Automatic filter core cleaning device for petroleum exploitation

A technology of automatic cleaning and filter element, applied in filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of poor device practicability, unable to know whether the filter element is replaced, unable to clean the filter element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

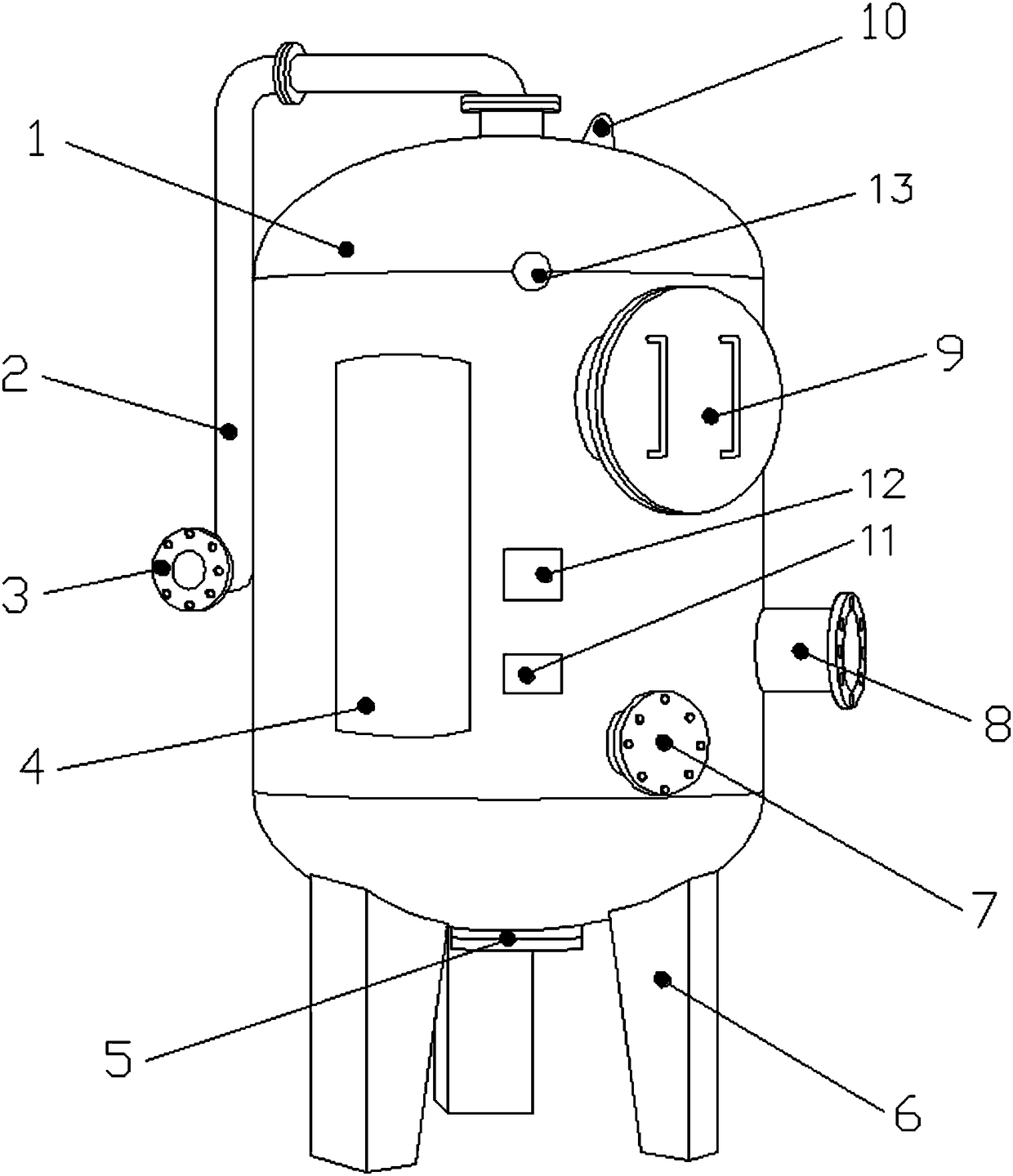

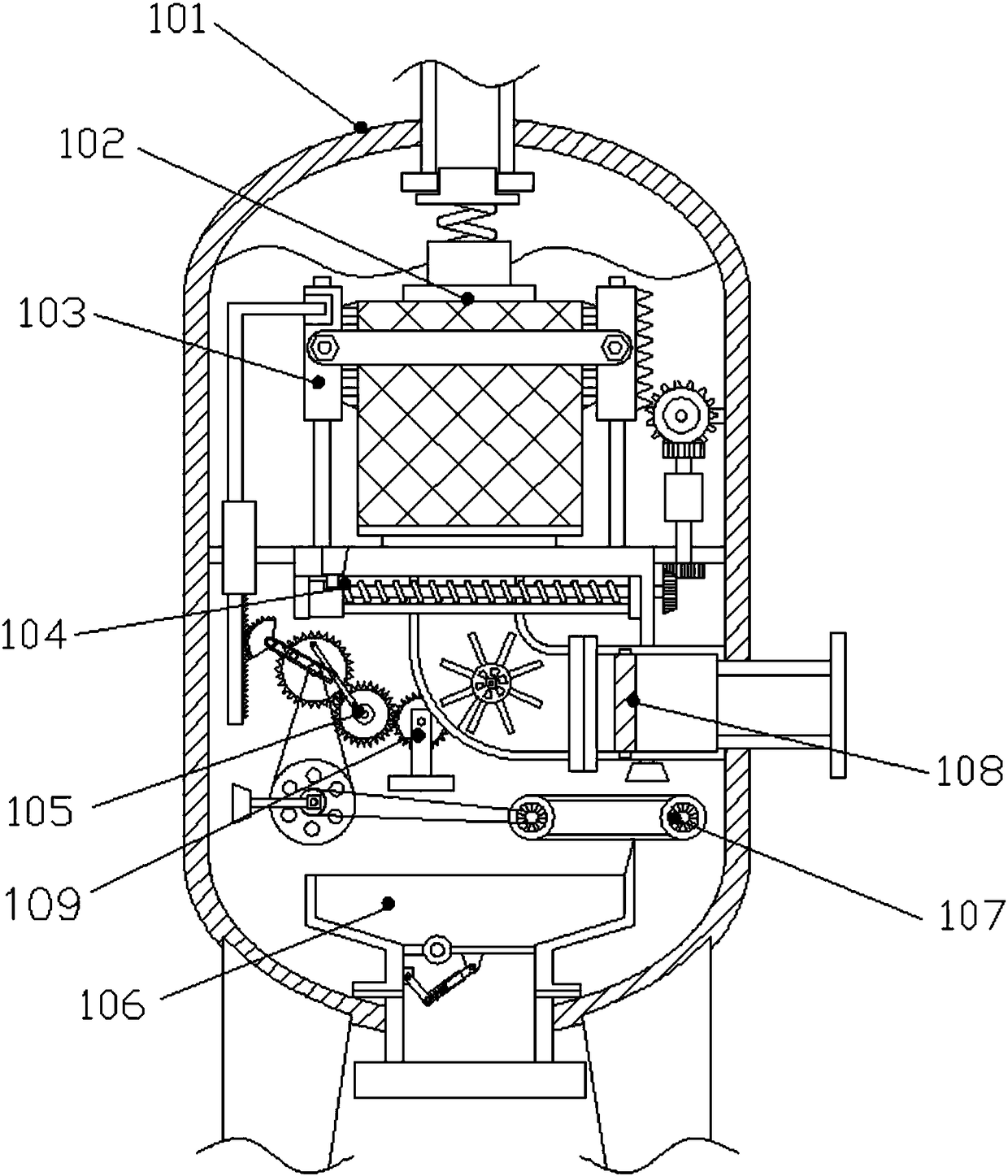

