the footbed cover to work in conjunction with the resilient midsole to absorb shock upon heel strike or other compression of the midsole to increase comfort. Preferably, the midsole has sections of different hardness in the heel area and the forefoot area.

Owner:C & J CLARK INT

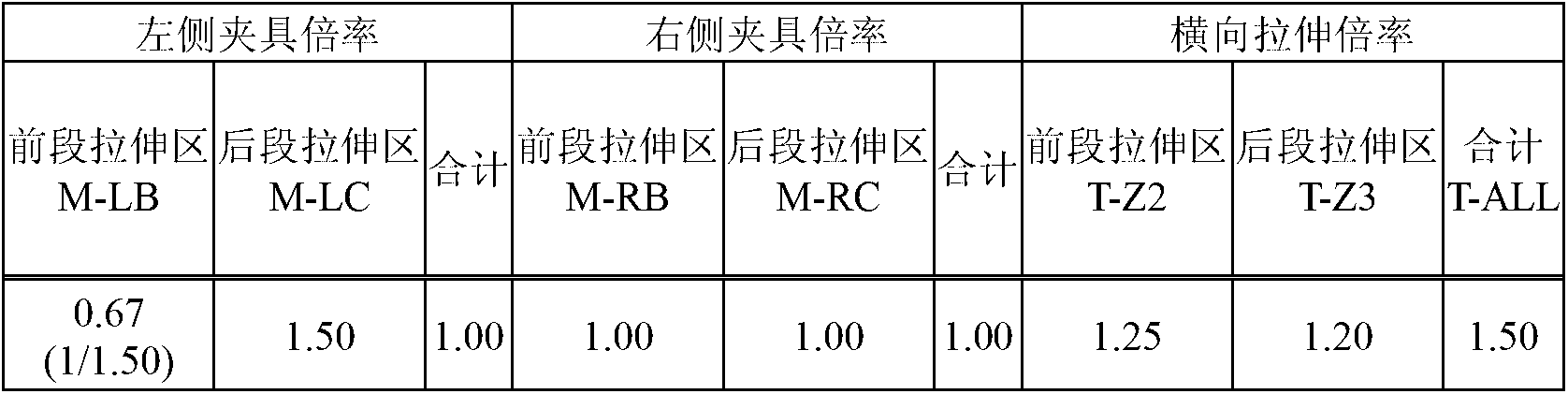

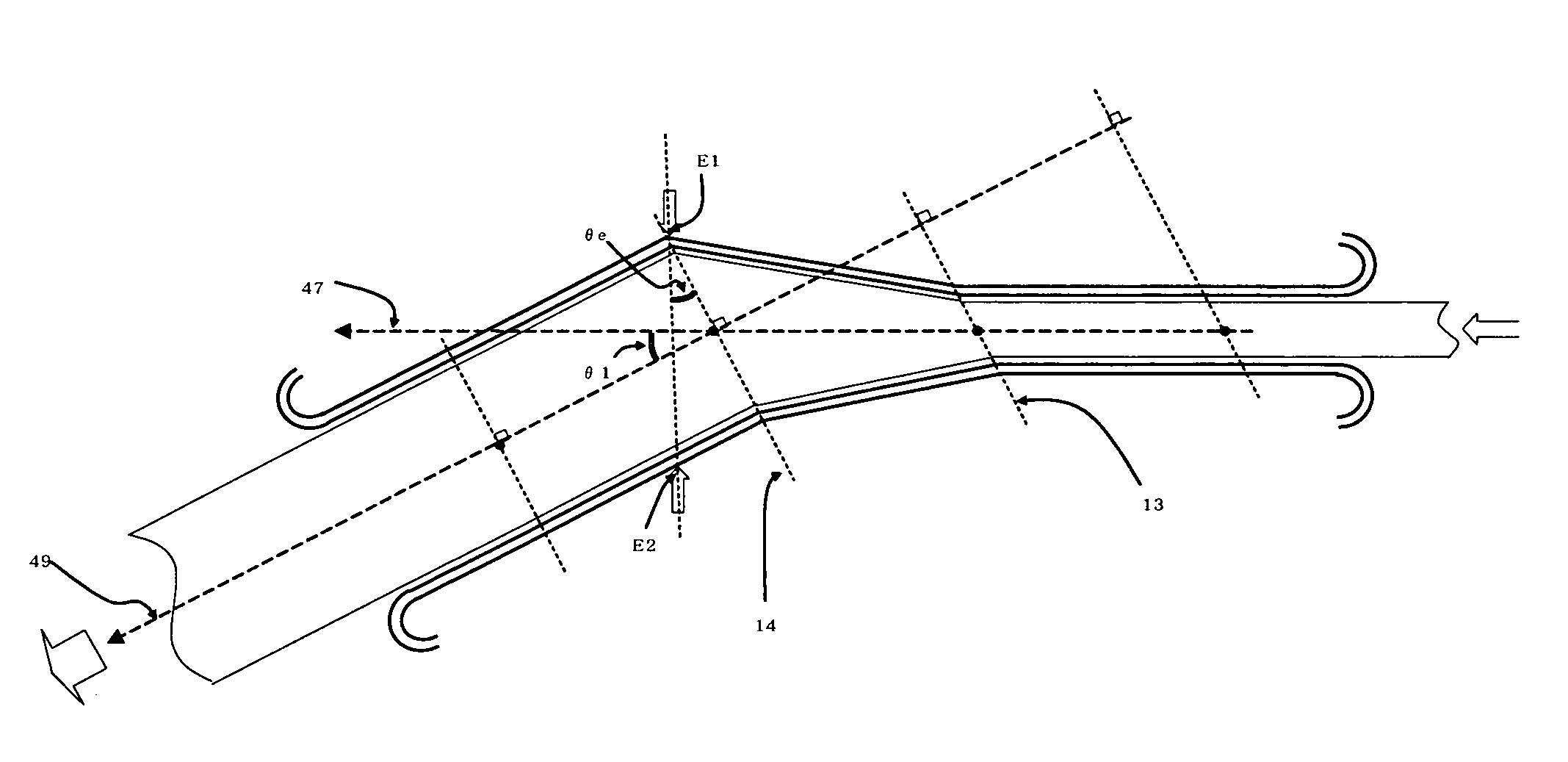

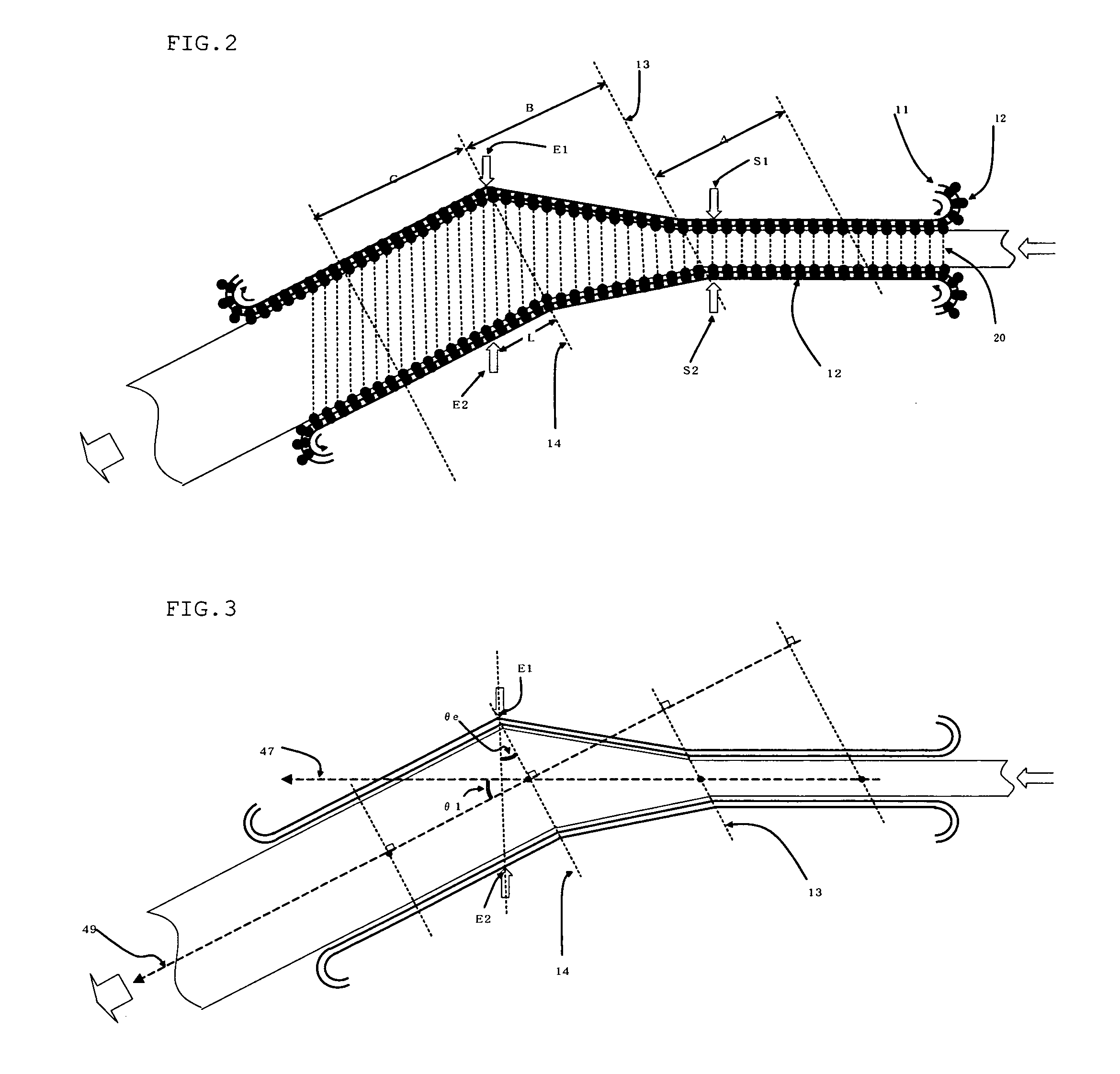

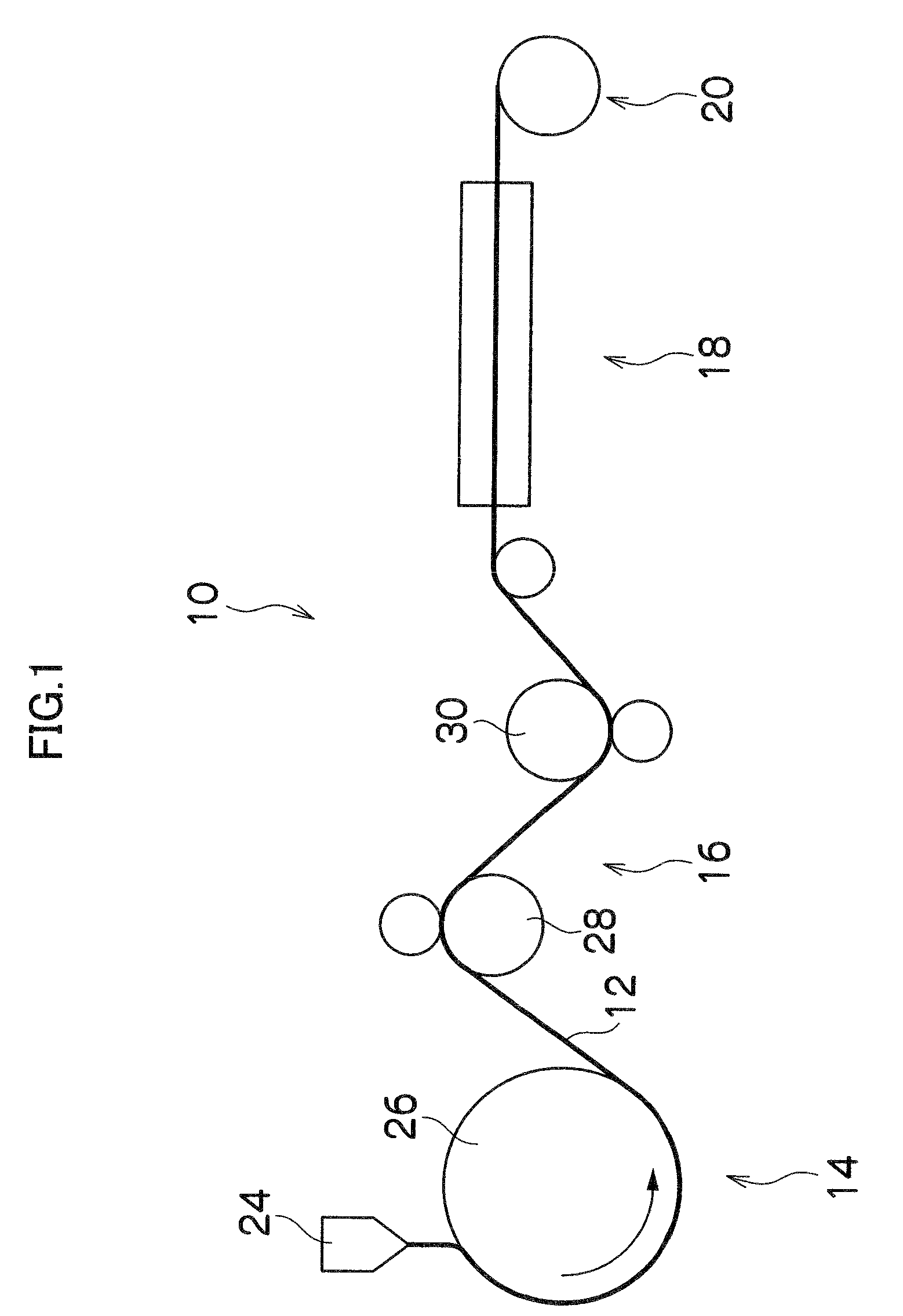

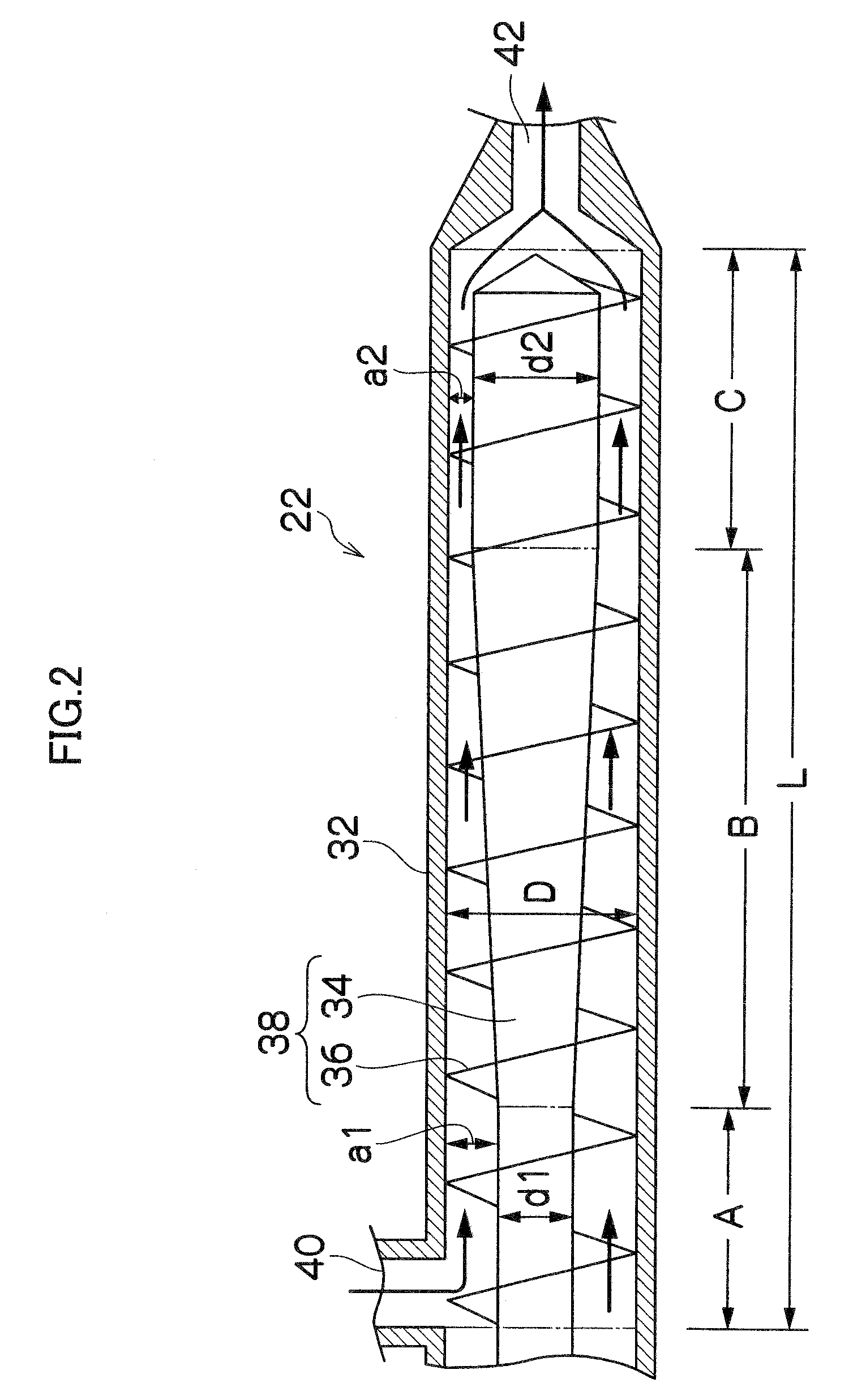

Method of manufacturing phase difference film and phase difference film roll

ActiveCN103052489AWeak two-way stretchImprove area utilization efficiencyOptical articlesPolarising elementsPhase differenceEngineering

One of the methods of manufacturing a phase difference film of the present invention provides a strip-shaped phase difference film which has a delayed phase axis that is inclined with respect to the longitudinal direction, an NZ coefficient closer to 1 than conventional values, and a weak biaxial stretchability (has strong uniaxial stretchability). In the manufacturing method is used a pair of clip sets that grip both peripheral edge parts of the strip-shaped raw film, and a heating and stretching apparatus having a stretching zone. At the time the clip sets grip the raw film, the traveling speed of the pair of clip sets is the same. The stretching zone has a first segment in which the traveling speed of one of the clip sets that have traveled into the zone is successively reduced, and after the first segment, a second segment in which the traveling speed of the above one of the clip sets that have traveled via the first segment is successively restored.

Owner:NIPPON SHOKUBAI CO LTD

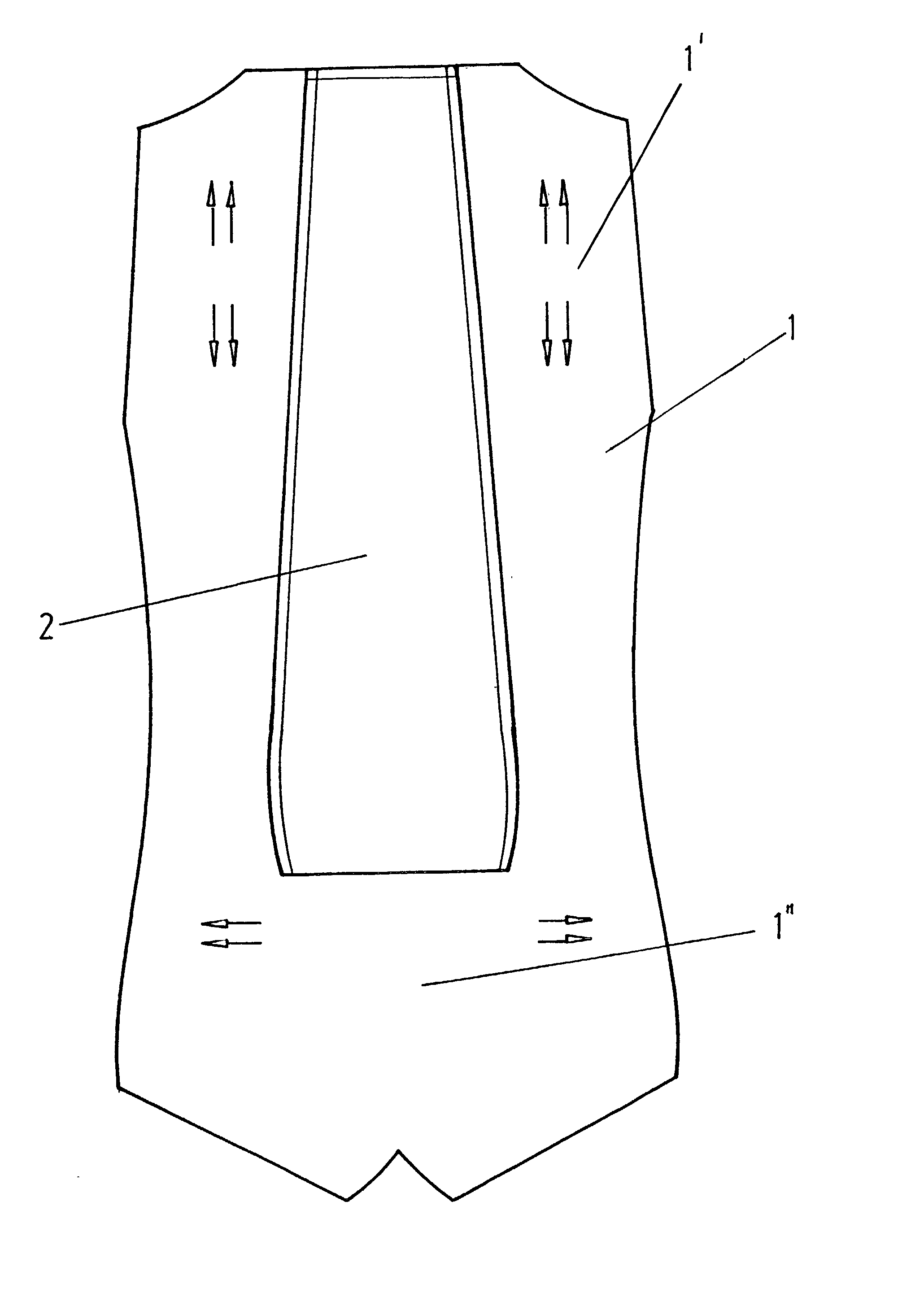

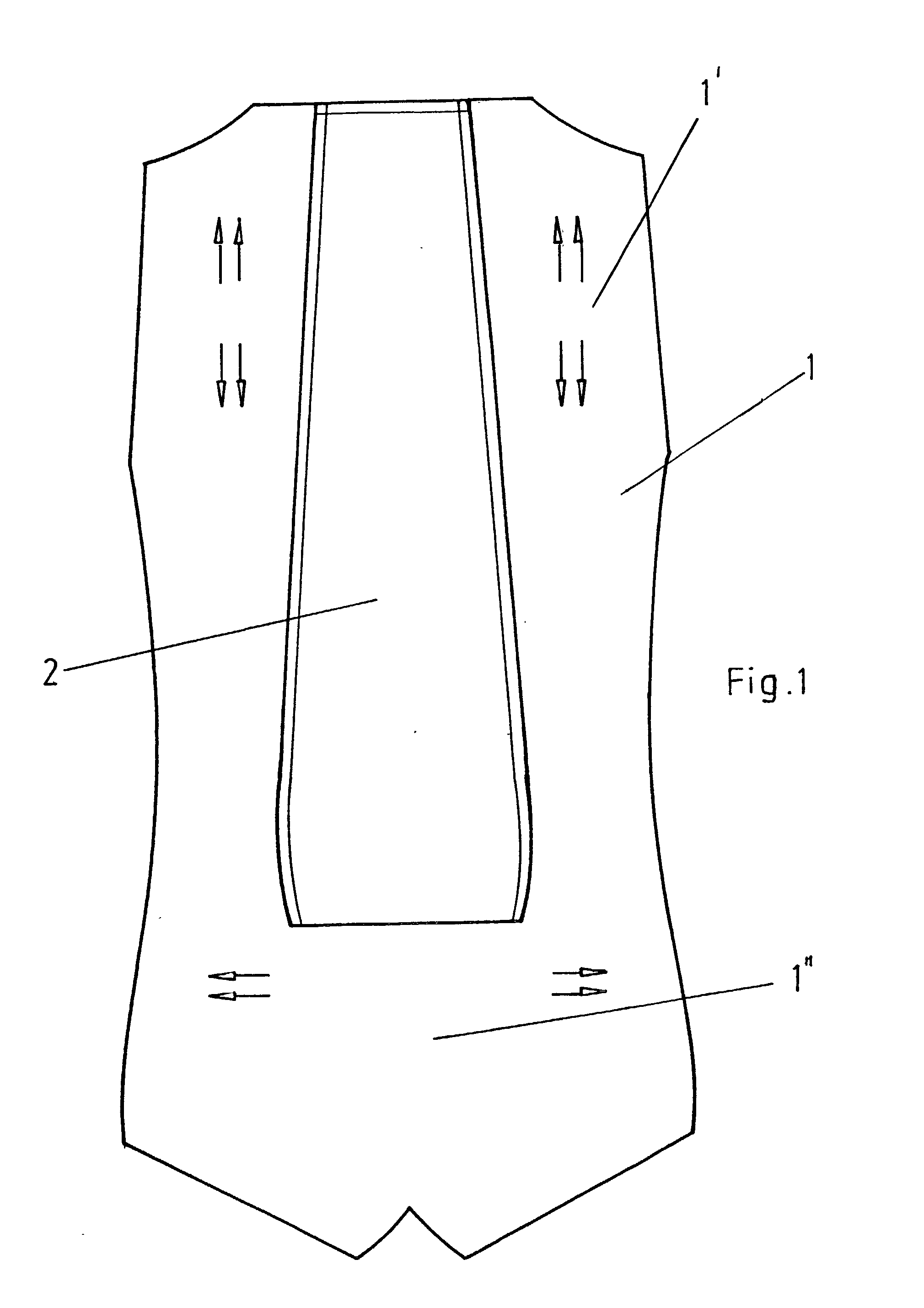

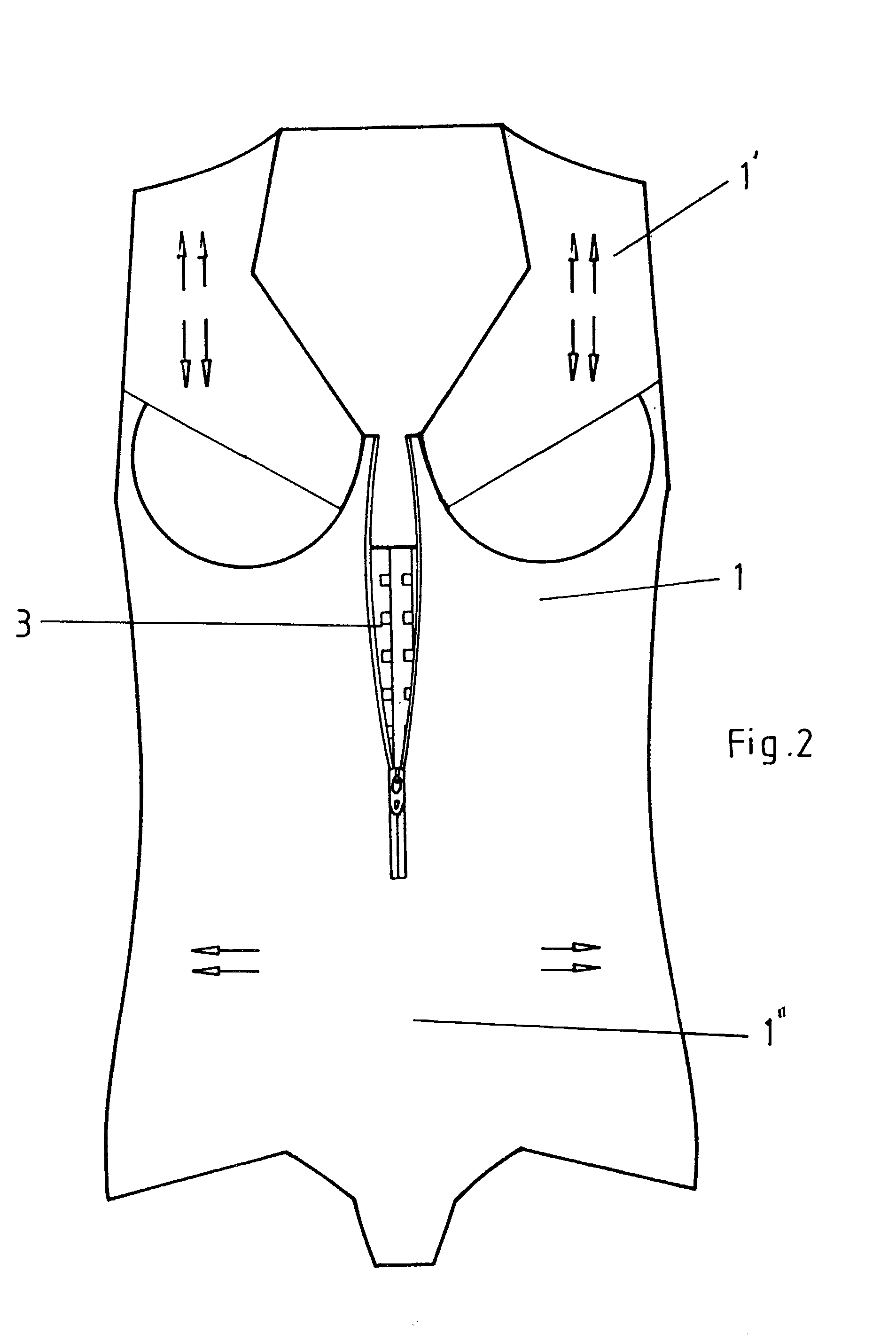

Orthopedic garment

The orthopedic garment is a one-piece garment especially suited for patients with osteoporosis and is made a cotton or synthetic fiber material and has different stretch zones each having a certain tension when applied. The rear area of the garment (1) is provided with a long pocket (2), which is open at the top or bottom and which accommodates a narrow rigid splint (4) that supports the vertical column of the spine. The splint is held inside the pocket (2) in a flexible manner or with a little play.

