Polyimide fiber and preparation method thereof

A polyimide fiber, polyamic acid spinning technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problem of high cost, tensile strength needs to be further improved, etc. problems, to achieve the effect of reducing raw material cost, compact arrangement and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention also discloses a preparation method of polyimide fiber, comprising:

[0034] Dissolve diamine compounds and biphenyl dianhydride in a solvent, and react at -5°C to 30°C for 5 to 20 hours to obtain a polyamic acid spinning solution. The molar ratio of the diamine compound to biphenyl dianhydride is 1:0.95~1.05, the diamine compounds are p-phenylenediamine and 2-(4-aminophenyl)-5-aminobenzimidazole with a molar ratio of 0.8~0.95:0.05~0.2; wherein, p-phenylene The structural formula of diamine is shown in formula I; the structural formula of 2-(4-aminophenyl)-5-aminobenzimidazole is shown in formula II; the structural formula of biphenyltetralic acid dianhydride is shown in formula III.

[0035]

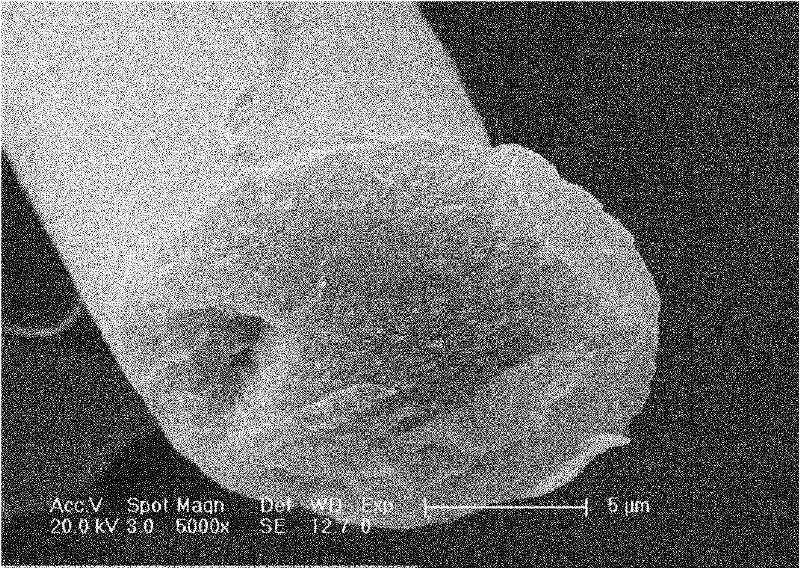

[0036] Spinning the polyamic acid spinning solution to obtain polyamic acid fibers;

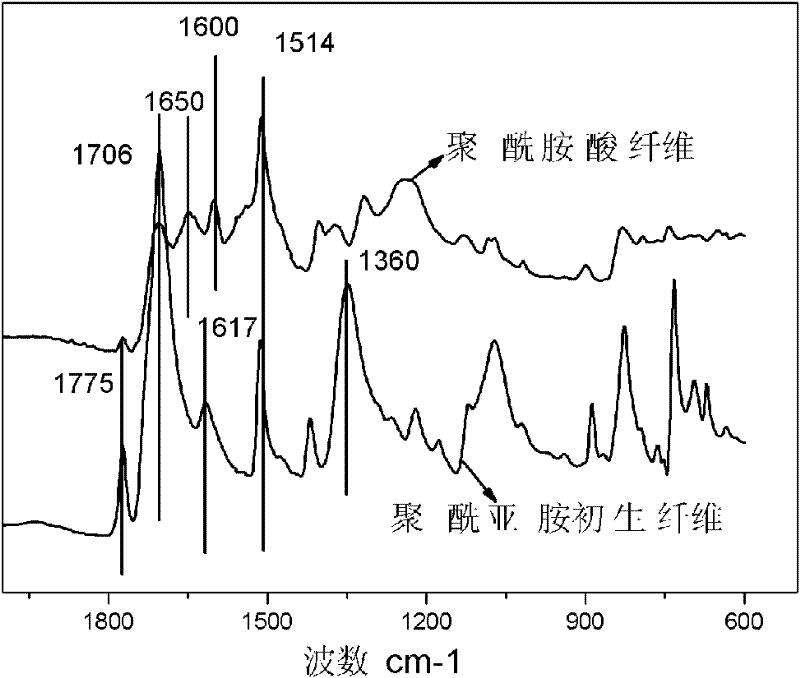

[0037] Carrying out imidization treatment to the polyamic acid fiber to obtain polyimide primary fiber;

[0038] The polyimide as-spun fiber is subjected to heat drawing treat...

