Modified calcium carbonate for anti-ultraviolet electric cable material, and preparation method thereof

An anti-ultraviolet and calcium carbonate technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of composite material performance degradation, two-phase interface defects, and weak matrix bonding force, etc., to achieve reduced dosage and uniform particle size , Good dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A preparation method of modified ground calcium carbonate for flame retardant cable material:

[0012] Weigh heavy calcium carbonate 100 by weight (kg), octylphenol polyoxyethylene ether 1, Pinga O 0.3, dioctyl maleate 1, zinc stearate 0.2, magnesium oxide 0.1, polyethylene wax 0.3, UV absorber UV-P 0.1, Chitosan 2, Polyphosphoric acid 1, Methyltriethoxysilane 3,

[0013] Dry the calcium carbonate at 82°C until the water content is less than 0.3%, then add it to the high-speed mixer, add octylphenol polyoxyethylene ether in proportion, add O flatly, and high-speed at a speed of 800-1000 rpm Stir for 4 minutes, then add dioctyl maleate, stir at high speed for 6 minutes, then add zinc stearate, magnesium oxide, polyethylene wax, ultraviolet absorber UV-P, chitosan, polyphosphoric acid, methyl Triethoxysilane was then stirred at a high speed of 1000-1200 rpm for 18 minutes, then dried and ground to obtain modified calcium carbonate.

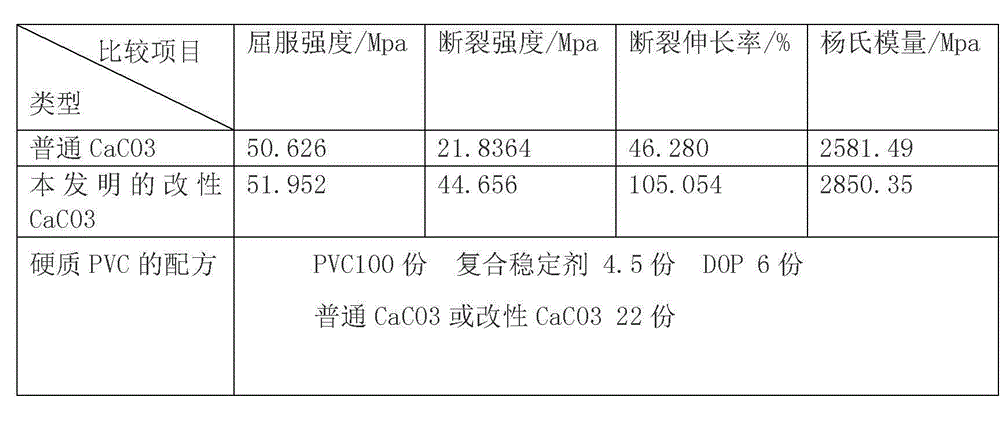

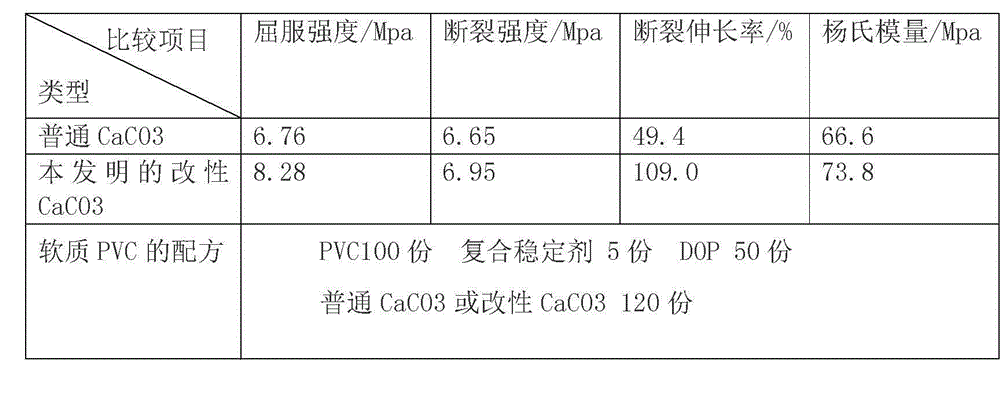

[0014] We made hard and soft PVC tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com