Owner:MEDI GMBH & CO KG

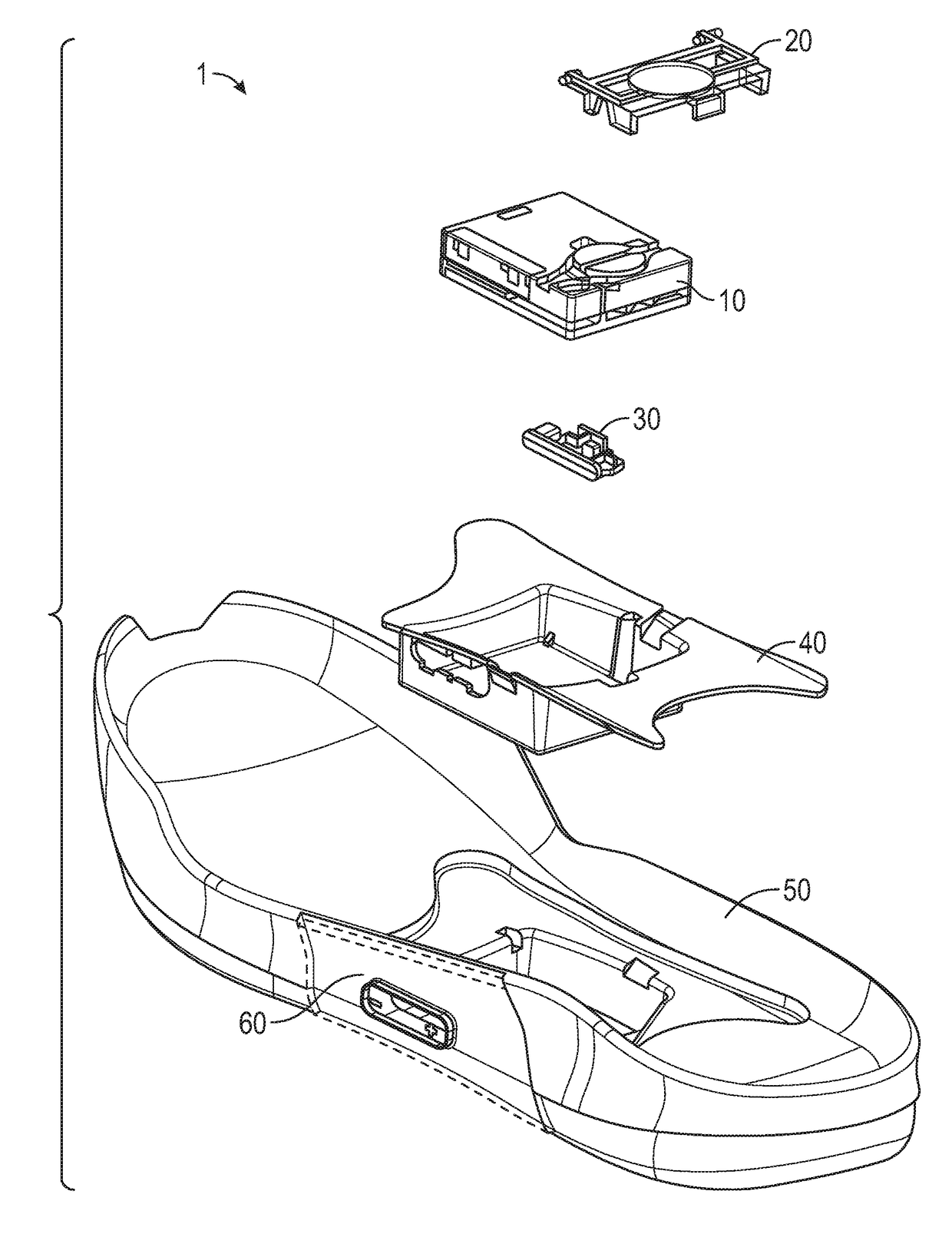

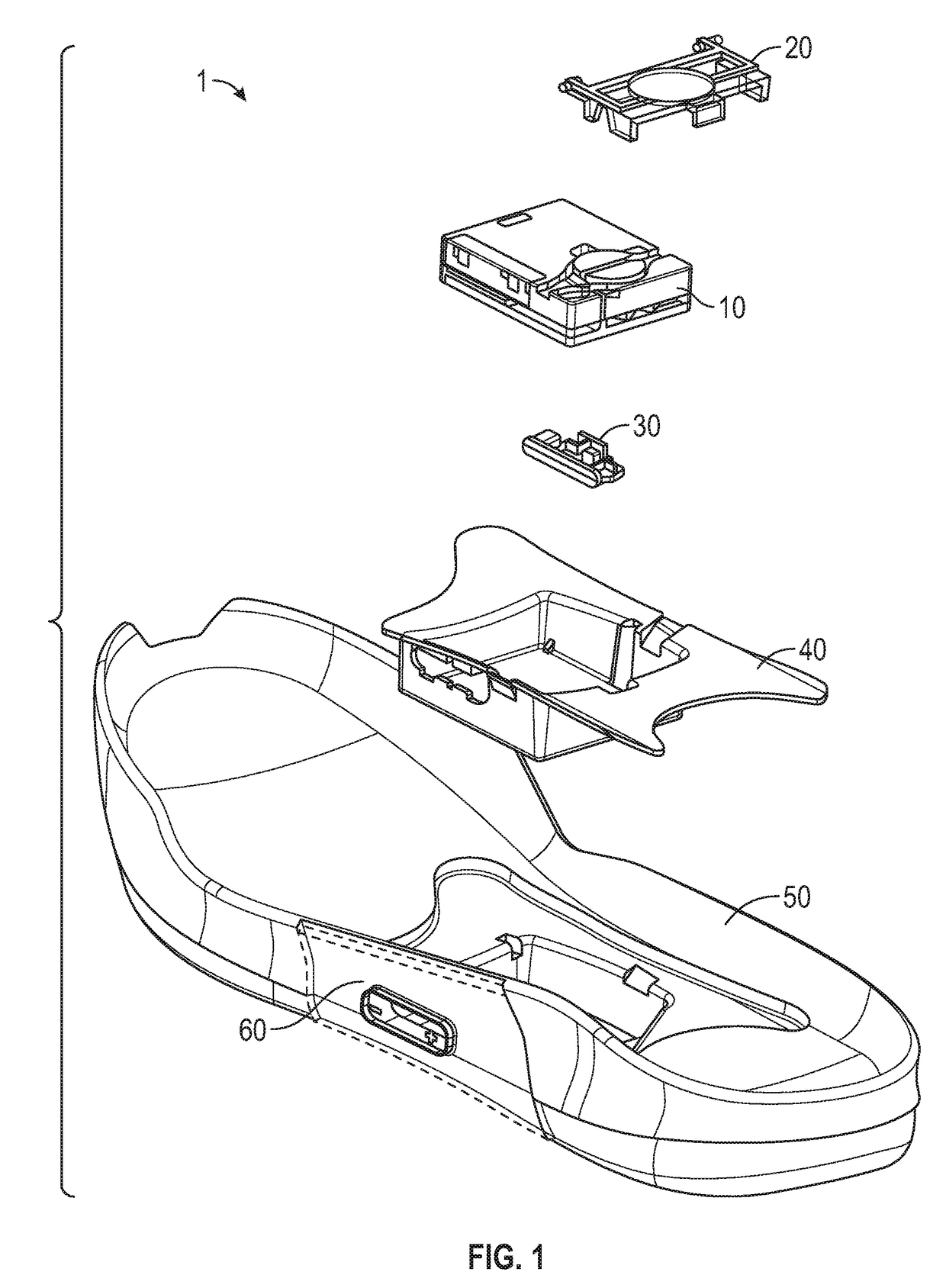

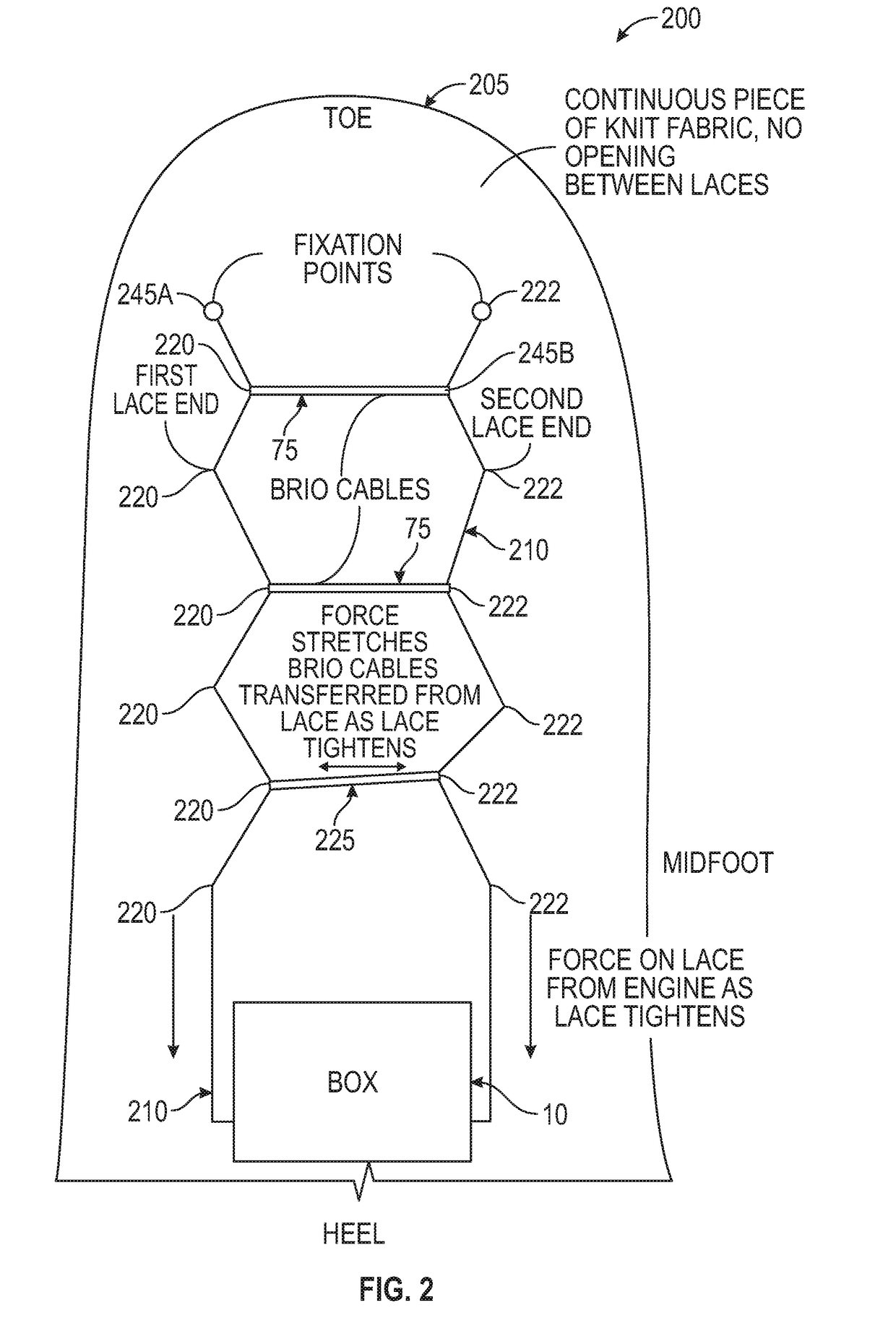

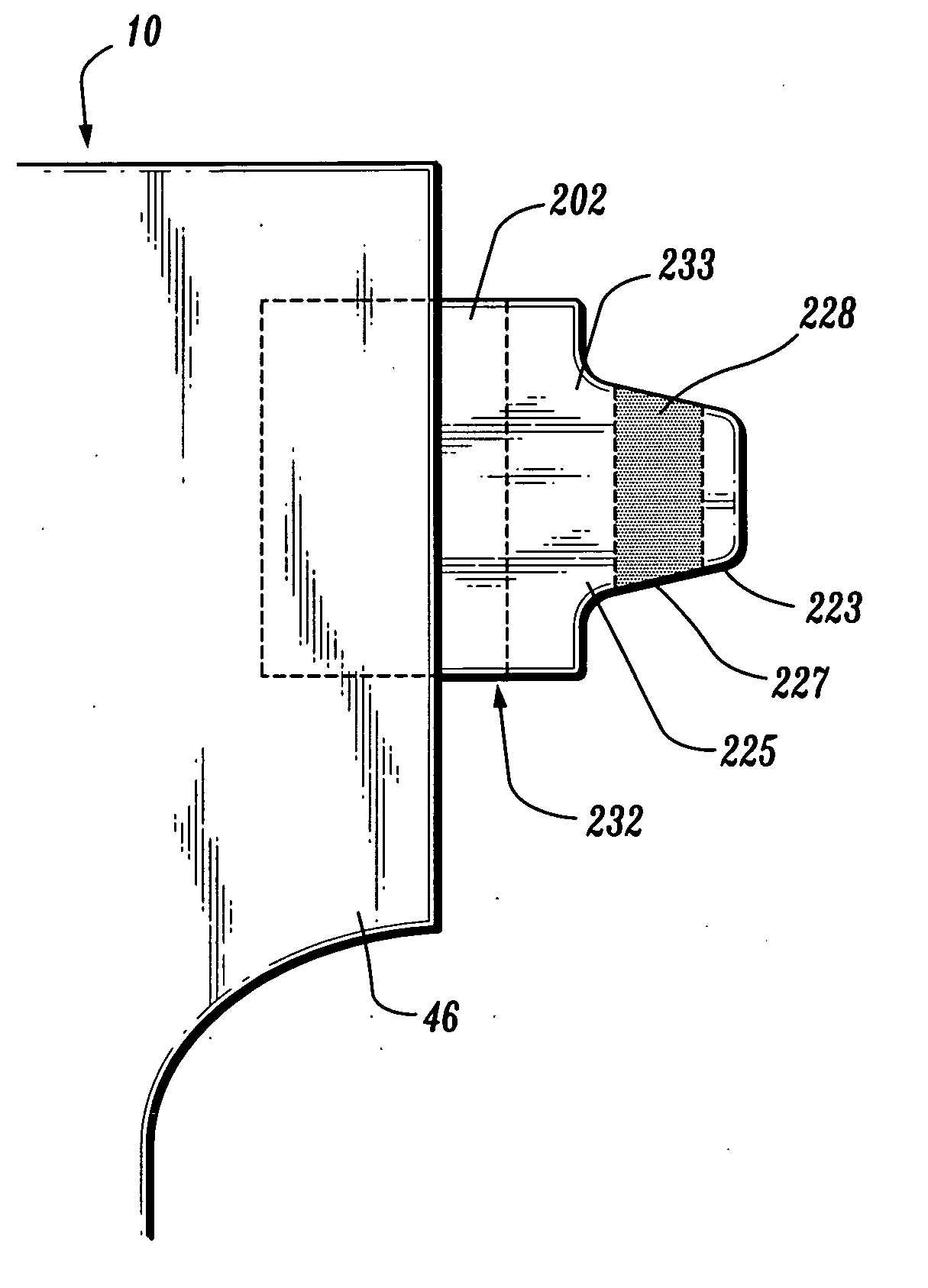

Automated footwear platform having lace cable tensioner

A footwear assembly can comprise, an upper, a lace cable, a plurality of lace guides and a tensioner. The tensioner can comprise a tensioning member secured to a side of the upper proximate a toe box and the lace cable, and a floating overlay attached to a side of the upper proximate a toe box and the lace cable. The tensioning members can comprise an elastic member. The tensioning members can be configured to provide a stiff lockout zone and an elastic stretch zone.

Owner:NIKE INC

Method of making closure tabs with minimal waste

An absorbent article fastener is provided that includes an absorbent article fastener that is configured for engagement with a landing zone of an absorbent article. The fastener includes an integral substrate having a stretch zone and a shaped deadened zone. A mechanical closure material is mounted with the deadened zone such that the substrate is configured for releasable engagement with the landing zone of the absorbent article. A surface area ratio of the mechanical closure material to the substrate is less than 65%. A method of manufacturing the absorbent article fastener is also provided.

