Composite powder, magnetic powder core for magnetic powder and preparation method thereof

A composite powder and magnetic powder core technology, which is applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem that the required characteristics of magnetic powder core are not ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

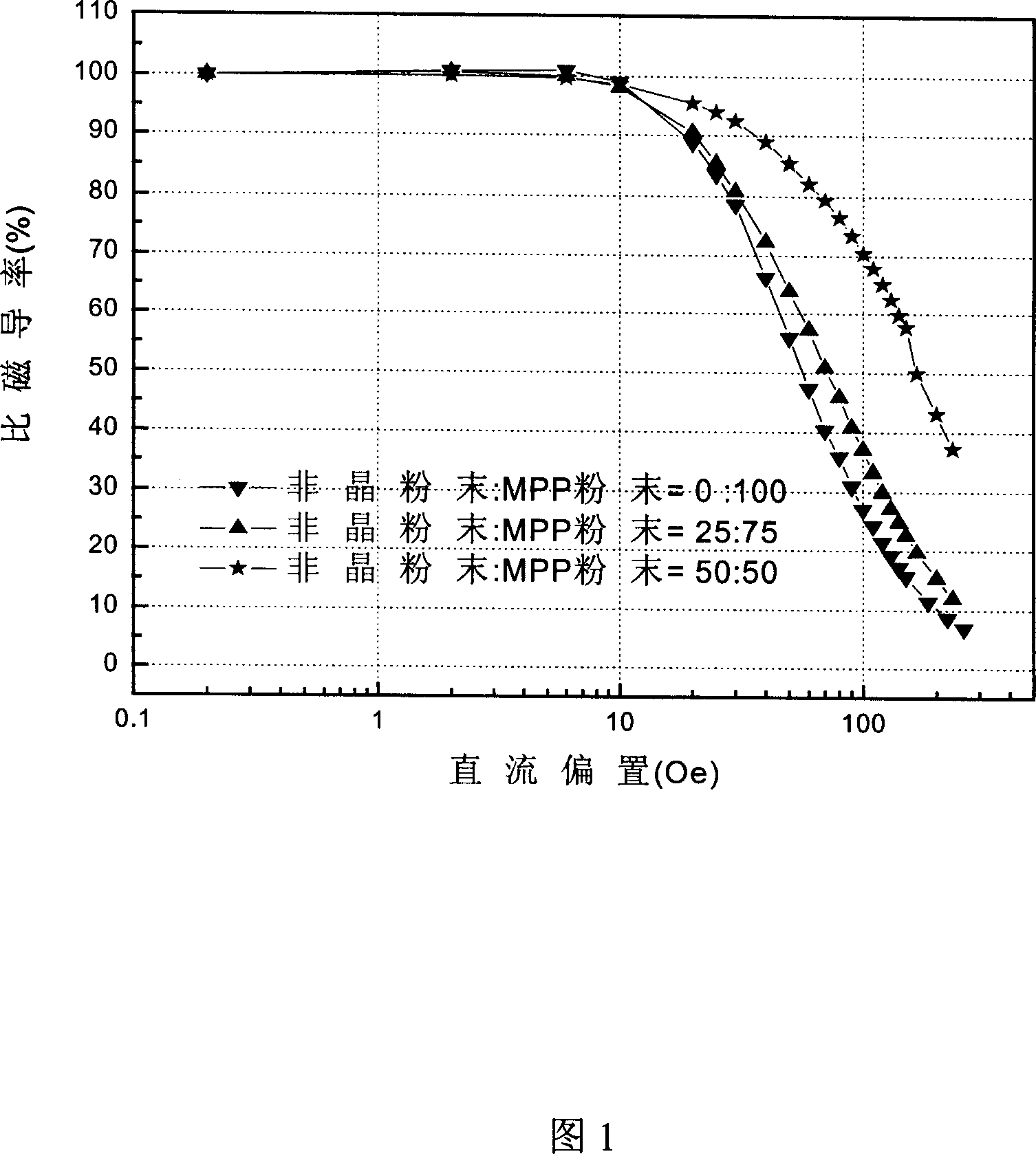

[0106] This embodiment adopts water atomization method to prepare amorphous Fe 69 Ni 5 Al 4 sn 2 P 10 C 2 B 4 Si 4 Alloy powder and MPP powder. The pre-annealing process of MPP powder is 650℃×60 minutes;

[0107] Fe 69 Ni 5 Al 4 sn 2 P 10 C 2 B 4 Si 4 The pre-annealing process of the powder is 450°C×60 minutes, and the annealing process adopts a vacuum atmosphere. The negative 300-mesh powder was obtained by sieving respectively, and mixed to prepare composite powder. The mixing ratio is shown in Table 1.

[0108] Table 1

[0109] serial number

The mixing ratio

DC Bias Characteristics

Amorphous

powder

MPP

powder

Specific permeability

(500e)

Raise the ratio

(500e)

Specific permeability

(1000e)

Raise the ratio

(1000e)

1

25%

75%

63.9%

14.1%

37.0%

36.5%

2

50%

50%

85.4%

52.5%

70.4%

159.8%

...

