Low-temperature vacuum dehydration and drying equipment as well as process thereof

A low-temperature vacuum and complete equipment technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of increasing the pressure on environmental protection and safety, occupying a large area, and unable to achieve material reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

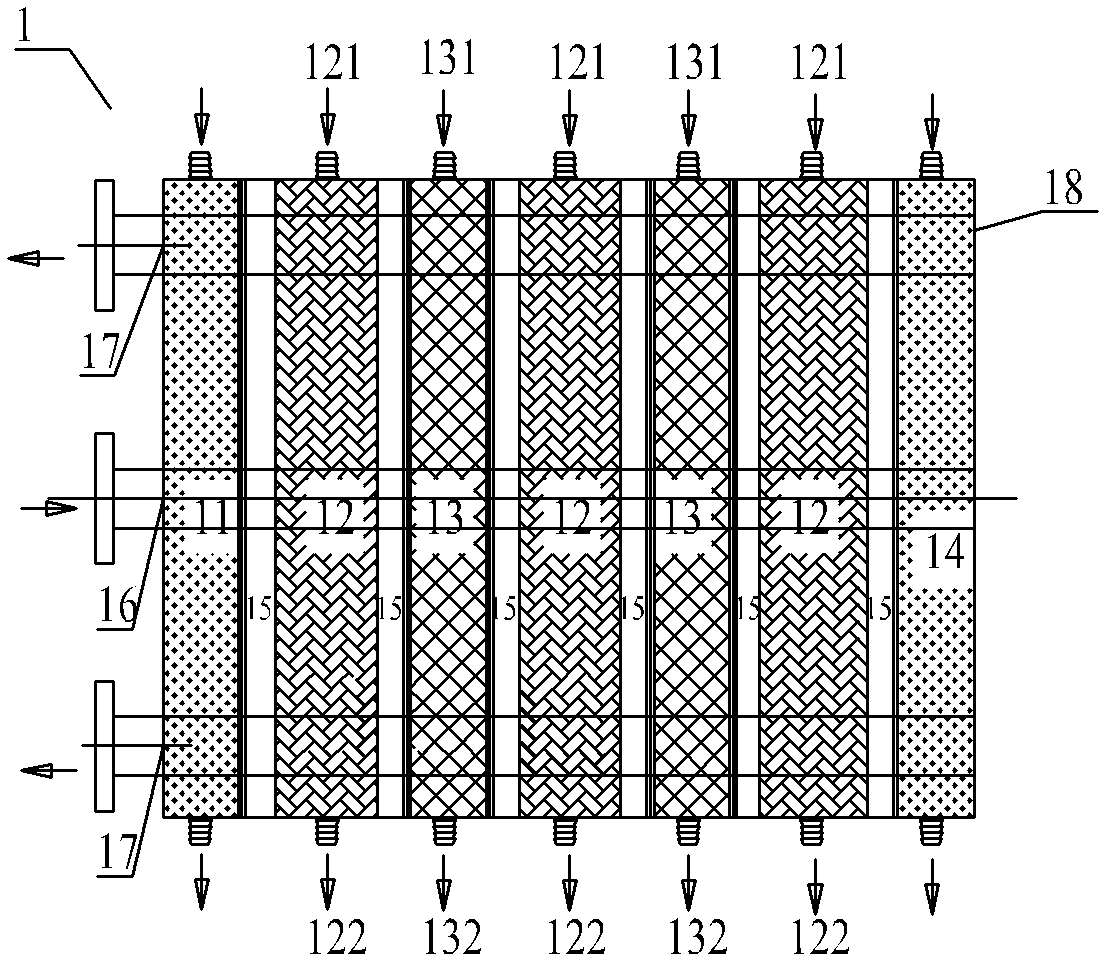

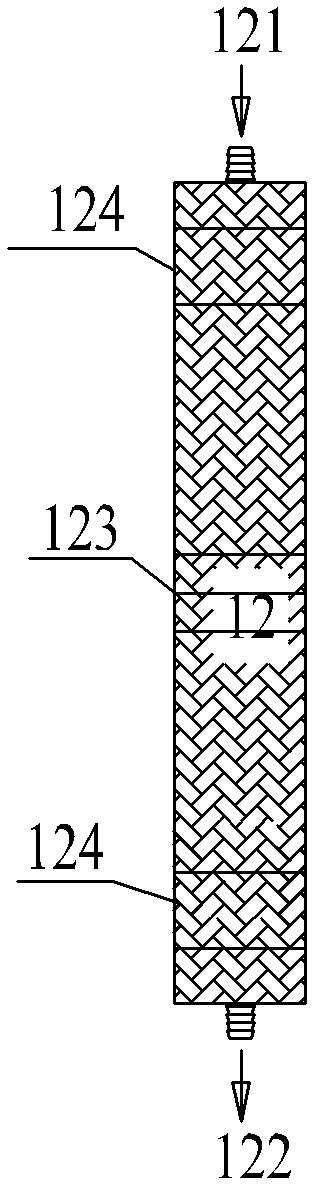

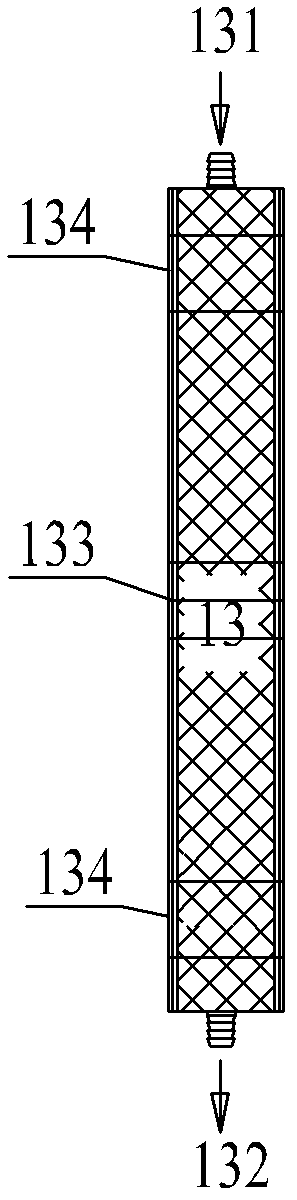

[0033] see figure 1 , which is a complete set of low-temperature vacuum dehydration and drying equipment involved in the present invention. A filtration system 1 is included, and the filtration system 1 includes at least one membrane filter plate 13 and at least one heating filter plate 12 , and a material chamber 15 is formed between the heating filter plate 12 and the membrane filter plate 13 . See figure 2 , The filtration system 1 includes a head plate 11 and a tail plate 14, the membrane filter plate 13 and the heating filter plate 12 are multiple pieces, and are arranged alternately between the head plate 11 and the tail plate 14. See Figure 4 , the membrane filter plate 13 is a frame structure, including a substrate, a membrane, and a filter cloth. A diaphragm inner cavity is formed in the base plate, and compressed air, hot and cold water, steam or heat transfer oil can be fed into the diaphragm inner cavity. The rubber diaphragm is coated on the left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com