Owner:FIRST QUALITY RETAIL SERVICES

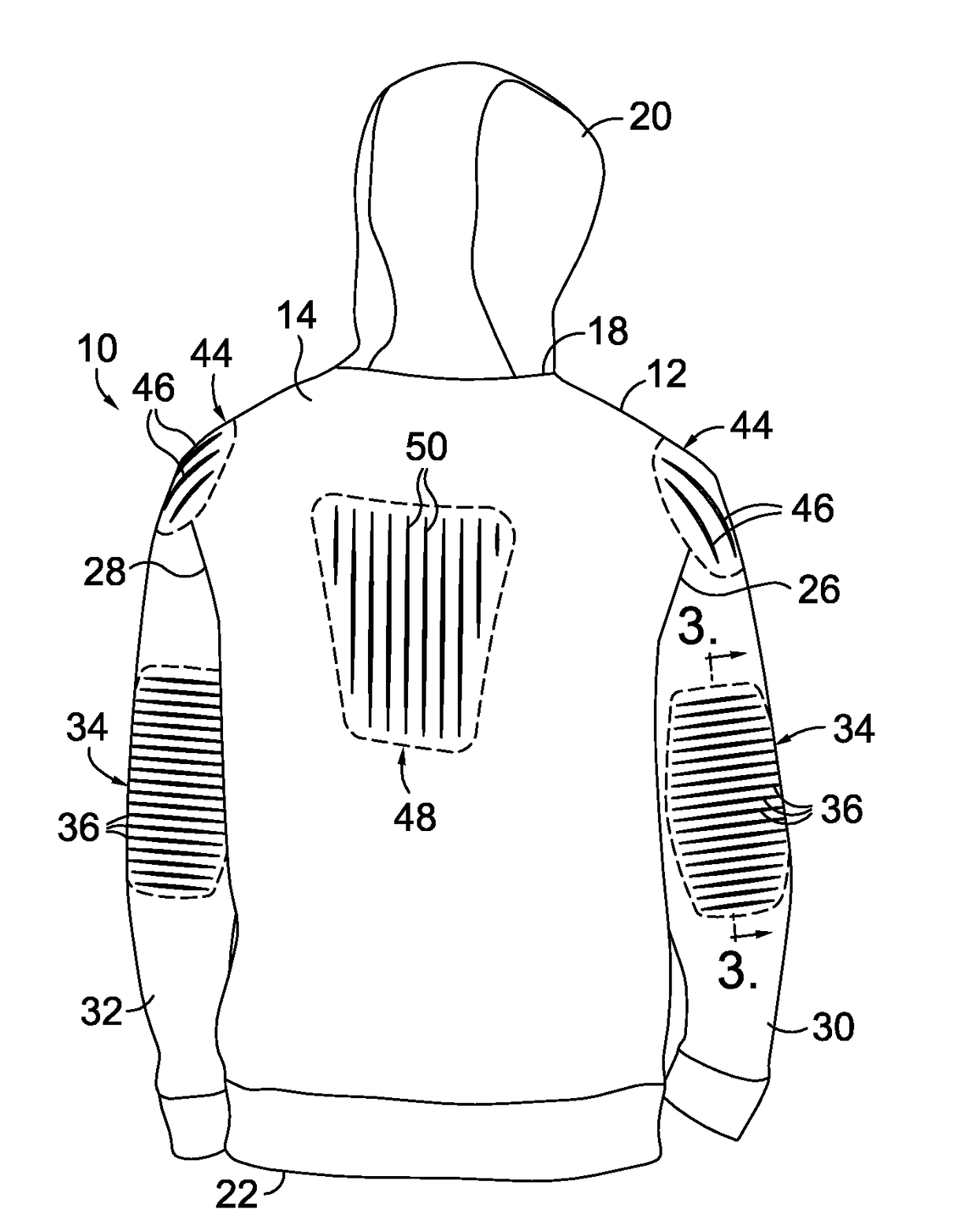

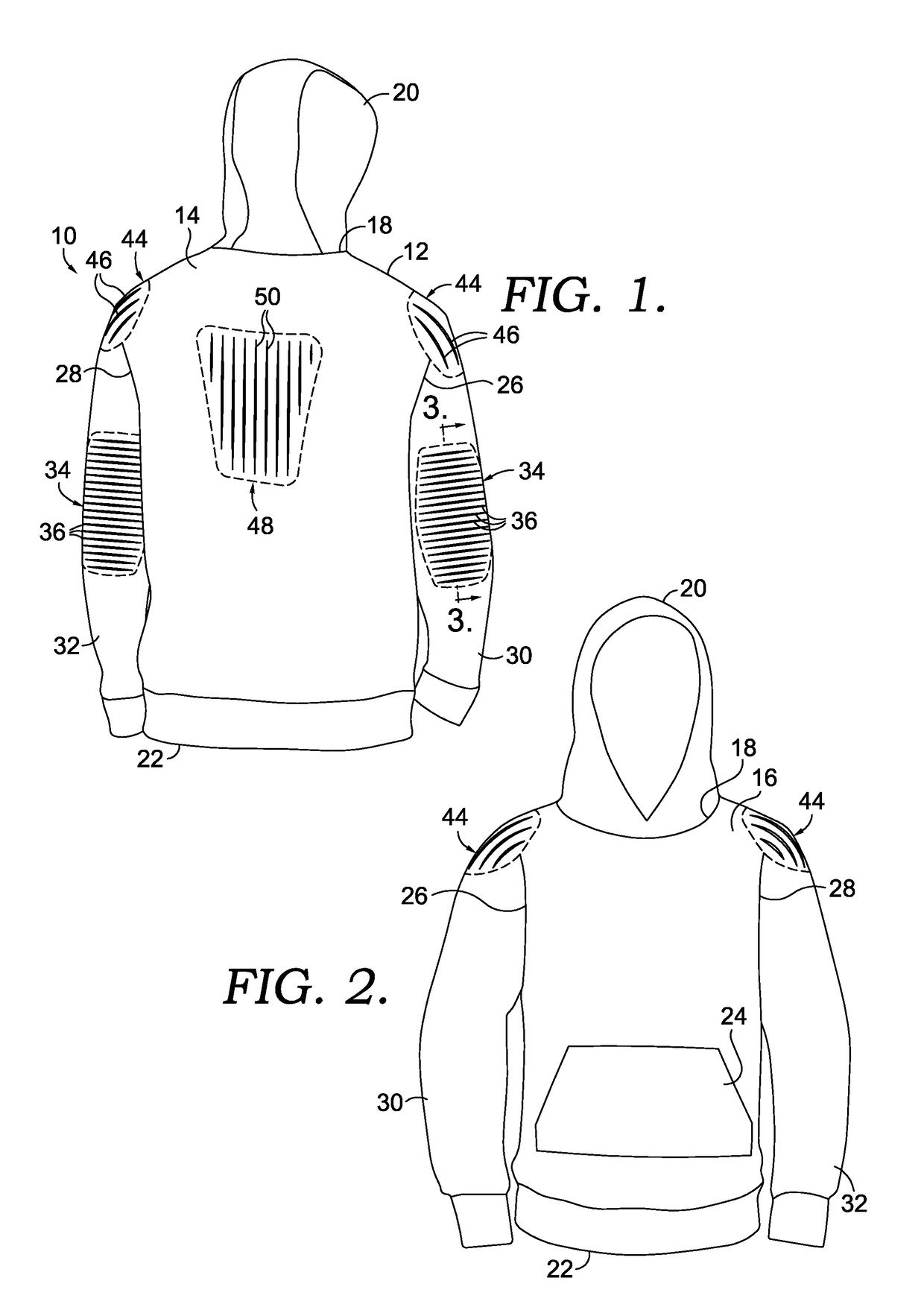

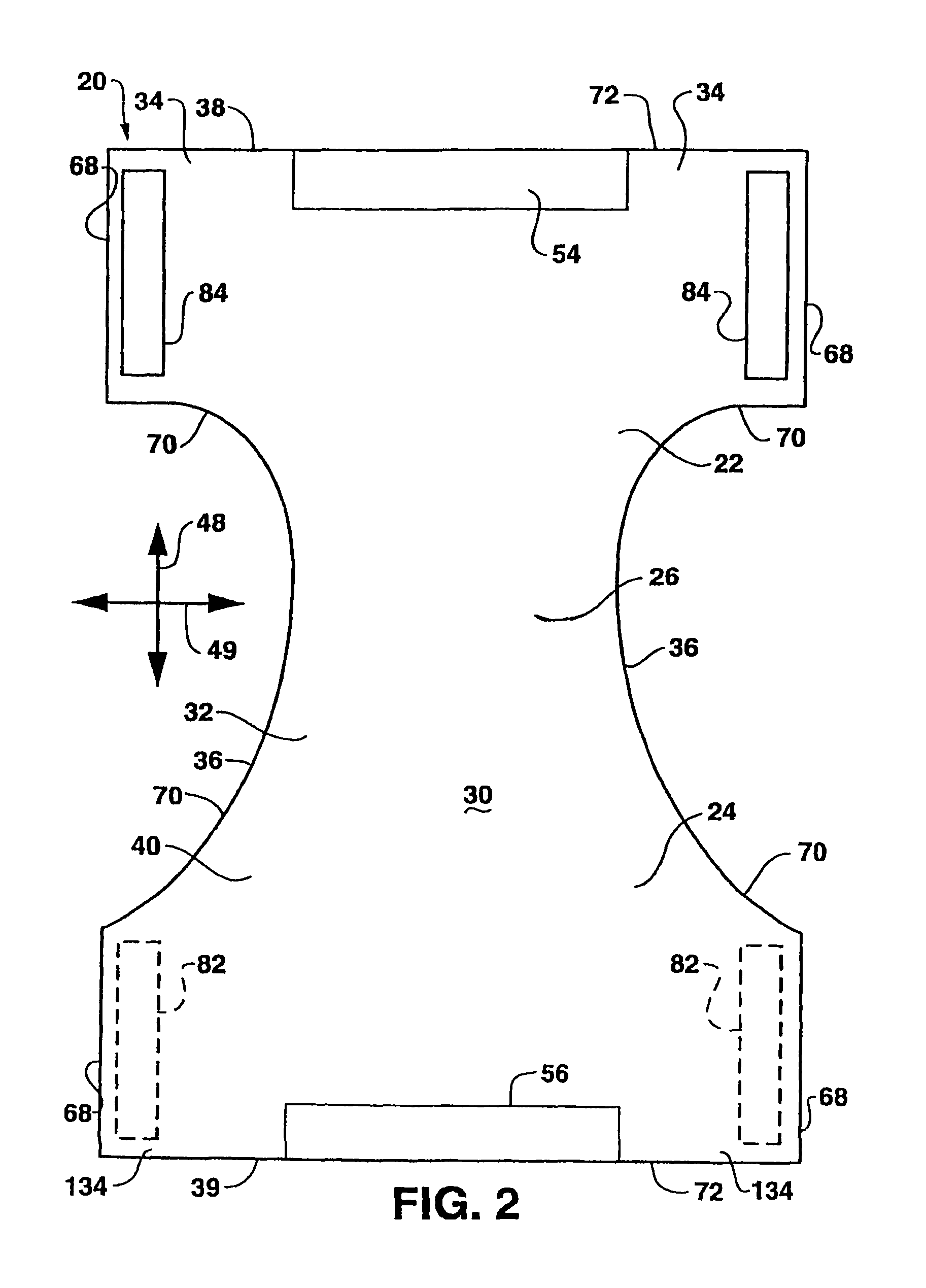

Garment having selected stretch zones

ActiveUS20180049494A1Improve tensile propertiesGood flexibilityGarment special featuresOvergarmentsEngineeringStretch zone

A garment portion made primarily from a material with low-stretch characteristics, having defined stretch zones with greater flexibility is provided herein. The stretch zones have slits through the garment portion. An interior layer having higher stretch characteristics than the garment body portion is affixed to the internal surface of the garment body portion in the area of the stretch zone. The result is a garment portion that is primarily constructed with a low-stretch material that has stretch zones allowing greater flexibility.

Owner:NIKE INC

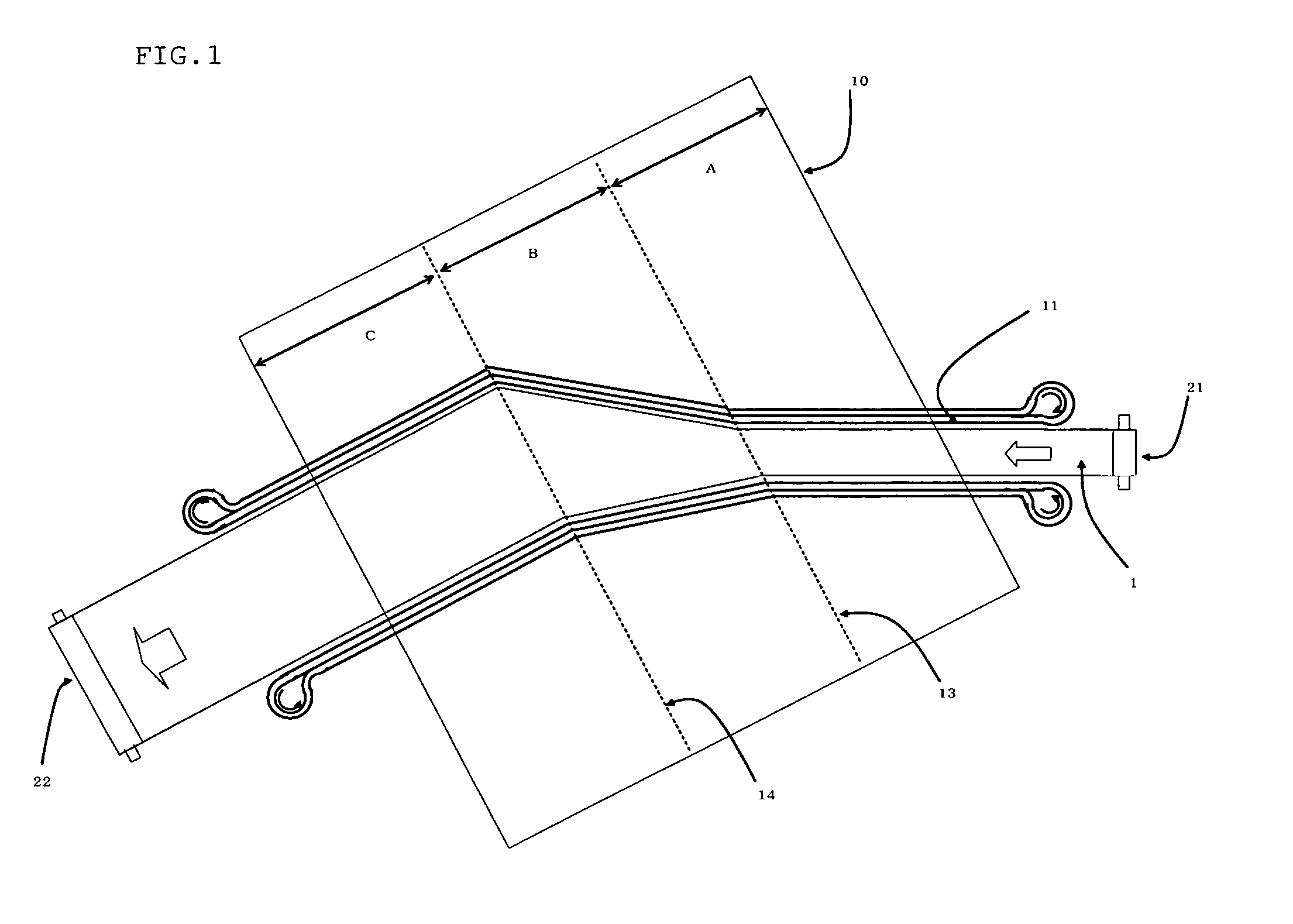

Method for Producing Long Obliquely Stretched Film

ActiveUS20100002170A1Increase production capacityPrevents a drop in contrastLayered productsPolarising elementsEngineeringStretch zone