Embodiment 2

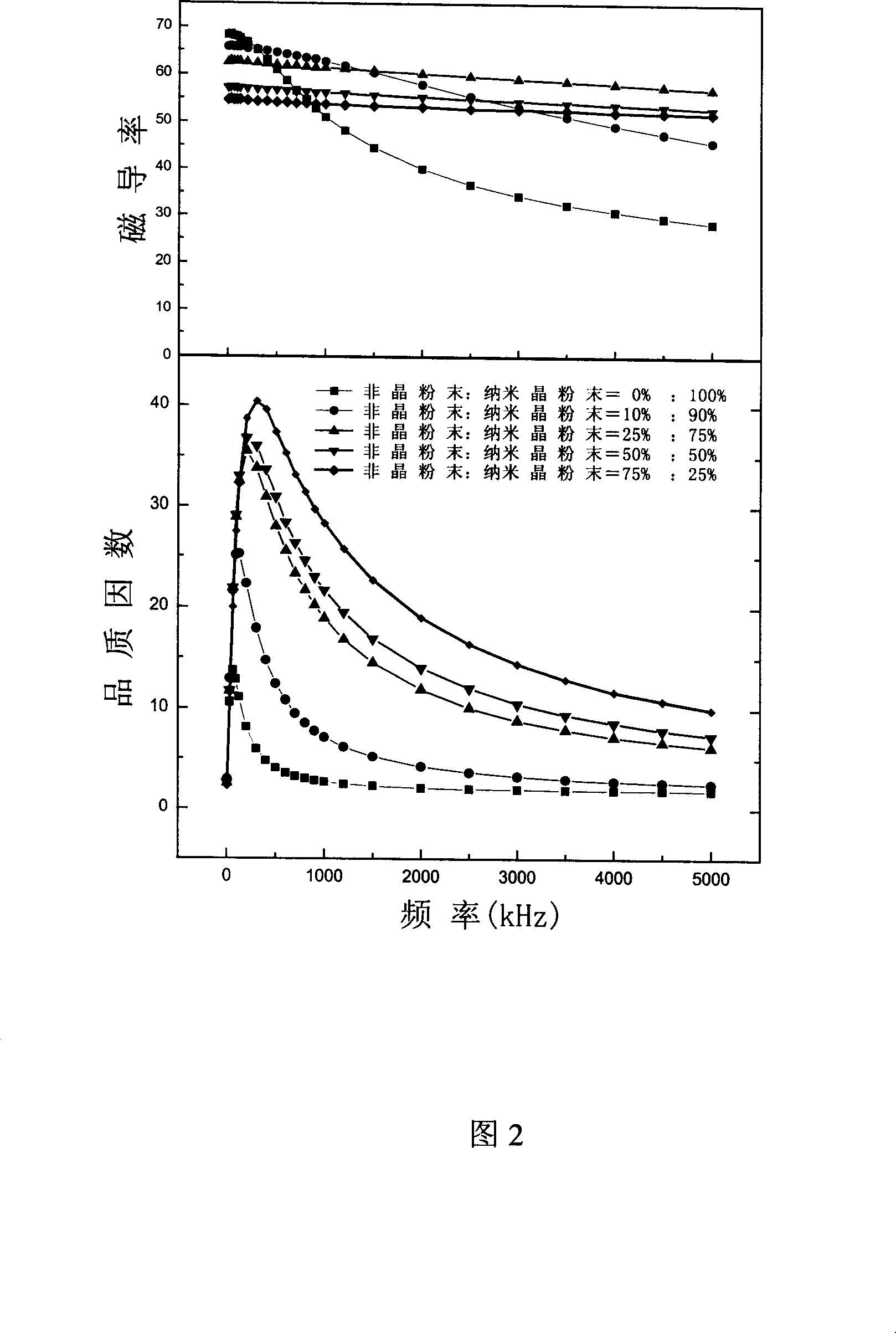

[0113] This embodiment adopts water atomization method to prepare amorphous Fe 69 Ni 5 Al 4 sn 2 P 10 C 2 B 4 Si 4 alloy powder. Nanocrystalline Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 The preparation method of the alloy powder includes: 1. preparing an amorphous alloy strip by a single-roller quick quenching method; 2. annealing isothermally at 550° C. for 30 minutes in a nitrogen atmosphere; 3. obtaining nanocrystalline powder by ball milling with a planetary ball mill. where Fe 69 Ni 5 Al 4 sn 2 P 10 C 2 B 4 Si 4 The pre-annealing process of the powder is 450°C×60 minutes, and the annealing process adopts a vacuum atmosphere; the annealing process of the nanocrystalline powder is 550°C×30 minutes, and the annealing atmosphere is a nitrogen atmosphere. Sieve negative 400 mesh amorphous Fe 69 Ni 5 Al 4 sn 2 P 10 C 2 B 4 Si 4 and minus 100 mesh to plus 200 mesh nanocrystalline powder, and mixed to prepare composite powder, the mixing ratio is shown in Table 2...

