Drafting unit

A component, drafting technology, used in drafting equipment, textiles and papermaking, spinning machines, etc., can solve the problems of obtaining measurable results for discontinuous fibers, achieve limited cost, reduce neps formation, increase The effect of the draft ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

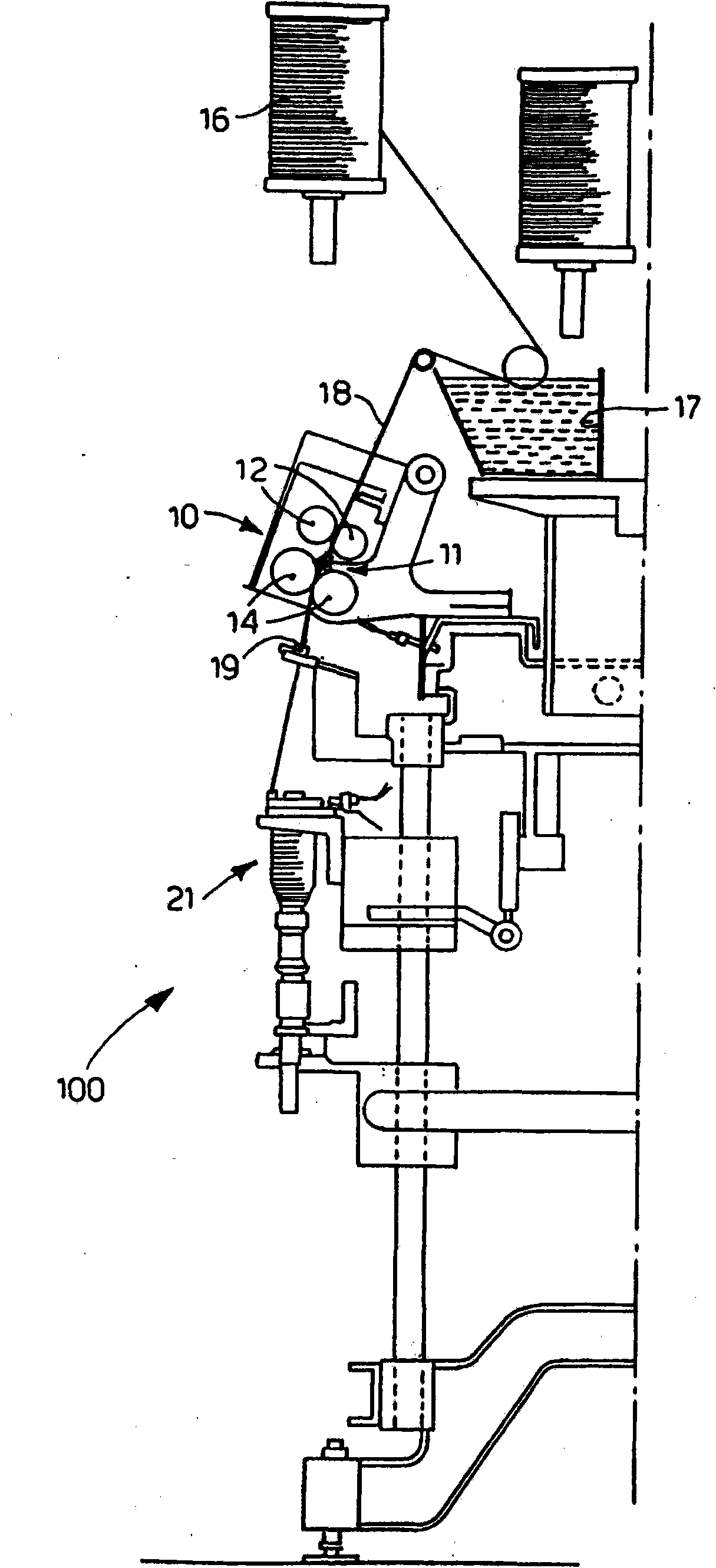

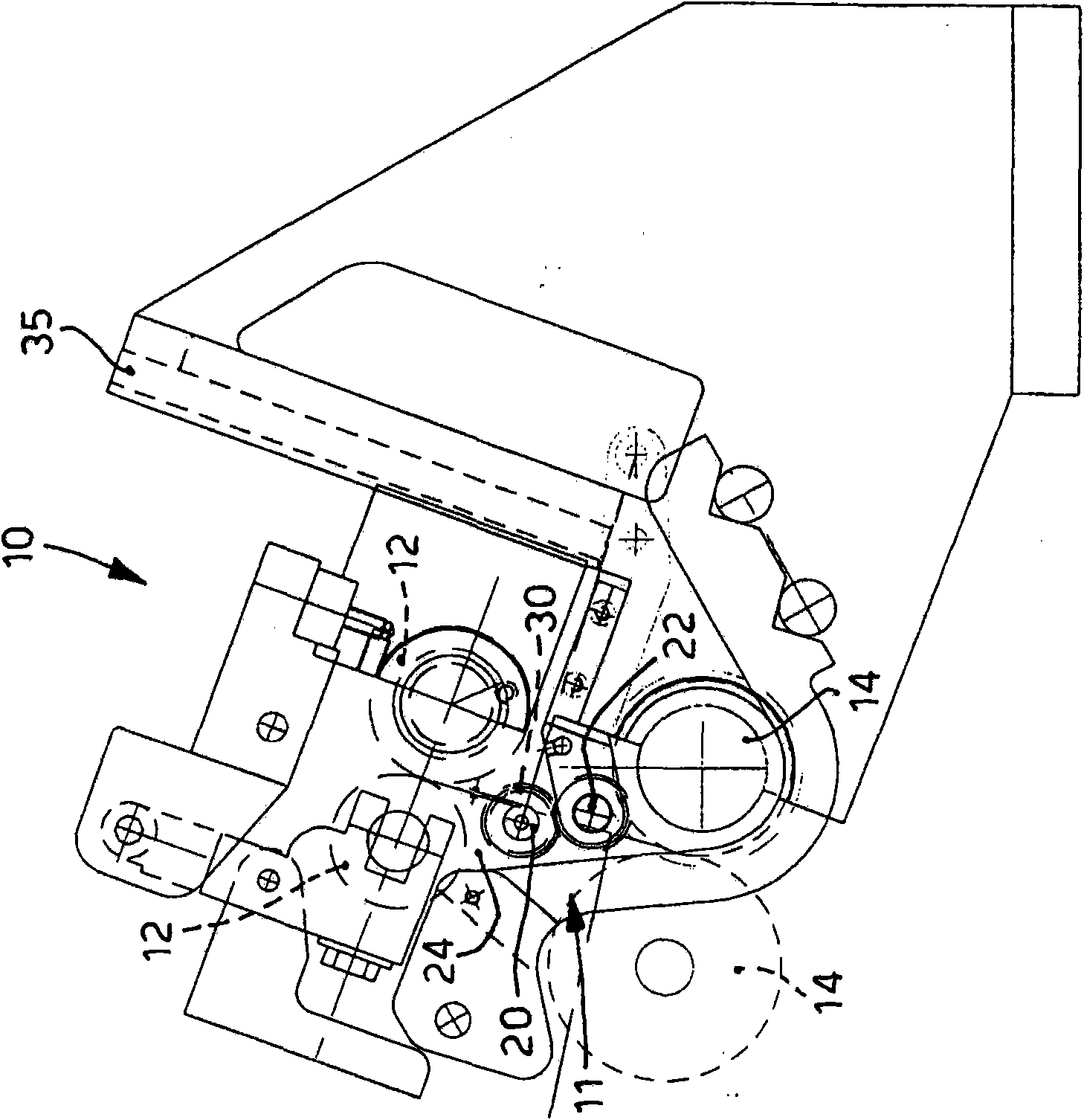

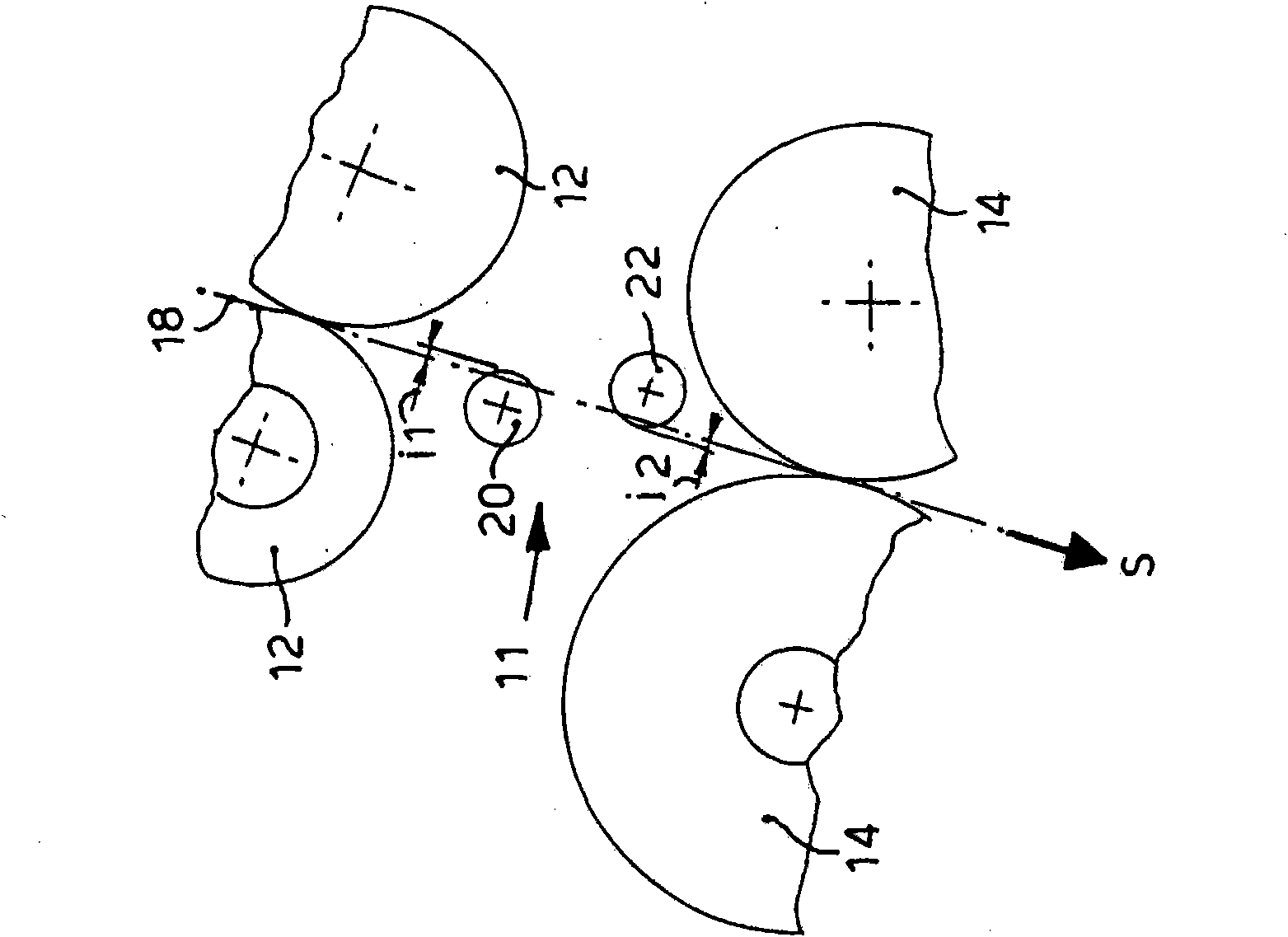

[0055] refer to figure 1 , the drafting unit 10 of the present invention is installed in a spinning machine 100 for flax. The drafting unit 10 receives a sliver or sliver 18 of flax fed from a bobbin 16 after the sliver or sliver has been immersed in a water-filled box 17 (wet spinning) and passed through a sliver guide.

[0056] The sliver 18 comprises long and short discontinuous fibers of flax cord, which have varying counts, have varying diameters comprised between about 18 microns to 50 microns, and also have diameters comprised between 20 mm to 100 mm. Varying length.

[0057] By long fibers we mean fibers whose length is comprised between 50 mm and 100 mm.

[0058] By staple fibers we mean fibers whose length is comprised between 20 mm and 50 mm.

[0059] Once drafted in the drafting section 10, the sliver 18 is sent via the yarn guide 19 to the spinning machine 21, where it continues in the preparation of the linen yarn.

[0060] At least in the drafting unit 10, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com