Owner:ZEON CORP

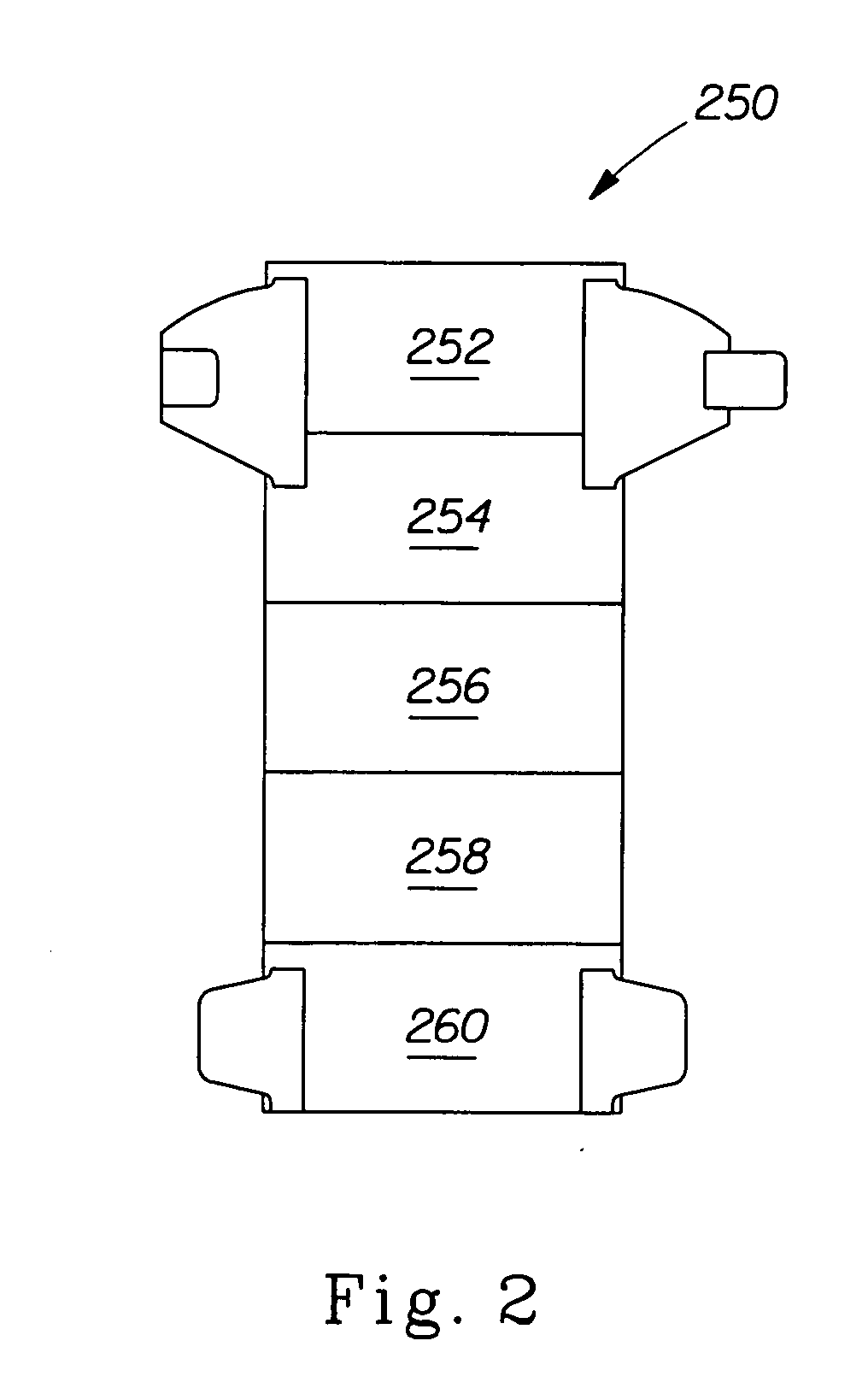

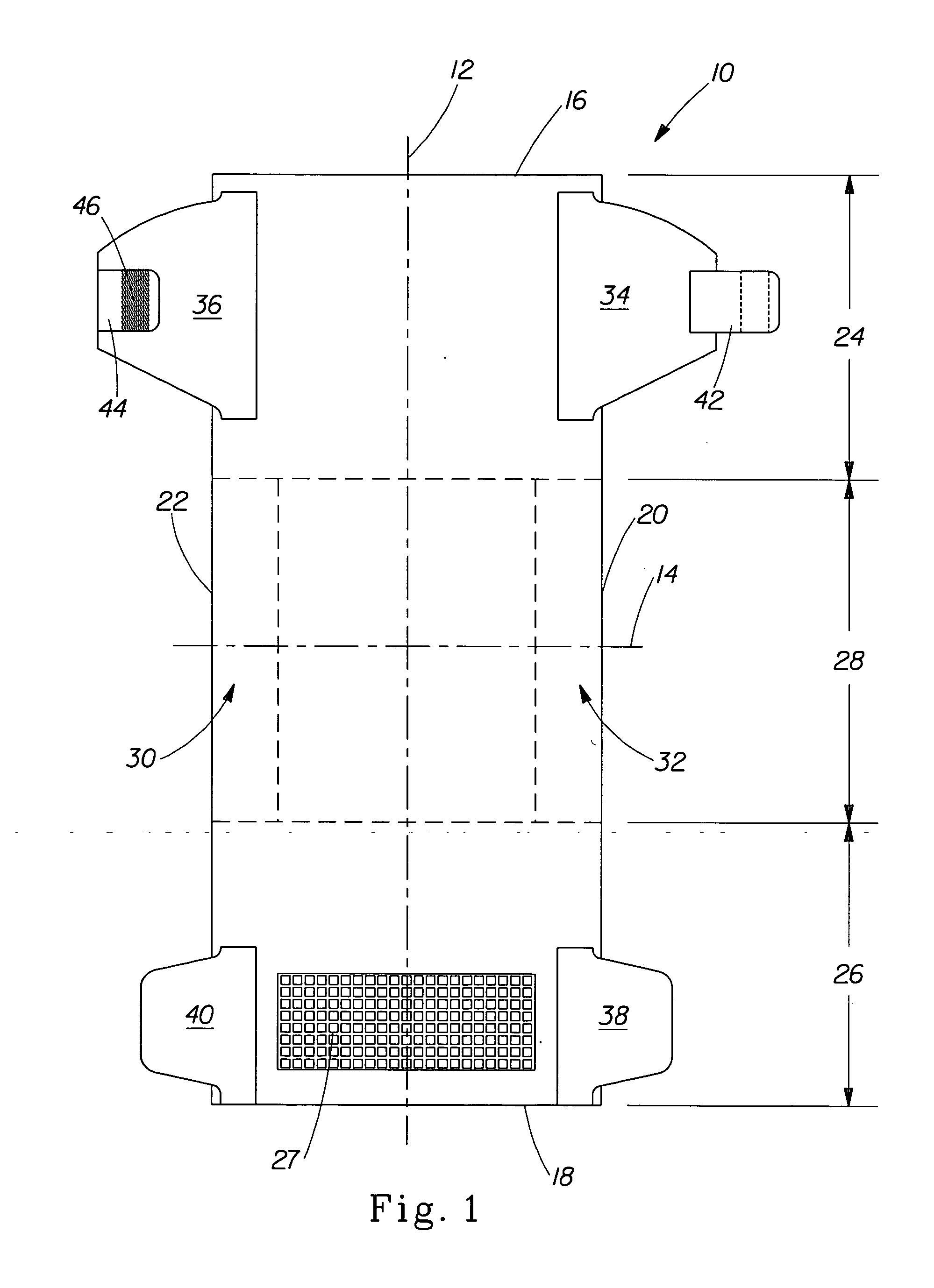

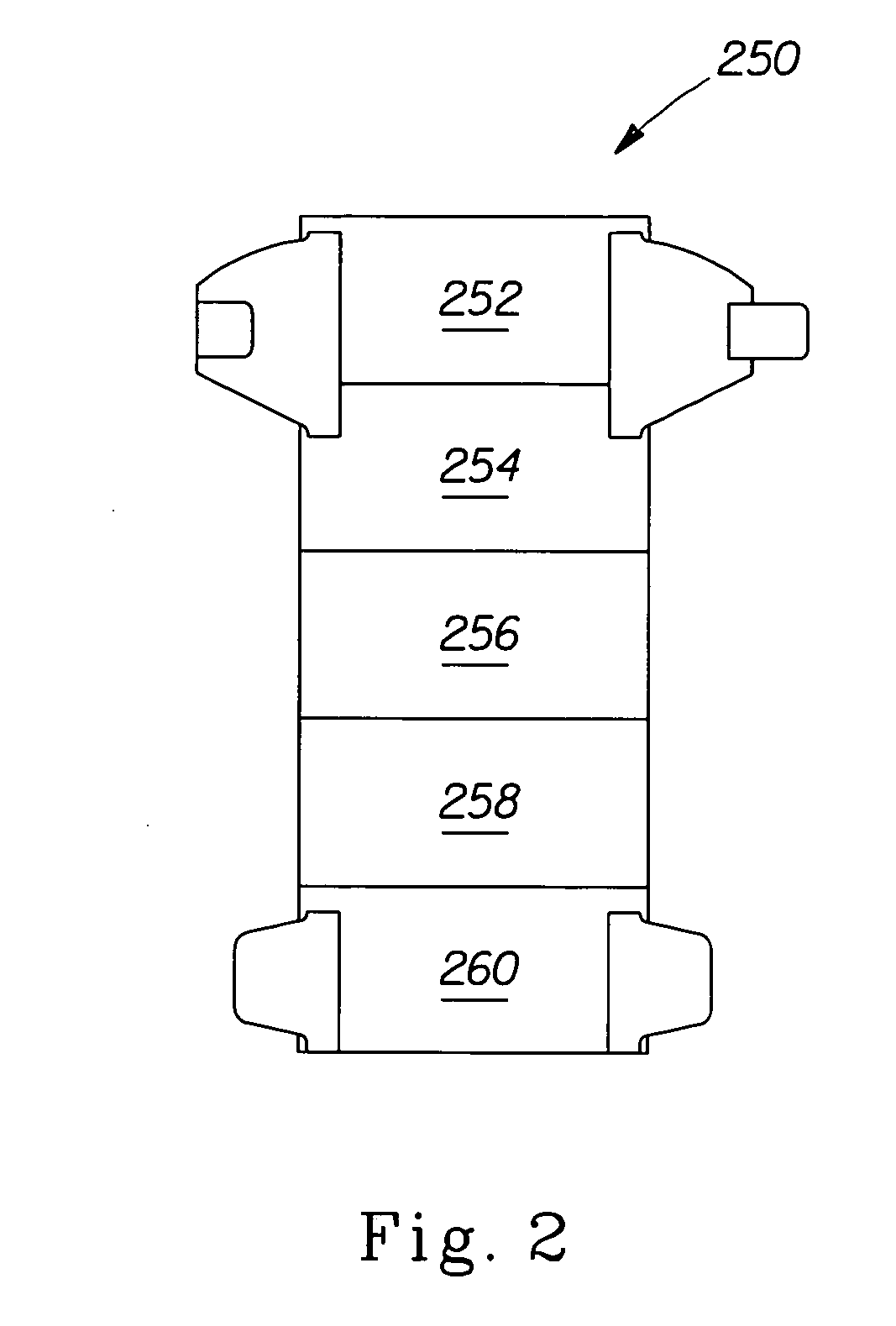

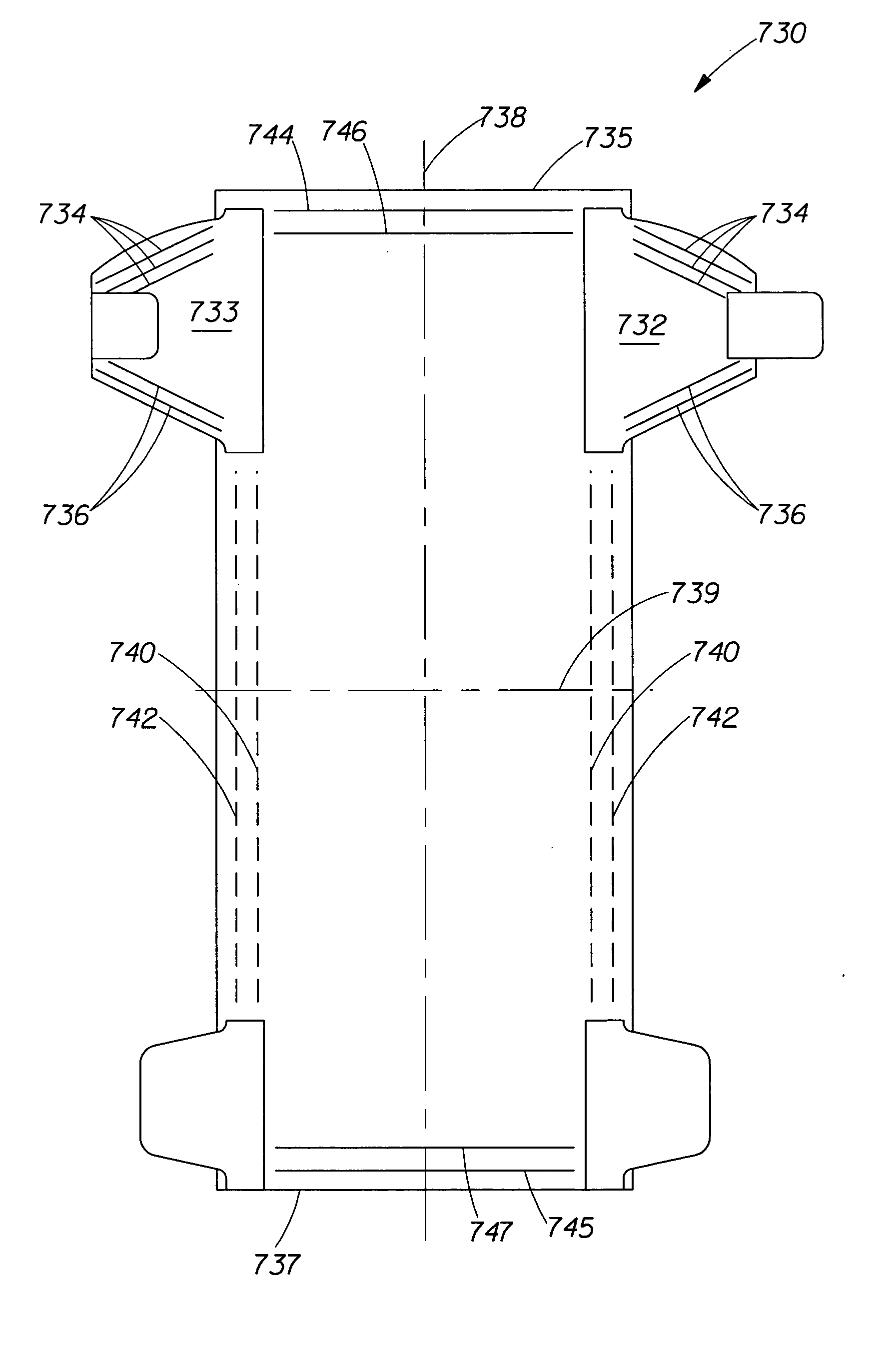

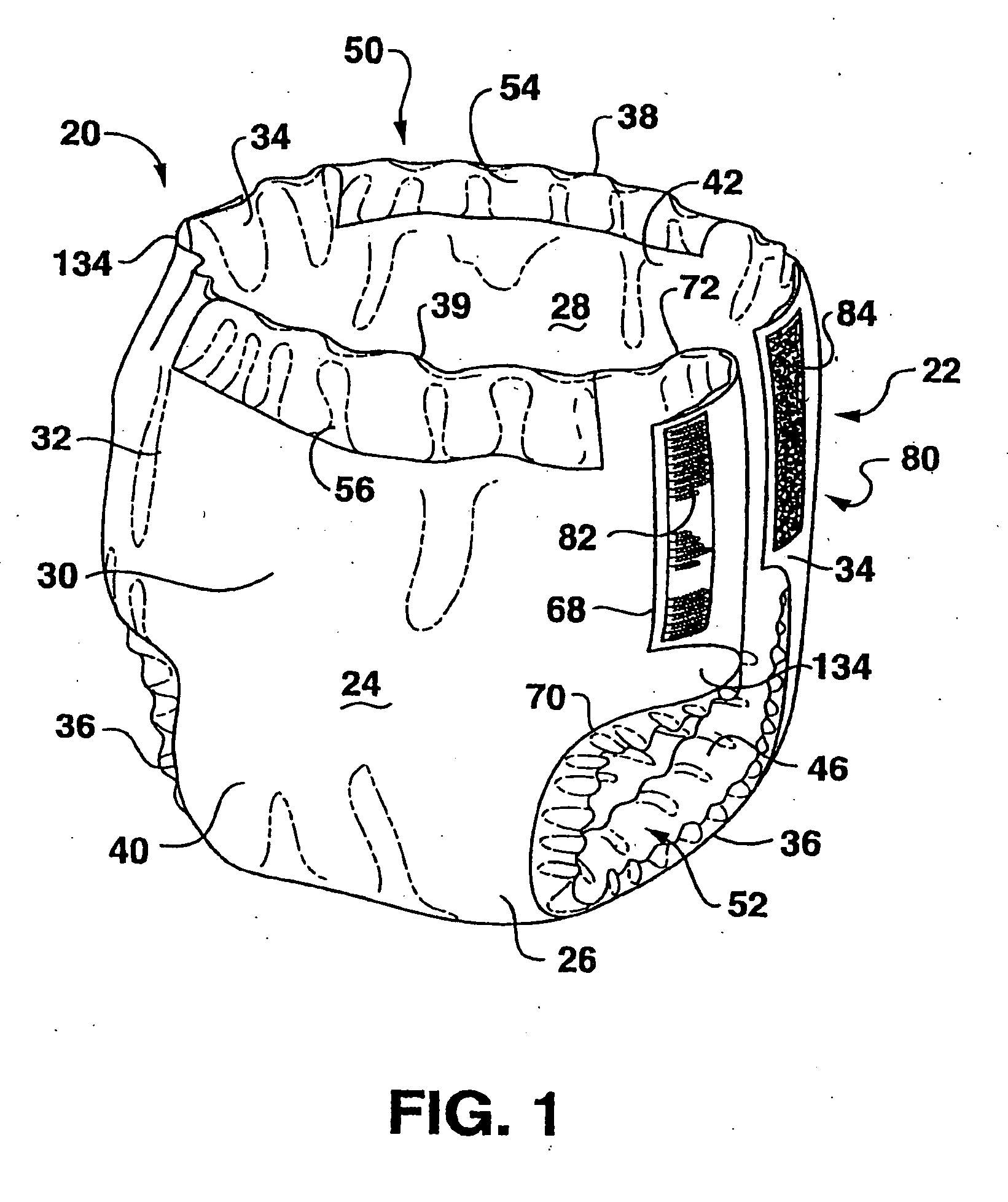

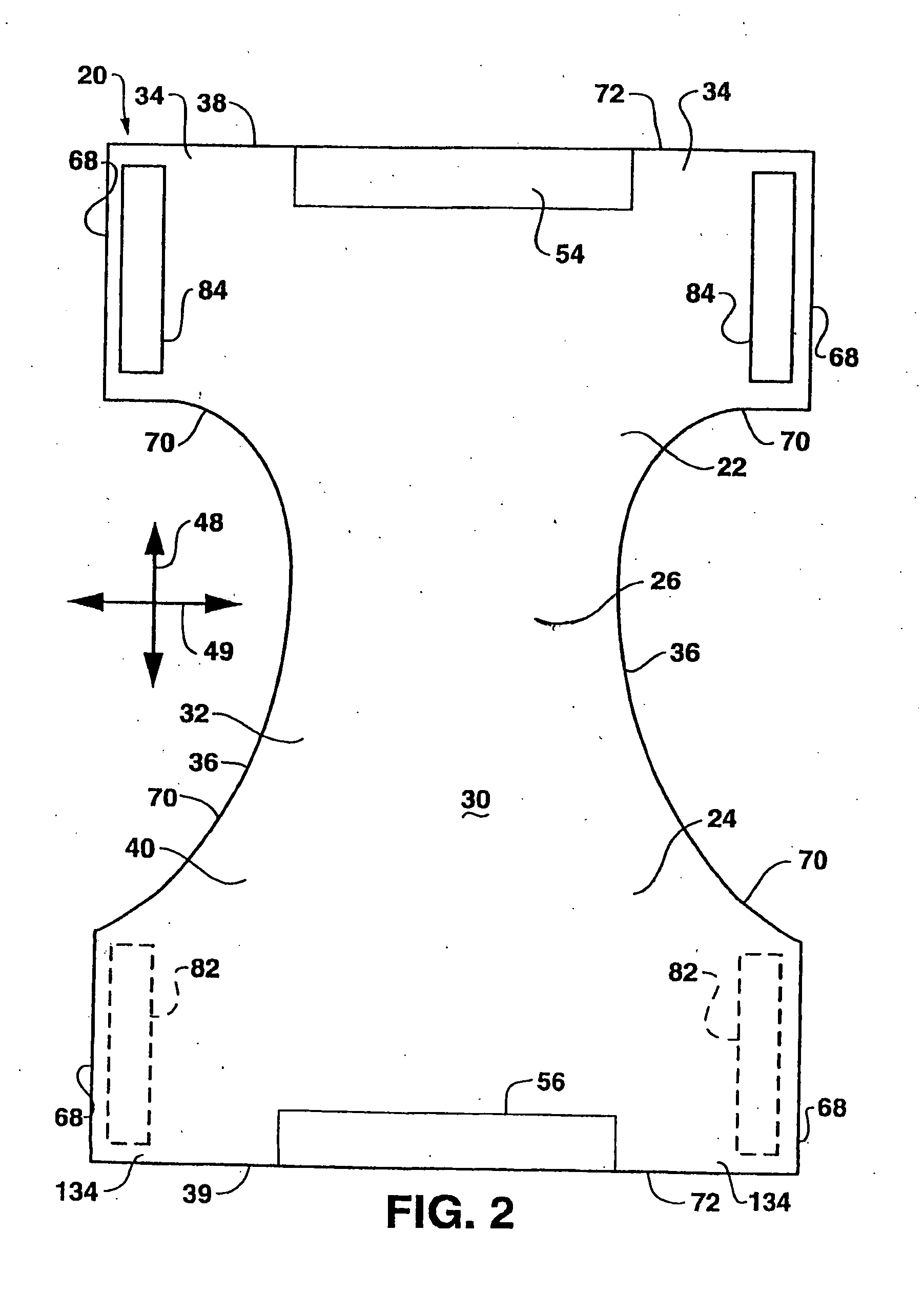

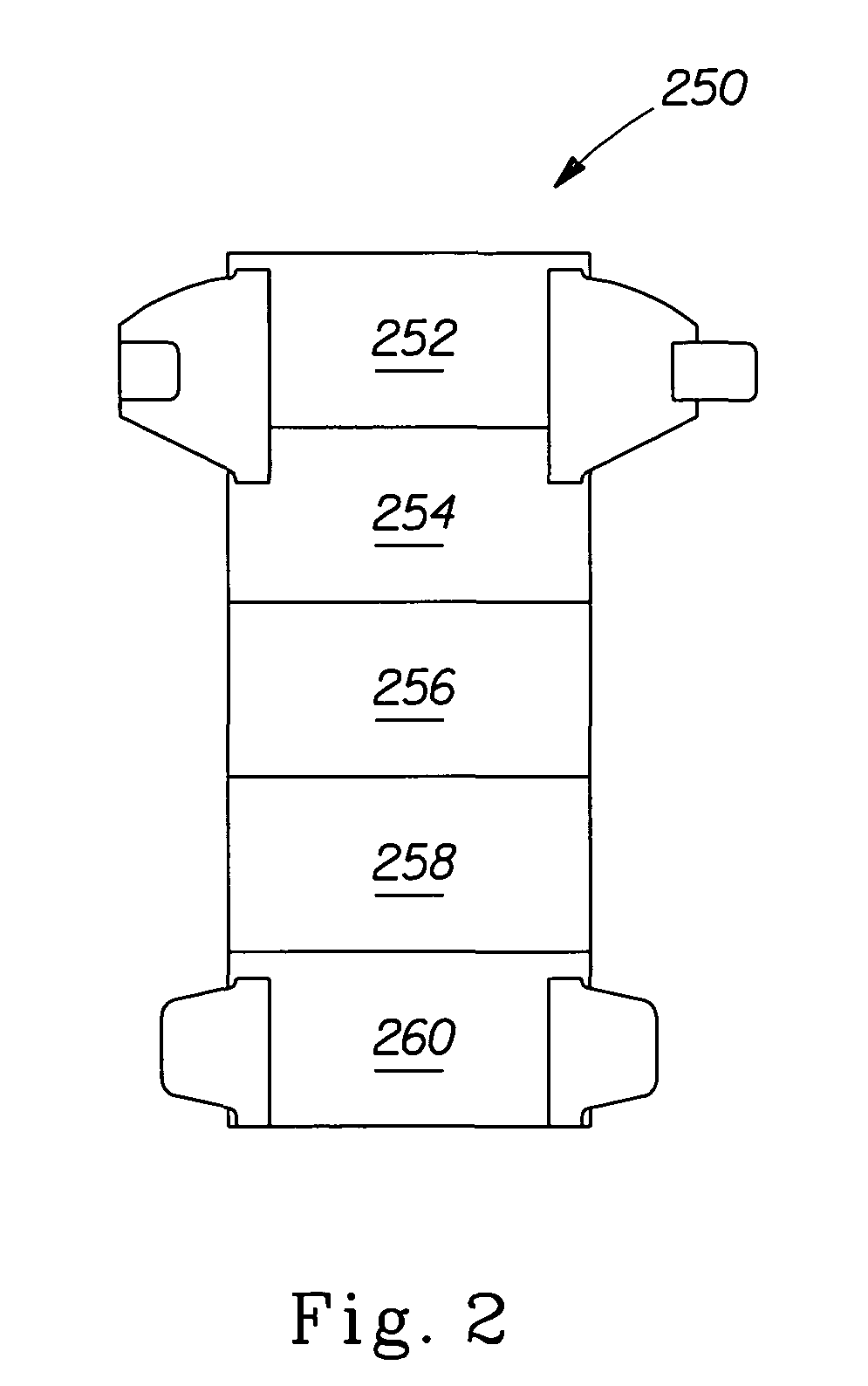

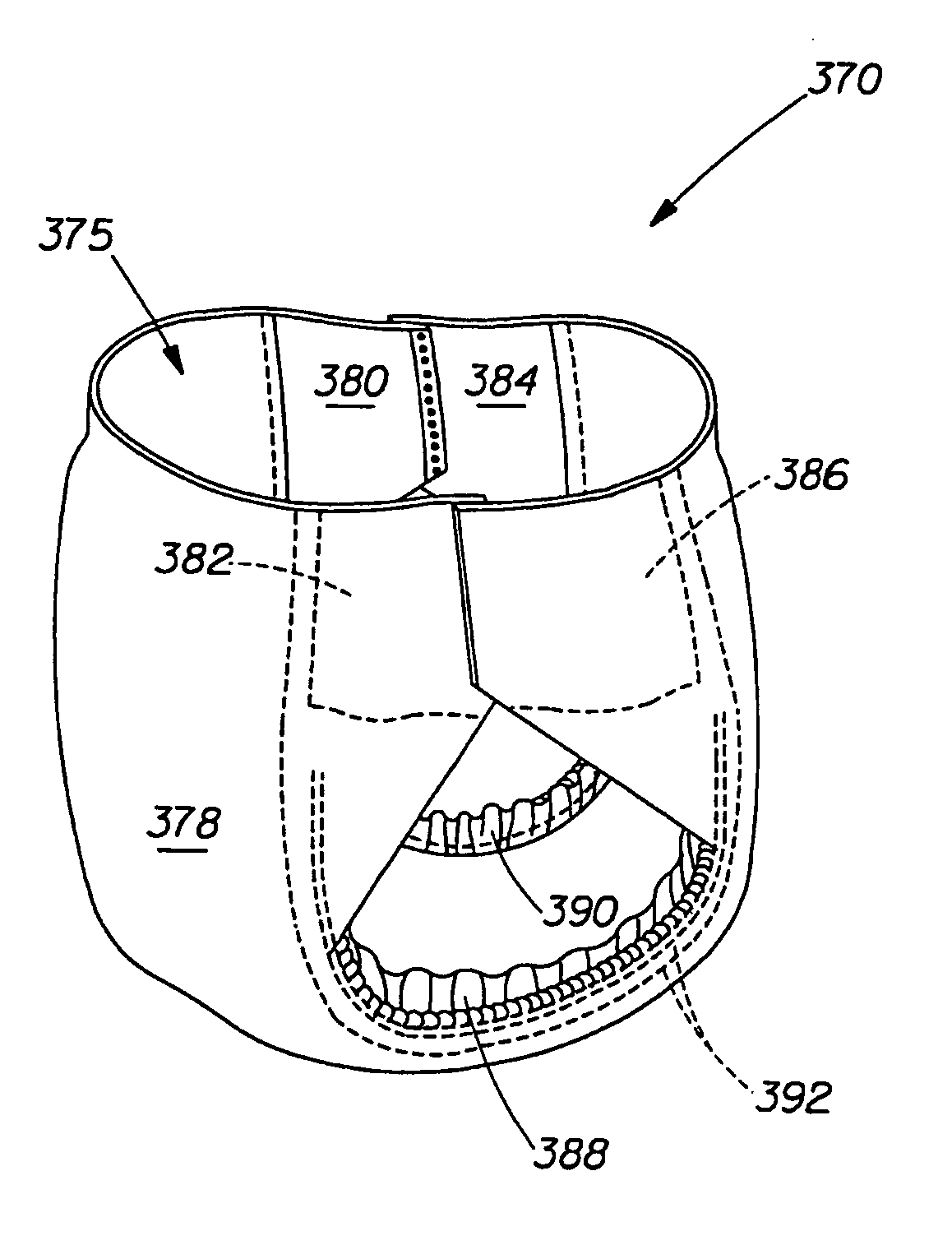

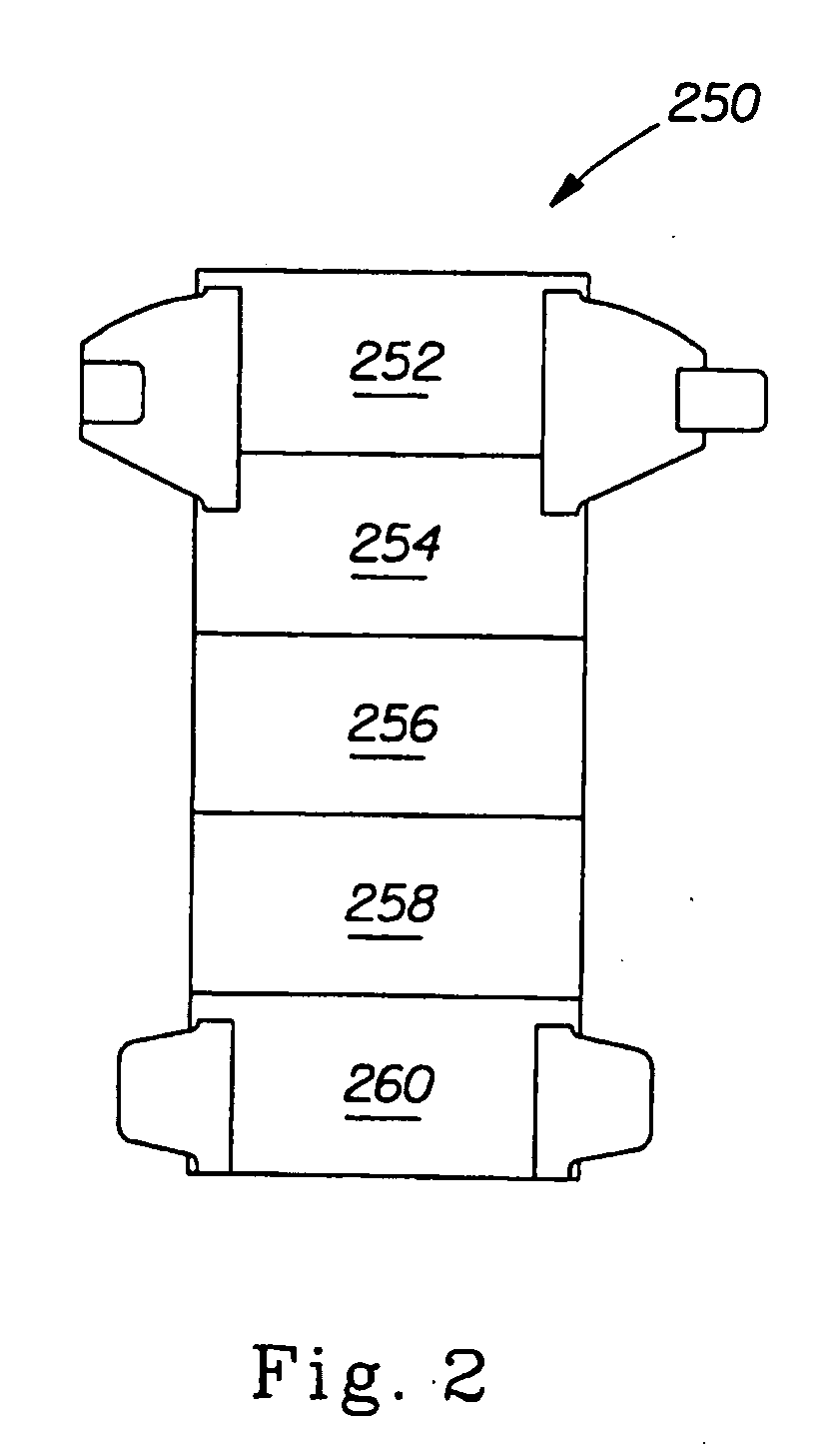

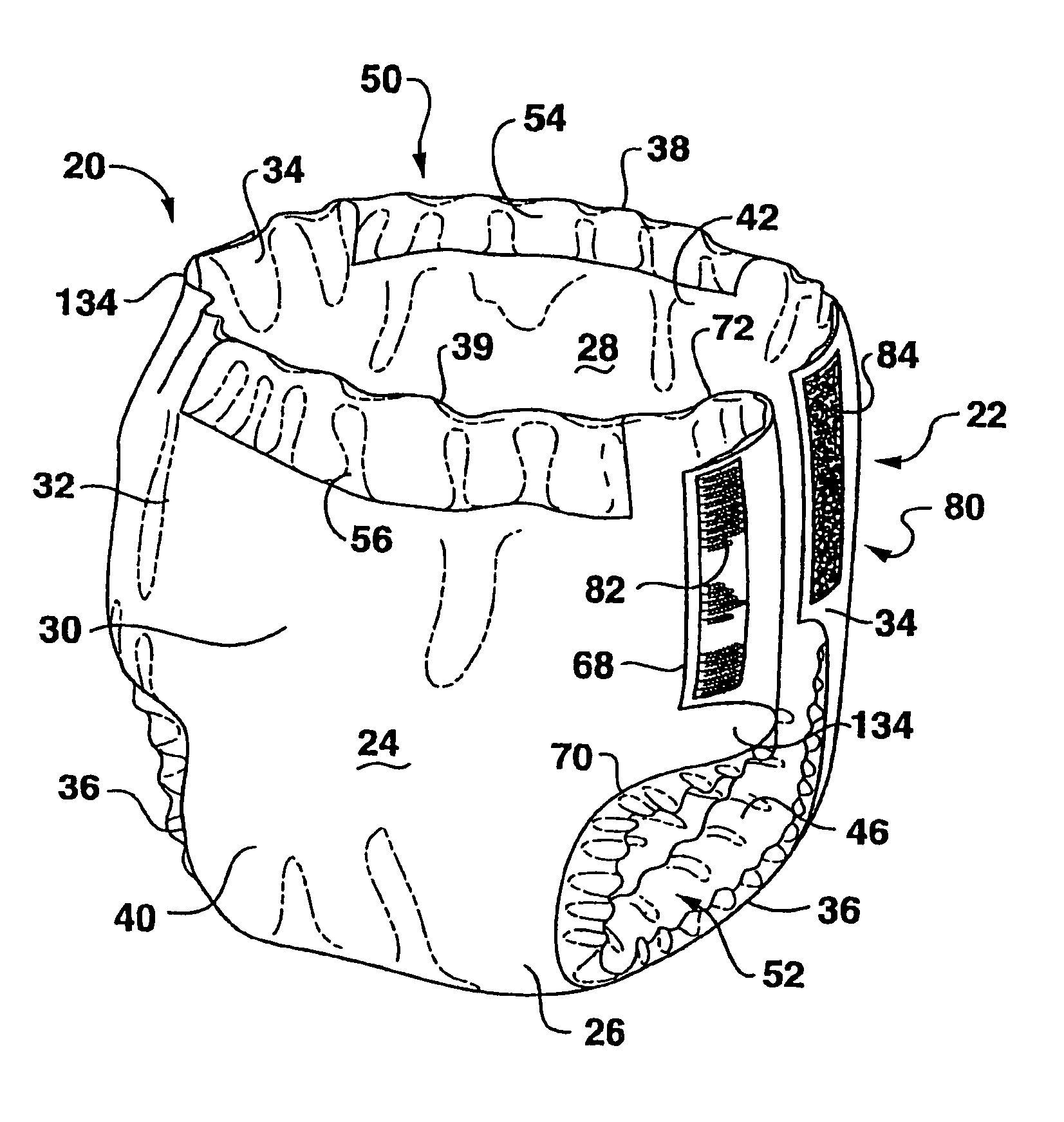

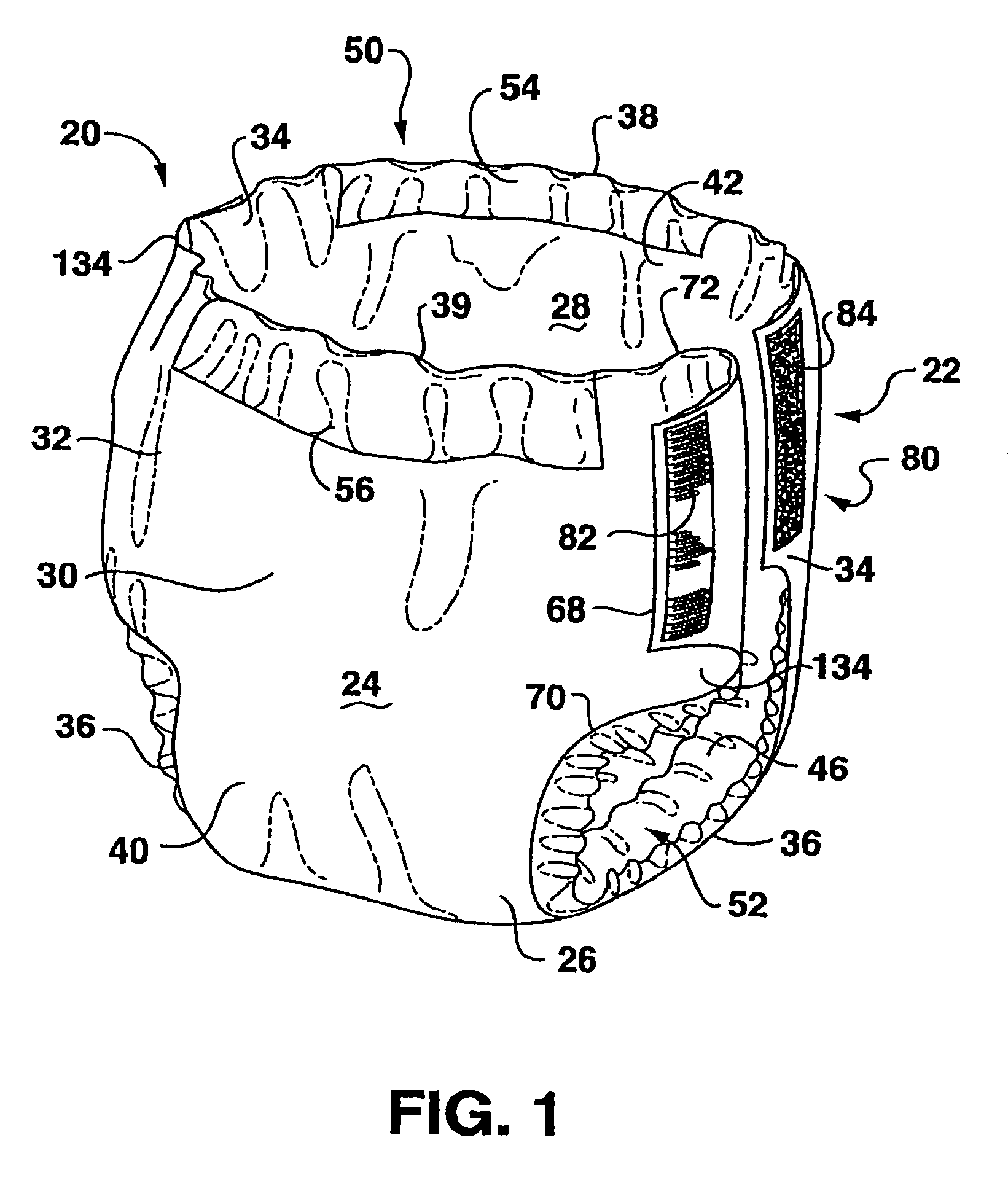

Absorbent garments with multipart liner having varied stretch properties

ActiveUS20070142812A1Carefully controlled stretch propertyImprove fitBaby linensTamponsEngineeringMiddle zone

Absorbent articles with stretch direction properties are disclosed, having at least three stretch zones. A first edge zone and a second edge zone are separated by a middle zone. The middle zone, which may the same length as each edge zone, has different stretch-direction characteristics than the edge zones. The middle zone may stretch in a single direction, whereas the edge zones may stretch in a different single direction or in bi- or multi-axial directions. The flaps may be created from the edge zones. Through this construction, the absorbent article exhibits improved fit and appearance.