Embodiment 3

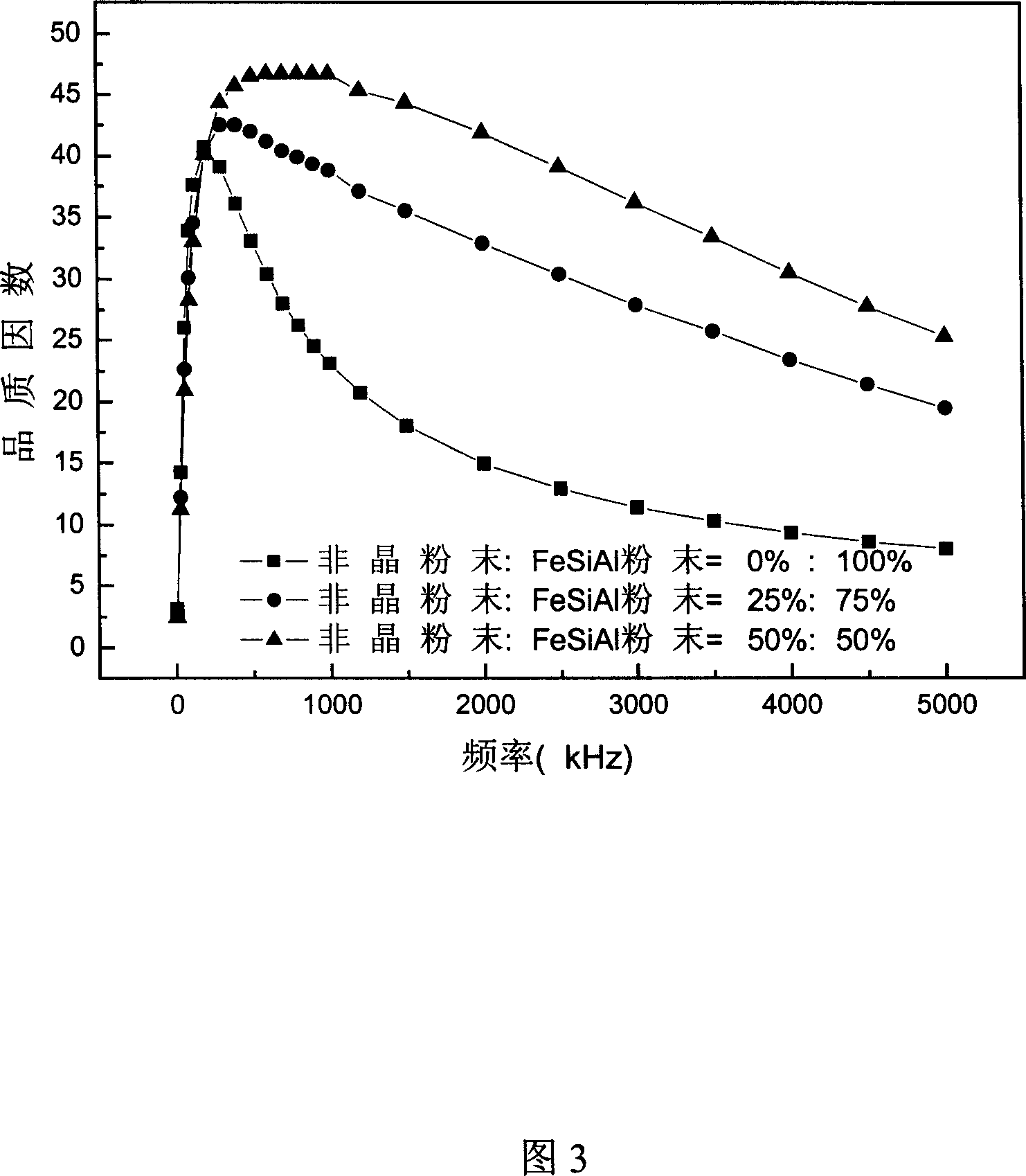

[0119] This embodiment adopts water atomization method to prepare amorphous Fe 69 Ni 5 Al 4 sn 2 P 10 C 2 B 4 Si 4 Alloy powder, the sendust powder is prepared by crushing method. where Fe 69 Ni 5 Al 4 sn 2 P 10 C 2 B 4 Si 4 The pre-annealing process of the powder is 450°C×60 minutes, and the annealing process adopts a vacuum atmosphere; the annealing process of the sendust powder is 600°C×30 minutes, and the annealing atmosphere is a hydrogen atmosphere. Sieve negative 400 mesh amorphous Fe 69 Ni 5 Al 4 sn2 P 10 C 2 B 4 Si 4 powder and sendust powder, and mixed to prepare composite powder, the mixing ratio is shown in Table 3. The preparation method of the composite magnetic powder core is the same as that of Example 2.

[0120] The quality factor of the composite magnetic powder core and the quality factor of the comparative sendust powder core are shown in Figure 3. It can be seen that the addition of amorphous powder can significantly improve the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com