Yarn traction device

A pulling equipment and spinning technology, applied in the field of spinning pulling equipment for yarn production, can solve problems such as difficulty in controlling the temperature of the yarn, and achieve the effect of reducing the number and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

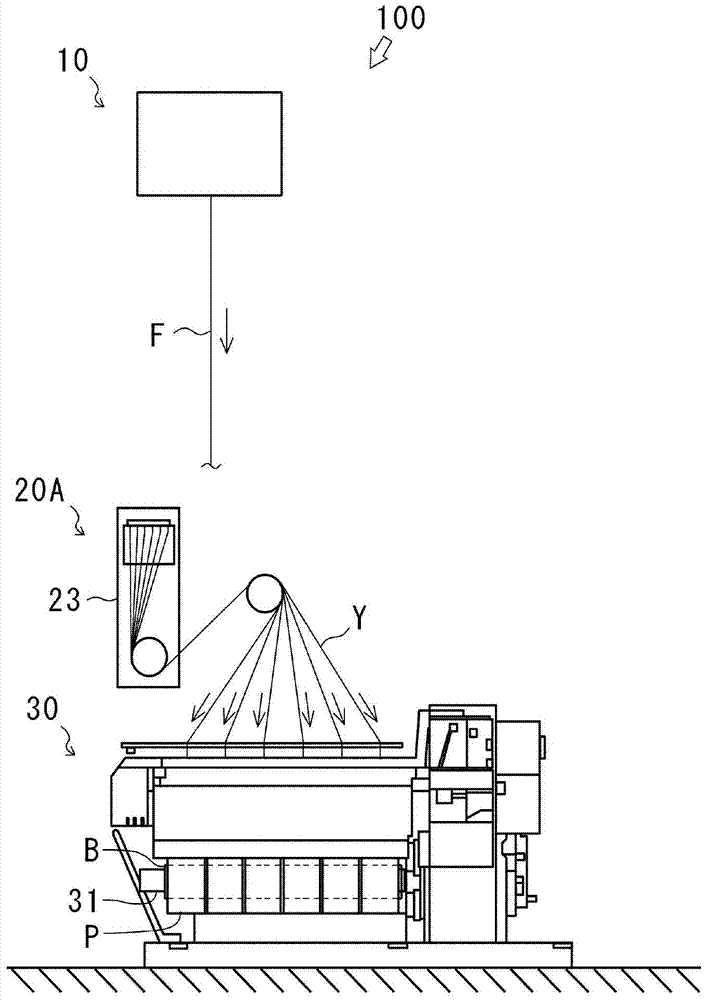

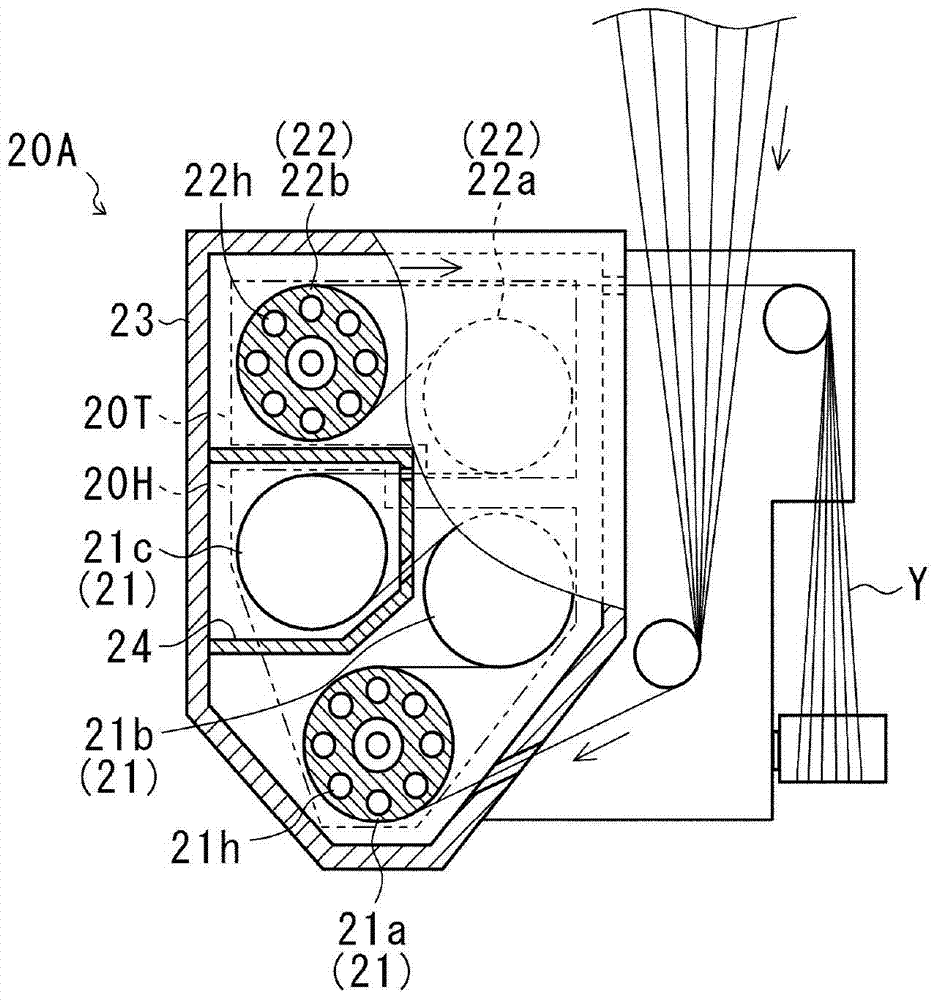

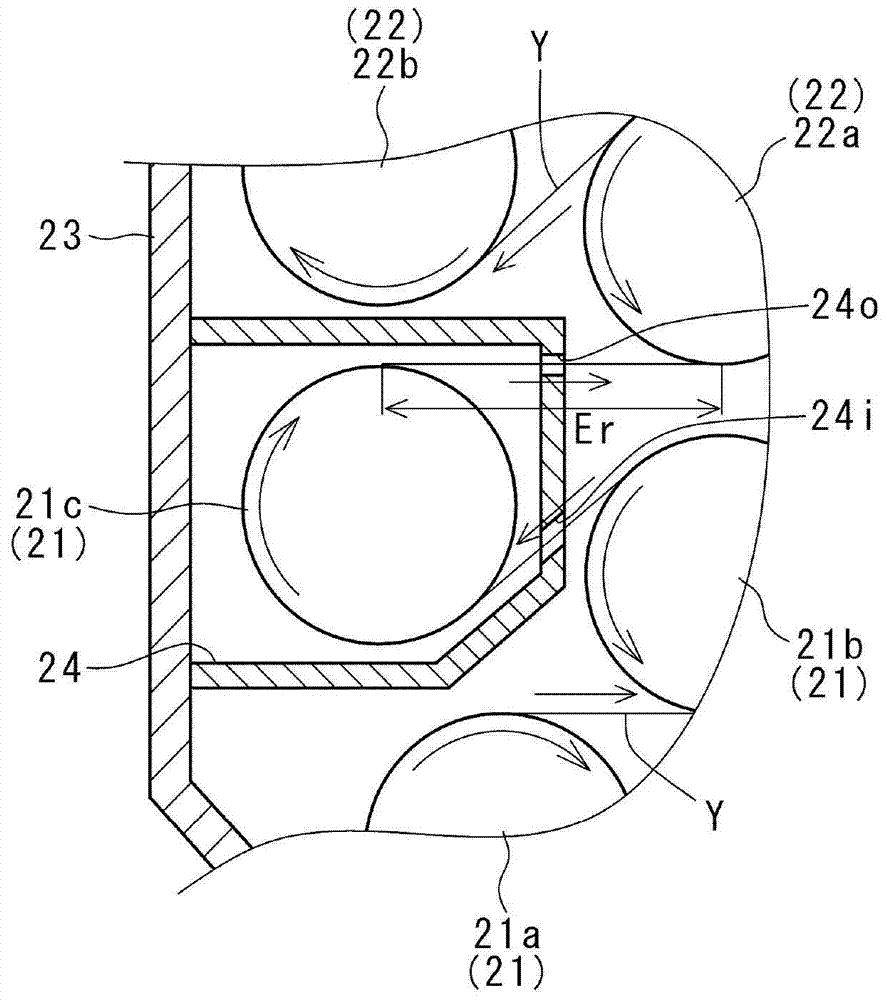

[0027] First, a spinning drawing device 100 according to an embodiment of the present invention will be described.

[0028] figure 1 It is a figure which shows the whole structure of the spinning drawing-up apparatus 100. In general, spinning drawing equipment is divided into equipment for producing fully drawn yarn (FDY) in which the yarn is completely drawn, and equipment for producing partially oriented yarn (POY) in which the yarn is partially drawn. The spinning take-up facility 100 of this embodiment is a facility for producing fully drawn yarn (FDY).

[0029] The spinning take-up device 100 spins out the single fiber F, makes the yarn Y formed by bundling the single fiber F into a desired characteristic, and winds the yarn Y to form a package P. The spinning take-up facility 100 is mainly composed of a spinning device 10 , a godet roll group 20A, and a winding device 30 .

[0030] The spinning device 10 spins a plurality of single fibers F. The synthetic fiber raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com