Owner:KIMBERLY-CLARK WORLDWIDE INC

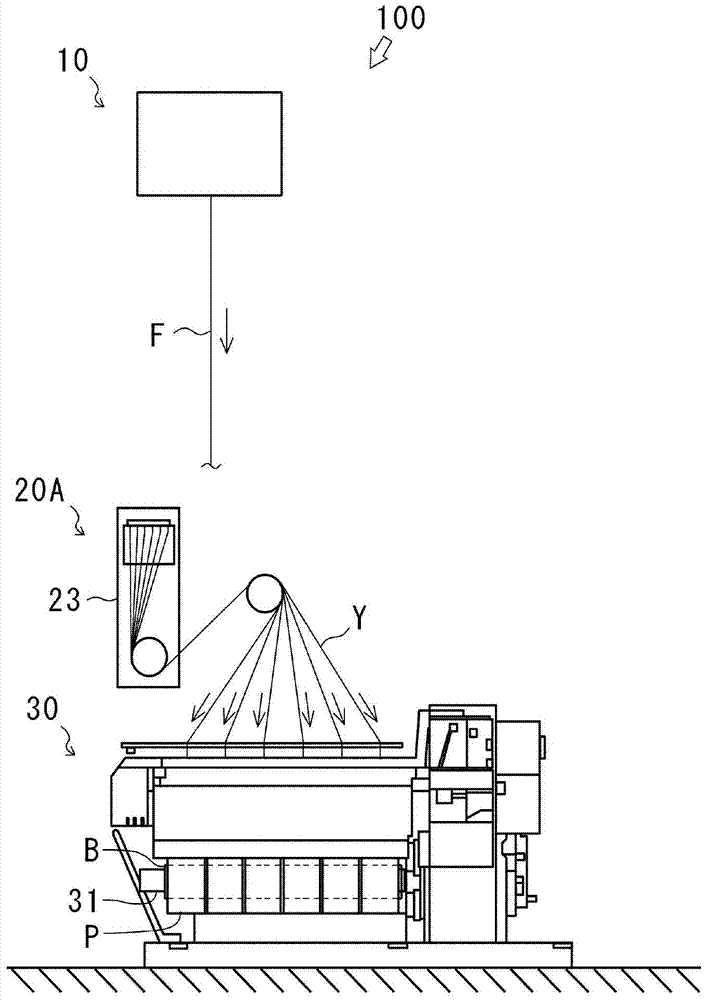

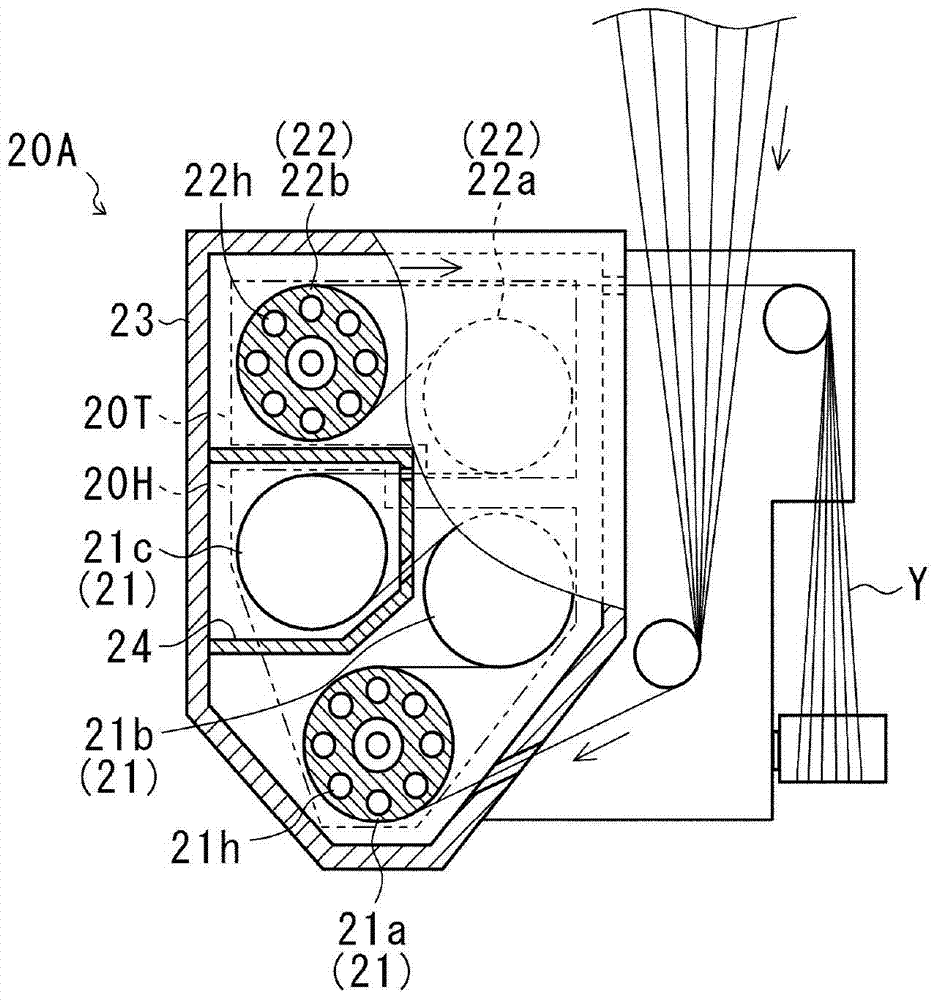

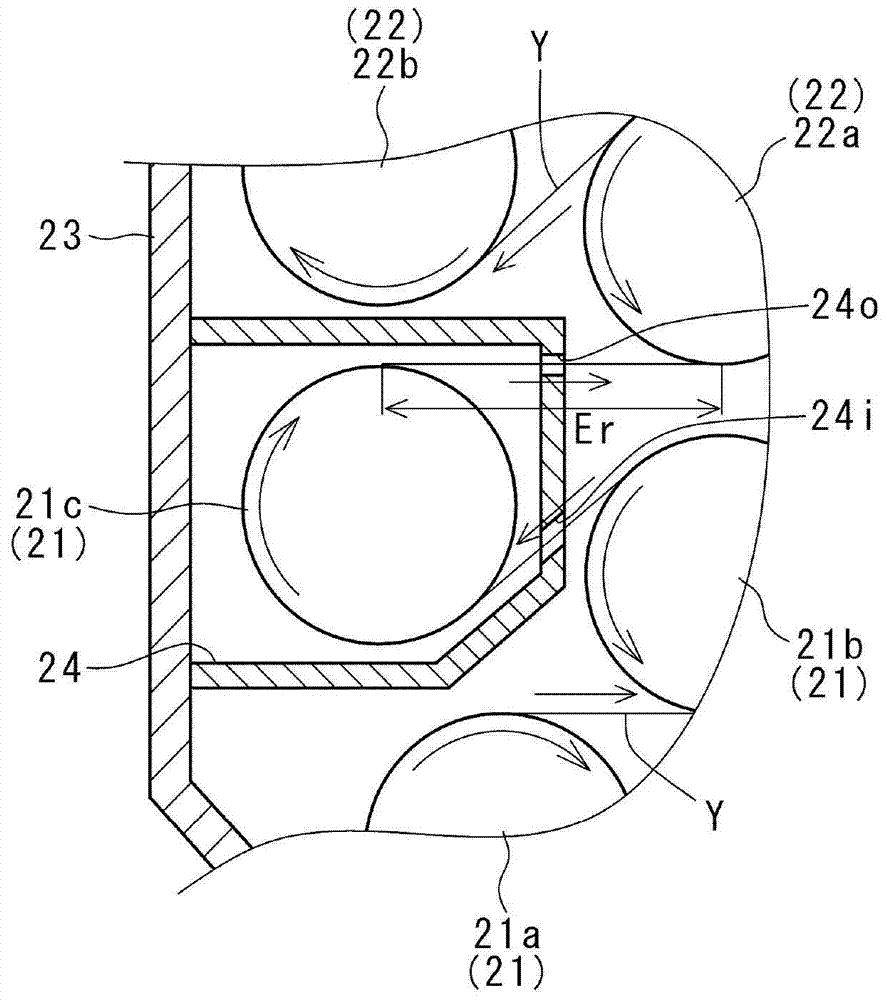

Yarn traction device

InactiveCN103835010ATemperature controlImprove qualityArtificial filament heat treatmentStretch-spinning methodsYarnEngineering

The invention provides a yarn traction device which can control the temperature of yarn in a stretching zone with high precision and produce yarn with high quality. The yarn traction device (100) comprises one or more than one heating rollers (21a, 21b, 21c) heating yarn (Y) to a stretching temperature (Th) and one or more than one tempering rollers (22a, 22b) heating the yarn (Y) to a tempering temperature (Tt). The yarn (Y) is stretched between the heating roller (21c) on the most downstream side in the feeding direction of the yarn (Y) and the tempering roller (22a) on the most upstream side. The yarn traction device also comprises a heat preservation box (23) used for receiving the heating rollers (21a, 21b, 21c) and the tempering rollers (22a, 22b). The heating roller (21c) on the most downstream side is covered by a shield cover (24).

Owner:TMT MACHINERY INC

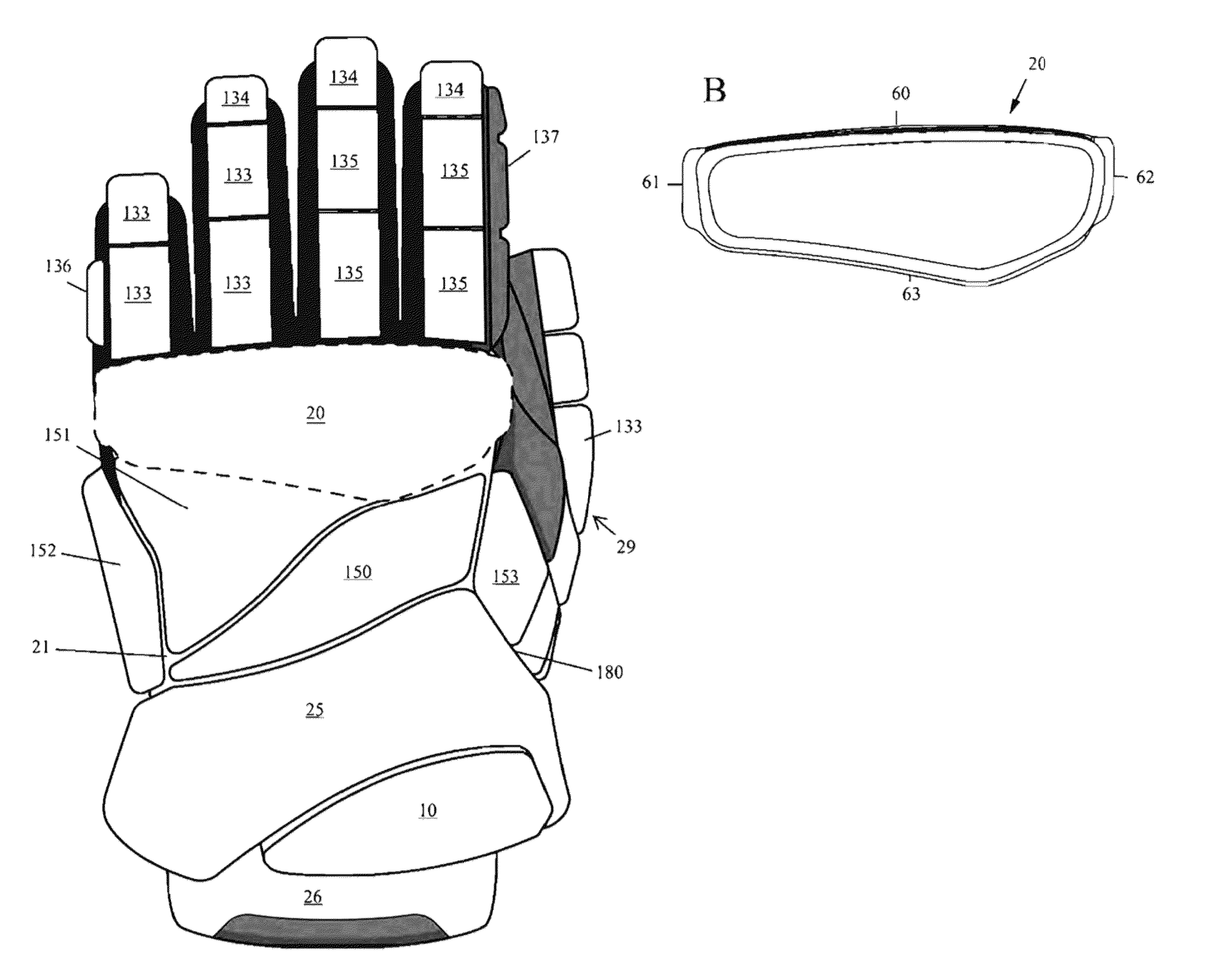

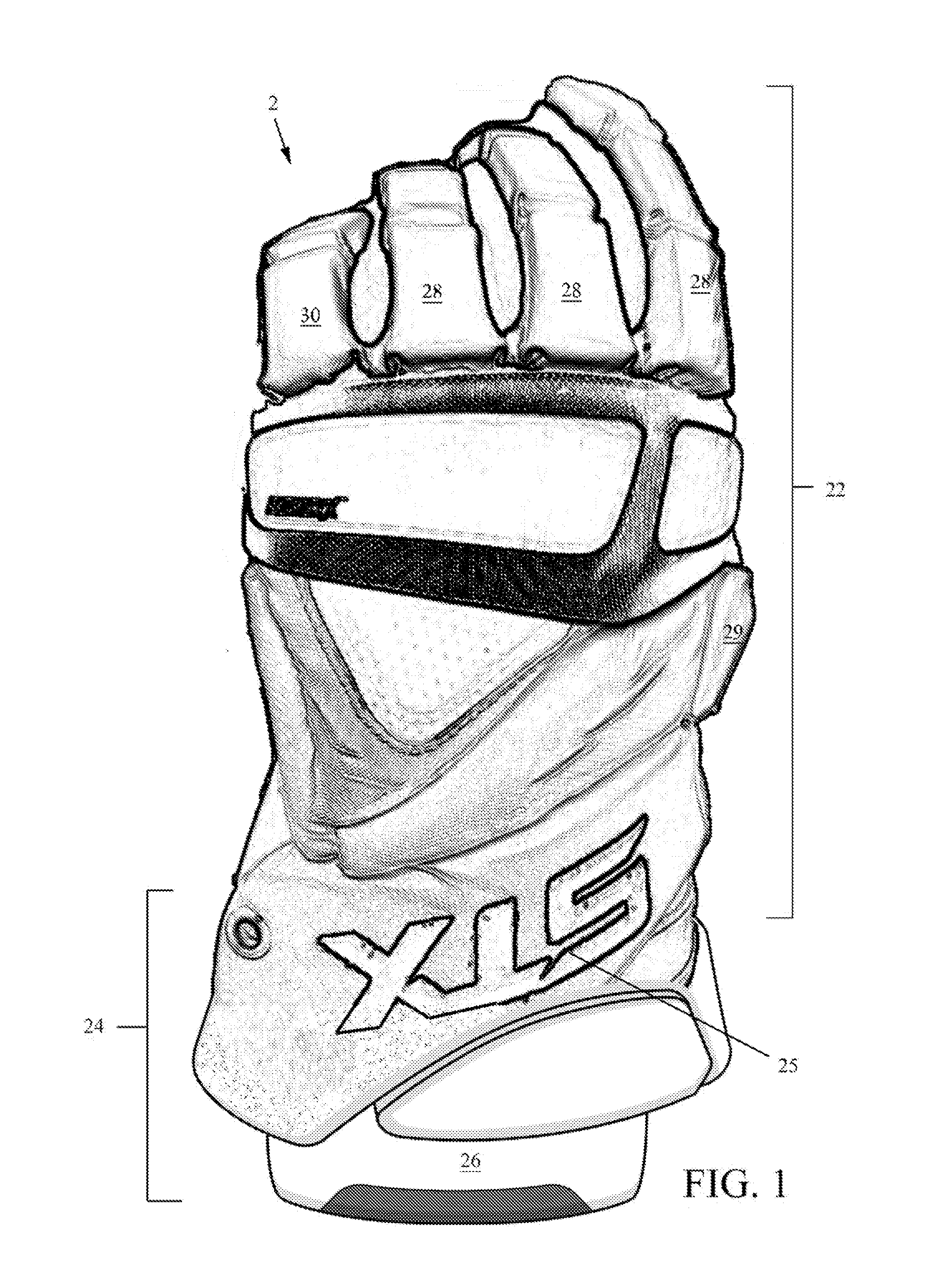

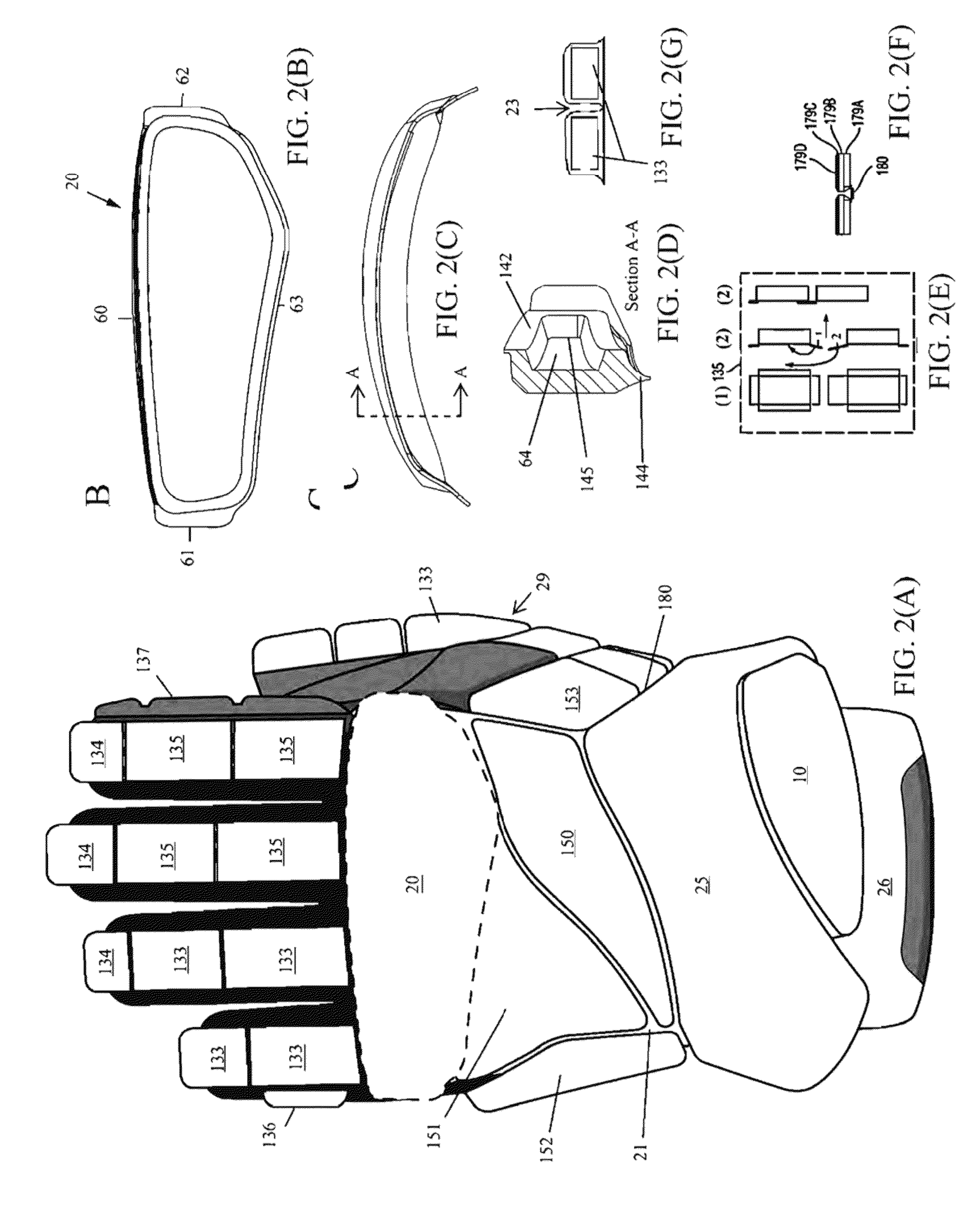

Protective sports glove

InactiveUS20160082342A1Improve protectionIncrease flexibilityGlovesKitchen equipmentEngineeringCushion