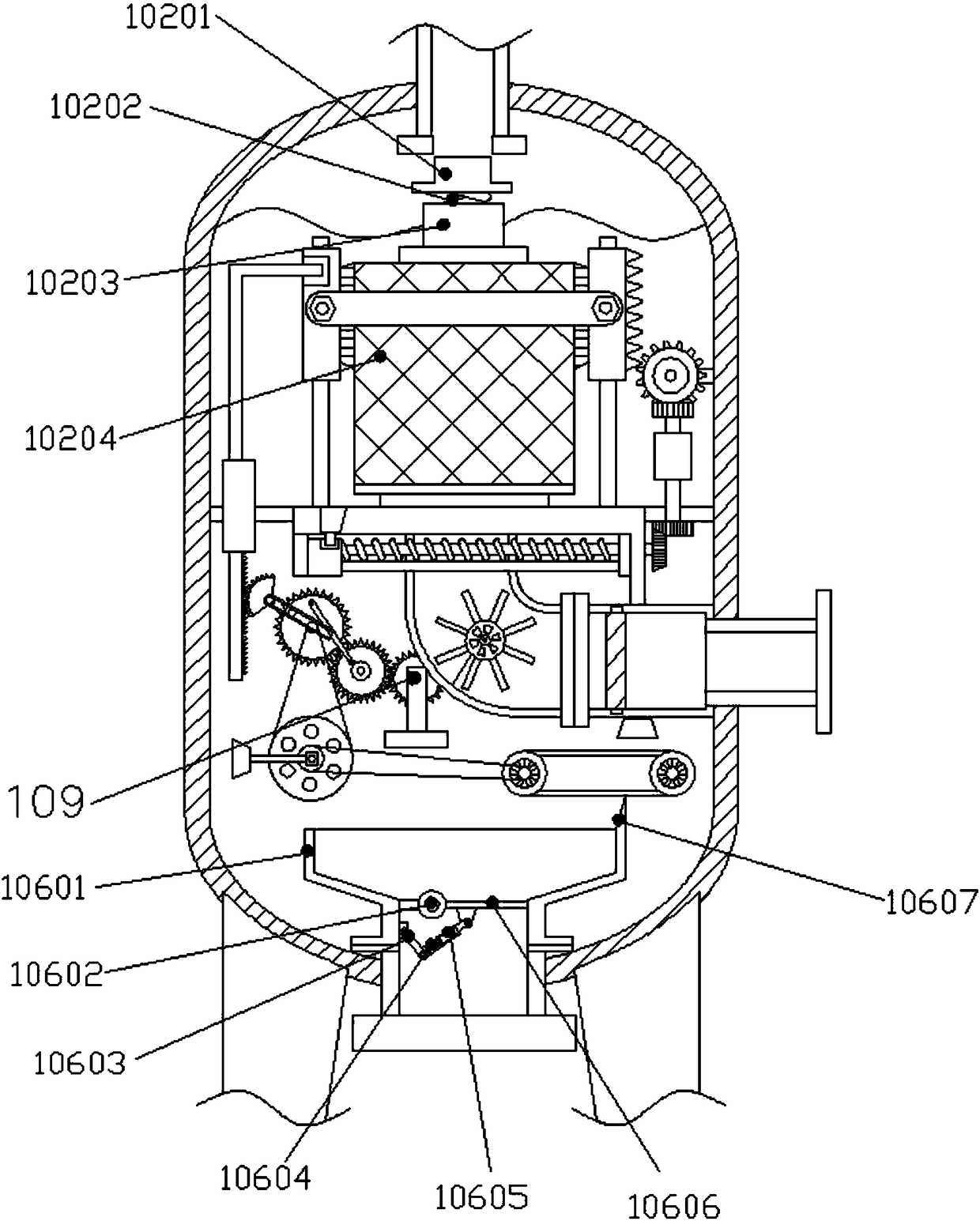

[0027] see Figure 1-Figure 8, the present invention provides an automatic cleaning device for a filter core used in petroleum exploitation, a filter core automatic cleaning device for petroleum exploitation, the structure of which includes a filter tank main body 1, an oil introduction pipe 2, a connecting flange 3, a product nameplate 4, and a filter residue Discharge port 5, anti-skid support feet 6, observation port 7, oil discharge pipe 8, equipment inspection door 9, fixed lifting ring 10, cleaning switch 11, timer 12 and alarm 13, and the oil introduction pipe 2 is bolted to the filter tank The left side of the main body 1 is parallel to the main body 1 of the filter tank. The back side of the product nameplate 4 is glued to the left side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com