Method and apparatus for longitudinal orientation of thermoplastic film material

A longitudinally oriented, thermoplastic polymer technology, applied in the field of longitudinally oriented thermoplastic film materials, capable of solving problems such as film folding or wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] Extruded 100 micron thick tubular film from the following ingredients:

[0087] The middle layer, a total of 70%: 100% HMWHDPE;

[0088] Inner surface layer, total 10%: LLDPE with m.f.i.=1.

[0089] Outer surface layer, total 20%: 60% metallocene PE + 40% LLDPE; m.f.i.=1.

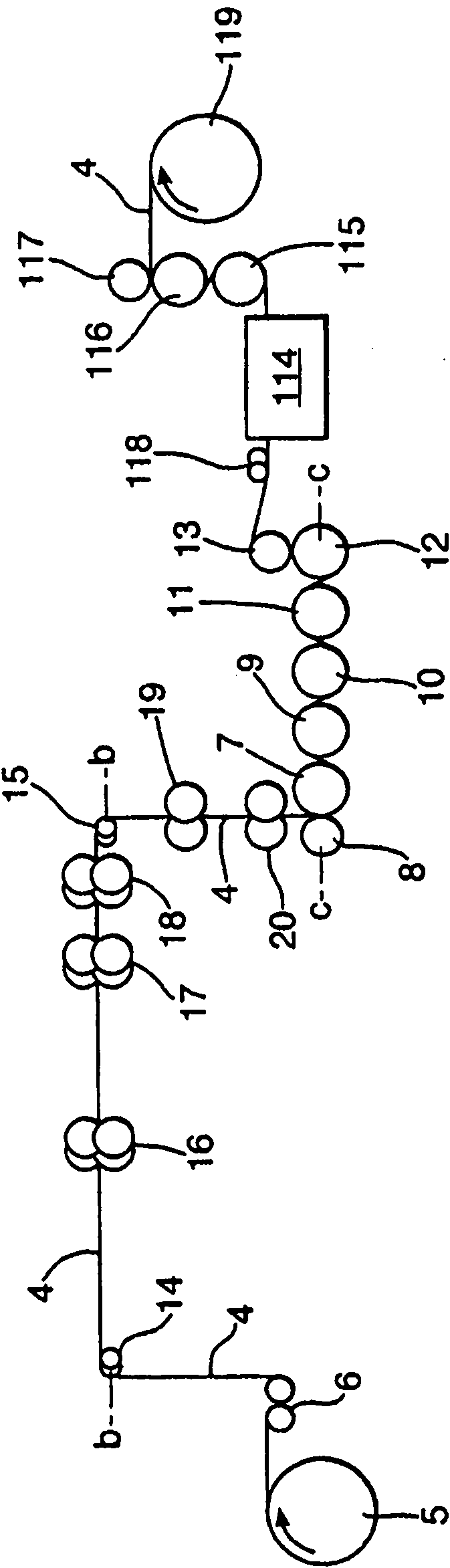

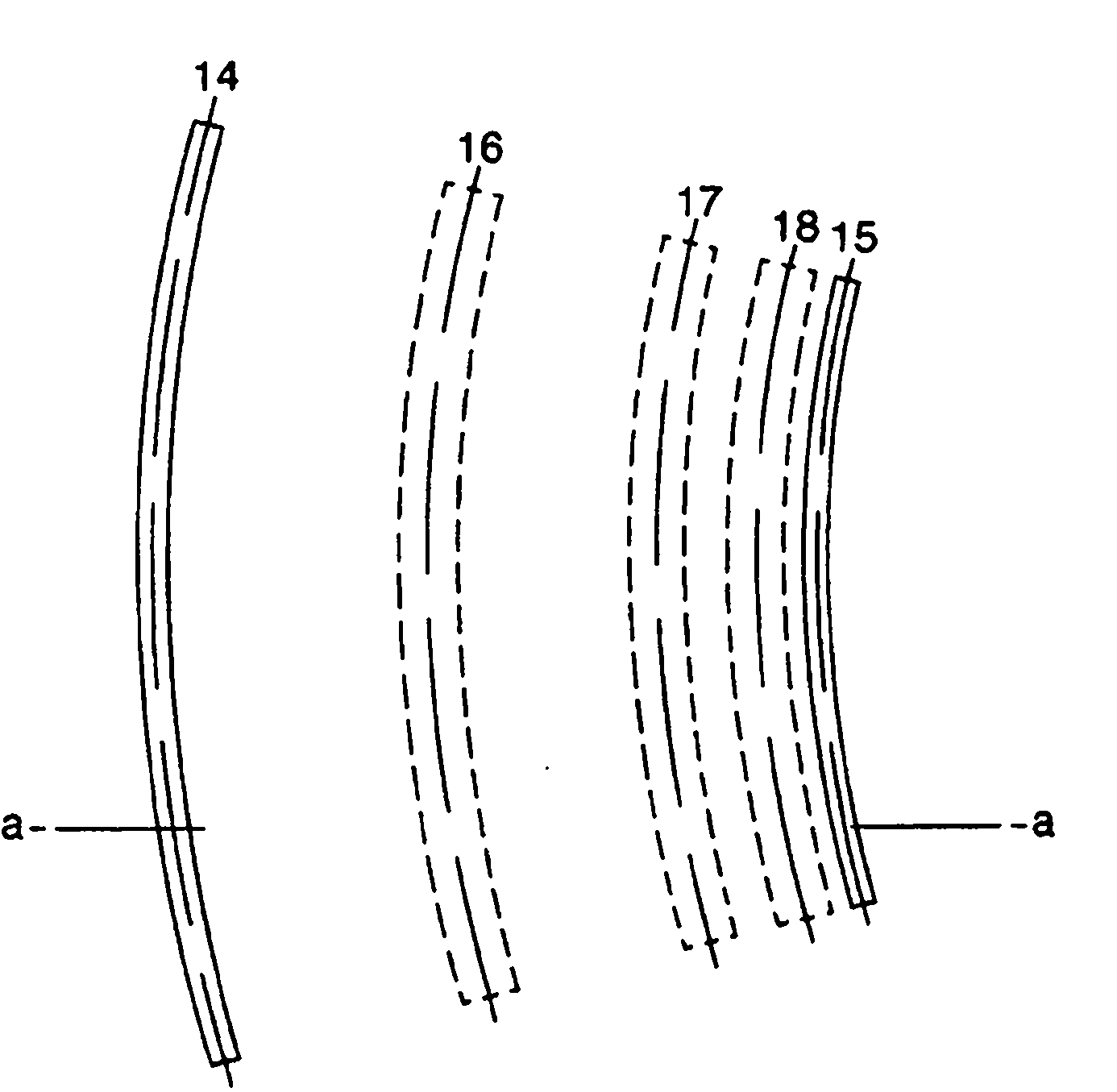

[0090] The width of the flattened film: 54 cm. At 15°C, the Figure 2a The flattened film is pleated and stretched in the device of and b, and modified as follows:

[0091] The radius of the banana-shaped roller 15 is 1.00 m and the radius of the banana-shaped roller 14 is 1.50 m, which still gives a degree of pleating of 1.5:1. Stretching takes place in only two steps. The grooved roller pair 16 is omitted. The roller pair 18 has a radius of 1.06 meters, and the roller pair 17 has a radius of 1.15 meters. The pitch of the driven, grooved roller 7 is 15 mm, and accordingly it is similar to Figure 4a Related calculations to calculate the pitch of other grooved rolls.

[0092] The temperature of the stretch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com