Owner:WM T BURNETT IP

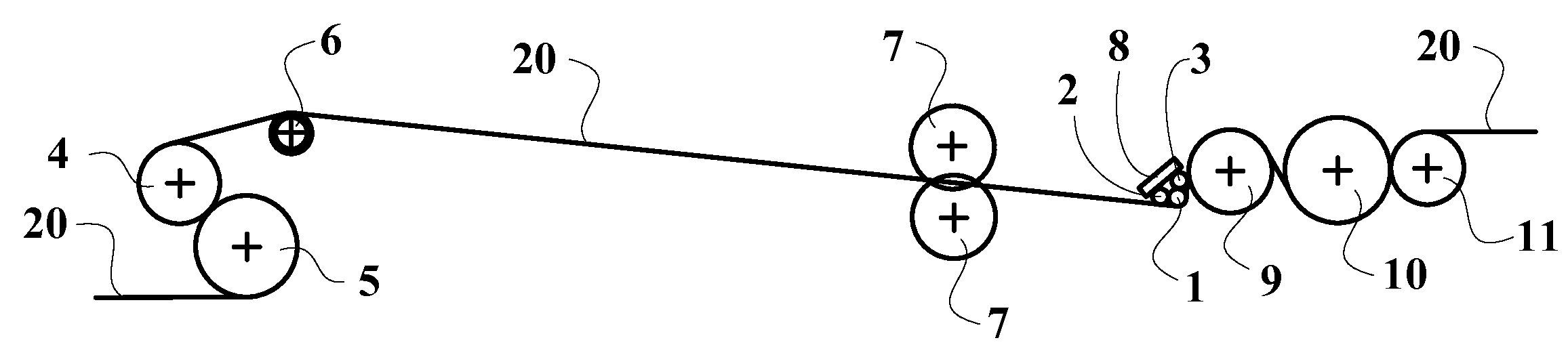

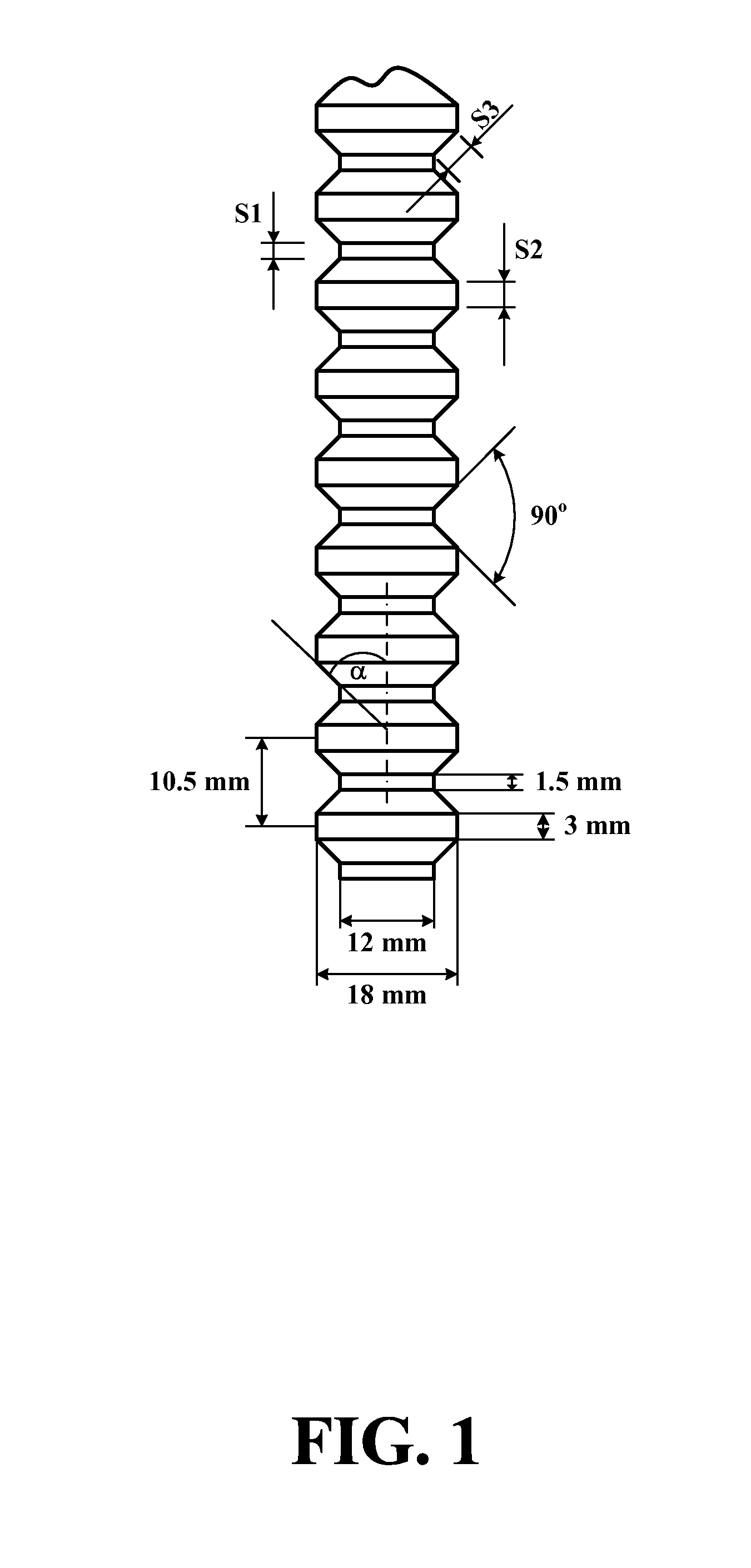

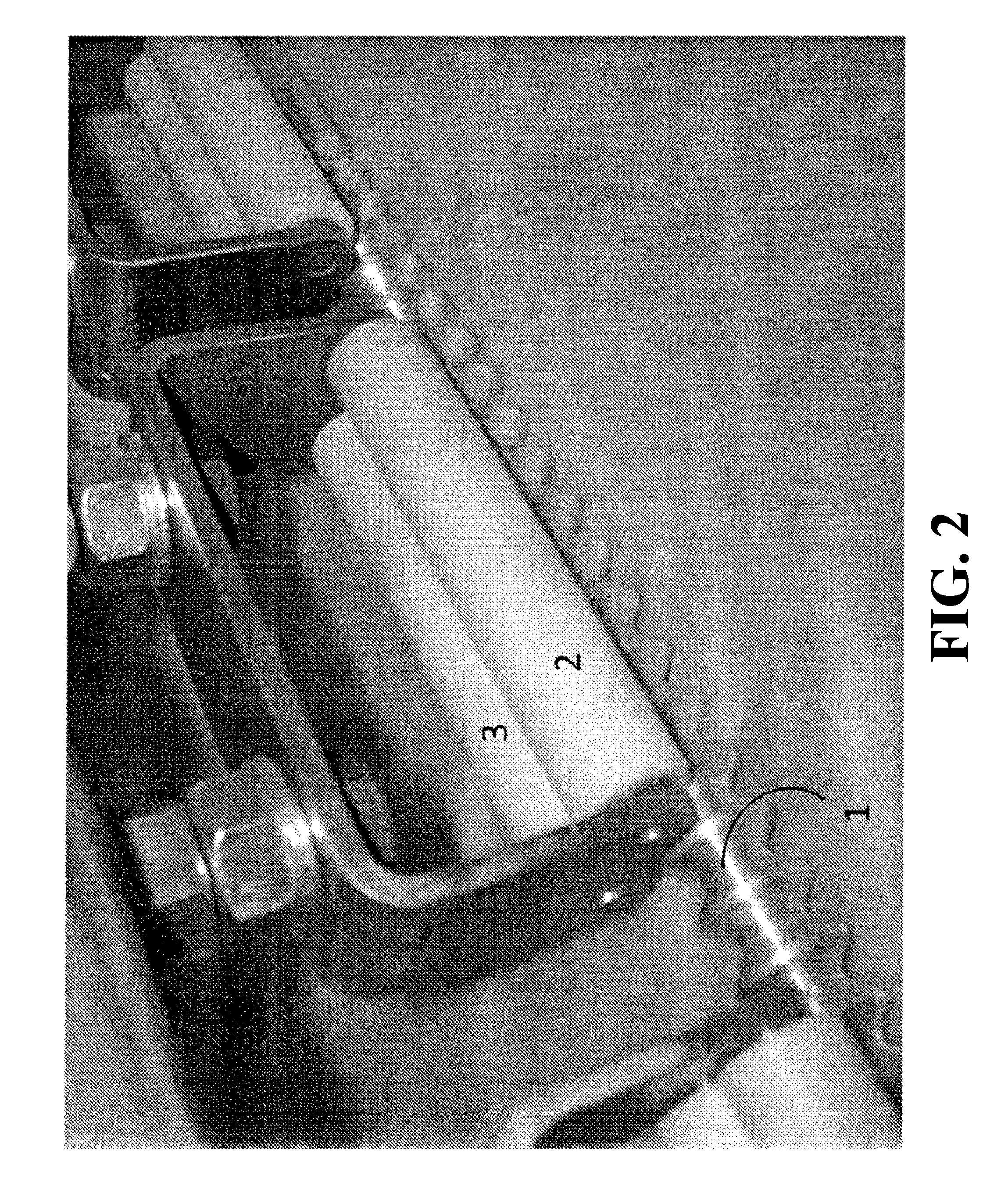

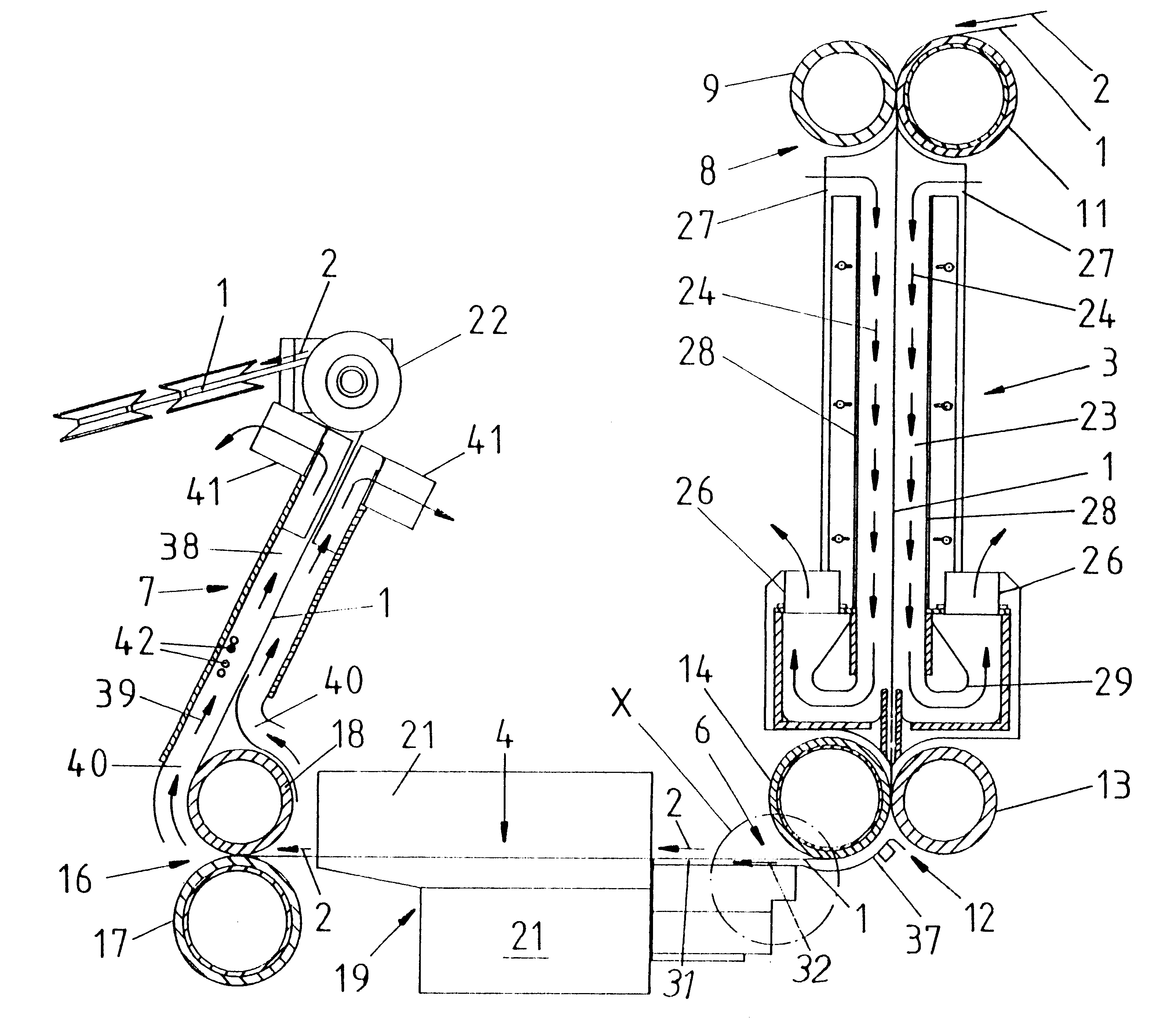

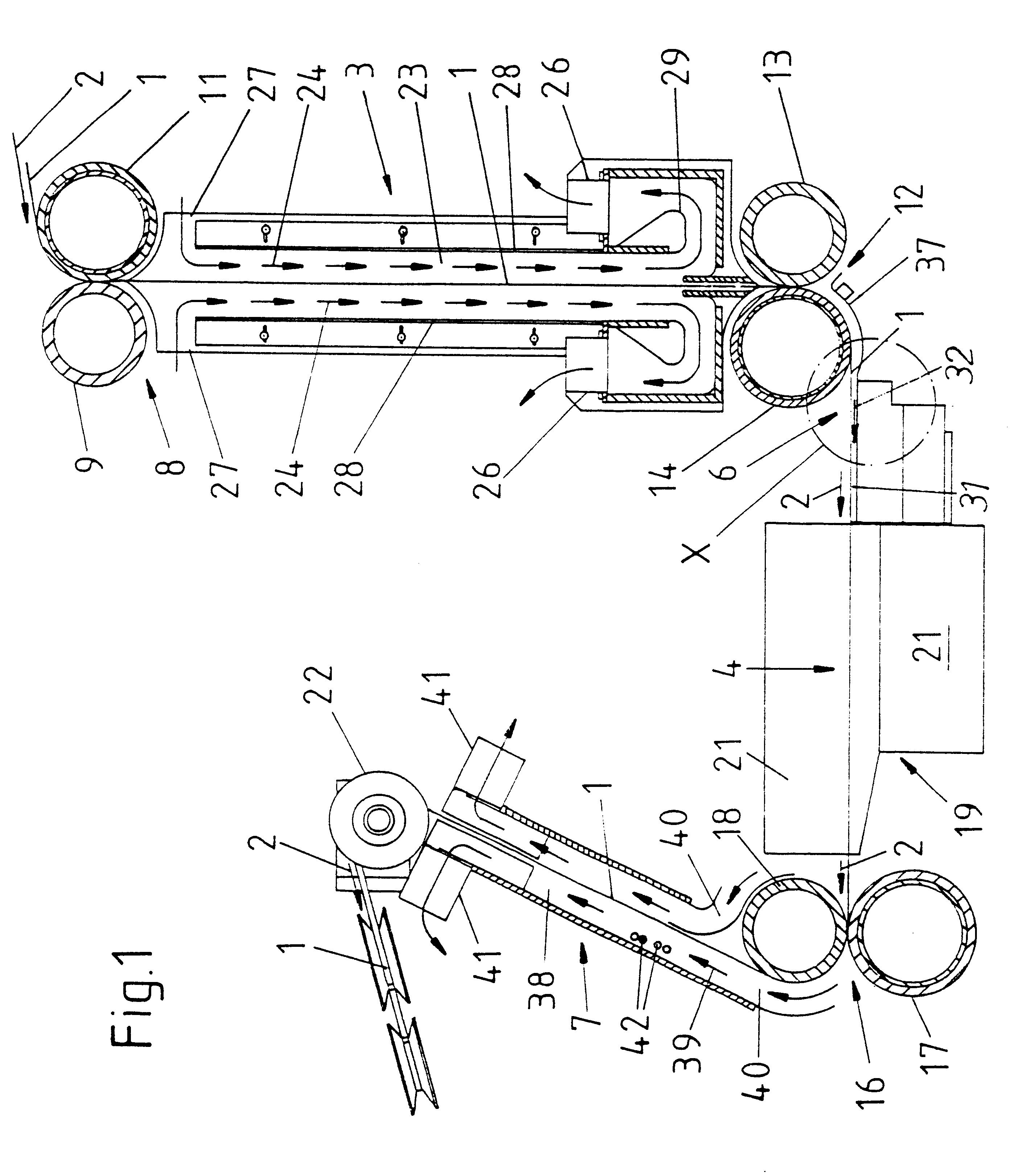

Method for longitudinal stretching a film in solid state and apparatus to carry out the method

ActiveUS20120126445A1Irregularity in stretchingOvercome irregularitiesDough-sheeters/rolling-machines/rolling-pinsConfectioneryPuncture resistanceEngineering

Method and apparatus for longitudinal orientation of thermoplastic film material (20) comprises a width-reduction zone upstream of the longitudinal stretching zone (9, 10), through which the width of the film is gradually reduced so as to allow longitudinal stretching without necking. The width-reduction zone comprises at least two sets of pleating rollers (7, 1) comprising intermeshing grooves or discs for pleating the material. The downstream (1) rollers comprise a mini-roller defined by the following measures a) the pitch of the corrugations, measured from middle of tip to middle of each neighbouring tip is 20 mm or less; b) the perimeter from middle of a tip to the middle of each neighbouring tip measured along the corrugated roller surface, divided by the said pitch is in the range between 1.10 and 1.80; and c) the diameter of the mini-roller, measured at the tips of the corrugations, is at the highest 4 times the said pitch. Preferably a pair of mini-roller sets is arranged on opposing sides of the film in reciprocating mounts enabling alternate entwining of the film around one then the other mini-roller. The method allows achievement of high tensile strength, yield point, resistance to tear propagation and puncture resistance, especially for polyethylene and polypropylene films.

Owner:THE SUPREME IND

Absorbent articles with stretch zones comprising slow recovery elastic materials

An absorbent article may have at least one stretch zone comprising a slow recovery elastomer wherein the slow recovery elastomer exhibits a normalized unload force of greater than about 0.04 N / mm2 at 37° C.; and the slow recovery elastomer exhibits at least about 20% post elongation strain at 22° C. after 15 seconds of recovery from a 400% strain. The absorbent article may additionally comprises one or more of a liquid permeable topsheet, a liquid impermeable backsheet, an absorbent core, an ear, a side panel, a waist feature, a fastener component, a leg cuff, a gasketing cuff, and a barrier cuff, wherein the feature comprises at least a part of the stretch zone.

Owner:PROCTER & GAMBLE CO

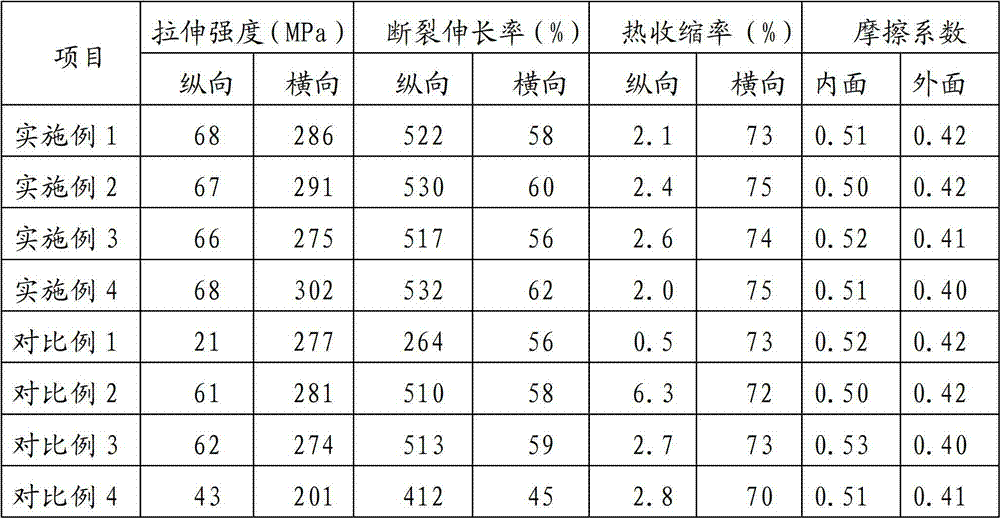

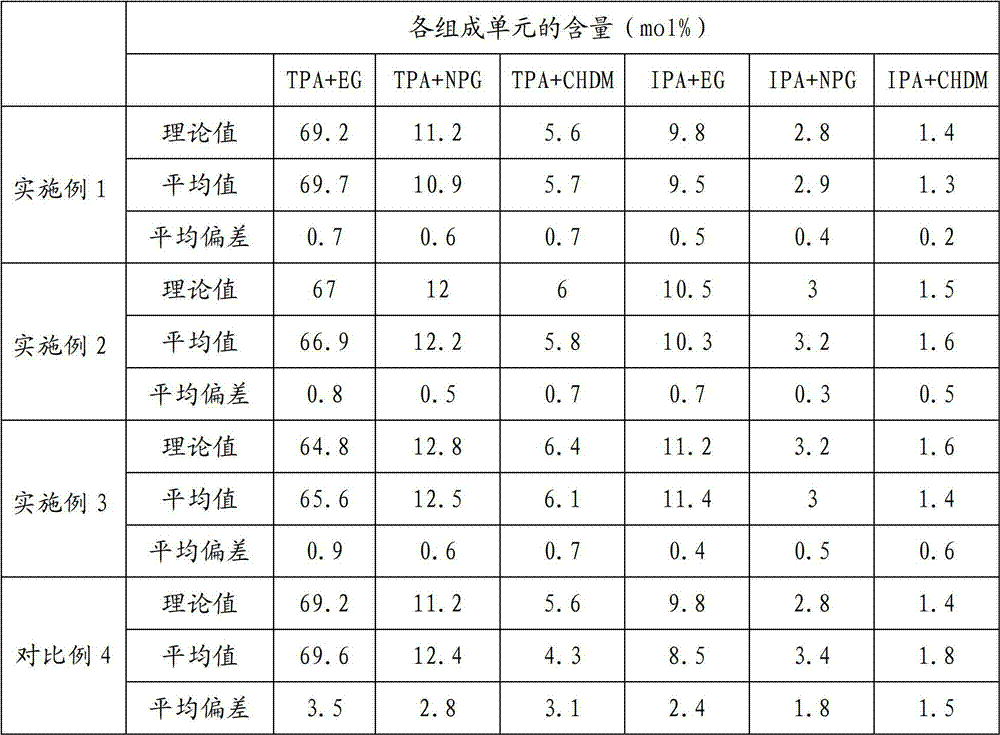

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

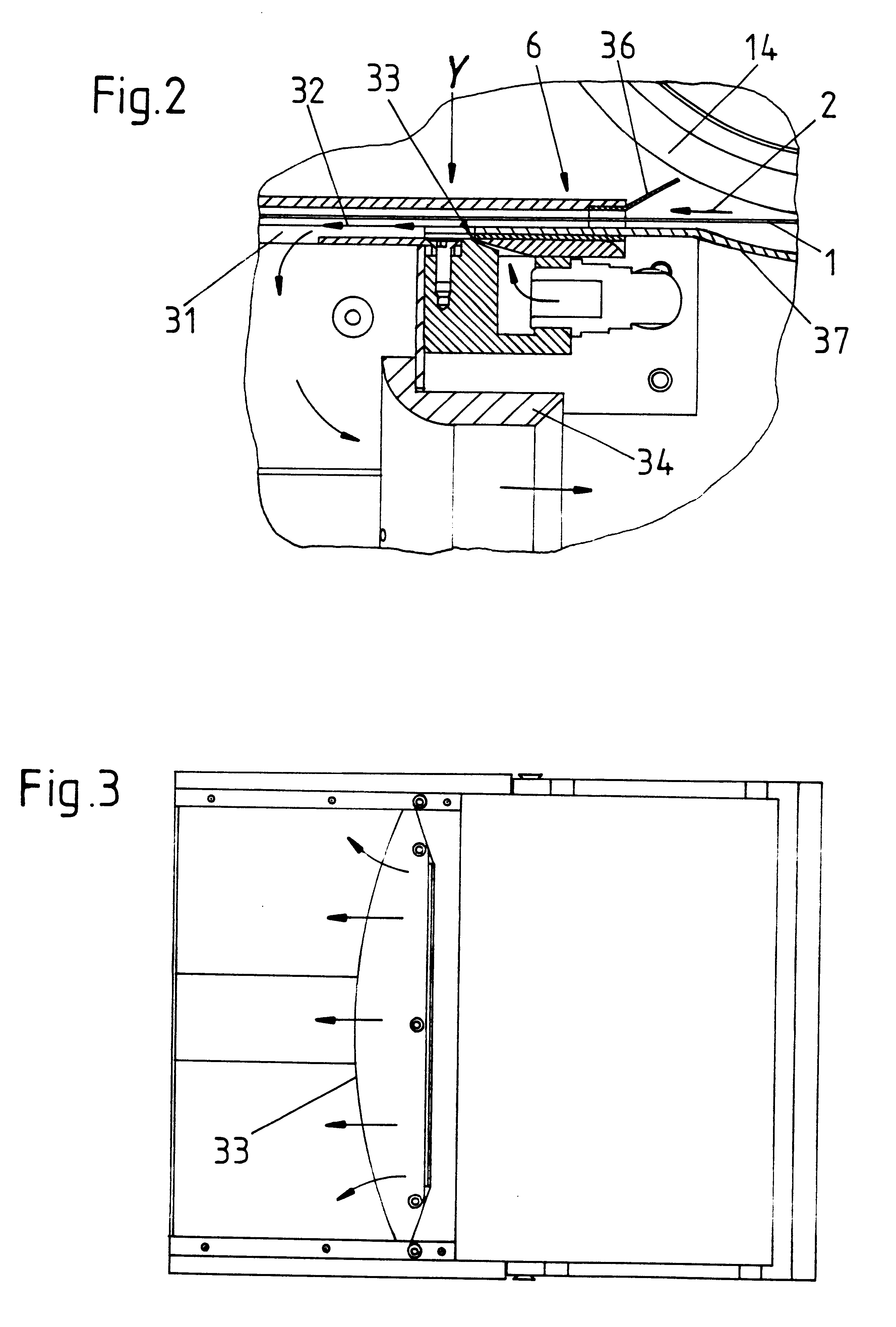

Method of and apparatus for making filter mouthpieces for rod-shaped articles of the tobacco processing industry

InactiveUS6263882B1Take up small amountReduce widthCigar manufacturePaper/cardboard wound articlesPlasticizerFilter material

A tow of filamentary filter material for tobacco smoke which is to be converted into a rod-like filler of a filter rod is conveyed along an elongated path first through a stretching or tensioning zone where the filaments are stretched and the tow is converted into a relatively wide flat web, thereupon along a relaxing portion of the path wherein the tensioning action upon the filaments is reduced, thereupon along a third portion wherein at least one side of the running web is contacted by droplets of an atomized plasticizer, and thereafter along a fourth portion of the path wherein the web is gathered by reducing its width so that it more closely resembles a rod which is thereupon draped into a web of cigarette paper or other suitable wrapping material. A wind tunnel surrounds at least one portion of the path to confine at least one stream of air which is caused to flow in the direction of advancement of the tow. A tunnel can surround the stretching zone, the relaxing and / or the fourth portion of the path.

Owner:HAUNI MASCHINENBAU AG

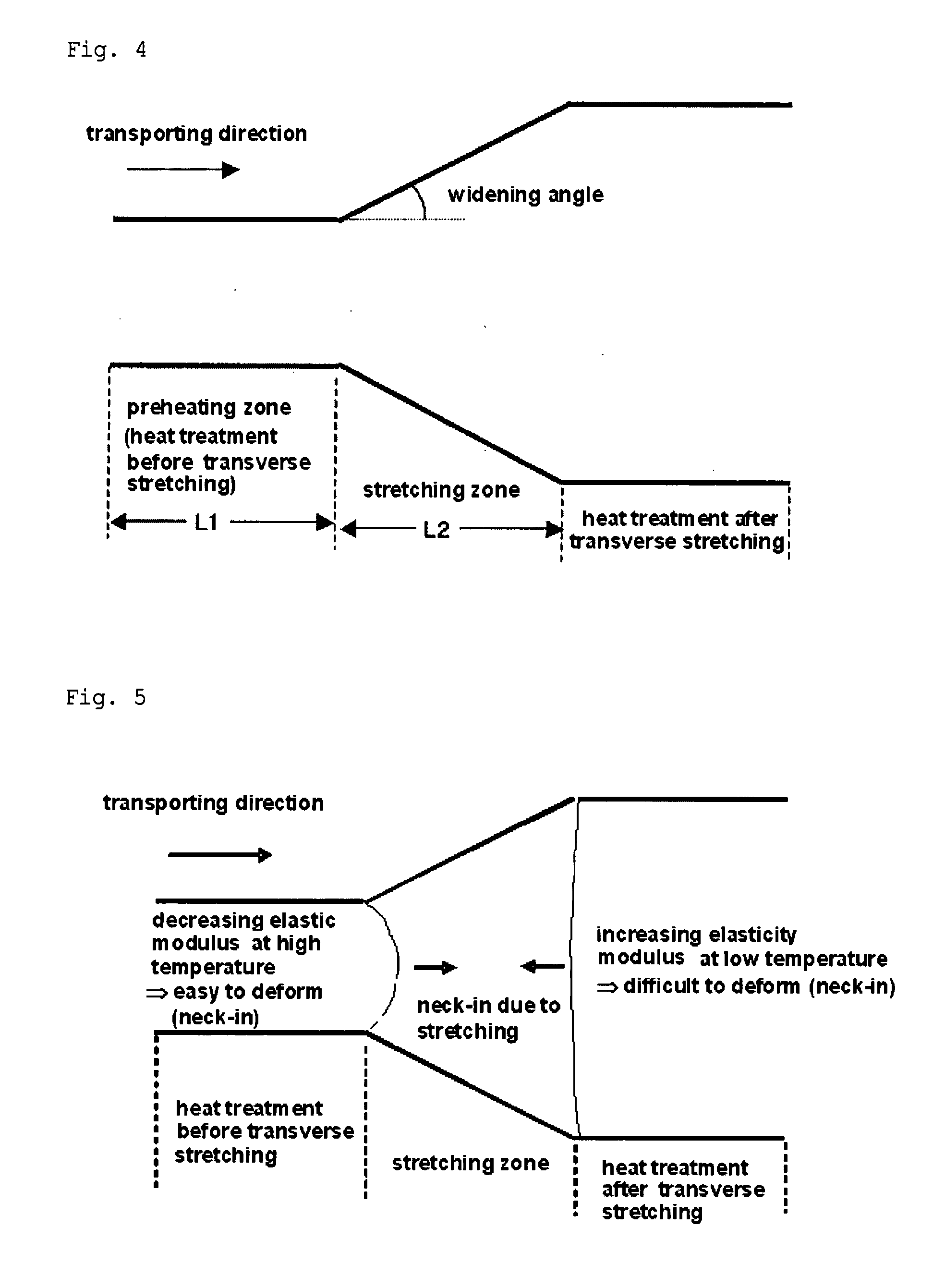

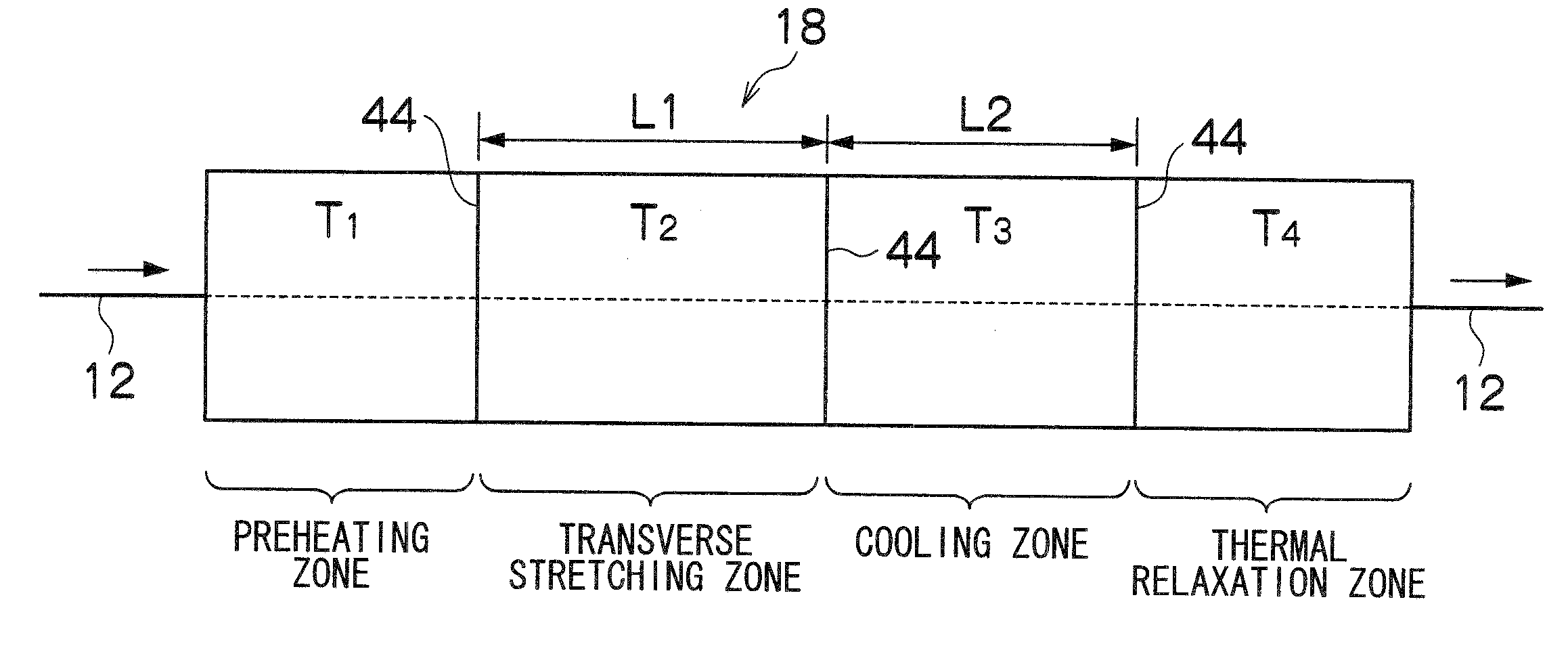

Method of producing transparent thermoplastic film and transparent thermoplastic film