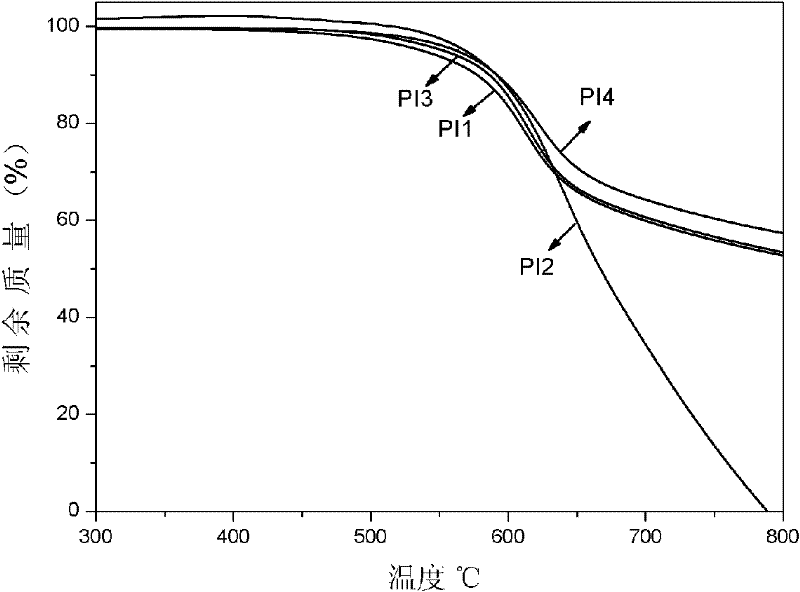

Embodiment 1

[0059] Dissolve 0.475mol p-phenylenediamine and 0.025mol 2-(4-aminophenyl)-5-aminobenzimidazole in 1000ml N,N-dimethylacetamide, add 0.520mol 3,3' under stirring , 4,4'-biphenyltetraacid dianhydride, react at -5°C to 30°C for 10 hours to obtain a viscous polyamic acid spinning solution, and filter;

[0060] The above-mentioned filtered polyamic acid spinning solution is spun and formed by using the dry-jet wet spinning method, and the polyamic acid spinning solution at room temperature is accurately metered by a metering pump, and is extruded from the spinneret and enters through the air layer. In the coagulation bath of N,N'-dimethylacetamide and water with a volume ratio of 40:60, the spinneret has 30 holes, the hole diameter is Ф0.20mm, the spray ratio is 3.0 times, and the spinneret speed is 30m / min , the height of the air layer is 70mm, and the polyamic acid fiber is obtained;

[0061] After the polyamic acid fiber is heat-dried, it is treated in a gradient heating heat ...

Embodiment 2

[0066] Dissolve 0.45mol p-phenylenediamine and 0.05mol 2-(4-aminophenyl)-5-aminobenzimidazole in 1000ml N,N-dimethylacetamide, add 0.520mol 3,3' under stirring , 4,4'-biphenyltetraacid dianhydride, react at -5°C to 30°C for 10 hours to obtain a viscous polyamic acid spinning solution, and filter;

[0067] The above-mentioned filtered polyamic acid spinning solution is spun and formed by using a dry-wet method, and the spinning slurry at room temperature is accurately metered by a metering pump, and then extruded from the spinneret and entered through the air layer with a volume ratio of 40: In the coagulation bath of 60 N,N'-dimethylacetamide and water, the spinneret has 150 holes, the hole diameter is Ф0.10mm, the spinning speed is 100m / min, the spray ratio is 4.0 times, and the air layer height is 50mm to obtain polyamic acid fiber;

[0068] After heat-drying the polyamic acid fibers, they are treated in a gradient temperature-raising heat treatment furnace under a nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com