Modified heavy calcium carbonate for fire retardation electric cable material, and preparation method thereof

A technology for heavy calcium carbonate and flame-retardant cables, which is applied in fibrous fillers, dyed low-molecular organic compound treatment, dyed high-molecular organic compound treatment, etc., and can solve the problems of composite material performance degradation, two-phase interface defects, and matrix bonding force Weakness and other problems, to achieve the effect of improving flame retardant performance, uniform particle size, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A preparation method of modified ground calcium carbonate for flame retardant cable material:

[0011] Weigh 100 heavy calcium carbonate, 0.4 sodium butylnaphthalene sulfonate, 0.6 fatty alcohol polyoxyethylene ether sodium sulfate, 1.5 epoxidized triglyceride, 0.2 stearic acid, and 0.1 barium stearate by weight (kg). , Dimethicone 0.2, Carboxymethyl Cellulose 1, Aluminum Oxide 0.7, Triphenyl Phosphate 2, Isopropyl Distearoyl Aluminate 1,

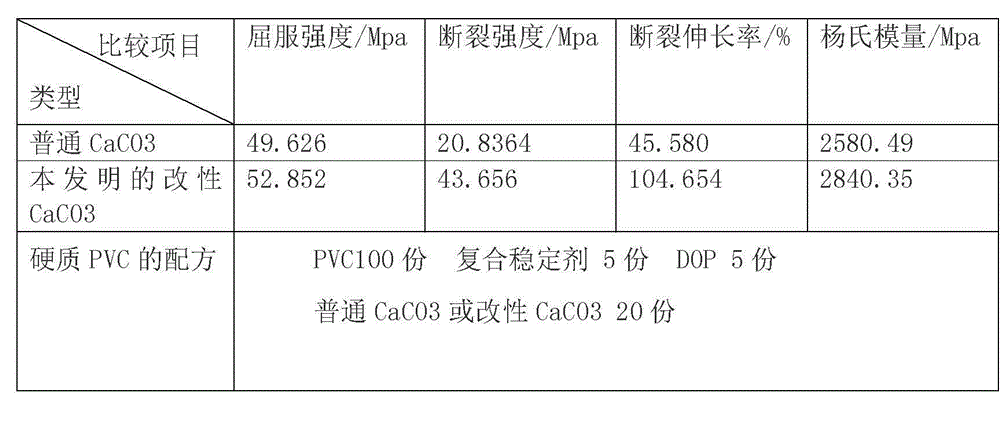

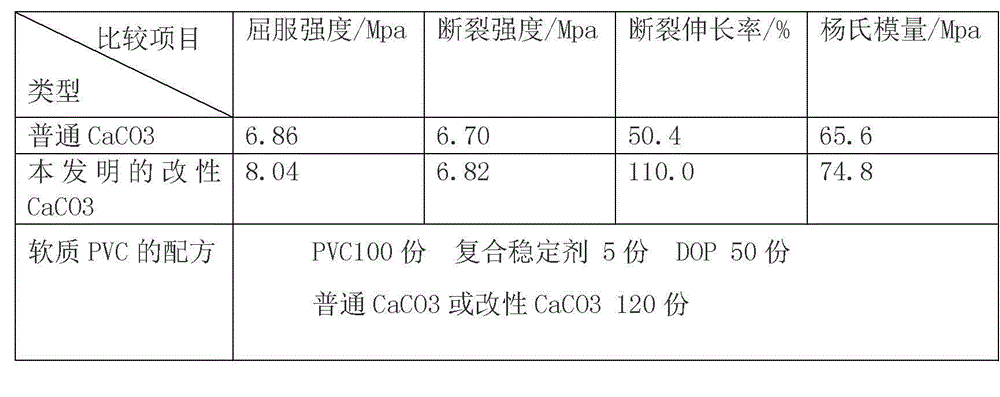

[0012] Preparation method: Dry heavy calcium carbonate at 55°C until the water content is 0.4%, then add it to a high-speed mixer, add sodium butylnaphthalene sulfonate, sodium fatty alcohol polyoxyethylene ether sulfate, cyclo Oxidized triglycerides, stearic acid, barium stearate, simethicone, carboxymethyl cellulose, aluminum oxide, triphenyl phosphate, isopropyl distearyloxyaluminate and 4- 5kg of water was stirred at a high speed of 1200-1400 rpm for 15 minutes, then dried and ground into nanometer powder to obtain modified calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com