InactiveUS20070286998A1Synthetic resin layered productsCellulosic plastic layered productsPlastic propertyChemistry

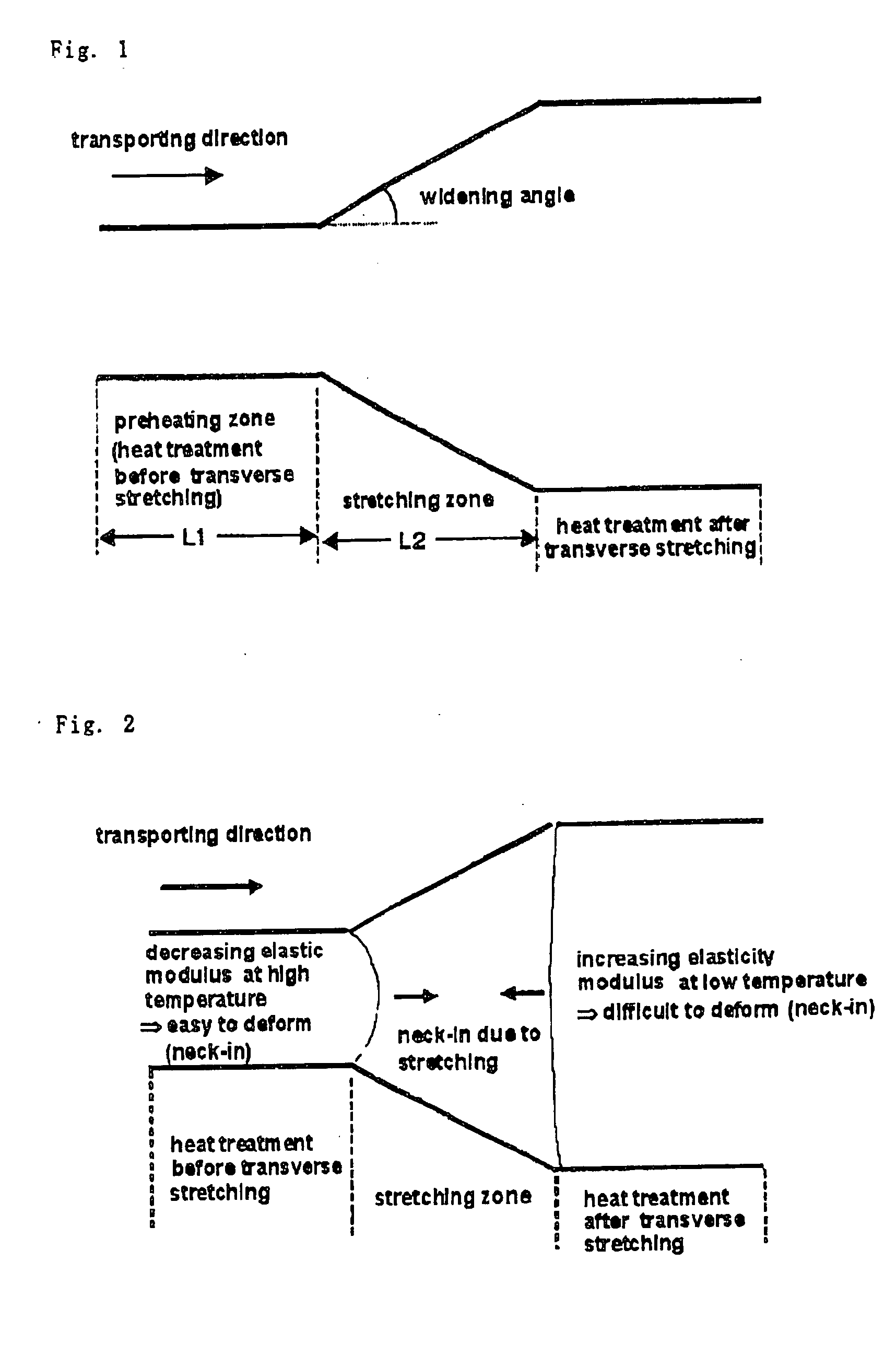

A method of producing a transparent thermoplastic film comprising transversely stretching a film by 1 to 200%, in which the ratio (L2 / L1) of a length (L2) of a transverse stretching zone to a length (L1) of a preheating zone is within the range of 0.5 to 30.

Owner:FUJIFILM CORP

Disposable absorbent articles with zones comprising elastomeric components

Absorbent articles having a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core disposed between said topsheet and said backsheet are disclosed. The absorbent articles include a thermoplastic elastomer joined to or disposed in a stretch zone on at least one component or region of the absorbent article to impart an elastic resistance that provides sizing or shaping capabilities to the article. The absorbent article can be in the form of diapers, pull-on diapers, training pants, sanitary napkins, wipes, bibs, incontinence briefs or inserts.

Owner:PROCTER & GAMBLE CO

Method for producing thermoplastic film

InactiveUS20090115100A1Relieve stressGood dimensional stabilityCeramic shaping apparatusFlat articlesChemistryStretch zone

The present invention provides a method for producing a thermoplastic film which makes it possible to improve the optical properties of the thermoplastic film obtained by stretching and a thermoplastic film manufactured thereby. The transverse stretching section in which a cellulose acylate film is transversely stretched includes: a preheating zone, a transverse stretching zone, a cooling zone and a thermal relaxation zone, and the cellulose acylate film having been cooled in the cooling zone is immediately subjected to thermal relaxation treatment in the thermal relaxation zone.

Owner:FUJIFILM CORP

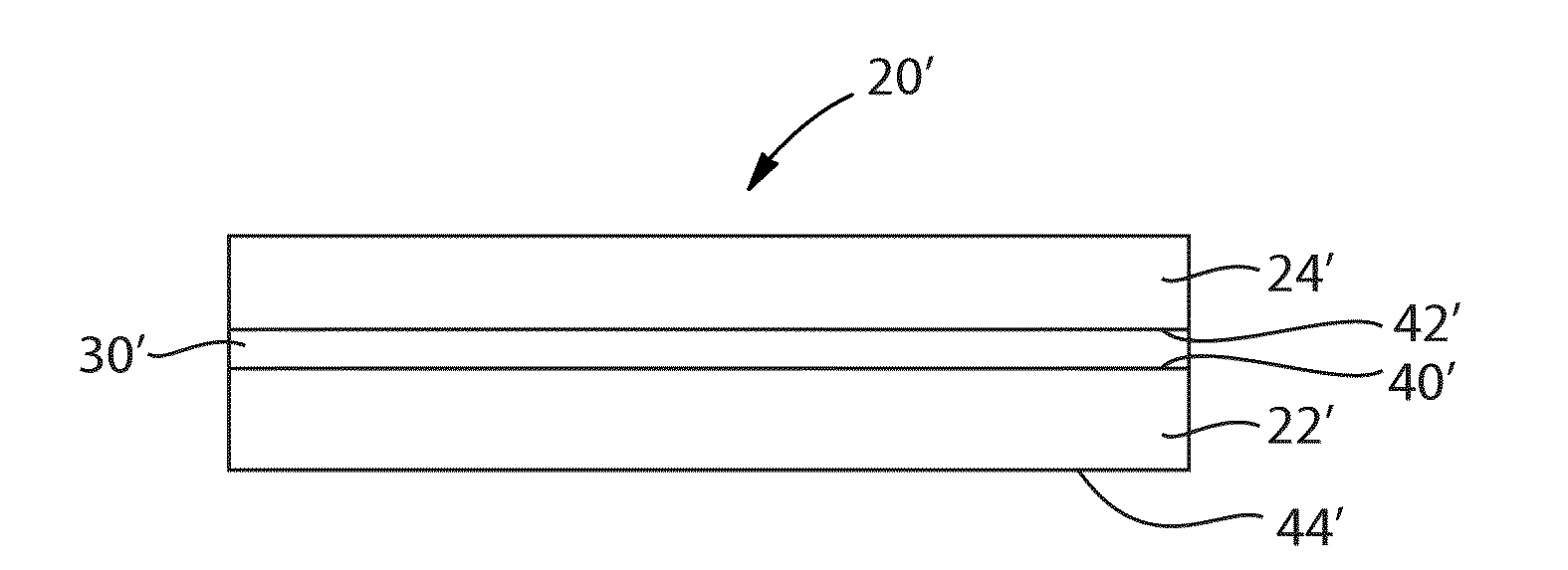

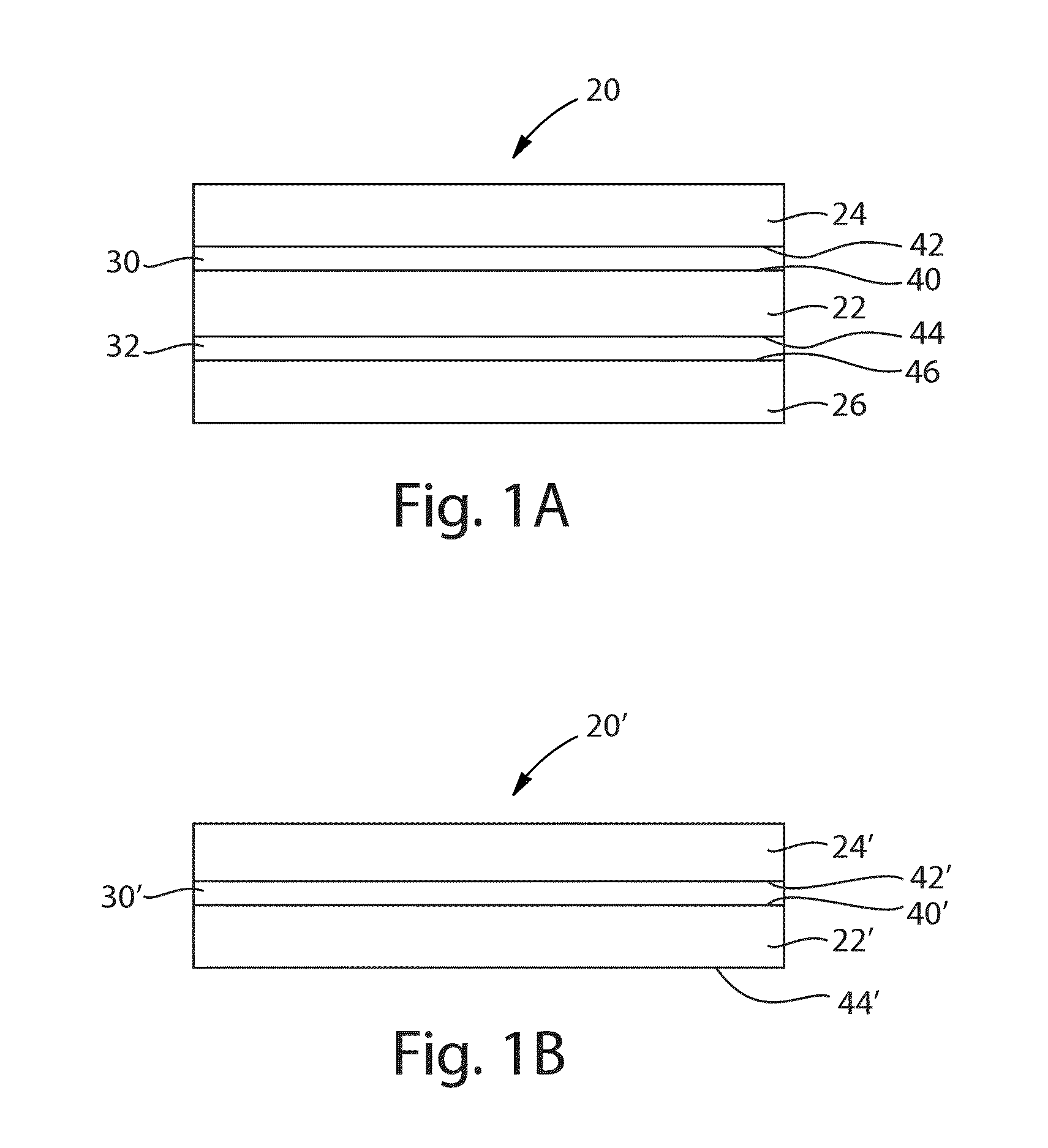

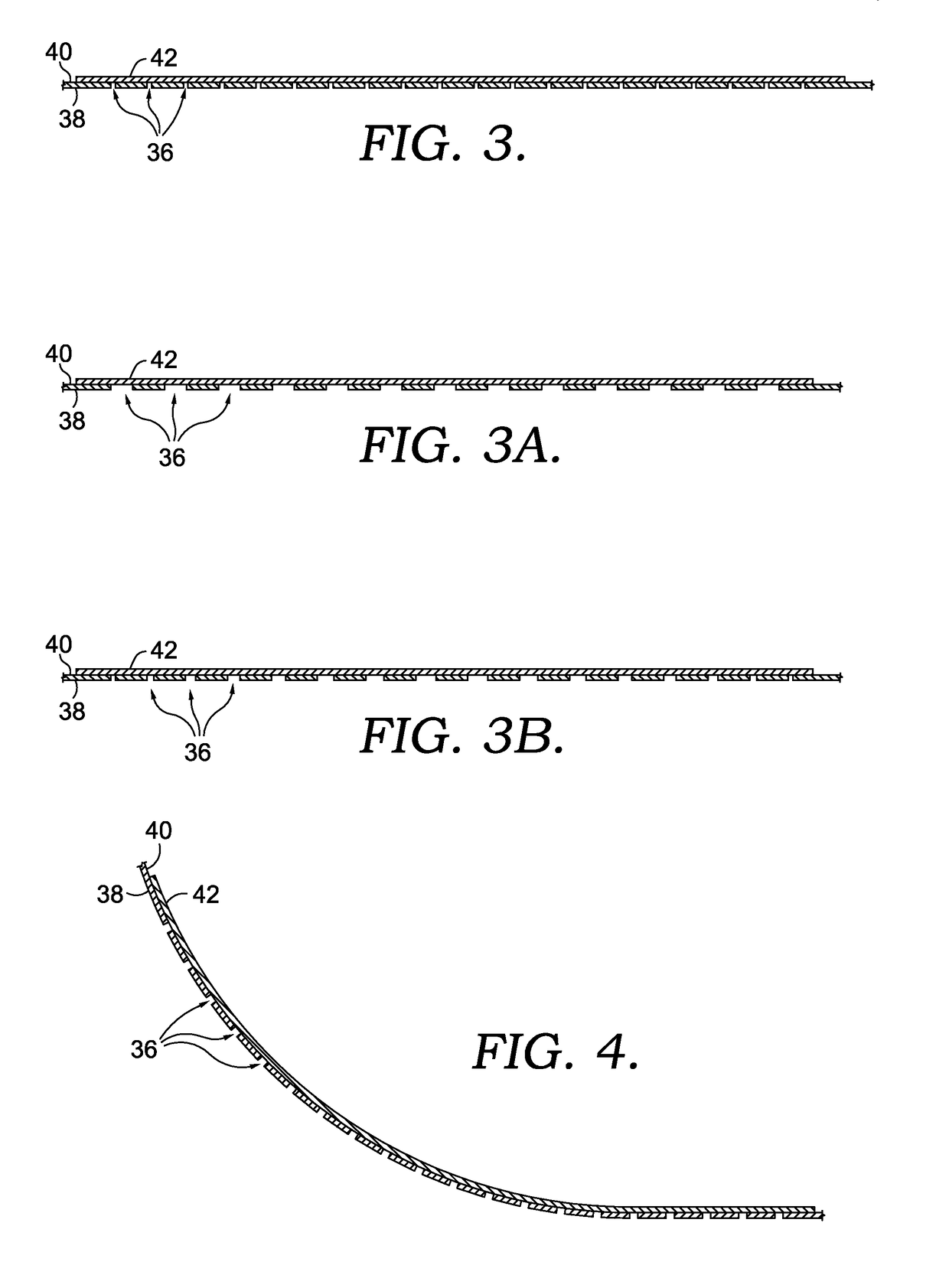

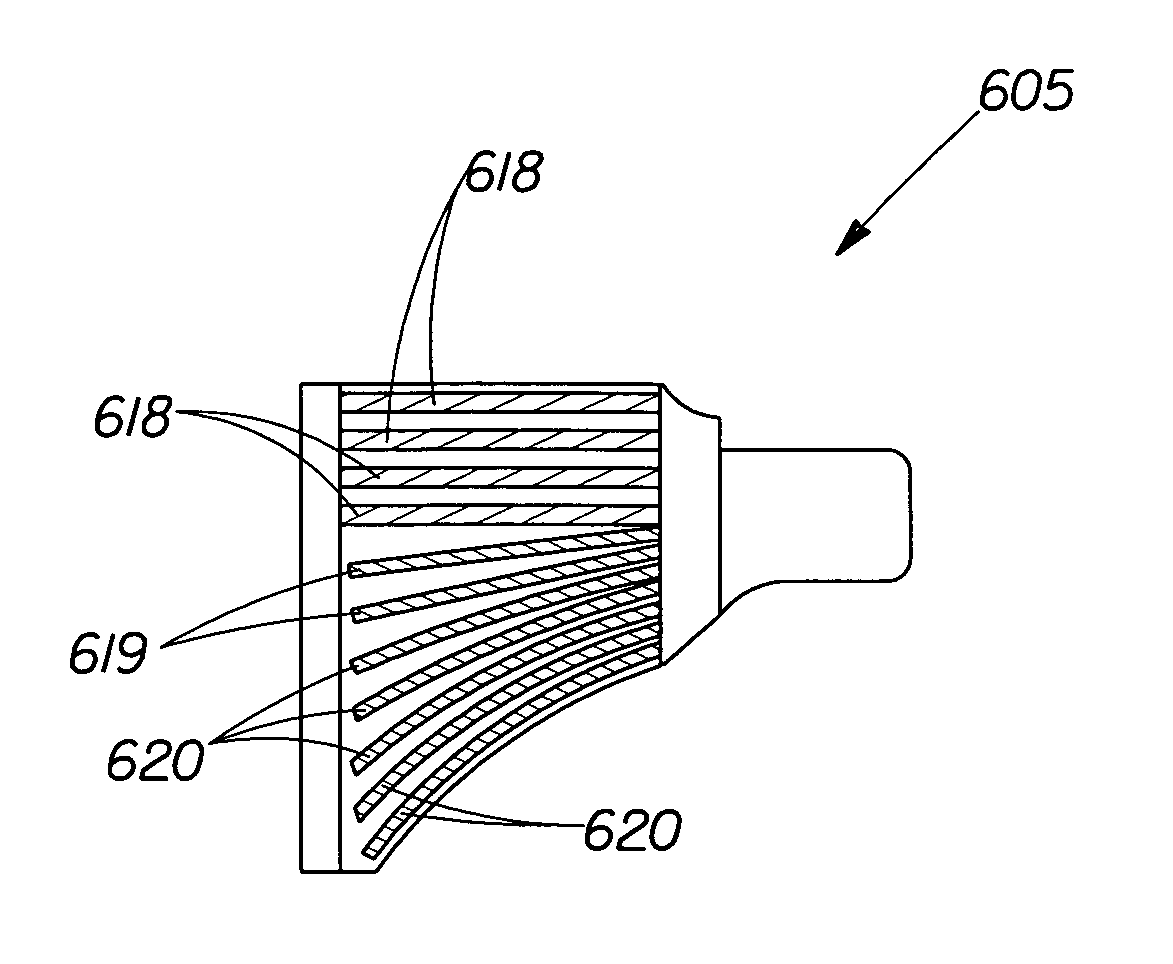

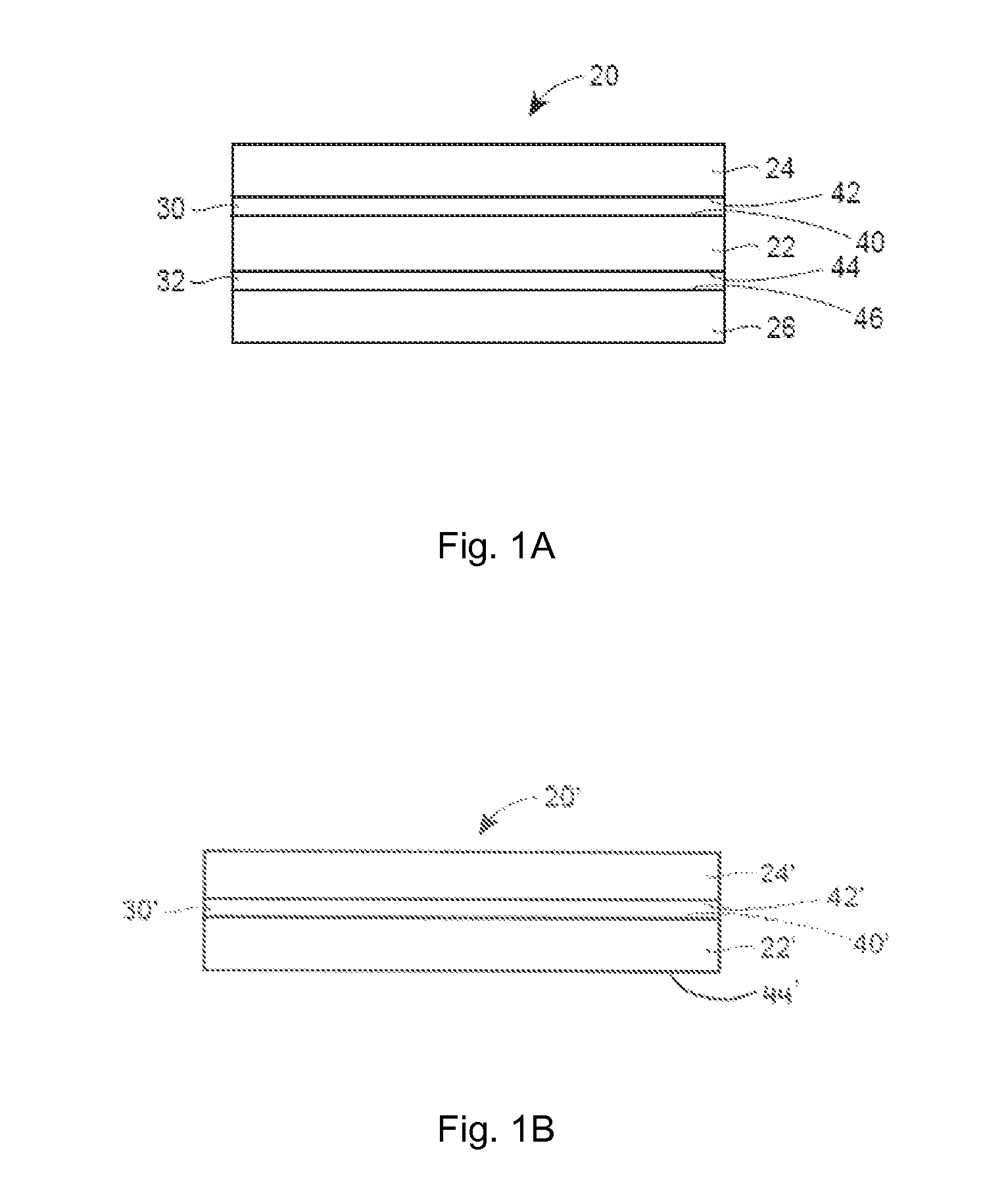

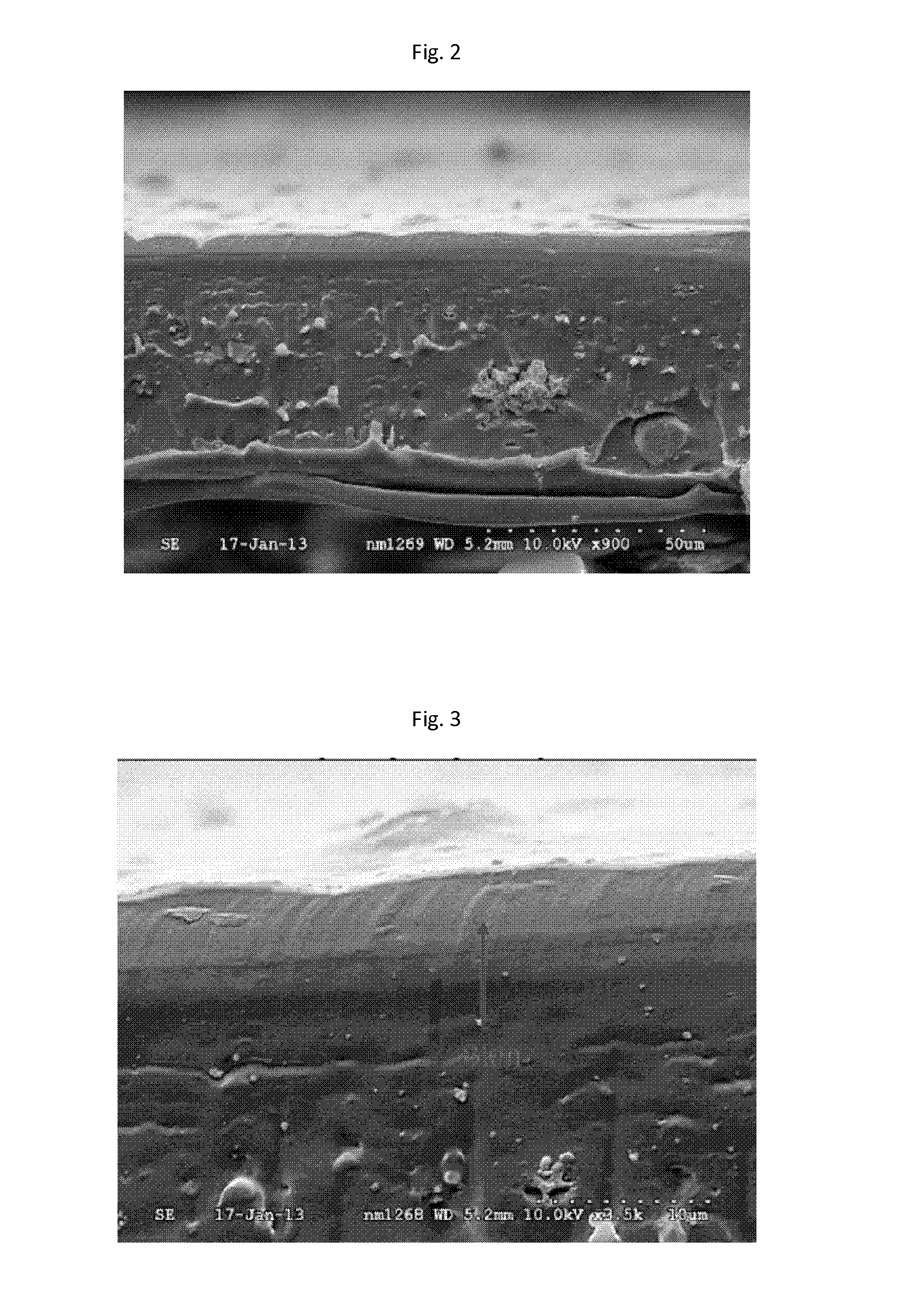

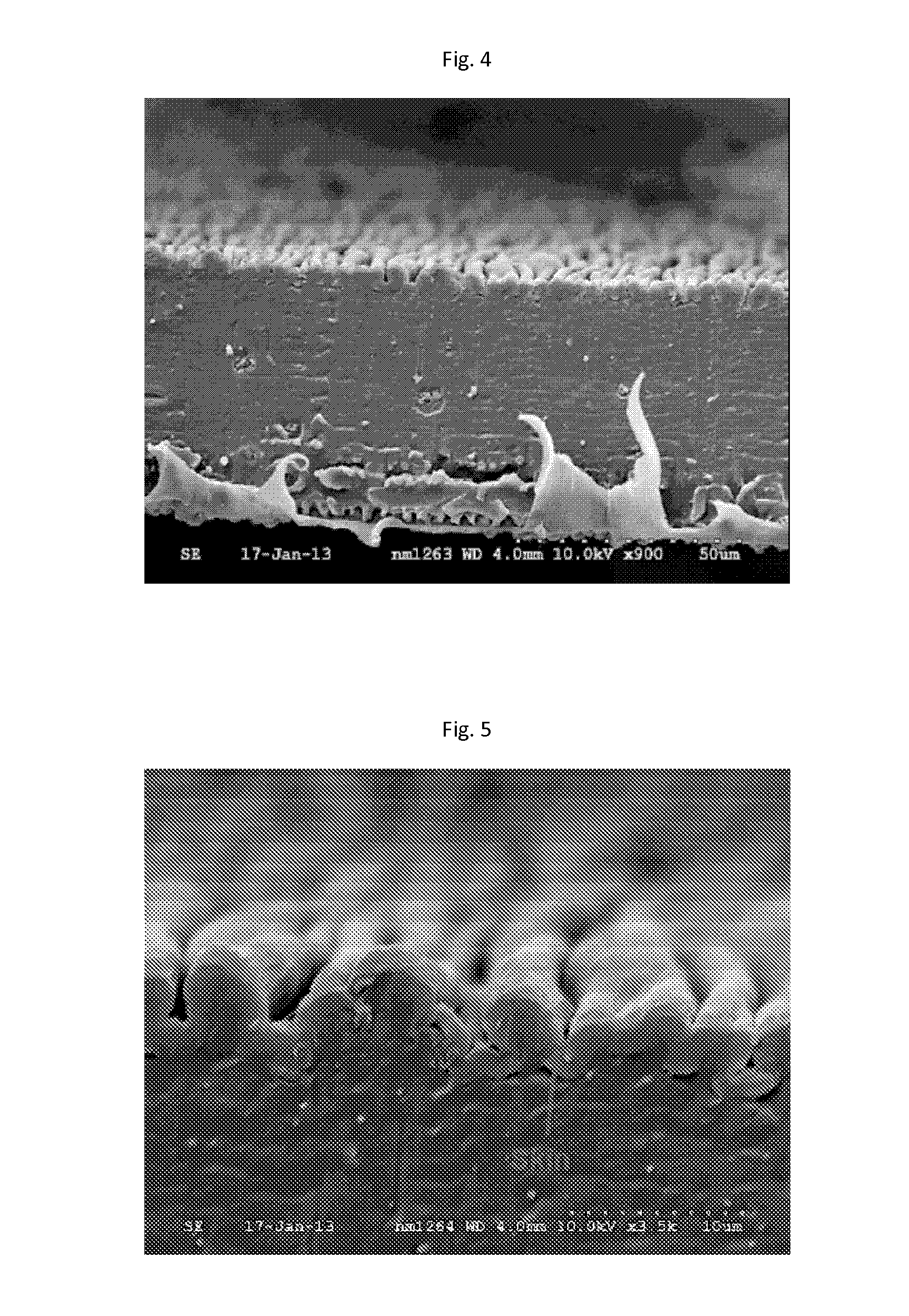

Stretch laminate

InactiveUS20140329053A1Increase the gapPersonal careSynthetic resin layered productsElastomerAdhesive

A stretch laminate has at least one cover web, an elastomeric film attached to the cover web and having two opposite faces, and a skin on at least one of the faces. An adhesive at an anchor zone between the skin and the cover web bonds the skin to the cover web at the anchor zone, leaving a stretch zone free of adhesive adjacent the anchor zone. The skin having wrinkles in the anchor zone but not in the stretch zone.

Owner:MONDI GRONAU

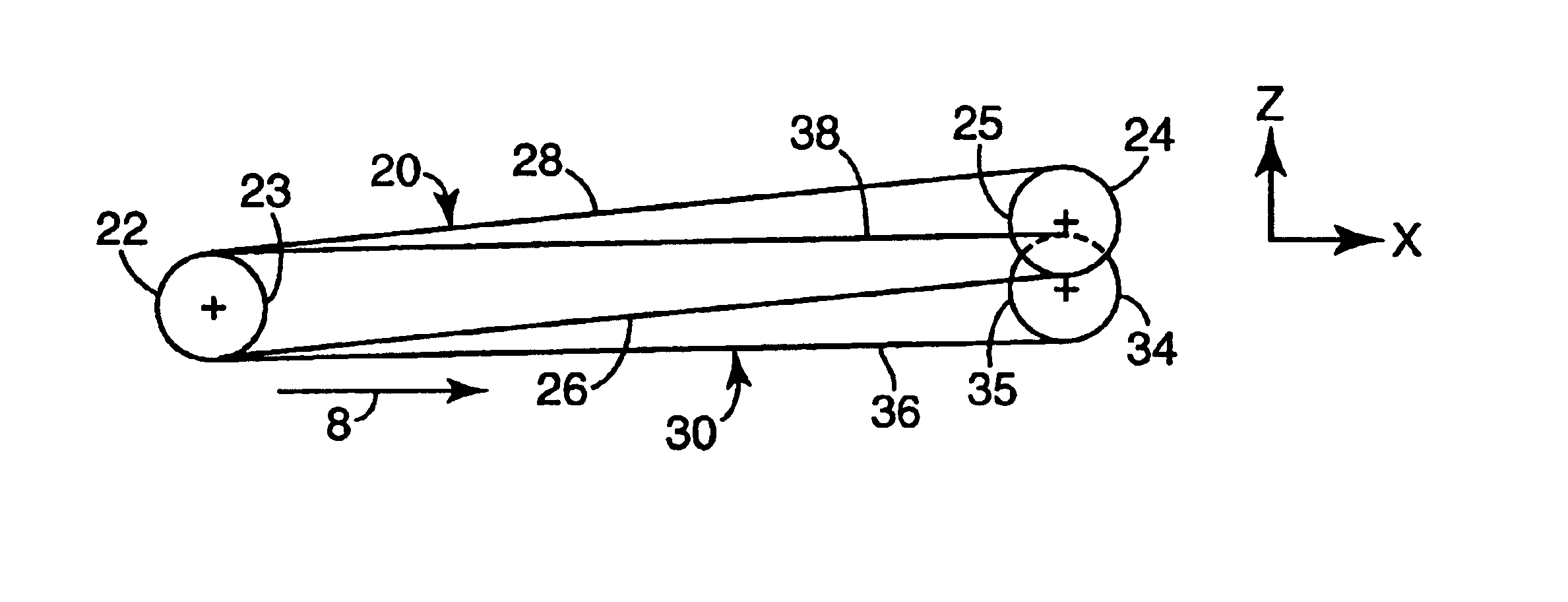

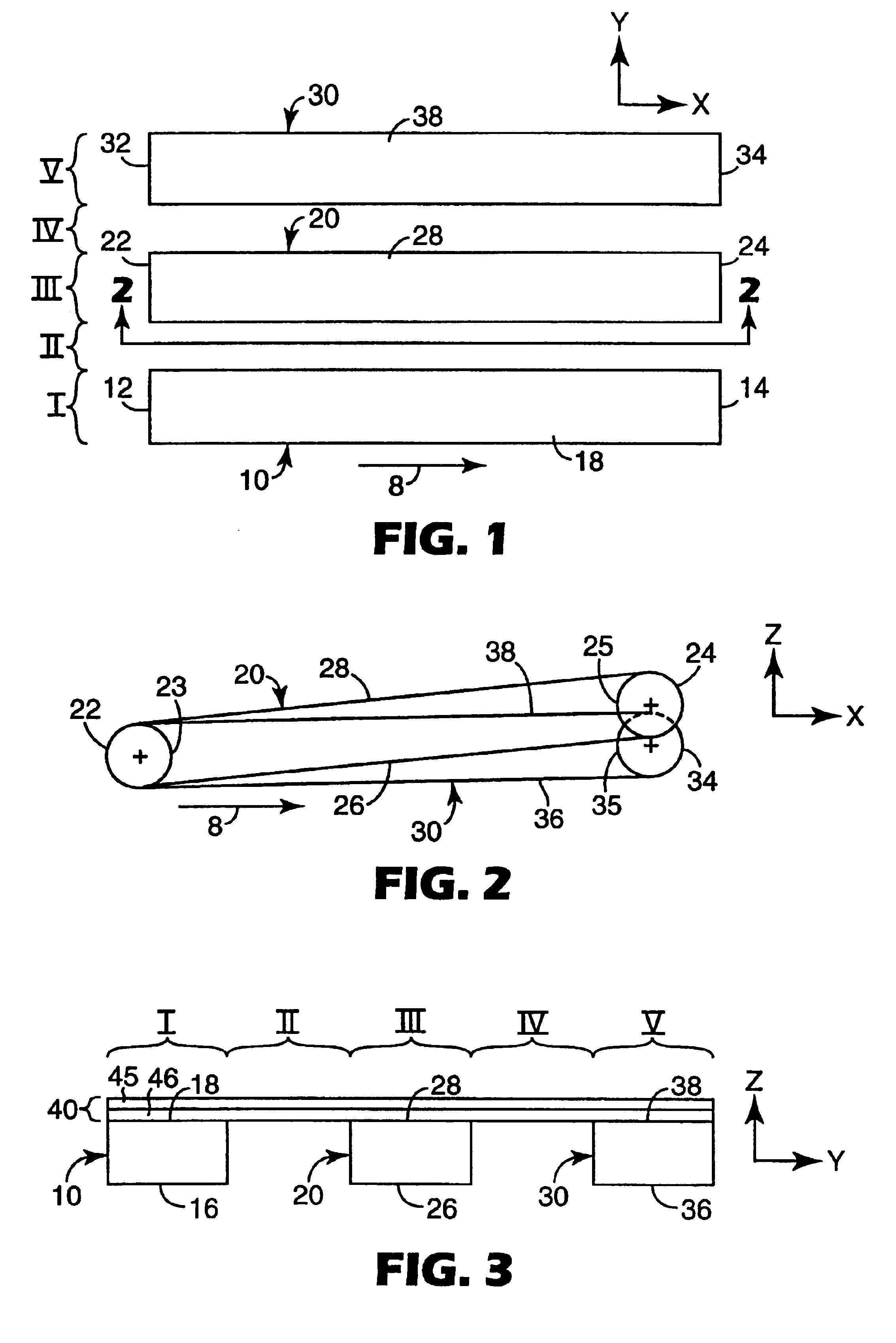

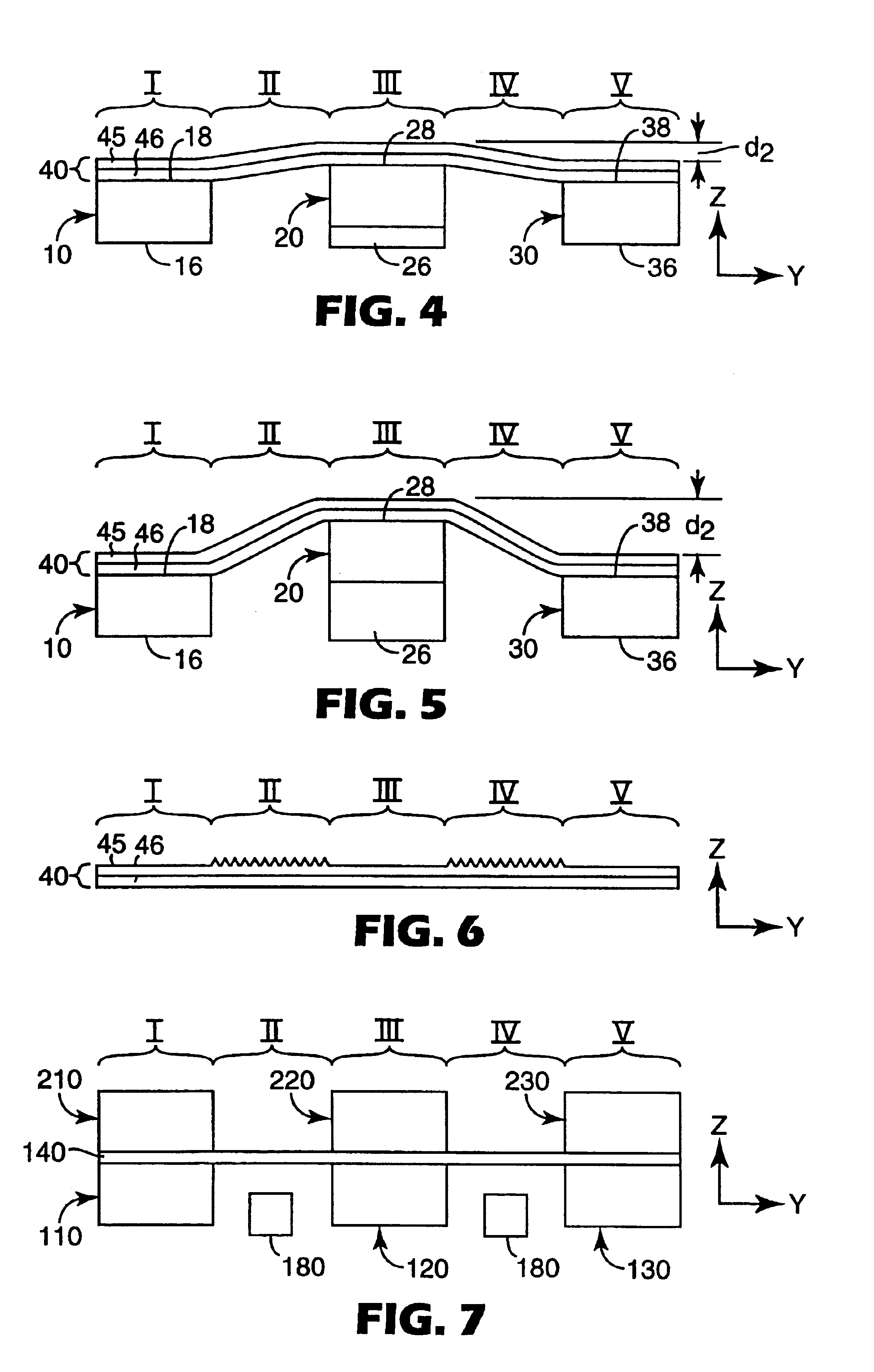

Zoned stretching of a web

InactiveUS6938309B2Marking can be preventedReduce potential problemNon-woven fabricsStretchingEngineeringLinear rate

Apparatus and methods for stretching one or more zones of a web are disclosed. Webs including stretched or activated zones are also disclosed. Each of the zones in the web is stretched in the cross-web direction, i.e., the direction transverse to the down-web direction. The stretching it can be performed continuously as the web is advancing through the apparatus in the down-web direction. The stretching can occur in the absence of physical contact with the stretched zone of the web. Strain induced on the stretched zones can be introduced gradually over a stretch distance. The strain may increase at a linear rate. The stretching methods and apparatus may be used to activate an elastic zone or zones within a web.

Owner:3M INNOVATIVE PROPERTIES CO

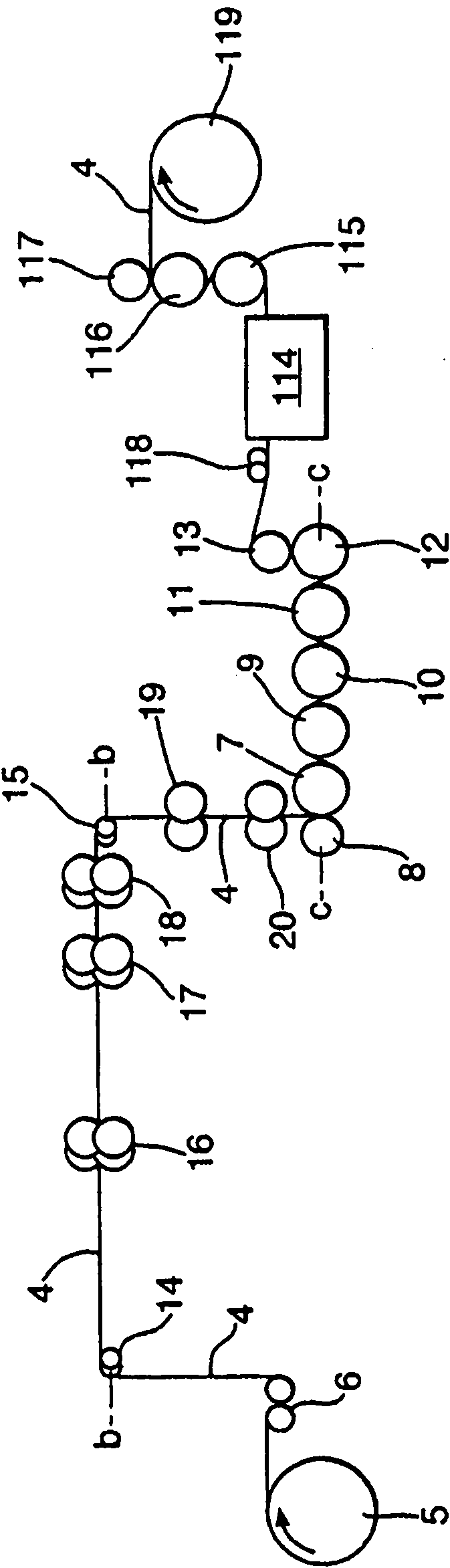

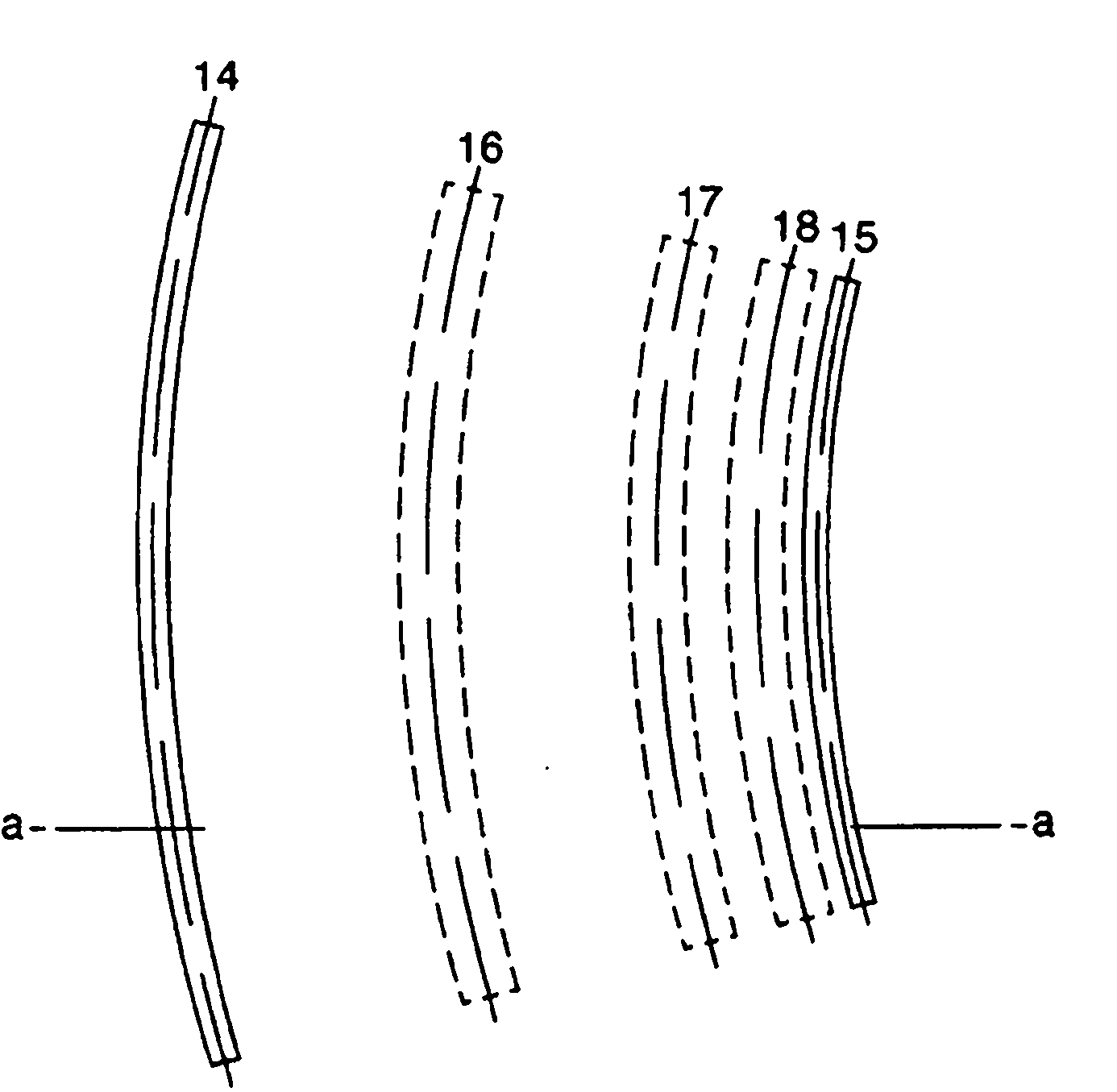

Method and apparatus for longitudinal orientation of thermoplastic film material

Method and apparatus for longitudinal orientation of thermoplastic film material (4) comprises a width-reduction zone upstream of the longitudinal stretching zone, through which the width of the film is gradually reduced so as to allow longitudinal stretching without necking. The width-reduction zone comprises at least one, preferably several, pairs of pleating rollers (16, 17) comprising intermeshing grooves or discs for pleating the material, the length of said width reduction zone preferably being less than 3 times the original width of the film. The width-reducing zone has upstream (14) and downstream (15) rollers or roller assemblies, with curved axes and optionally also conveyor belts for providing smooth width reduction. Longitudinal stretching is preferably between at least two, and preferably more than two, pairs of stretching rollers (9, 10, 11, 12) which are relatively close together. The pleats may be provided in several stages with increasing pleats per stage, while guiding means preferably lay all the pleats to one side. The method allows achievement of high tensile strength, yield point, resistance to tear propagation and puncture resistance, especially for polyethylene and polypropylene films.

Owner:THE SUPREME IND

Absorbent garments with multipart liner having varied stretch properties

Absorbent articles with stretch direction properties are disclosed, having at least three stretch zones. A first edge zone and a second edge zone are separated by a middle zone. The middle zone, which may the same length as each edge zone, has different stretch-direction characteristics than the edge zones. The middle zone may stretch in a single direction, whereas the edge zones may stretch in a different single direction or in bi- or multi-axial directions. The flaps may be created from the edge zones. Through this construction, the absorbent article exhibits improved fit and appearance.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com